Documente Academic

Documente Profesional

Documente Cultură

Aurora Regenerative Turbine 150 Series Brochure

Încărcat de

thehammer2Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aurora Regenerative Turbine 150 Series Brochure

Încărcat de

thehammer2Drepturi de autor:

Formate disponibile

REGENERATIVE TURBINE PROCESS PUMPS FOR LOW FLOW, HIGH PRESSURE APPLICATIONS

WWW.AURORAPUMP.COM

AURORA 150 SERIEs APCO-CHEM

REGENERATIVE TURBINE PROCESS PUMPS FOR LOW FLOW, HIGH PRESSURE APPLICATIONS

Regenerative Turbine Process Pumps for Low Flow, High Pressure Applications

Capacities to 115 GPM Heads to 1200 Feet Temperatures to 500 F Meets ANSI B73.1 Std. Process Industry Field Proven For:

Chemicals Petrochemicals Refinery Pulp and Paper General Industry

AURORA 150 SERIEs APCO-CHEM

Sealing Flexibility

Shaft Arrangement with shaft sleeve. Seal Types single or double, inside, balanced or unbalanced. Glands plain, flush, quench, vent and drain. Seat Mounting flexibly mounted O-ring or clamped stationary seat. Flush Plans ANSI and API configurations available.

Type 1B Single inside

Services:

Boiler Feed Condensate Chemical Transfer Injection Steep head capacity curves for applications that require minimal flow change. Ability to handle vapors up to 20% by volume. Steady floweliminates pulsation problems associated with other pump designs. Back pull-out design for low cost, one craft maintenance. Top vertical centerline discharge. Pump has known shut-off pressure as opposed to positive displacement designs. Reduced down-time for bearing and seal maintenance. Pump built to ANSI B73.1 dimensional standards for maximum interchangeability. Lower operating costs than standard centrifugal pumps at low flow conditions. Balanced double suction impeller design reduces axial thrust.

2

Type 1100 Single inside seal cartridge seal

Design Features:

Type 88 Double seal or tandem cartridge

John Crane Inc., Seal Pictures

REGENERATIVE TURBINE PROCESS PUMPS FOR LOW FLOW, HIGH PRESSURE APPLICATIONS

Optimal Hydraulic Coverage

APCO-CHEM Turbine Pumps

Specific speed (NS)1 can be thought of as a hydraulic index number indicating a specific type of pump best suited for a particular application. The Hydraulic Institute lists a range of NS from 500 through 20,000 for centrifugal pumps starting at a straight radial impeller and progressing through an axial-flow design.2 But, what about NSs below 500? This is where the unique APCO-CHEM regenerative turbine can best serve those special pumping applications. Consider the following pumping requirements at 3500 RPM.

Head (ft.) Flow (GPM) NS 600 10 91 600 30 158 600 60 224 600 90 274

Now try to find a good centrifugal pump that would meet those pumping requirements at a reasonable efficiency, NPSH requirement and operating life. Rather difficult! However, look at the quality performance a regenerative turbine can give to those requirements. Specific speed, then, is an index that indicates the type of pump best suited for the myriad pumping applications in the marketplace. NS below 500 can best be handled by regenerative turbines that have the inherent hydraulic capabilities of pumping low flows and high head requirements.

Example:

150 Series Turbine Type Pumps

Select a pump for 20 GPM, 320 feet total dynamic head, with 3 foot NPSH available. Enter curve at 320 feet and move to right to 3' NPSH line. Read down to 20.5 GPM to determine the BHP, go back to 320 foot line and continue to right to solid head-capacity curve, then down to BHP curve, then to right and read 4.7 BHP. For application where NPSH available exceeds that as shown by dotted lines, select pump capacity and BHP on solid lines.

Specific Speeds NS = (RPM) (GPM)1/2 (FT. of Head)3/4 2 See ANSI/HI 1.11.51994 standards page 3.

1

WWW.AURORAPUMP.COM

REGENERATIVE TURBINE PROCESS PUMPS FOR LOW FLOW, HIGH PRESSURE APPLICATIONS

APCO-CHEM Design Features of the One and Two Stage Turbine Type Pump

A. B. C. D. E. F. G. H. I.

Double suction and floating impeller balances axial thrust load. Sealing flexibility (mechanical seal or packing). Rigid shaft and short bearing span increase mechanical seal life. Oil or grease lubrication. Single row radial and double row thrust bearings for extended life. Hook type shaft sleeve allows expansion for temperature changes. Replaceable channel rings allow ease of maintenance. Two-stage design for ultra high heads. Balancing holes reduce axial thrust.

Models 151 and 152 (Single Stage Design)

D C E E F

Models 153 and 154 Liquid End

H I

Optional Design Features

Jacketed stuffing box for cooling or heating mechanical seal cavity. Jacketed bearing frame provides bearing cooling for high temperature services. Case centerline mounting for high temperature services (not available on Model 151).

REGENERATIVE TURBINE PROCESS PUMPS FOR LOW FLOW, HIGH PRESSURE APPLICATIONS

Process Turbine Pump Principles of Operation

Turbine pumps derive their name from the many buckets machined into the periphery of the rotating impeller. They have long since been recognized for their effectiveness in the areas of low flow, high head application. The turbine pump offers higher heads than centrifugal pumps. Because the head capacity curve is steep in a turbine pump, a greater degree of flexibility is available to the process engineer. Turbine pumps having top center line discharge are self-venting and have the ability to handle vapors without vapor lock. This characteristic allows handling of boiling liquids and liquefied gases at suction heads slightly over the vapor pressure. The turbine pump also has higher efficiencies at low flows than a centrifugal pump. Turbine pumps use close running clearances and are normally used on clean liquid applications. Viscous materials up to 500 S.S.U. can be pumped. Turbine pumps are unique in operation. The pumped liquid is directed by the liquid passage so that the liquid circulates in and out of the impeller buckets many times on its way from the pump inlet to the pump outlet. Both centrifugal and shearing action combine to impart additional energy to the liquid each time it passes through the buckets. Heads over 900 feet are successfully developed in a single stage. The impeller runs at very close axial clearances with the pump channel rings to minimize recirculation losses. The channel rings provide a circular channel around the blade area of the impeller, from the inlet to the outlet. Liquid entering the channel from the inlet is picked up immediately by the buckets on both sides of the impeller and pumped through the channel (Figure 1) by a shearing action. The flow of the liquid within the impeller buckets is illustrated in Figure 2. This process is repeated over and over, each cycle imparting more energy until the liquid is discharged. This flow is smooth and continuous. In two stage pumps, the liquid is directed to a second stage impeller where the process is repeated, doubling the discharge head. By offsetting the discharges by 180, the radial loads on the bearing are nearly balanced and shaft deflection is minimized.

WWW.AURORAPUMP.COM

REGENERATIVE TURBINE PROCESS PUMPS FOR LOW FLOW, HIGH PRESSURE APPLICATIONS

Performance Data and Special Features

3500 RPM 1750 RPM

Pump Part Casing Impeller Shaft Channel rings Sleeve Gland Stuffing box

Materials of Construction Material Code* 14 19 316 Stain. Stl. ASTM A743 Ductile Iron ASTM A395 316 Stain. Stl. ASTM A743 Ductile Iron ASTM A395 316 Stain. Stl. ASTM A743 Steel AISI C1045 316 Stain. Stl. ASTM A743** Cast Iron ASTM A48 316 Stain. Stl. AISI 316 Hnd. Stain. Stl. ASTM A276 316 Stain. Stl. AISI 316 Ductile Iron ASTM A395 316 Stain. Stl. ASTM A743 Ductile Iron ASTM A395

22 Alloy 20 ASTM A743 CN7M Alloy 20 ASTM A743 CN7M Carpenter 20 Alloy 20 ASTM A743 CN7M** Carpenter 20 Alloy 20 ASTM A743 CN7M Alloy 20 ASTM A743 CN7M

Pumps come standard with packing. Braided acrylic with graphite/TFE (Teflon lantern ring furnished upon request.) * Other material combinations available. ** Chromium oxide ceramic coated sealing surfaces.

Modular Design

REGENERATIVE TURBINE PROCESS PUMPS FOR LOW FLOW, HIGH PRESSURE APPLICATIONS

Performance Data and Special Features

Pressure and Temperature Capability

Maximum Temperature Limitations for Pumped Liquid Pump Models Description 151 Mechanical Seal without 300F stuffing box cooling (see Note 1). Mechanical Seal with water cooled stuffing box and water N/A jacketed frame. Packing without stuffing box 300F cooling (see Note 2). Packing with water cooled N/A stuffing box and jacketed frame. 152-3-4 300F 500F 300F 500F Stuffing Box General

Construction Details

Series 150 Discharge flanges(300) Suction flange Number of stages Casing wall thickness Nominal impeller dia. Corrosion allowance Impeller clearance Rotation from cplg Bore Depth O.D. sleeve Packing size Distance to first obstruction Total rings 151 1 1-1/2 1 1/2 4-1/2 Pump Model 152 153 1-1/2 1 1/2 3 3 1 2 5/8 3/4 6 1/8 0 .005' To 0.007' CW 154 2 3 2 3/4

NOTES: 1. Pumps with standard mechanical seals on continuous duty water applications MUST NOT exceed 180F without providing cooling at the stuffing box. Special seal face materials will increase this limit refer to factory. 2. Pumps with packing on water applications MUST NOT exceed 250F without providing cooling at the stuffing box. 3. For temperatures above 300F in Models 152, 153 and 154, the centerline casing support is recommended.

Tapped Openings Purpose Lantern ring connection Frame adapter drain Discharge gauge connection** Suction gauge connection** No. of Taps 1 1* 1 1 151 1/4 NPSF 1/2 NPSF 1/4 NPT 1/4 NPT

1-3/4" 2" 1-1/8" 3/8 Sq. 1-15/16 5

2-1/2" 2-5/8" 1-3/4" 5/8 Sq. 2-9/16 5

Series 150 Dia. at impeller Dia. at sleeve Dia. between bearings Dia. at coupling end Keyway Maximum deflection Radial bearing Thrust bearing Bearing centers Radial brg. and 1st stg. Radial brg. and 2nd stg. center Min. B10 bearing life

Tap Size

* Model 151 has 2 taps. ** Optional

Code For Pressure Temperature Charts A B C

MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) 400 MODEL 151

316 SS Ductile iron Alloy 20

MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) 400 MODEL 152 600 MODEL 153/154

Bearings

152-3-4 1/4 NPSF 1/2 NPSF 1/4 NPT 1/4 NPT

151 11/16" 7/8" 1-9/16" 7/8" 3/16 Sq. 306 5306 5.37" 5.37" 5.75"

Pump Model 152 153 1-1/8" 1-1/2" 2-1/8" 1-1/8" 1/4 Sq. 0.002" 309 5309 6.87" 6.56" 6.87" 2 years

154

Shaft

A&C B MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) MODEL 153/154 600 A&C MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) 500 MODEL 153/154

A&C

MODEL 151 MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) 400 400

MODEL 151

300 MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) A&C 200 B 400

MODEL 152 MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) 400

MODEL 152

300 A&C B MAX. CASE WORKING PRESSURE (psig) (Differential pressure plus suction pressure) 100 600

500

A&C B

200

A & C 400

300

300 A&C 200B

300

300

500

A100 &C B 0 -200

300

200

200

200 600 100 0 -200

400

400 600 300

200

100

100

0 200 400 WORKING TEMPERATURE (F) 100

0 200 400 WORKING TEMPERATURE (F) 300

100 200 0 100 -100 0 200 400 WORKING TEMPERATURE (F) 600

-200

0 0 -200 200 0 400 200 600 400 WORKING TEMPERATURE WORKING (F) TEMPERATURE (F)

0 600

-200

0 0 -200 200 0 400 200600 400 WORKING TEMPERATURE WORKING (F) TEMPERATURE (F)

200 600 100

WWW.AURORAPUMP.COM

-100

0 0 200-100 0 400 200 600 400 WORKING TEMPERATURE WORKING (F) TEMPERATURE (F)

7

600

Dimensional Data and Engineering Specifications

Model 151 152 153 154 Discharge Suction A Size Size 1 x 1-1/2 x 6 1 1-1/2 17-1/2 1-1/2 x 3 x 6 1-1/2 3 23-1/2 1-1/2 x 3 x 6 1-1/2 3 *23-1/2 2x3x6 2 3 *23-1/2 Pump Size D 5B 8B 8B 8B X 6-1/2 8-1/2 8-1/2 9-1/2 Y 7B 12-1/2 12-1/2 12-1/2 B 4 4 4* 4* Sp 3-1/2 3-1/2 3-1/2 3-1/2

Dimensions Determined by Motor Model 151 151 152 153 154 1T 2T 1 2 3 Motor Motor Frame Size C MAX 56 - 145T 182 - 215T 143T - 215T 245T - 286TS 324T - 365TS HA 10 12 12 15 18 HB 35 39 45 52 58 HG 3 3-1/4 3-3/4 4-1/8 4-3/4 Bedplate HF 32-1/2 36-1/2 42-1/2 49-1/2 55-1/2 HH 3/4 3/4 3/4 3/4 1 HE 4 4-1/2 4-1/2 6 7

The contractor shall furnish (and install as shown on plans) Aurora Model (151 17-1/2" ANSI horizontal flexible coupled) (152 23-1/2" ANSI horizontal flexible coupled) (153 23-1/2", 154 23-1/2" ANSI horizontal flexible coupled) back pull-out regenerative turbine pump(s) size____ x ____ x____ The pump shall be constructed with (ductile iron) (316 stainless steel) pressure containing parts having a minimum tensile strength of (60,000 psi ductile iron) (80,000 psi 316 stainless steel) and shall be of sufficient thickness to withstand stresses and strains at full operating pressures. Casings shall be subject to a hydrostatic pressure test at 150% of the specified duty point. The pump shall be capable of delivering at design conditions a capacity of ____ GPM when operating against a Total Dynamic Head of____ feet, with a temperature of____F, ____ Liquid specific gravity ____. Pump shall operate at a maximum synchronous speed of ____ RPM. A unit operating at a lesser rotative speed will be considered, but in no event will a pump operating at more than the maximum speed specified be acceptable. Each pump is to be furnished with a (standard) (water cooled) stuffing box with (____mechanical seal) (packing). The unit must be equipped with (316 stainless steel) (440C hardened

stainless steel, pack pumps) pin locked shaft sleeve that extends the length of the stuffing box. The pump shaft extension shall be O-ring sealed from the pumped liquid. The discharge shall be in a vertical position and the pump shall be self-venting. The impeller shall be hydraulically self-centering and no external adjustment shall be necessary. Pump and motor are to be mounted on a common (ANSI cast iron) (steel) baseplate. The pump shaft shall be made of high grade____ steel or equal. The minimum diameter acceptable will be____". The shaft shall be installed in a cast iron power frame. Pumps shall have a shaft designed for .002" deflection at the face of the stuffing box with the pump running under maximum load condition. (Oil) (Grease) lubricated ball bearings, having a 2- year minimum life (AFBMA B-10) under the maximum condition of load protected by separate oil seals and slingers, shall be used. The pump shall be flexible coupled to standard horizontal NEMA ____hp, ____phase, ____Hertz, ____volts, ____ RPM (drip-proof) (totally enclosed) (hazardous location) motor. Alignment shall be checked in accordance with the standards of the Hydraulic Institute after installation and there shall be no strain transmitted to the pumps.

ER E D Q U

HY

19 17

800 AIRPORT ROAD, NORTH AURORA, ILLINOIS 60542 WWW.AURORAPUMP.COM

Teflon is a registered trademark of E.L. duPont Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice. A-02-1007 07/15/13 2013 Pentair Ltd. All Rights Reserved.

ISO 9001

AU LI

DR

ST EGI

TY SYSTEM ALI

IN ST IT UT E

S-ar putea să vă placă și

- Paper Fan PumpsDocument8 paginiPaper Fan PumpsnazeerÎncă nu există evaluări

- Brochure BEGEMANN PA Pumps-Low ResolutionDocument6 paginiBrochure BEGEMANN PA Pumps-Low ResolutionIsaac RubioÎncă nu există evaluări

- Third Row LEftDocument4 paginiThird Row LEftAlfredo Mendez VazquezÎncă nu există evaluări

- Rotating EquipmentDocument202 paginiRotating EquipmentJithin Rajan Joseph100% (1)

- Equipment:: Figure 1: Vertical Turbine PumpDocument8 paginiEquipment:: Figure 1: Vertical Turbine PumphamizanÎncă nu există evaluări

- Api CPRDocument7 paginiApi CPRMarco OrdoñezÎncă nu există evaluări

- Itt PumpDocument6 paginiItt Pumpnaser712Încă nu există evaluări

- Aurora Pump 6-491-12aDocument28 paginiAurora Pump 6-491-12ajuan yenqueÎncă nu există evaluări

- LSP LowSpeedHighPressurePumps E00522Document7 paginiLSP LowSpeedHighPressurePumps E00522Sigit PramonoÎncă nu există evaluări

- Aturia Process Api610 092012low1Document4 paginiAturia Process Api610 092012low1Goce VasilevskiÎncă nu există evaluări

- p01 11Document8 paginip01 11prihartono_diasÎncă nu există evaluări

- CepDocument7 paginiCeppramod_tryÎncă nu există evaluări

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDocument6 paginiDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezÎncă nu există evaluări

- Selection - Guide - Rurh PumpsDocument44 paginiSelection - Guide - Rurh PumpsFilipe AfÎncă nu există evaluări

- Steam TurbineDocument10 paginiSteam TurbineAmeya Ranade100% (1)

- BBS E00584Document8 paginiBBS E00584gloohuis463Încă nu există evaluări

- b3311 722-2Document7 paginib3311 722-2Arnaldo BenitezÎncă nu există evaluări

- Compresores Serie-A ChampionDocument4 paginiCompresores Serie-A ChampionFrancisco100% (1)

- SERIE P eDocument3 paginiSERIE P erasottoÎncă nu există evaluări

- Centrifugal PumpsDocument6 paginiCentrifugal Pumpshenkis73Încă nu există evaluări

- Brochure BEGEMANN BS Pumps-Low ResolutionDocument6 paginiBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorÎncă nu există evaluări

- KSB Centrifugal PumpsDocument12 paginiKSB Centrifugal Pumpswoodywheel100% (1)

- Pump ZM B PDFDocument12 paginiPump ZM B PDFRamon PachecoÎncă nu există evaluări

- NP Pumps BlackmerDocument4 paginiNP Pumps BlackmerrasottoÎncă nu există evaluări

- Ebsray V40Document8 paginiEbsray V40damedifyoudoÎncă nu există evaluări

- Phased Out Products: Gear Pumps and Motors General ProductsDocument18 paginiPhased Out Products: Gear Pumps and Motors General ProductsAndrei VladÎncă nu există evaluări

- Taco Expansion TankDocument16 paginiTaco Expansion Tanksas999333Încă nu există evaluări

- SubmersiblePropellerPump VUPX E10359Document8 paginiSubmersiblePropellerPump VUPX E10359hafezasadÎncă nu există evaluări

- MC HighPressureStageCasingPump E10026Document6 paginiMC HighPressureStageCasingPump E10026govindkaniÎncă nu există evaluări

- 300-9 4Document16 pagini300-9 4avabhyankar9393Încă nu există evaluări

- Boletin Tecnico No. 3 Turbinas de Vapor ElliottDocument12 paginiBoletin Tecnico No. 3 Turbinas de Vapor Elliottcristobal_tl227750% (2)

- Catálogo General UPA 50 HZ 2 PARTEDocument20 paginiCatálogo General UPA 50 HZ 2 PARTENao Oi OiÎncă nu există evaluări

- AH AV CatalogDocument16 paginiAH AV CatalognomurapreÎncă nu există evaluări

- Vogel Pompen P PVaDocument12 paginiVogel Pompen P PVaeddy1588100% (1)

- Indupump Process Pump Brochure SmallDocument16 paginiIndupump Process Pump Brochure SmalljasonventÎncă nu există evaluări

- BB3 Catalogue 2015Document8 paginiBB3 Catalogue 2015nima hasanzadehÎncă nu există evaluări

- Kunkle OverviewDocument8 paginiKunkle Overviewsamix999Încă nu există evaluări

- Pumps, Tanks, & AccessoriesDocument8 paginiPumps, Tanks, & Accessoriesسامح الجاسمÎncă nu există evaluări

- Submersible Propeller Pump Type ABS VUPXDocument8 paginiSubmersible Propeller Pump Type ABS VUPXAgus SalmanÎncă nu există evaluări

- Centrifugal Pumps: A World of Steady and Dependable Flow ControlDocument14 paginiCentrifugal Pumps: A World of Steady and Dependable Flow ControlYimmy Alexander Parra MarulandaÎncă nu există evaluări

- Pump SCE B 2Document8 paginiPump SCE B 2Zankar R ParikhÎncă nu există evaluări

- Bombas CentrifugasDocument12 paginiBombas CentrifugasIsaac Deusdedit Salazar EhuanÎncă nu există evaluări

- Imo Pumps 8l SeriesDocument6 paginiImo Pumps 8l SeriesNelson OrconÎncă nu există evaluări

- GouldsDocument11 paginiGouldsKaren Isabel Ambiado Rivas100% (1)

- GR KPL&KWMDocument12 paginiGR KPL&KWMHeri SulasionoÎncă nu există evaluări

- Products That Perform...By People Who CareDocument20 paginiProducts That Perform...By People Who CareFalak KhanÎncă nu există evaluări

- Cabezotes Gardner DenverDocument8 paginiCabezotes Gardner DenverChristian CardenasÎncă nu există evaluări

- Bornemann - Twin Screw Pumps - Series W, V, U and TDocument16 paginiBornemann - Twin Screw Pumps - Series W, V, U and Tfwkl100% (1)

- Brochure Tank FarmDocument7 paginiBrochure Tank FarmSagar DasÎncă nu există evaluări

- HPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Document29 paginiHPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Ashwin NarayanÎncă nu există evaluări

- RAJAMANE Full - Catalog - 09 PDFDocument25 paginiRAJAMANE Full - Catalog - 09 PDFchidambaram kasi100% (1)

- NRVSB 0062 enDocument7 paginiNRVSB 0062 enshashikanth79Încă nu există evaluări

- Forum Fluid End Pump PartsDocument18 paginiForum Fluid End Pump PartsriskvisionÎncă nu există evaluări

- Tubine Bypass SystemDocument12 paginiTubine Bypass Systemkalyanm203515Încă nu există evaluări

- Vertical Sump PumpDocument6 paginiVertical Sump Pumpsahildhingra100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- 421-110 - Falk Steelflex Grid Couplings - CatalogDocument44 pagini421-110 - Falk Steelflex Grid Couplings - CatalogErik Garcia ZamoraÎncă nu există evaluări

- Data Sheet: Atlas Series Bolted Type HolderDocument2 paginiData Sheet: Atlas Series Bolted Type Holderthehammer2Încă nu există evaluări

- K209 FDocument4 paginiK209 Fthehammer2Încă nu există evaluări

- Fisher CV ValuesDocument220 paginiFisher CV Valuesthehammer2100% (3)

- Tecnicas para Cartas de Amor U OdioDocument4 paginiTecnicas para Cartas de Amor U OdioChristian Gabriel Stampacchio100% (16)

- R.1.47.01 Atlas Rupture DiscDocument2 paginiR.1.47.01 Atlas Rupture Discthehammer2Încă nu există evaluări

- R.1.27.01-5 SRX Data SheetDocument4 paginiR.1.27.01-5 SRX Data Sheetthehammer2Încă nu există evaluări

- Tecnicas para Cartas de Amor U OdioDocument4 paginiTecnicas para Cartas de Amor U OdioChristian Gabriel Stampacchio100% (16)

- Data Sheet: Ho/Hov SeriesDocument3 paginiData Sheet: Ho/Hov Seriesthehammer2Încă nu există evaluări

- Chemical Resistance ChartDocument8 paginiChemical Resistance Chartthehammer2Încă nu există evaluări

- Crosby Pressure Relief Valve Engineering HandbookDocument93 paginiCrosby Pressure Relief Valve Engineering Handbookthehammer2100% (2)

- CPDocument12 paginiCPthehammer2Încă nu există evaluări

- The Outside Diameter As Their Nominal DiameterDocument75 paginiThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- Aurora Regenerative Turbine 150 Series Engineering DataDocument22 paginiAurora Regenerative Turbine 150 Series Engineering Datathehammer2Încă nu există evaluări

- Smith Silverline RegulatorsDocument36 paginiSmith Silverline Regulatorsthehammer2100% (1)

- The Outside Diameter As Their Nominal DiameterDocument75 paginiThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- CT-111 APCO-CHEM pump performance dataDocument22 paginiCT-111 APCO-CHEM pump performance datathehammer2Încă nu există evaluări

- Aurora Regenerative Turbine 150 Series Engineering DataDocument22 paginiAurora Regenerative Turbine 150 Series Engineering Datathehammer2Încă nu există evaluări

- Gumbo PlanDocument1 paginăGumbo Planthehammer2Încă nu există evaluări

- Gumbo PlanDocument1 paginăGumbo Planthehammer2Încă nu există evaluări

- NCEES AddressDocument1 paginăNCEES Addressthehammer2Încă nu există evaluări

- Gumbo PlanDocument1 paginăGumbo Planthehammer2Încă nu există evaluări

- Gumbo PlanDocument1 paginăGumbo Planthehammer2Încă nu există evaluări

- Gumbo PlanDocument1 paginăGumbo Planthehammer2Încă nu există evaluări

- APOLLO 8 Flight Plan and Key EventsDocument126 paginiAPOLLO 8 Flight Plan and Key Eventsthehammer2Încă nu există evaluări

- Astm A615-A615m-06Document6 paginiAstm A615-A615m-06NadhiraÎncă nu există evaluări

- Fatigue Curve For SCM440Document6 paginiFatigue Curve For SCM440Nagaraj RaoÎncă nu există evaluări

- Thermoelectricity: Seeback EffectDocument8 paginiThermoelectricity: Seeback EffectAbhi RamiÎncă nu există evaluări

- Test 1 With AnsDocument4 paginiTest 1 With AnsKavinesh GanesanÎncă nu există evaluări

- Chapter 1 - Internship ReportDocument5 paginiChapter 1 - Internship ReportperminderlbwÎncă nu există evaluări

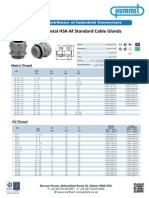

- Hummel Metal HSK-M Standard Cable Glands: Metric ThreadDocument2 paginiHummel Metal HSK-M Standard Cable Glands: Metric Threadalexandresq4283Încă nu există evaluări

- Room Air Conditioner Owner's Manual: Essential Safety TipsDocument21 paginiRoom Air Conditioner Owner's Manual: Essential Safety Tipsrizwan15100% (1)

- Conversion table of EN - Materials vs. US Materials (assorted by ASTM NoDocument1 paginăConversion table of EN - Materials vs. US Materials (assorted by ASTM NoNattapong PongbootÎncă nu există evaluări

- Allegheny Bradford Corporation: Craftsmen in StainlessDocument11 paginiAllegheny Bradford Corporation: Craftsmen in Stainlessアルビン ベネÎncă nu există evaluări

- Datasheet MCBDocument3 paginiDatasheet MCBNanda ramadhanÎncă nu există evaluări

- MATERIAL REQUISITION FOR H2S ABSORBENT MODULAR SKIDDocument21 paginiMATERIAL REQUISITION FOR H2S ABSORBENT MODULAR SKIDPrakash RajÎncă nu există evaluări

- Abu Dhabi Investment Council BuildingDocument7 paginiAbu Dhabi Investment Council BuildingJinaliDoshiÎncă nu există evaluări

- Basic Radiant Design & Construction ManualDocument12 paginiBasic Radiant Design & Construction ManualDavid JonesÎncă nu există evaluări

- Shell and Tube Heat ExchangersDocument13 paginiShell and Tube Heat ExchangersLieu Dinh PhungÎncă nu există evaluări

- Case 1Document19 paginiCase 1JonathanÎncă nu există evaluări

- ACO ShowerDrain S-LineDocument8 paginiACO ShowerDrain S-LinevanjaÎncă nu există evaluări

- Double Pipe Heat Exchanger - SsDocument72 paginiDouble Pipe Heat Exchanger - SsNathanian100% (2)

- SafeCable - Linear Heat Detection LHDDocument2 paginiSafeCable - Linear Heat Detection LHDMACHNUN ARIFÎncă nu există evaluări

- DAIKIN Error CodesDocument3 paginiDAIKIN Error Codesmazlie mazlanÎncă nu există evaluări

- Passive Techniques For Energy Efficiency of Buildings in Sri LankaDocument15 paginiPassive Techniques For Energy Efficiency of Buildings in Sri LankaZah MohamedÎncă nu există evaluări

- FP - EN - GreenFlux 200 - BB - 1014 - 1Document1 paginăFP - EN - GreenFlux 200 - BB - 1014 - 1tribolas100% (1)

- Bolted Connections StudentsDocument56 paginiBolted Connections StudentsKshitizÎncă nu există evaluări

- Ventilation Unit: Wolf Comfort SlimlineDocument44 paginiVentilation Unit: Wolf Comfort SlimlineHugo SousaÎncă nu există evaluări

- BILL OF QUANTITIES FOR DABHOI-BODELI ROAD WIDENINGDocument61 paginiBILL OF QUANTITIES FOR DABHOI-BODELI ROAD WIDENINGayman alnossaryÎncă nu există evaluări

- Data Acquisition in Mechanical Testing of Materials and It's ComponentsDocument19 paginiData Acquisition in Mechanical Testing of Materials and It's ComponentsMuhammad FahadÎncă nu există evaluări

- Assignment No 1Document8 paginiAssignment No 1Ar VinÎncă nu există evaluări

- Test MatrixDocument18 paginiTest MatrixBipul PoudelÎncă nu există evaluări

- Magneto CaloricDocument13 paginiMagneto CaloricMarcelo MartinsÎncă nu există evaluări

- HRSG Erection GuideDocument56 paginiHRSG Erection GuideUtku Kepcen50% (2)

- Samsung AirDocument55 paginiSamsung AirElectropartes Nicaragua100% (3)