Documente Academic

Documente Profesional

Documente Cultură

Temperature Dependent Current-Voltage Characteristics of P-Type Crystalline Silicon Solar Cells Fabricated Using Screen-Printing Process

Încărcat de

Alexander DeckerDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Temperature Dependent Current-Voltage Characteristics of P-Type Crystalline Silicon Solar Cells Fabricated Using Screen-Printing Process

Încărcat de

Alexander DeckerDrepturi de autor:

Formate disponibile

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.

11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

Temperature Dependent Current-voltage Characteristics of Ptype Crystalline Silicon Solar Cells Fabricated Using Screenprinting Process

Hyun-Jin Song, Won-Ki Lee, Chel-Jong Choi* School of Semiconductor and Chemical Engineering, Semiconductor Physics Research Center, Chonbuk National University, Jeonju 561-756, Korea *Email address of corresponding author: cjchoi@chonbuk.ac.kr Abstract We have fabricated p-type crystalline silicon (Si) solar cells using screen-printing process and investigated their electrical properties. Ph screen printing process led to the uniform formation of n+ emitter. As a result of interaction between Ph-dopant paste and Si substrate, a phosphosilicate glass layer was formed on n+ emitter surface. The current-voltage characteristics were carried out in the temperature range of 175 450 K in steps of 25 K. The variation in current level at a particular voltage strongly depended on temperature, indicating that the current transport across the junction was a temperature activated process. The reverse leakage current gradually increased with increasing measurement temperature up to 350 K, above which it rapidly increased. Arrhenius plot of the leakage current revealed that reverse leakage current in low and high temperature regions were dominated by the tunneling mechanism, and generation and recombination mechanism, respectively. Keywords: P-type Si solar cell, screen-printing, I-V, tunneling, generation and recombination, reverse leakage current 1. Introduction Crystalline silicon (Si) solar cells constitute of above 85% of the world photovoltaic (PV) market with a tendency to increase their market share due to the combination of comparatively higher conversion efficiency, long-term stability and optimized manufacturing techniques (Green et al., 2012). The development of fast and cost-effective processing technologies for high efficient crystalline Si solar cells plays a key role in the largescale penetration of PV in the total energy system. Analysis of the current-voltage (I-V) characteristics of crystalline Si solar cells obtained only at room temperature does not give detailed information about the current transport through emitter. In fact, I-V analysis at room temperature neglects many possible effects that cause the high leakage current. The temperature dependence of I-V characteristics gives a better understanding of the leakage mechanism involved in crystalline Si solar cells. Previously, many researchers reported on the physical properties of screen-printed Ag contacts on an n+ emitter surface in crystalline Si solar cells. For instance, Ballif et al. (Ballif et al., 2003) investigated the structural and electronic properties of Ag thick film contacts screen printed on P-diffused Si wafers. Li et al. (Li et al., 2009) demonstrated the microstructural properties of the Ag/emitter contact of crystalline Si solar cells fired at temperatures from below to above optimal conditions by means of electron microscopy, and reported the evolution of interfacial microstructure from one richly decorated nanometer-size Ag colloids into one with many Ag crystallites grown onto the emitter surface. They suggested that the tunneling mechanism is responsible for the current extraction in these cells. Jeong et al. (Jeong et al. 2010) investigated the microstructural and chemical properties of screen-printed Ag contacts on an n+ emitter surface in crystalline Si solar cells. In the present work, we have investigated the reverse current leakage mechanism of p-type crystalline Si solar cells fabricated using screen printing process using I-V characteristics measured at the temperature range of 175 K 450 K in steps of 25 K. 2. Experimental Details Figure 1 shows the schematic diagram and key process flow of screen-printed p-type crystalline Si solar cell used in this work. Czochralski (CZ) (100) boron doped p-type monocrystalline Si wafers having a resistivityof 2 5 cm, a thickness of about 220 mm and size of 4.0 cm 4.0 cm were used as a starting material. After removing the native oxide using a buffered oxide etchant (BOE), saw damage on the surface was etched using a KOH solution. The wafer was then rinsed with deionized water. Surface texturing was carried out using a mixture of KOH and isopropyl alcohol. Phosphorus (Ph) screen printing was used to form an n+ emitter region in the textured Si surface followed by furnace annealing at 840C for 20 min under flowing O2 ambient. The 27 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

wafers were then dipped in BOE to remove phosphosilicate glass layers formed as a result of the reaction between phosphorous paste and Si. The sheet resistance of the screen printed n+ emitters was measured to be 64 /square. The 80 nm thick SiNx film was used as an antireflection layer deposited on the surface using plasma enhanced chemical vapor deposition (PECVD). Next, an Al paste was screen-printed on the backside and dried at 200 C. The Ag grid was then screen-printed on top of the SiNx film and Ag and Al contacts were co-fired (single firing step) in a lamp-heated belt furnace. During co-firing process, Ag Ohmic contact to n+ emitter and Al back surface field (BSF) were formed. The efficiency of the manufactured p-type crystalline Si solar, measured using solar simulator at the condition of AM 1.5 Global with flash illumination, was found to be 16.6 %. Open-circuit voltage (Voc), short-circuit current density (Jsc), and fill factor (FF) were summarized in table 1. Microstructure of Ph screen-printed n+ emitter was characterized transmission electron microscopy (TEM) equipped with energy dispersive X-ray spectroscopy (EDX). The I-V measurements were carried out using precision semiconductor parameter analyzer (Agilent 4156C) in the temperature range of 175 K 450 K in steps of 25 K.

Figure 1. Schematic diagram and key process flow of screen-printed p-type crystalline Si solar cell used in this work. Table 1. Summary of Voc, Jsc, FF, and efficiency of p-type crystalline Si solar cell manufacture using screen printing process Voc 568.1 mV Jsc 39.0 mA/cm2 FF 74.97 % Efficiency 16.6 %

3. Results and Discussion Figure 2 represents cross-sectional bright field TEM image obtained from the Ph screen printed n+ emitter. In order to reveal the Ph distribution, TEM specimen was chemically etched using using a mixture of HF:HNO3: CH3COOH (1:100:25) for 5 s. The image clearly showed dark thickness fringes formed as a result of the concentration-dependent etch in the Ph doped region. Such fringes can be converted into isoconcentration contours since they consist of the same concentration points. The relatively even isoconcentration contours indicated that Ph screen printing process led to the homogenous Ph diffusion to Si substrate, resulting in the uniform formation of n+ emitter. The chemically delineated junction depth, defined as the distance from emitter surface to the last visible isoconcentration contour was found to be ~ 70 nm. In particular, a layer with a thickness of ~ 20 nm was clealy visible on the n+ emitter as indicated by an arrow. For the identification of such a layer, EDX line profiling was carried out using a scanning electron probe with a size of 1 nm over the sample (Fig. 3). The STEM-EDX line profiling exhibited that this layer consisted of O, Si, and P atoms. This suggests that during the Ph screen printed emitter process, interaction between Ph-dopant paste and Si substrate caused by 28 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

thermal treatment resulted in the formation of a phosphosilicate glass (PSG) layer on Si surface.

Figure 2. Cross-sectional bright field TEM image obtained from the Ph screen printed n+ emitter.

Figure 3. EDX line profile for O, Ph, and Si atoms taken from Ph screen printed n+ emitter

Figure 4(a) shows the I-V characteristics of p-type crystalline Si solar fabricated using screen printing process measured at the temperatures ranging from 175 to 450 K. Regarless of measurement temperature, rectification behavior was clearly visible, which is typical feature of n+/p junction. In particular, at low temperatures, the variation of reverse leakage current at a particular voltage (2 V) with temperature was very low while a relatively large current variation was observed at high temperatures, as shown in Fig. 4(b). Such a variation of reverse leakage current depending on measurement temperature could be associated with the current transport across the n+/p junction governed by a temperature activated process. Namely, only few electrons are able to flow across of the junction at low temperatures. However, at higher temperatures, more and more electrons have sufficient energy to flow across the junction.

29 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

Figure 4. (a) I-V characteristics of p-type crystalline Si solar fabricated using screen printing process measured at the temperatures ranging from 175 to 450 K, and (b) plot of reverse leakage current measured at 2 V versus temperature. In order to investigate the leakage mechanism, Arrhenius plot of the leakage current of the manufactured cell was used, as shown in Fig. 5. The reverse leakage current was measured at 2 V in the temperature range 175 K 450 K. The temperature dependence of the reverse leakage current as revealed by the slope of the Arrhenius plot provides useful insight into the mechanism for reverse leakage current (Lee et al., 1998). The activation energy (EA) of reverse leakage current is close to the band gap of silicon (Eg) when dominated by diffusion and close to half the band gap (Eg/2) when dominated by generation and recombination. From the linear fit to slope of Arrhenius plot, EA of 0.50 eV was obtained in the high temperature region which is close to half of the band gap (Eg). This suggests the possibility of the leakage current to be dominated by generation and recombination mechanism. Further, almost zero activation energy was obatained at the low temperature region, implying that the reverse leakage current is independent of the measurement temperature. Hence, the current in the low temperature region is dominated by the tunneling mechanism.

Figure 5. Arrhenius plot of the leakage current of p-type crystalline Si solar fabricated using screen printing process.

30 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

4. Conclusion We have investigated the reverse leakage current mechanism of screen-printed p-type crystalline Si solar cells with an efficiency of 16.6 %. During the Ph screen printing process, relatively uniform n+ emitter was formed with the PSG layer formed as a result of interaction between Ph-dopant paste and Si substrate. The I-V measurements showed that carrier conduction across n+ emitter was a temperature activated process. An increase in measurement temperature resulted in the increase in reverse leakage current. From the linear fit to slope of Arrhenius plot, generation and recombination mechanism could be a main cause of carrier conduction in reverse bias at high temperature while reverse leakage current was dominated by the tunneling mechanism at low temperature. Acknowledgements This work was supported by Human Resource Development Program (201040100660) of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant and Honam Leading Industry Office through the Leading Industry Development for Economic Region (R0001244) funded by the Ministry of Knowledge Economy, Korea. References Green Martin A., Emery K., Hishikawa Y., Warta W, & Dunlop Ewan D. (2012). Solar cell efficiency tables (version 39). Prog. Photovolt: Res. Appl., 20, 1220 Ballif C., Hulji D. M., Willeke G., & Hessler-Wyser A. (2003). Silver thick-film contacts on highly doped ntype silicon emitters: Structural and electronic properties of the interface. Appl. Phys. Letters., 82, 1878 1880. Li Z. G., Liang L., & Cheng L. K. (2009), Electron microscopy study of front-side Ag contact in crystalline Si solar cells. J. Appl. Phys., 105, 066102 (3 pages). Jeong M.-I., Park S.-E., Kim D.-H., Lee J.-S., Park Y.-C., Ahn K.-S., & Choi C.-J. (2010). Transmission electron microscope study of screen-printed Ag contacts on crystalline Si solar cells. J. Electrochem. Soc., 157, H934-H936 Lee H.D., Lee S.G., Lee S. H., Lee Y.J., & Hwang J.M. (1998). Characterization of corner-induced leakage current of a shallow silicided n+/p junction for quarter-micron MOSFETs. Jpn. J. Appl. Phys. 37, 1179-1183.

31 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

This academic article was published by The International Institute for Science, Technology and Education (IISTE). The IISTE is a pioneer in the Open Access Publishing service based in the U.S. and Europe. The aim of the institute is Accelerating Global Knowledge Sharing. More information about the publisher can be found in the IISTEs homepage: http://www.iiste.org CALL FOR JOURNAL PAPERS The IISTE is currently hosting more than 30 peer-reviewed academic journals and collaborating with academic institutions around the world. Theres no deadline for submission. Prospective authors of IISTE journals can find the submission instruction on the following page: http://www.iiste.org/journals/ The IISTE editorial team promises to the review and publish all the qualified submissions in a fast manner. All the journals articles are available online to the readers all over the world without financial, legal, or technical barriers other than those inseparable from gaining access to the internet itself. Printed version of the journals is also available upon request of readers and authors. MORE RESOURCES Book publication information: http://www.iiste.org/book/ Recent conferences: http://www.iiste.org/conference/ IISTE Knowledge Sharing Partners EBSCO, Index Copernicus, Ulrich's Periodicals Directory, JournalTOCS, PKP Open Archives Harvester, Bielefeld Academic Search Engine, Elektronische Zeitschriftenbibliothek EZB, Open J-Gate, OCLC WorldCat, Universe Digtial Library , NewJour, Google Scholar

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Assessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaDocument10 paginiAssessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaAlexander DeckerÎncă nu există evaluări

- Assessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaDocument11 paginiAssessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaAlexander DeckerÎncă nu există evaluări

- Assessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaDocument10 paginiAssessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaAlexander DeckerÎncă nu există evaluări

- Analysis of Teachers Motivation On The Overall Performance ofDocument16 paginiAnalysis of Teachers Motivation On The Overall Performance ofAlexander DeckerÎncă nu există evaluări

- An Overview On Co-Operative Societies in BangladeshDocument11 paginiAn Overview On Co-Operative Societies in BangladeshAlexander DeckerÎncă nu există evaluări

- Analysis of Blast Loading Effect On High Rise BuildingsDocument7 paginiAnalysis of Blast Loading Effect On High Rise BuildingsAlexander DeckerÎncă nu există evaluări

- An Experiment To Determine The Prospect of Using Cocoa Pod Husk Ash As Stabilizer For Weak Lateritic SoilsDocument8 paginiAn Experiment To Determine The Prospect of Using Cocoa Pod Husk Ash As Stabilizer For Weak Lateritic SoilsAlexander DeckerÎncă nu există evaluări

- Agronomic Evaluation of Eight Genotypes of Hot Pepper (Capsicum SPP L.) in A Coastal Savanna Zone of GhanaDocument15 paginiAgronomic Evaluation of Eight Genotypes of Hot Pepper (Capsicum SPP L.) in A Coastal Savanna Zone of GhanaAlexander DeckerÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Tadahiro Ohmi (Auth.), André A. Jaecklin (Eds.) - Power Semiconductor Devices and Circuits-Springer US (1992) PDFDocument400 paginiTadahiro Ohmi (Auth.), André A. Jaecklin (Eds.) - Power Semiconductor Devices and Circuits-Springer US (1992) PDFYusuf ArdiÎncă nu există evaluări

- Transistor C4813 Datasheet - NECDocument2 paginiTransistor C4813 Datasheet - NECdhanysiregar100% (1)

- True USB GQ Universal Programmer Supported Device List (Re. 7.23)Document73 paginiTrue USB GQ Universal Programmer Supported Device List (Re. 7.23)ecutronicssÎncă nu există evaluări

- Analog Electronics: Module-1 Semiconductor DiodesDocument39 paginiAnalog Electronics: Module-1 Semiconductor DiodesAyesha HumeraÎncă nu există evaluări

- Data-Sheet Buk9640-100aDocument10 paginiData-Sheet Buk9640-100aMizael Medeiros dos SantosÎncă nu există evaluări

- Semiconductor Devices Are Electronic Components That Exploit The Electronic Properties of Semiconductor MaterialsDocument3 paginiSemiconductor Devices Are Electronic Components That Exploit The Electronic Properties of Semiconductor MaterialsNuwan SameeraÎncă nu există evaluări

- Ec8095-Vlsi Design-607796847-Ec 8095 NotesDocument163 paginiEc8095-Vlsi Design-607796847-Ec 8095 Noteshmpudur1968Încă nu există evaluări

- MESFETDocument2 paginiMESFETAtul KumarÎncă nu există evaluări

- AEC Module1 Clipping and ClampingDocument43 paginiAEC Module1 Clipping and ClampingVinay kumar havinalÎncă nu există evaluări

- Integrated Circuit - Wikipedia PDFDocument95 paginiIntegrated Circuit - Wikipedia PDFRiikaÎncă nu există evaluări

- GC EDRAM Overview 10 2021Document41 paginiGC EDRAM Overview 10 2021Pavan DhakeÎncă nu există evaluări

- Physics ProjectDocument46 paginiPhysics ProjectAdrije GuhaÎncă nu există evaluări

- Jfet Slide Present LatestDocument11 paginiJfet Slide Present LatestazzieraismailÎncă nu există evaluări

- 2SC1079 2SC1080Document4 pagini2SC1079 2SC1080isaiasvaÎncă nu există evaluări

- 051796F0.sch-1 - Thu Dec 15 11:09:57 2005Document25 pagini051796F0.sch-1 - Thu Dec 15 11:09:57 2005Aconatic tvhomeÎncă nu există evaluări

- Ut3n06g Ab3 R Ut3n06g Ae3 R Ut3n06l Tm3 T Ut3n06g Tm3 T Ut3n06l Tn3 R Ut3n06g Tn3 RDocument4 paginiUt3n06g Ab3 R Ut3n06g Ae3 R Ut3n06l Tm3 T Ut3n06g Tm3 T Ut3n06l Tn3 R Ut3n06g Tn3 RAlberto CruzÎncă nu există evaluări

- ELECS CompilationDocument74 paginiELECS CompilationRaine LopezÎncă nu există evaluări

- Transient Voltage Protection of MosfetsDocument1 paginăTransient Voltage Protection of MosfetsVarun NarisettyÎncă nu există evaluări

- Inkjet-Printed High Mobility Transparent-Oxide SemiconductorsDocument5 paginiInkjet-Printed High Mobility Transparent-Oxide Semiconductorsjulio perezÎncă nu există evaluări

- Diodes Group Body Marking - VishayDocument25 paginiDiodes Group Body Marking - VishayPelotaDeTrapoÎncă nu există evaluări

- B647 JingdaoDocument3 paginiB647 JingdaoАндрій МаланінÎncă nu există evaluări

- Mbrf10u100cta KecDocument4 paginiMbrf10u100cta KecHasanErkelÎncă nu există evaluări

- Logic FamilyDocument7 paginiLogic FamilyVenkatesh KatepalliÎncă nu există evaluări

- Extraction of Schottky Diode Parameters From Forward Current-Voltage CharacteristicsDocument4 paginiExtraction of Schottky Diode Parameters From Forward Current-Voltage CharacteristicsChandu KakarlaÎncă nu există evaluări

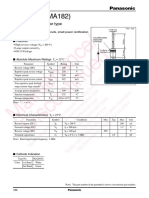

- MA182Document3 paginiMA182RegaÎncă nu există evaluări

- Memory DesignDocument66 paginiMemory Designshashank varshneyÎncă nu există evaluări

- Light Dependent Resistor LDR Physics Investigatory ProjectDocument18 paginiLight Dependent Resistor LDR Physics Investigatory ProjectDeepan KumarÎncă nu există evaluări

- Study of Porous Silicon Carbide Dopped With Lithium For Application in Supercapacitors PDFDocument1 paginăStudy of Porous Silicon Carbide Dopped With Lithium For Application in Supercapacitors PDFFernando SerranoÎncă nu există evaluări

- P-N Junction DiodeDocument32 paginiP-N Junction DiodeGulam Ahmed Rehan100% (1)

- Transistor Out AK 2021Document86 paginiTransistor Out AK 2021senthilnathan srinivasanÎncă nu există evaluări