Documente Academic

Documente Profesional

Documente Cultură

Development of A Low Cost Touch Trigger Probe For CNC Lathes

Încărcat de

Narayan ApteTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Development of A Low Cost Touch Trigger Probe For CNC Lathes

Încărcat de

Narayan ApteDrepturi de autor:

Formate disponibile

Journal of Materials Processing Technology 179 (2006) 117123

Development of a low cost Touch Trigger Probe for CNC Lathes

Marcelo Del Guerra a, , Reginaldo Teixeira Coelho b

a b

Escola de Engenharia de Sao Carlos-EESC-USP, Av. Trabalhador Sancarlense 400, CEP 13566-590, Sao Carlos, SP, Brazil Escola de Engenharia de Sao Carlos-EESC-USP, Av. Trabalhador Sancarlense 400, CEP 13566-590, Sao Carlos, SP, Brazil

Abstract The use of Touch Trigger Probes for CNC Machine Tools has become a world standard, mainly due to the reduction of machine setup time and the ability to promote workpiece accuracy on-machine measurements. However, some barriers still need to be transposed, like the measurement routines programming difculties, high costs of these equipments and the low number of technical literature about this subject. This work presents a review on the applications of Touch Trigger Probes on shop oor, discussing nowadays technologies used to generate the trigger signal. A new Touch Trigger Probe model based on a simple electrical contact is proposed, with the needed characteristics and low cost, to be used for CNC Lathes. The tests of the probe developed in the laboratory shown a repeatability of 0.003 mm (3 s or 99.73% condence interval). Those characteristics seem to be highly comparable to most needs for lathe applications in industries. 2006 Elsevier B.V. All rights reserved.

Keywords: Dimensional quality monitoring and control; Touch Trigger Probes; On-machine measuring systems; CNC Lathes

1. Introduction One of the, nowadays, most difcult challenges on manufacturing system developments is to achieve total dimensional control of parts produced, creating statistical data analyses and part-to-part control. This kind of integration may be reached by using devices commonly called Touch Trigger Probes attached to CNC Machine Tools. These equipments are used for measurements and calibrations based on projects specications, closedloop process control, dimensional control of parts manufactured, tool compensation, fast setup, process statistical data acquisition and more. It is very important in current manufacturing systems trends to make the use of these functions, making possible a part-to-part inspection control if necessary, which assures that dimensional errors are immediately detected, reducing scraps, avoiding that a full batch of pieces are scraped and reducing the costs due to parts reworks. To assist dimensional control on turning operations, this work starts introducing the Touch Trigger Probes characteristics, technologies used to generate the trigger signal. After that, this paper presents a simple and low cost wireless Touch Trigger

Probe, based on a direct electrical contact principle. A prototype is presented together with the repeatability and accuracy studies. 2. Touch Trigger Probes earlies The rst Touch Trigger Probe was invented to solve a specic inspection requirement, but went on to transform the design and revolutionize the use of coordinate measuring machines (CMMs) for post-process inspection of manufactured components. In the end of 1970s, almost all the major CMM manufacturers in the world were using RenishawsTM probes. Later, due to CNC advances including measurement functions and linear encoder on its axes, the use of such devices spread to machine tools, where they became a vital component on automated production systems, allowing companies, from automotive to aerospace, to deliver precise components, reducing scraps and maximizing productivity. David McMurtry developed the Touch Trigger Probes technology in 1972. The problem arose at Rolls-Royce plc, where he was Assistant Chief of Engine Design. At that time, he was facing the problem of measuring some complex pipe runs, of only 6 mm diameter, for the Olympus engines used on Concorde. The pipes had to t accurately between solid mountings, but the difculty came in measuring them once they had been manufactured. The solution found was the Touch Trigger Probe (TTP), which uses a simple principle to identify the contact between the probe

Corresponding author. E-mail addresses: mdguerra@sc.usp.br (M. Del Guerra), rtcoelho@sc.usp.br (R.T. Coelho). 0924-0136/$ see front matter 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.jmatprotec.2006.03.093

118

M. Del Guerra, R.T. Coelho / Journal of Materials Processing Technology 179 (2006) 117123

Fig. 1. A measurement system attached to a CNC Machine Tool.

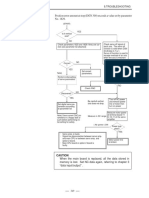

and the part to be measured. In 1973, David McMurtry registered a company called Renishaw that early become the leading provider of metrology and spectroscopy solutions to manufacturers and researchers around the world (Renishaw [1]). Due to the patented mechanism used by the company, other technologies needed to be developed by other companies that intended to join on this market. 3. Touch Trigger Probes main characteristics Independently of the technology used, the principle is based on the generation (or interruption) of an electrical signal at the moment the probes tip touches the part to be measured. This signal, generally called trigger signal, is sent to the interface that converts it to be read by a CNC or a CMM. At the moment that the machine receives the trigger signal, it instantly freezes and save the axis values for calculations and reports generation (see example in Fig. 1). The trigger signal transmission from the TTP to the probe interface can be established using basically three different communication technologies: infrared, radio frequencies or a simple wire cable. Infrared communication is used for conventional applications for standard lathes and milling machines; this technology provides high reliability, high transmission speed rates, low noise interferences and low implementation costs. It is close to a foolproof system, except when probe and receiver are out of visual contact, as when the probe is deep within a bore or other depression within the workpiece. For these cases and applications, a radio frequency system is recommended, (Tooling & Production [2]). Wire cable communication is used for tool setter probes which are mounted and xed on the machine tables. 4. Probing cycles and programming

To make probing effective and more affordable to a wide range of users, some of the main leading CNCs manufactures, such as Fanuc, Heidenhain, Okuma, Cincinnati Milacron and Siemens, are including, in its CNCs software, graphical userfriendly interfaces specially developed for probing. Heidenhain TNC control series, for example, are able to automatically or manually carry through three-dimensional measurements and enables check functions, such as checking the dimensional accuracy of holes, determining feeds for nishing, checking workpiece geometry and identifying deviations from tolerances, identifying workpieces prior to machining and scanning 3D surfaces. Also, probing cycles are being widely developed and can be activated by a single line of information (Zhou et al. [4]). Todays standard machine tools deliver accuracy and repeatability approaching levels formerly available only on CMMs. In addition, technology advances are making these machines easier to maintain. Test and calibration technology are now available to enable shops to ensure the accuracy and health of their machine tools. Telescoping ballbars are readily affordable by virtually any shop. A well-stocked toolbox should also contain either electronic levels or a good set of precision machine levels. Plants and large shops increasingly maintain their own laser interferometers and electronic levels, while rental equipment and diagnostics services are commercially available to small shops from various sources (Modern Machine Shop On Line [5]). Also, according to Modern Machine Shop On Line [6], CNC machines are, in general, very accurate and extremely repeatable. They compare favorably with the accuracy and repeatability of CMMs of similar size. With some care during the CNC inspection process, the factors that lead to interdependence between measurement error and cutting error can be minimized. 5. Technologies used to generate the trigger signal According to Shen and Moon [7], there is no trigger signal generated when the probe tip touches the workpiece. The probe will continue to move toward and the force between the probe tip and the workpiece will increase, causing a physical quantity (e.g., resistance) to reach a threshold setting. A trigger signal is generated when the physical quantity exceeds a threshold limit in the sensing system. The travel distance between the touch instant and the trigger instant is known as probe pretravel. Mainly caused by bending deection of the stylus shaft, it accounts for the majority of probe errors. Basically there are four different principles used to generate the trigger signal: electrical contact (kinematic contact), light (laser interferometry), deformation (strain-gauges) and the piezoelectric effect. 5.1. Kinematic contact

According to Modern Machine Shop On Line [3], few professionals will dispute the merits of probing for speeding part setup, setting tool offsets and performing in-process inspection, at least in theory. In practice, however, probe systems often have been viewed as difcult to use and expensive to buy. As a result, they have become tools used primarily by experienced programmers in high-production environments.

Currently, this is the most used Touch Trigger Probe widespread. Developed by David McMurtry, this principle revolutionized the use of the coordinate measurement machines. According to Fig. 2, it is a kinematic re-seating mechanism based on three small cylindrical pieces that stay seated on six other cylinders/spheres by the pressure caused by the

M. Del Guerra, R.T. Coelho / Journal of Materials Processing Technology 179 (2006) 117123

119

Cumulative errors happen when using stylus longer than 30 mm due to the fact that the touching force necessary to generate the trigger signal bends the stylus and this deection is proportional to its length. The acquisition cost of these equipments is relatively high if compared to other systems that provide similar benets. This equipment is very well known and the brand that manufactures them is associated with very high quality. 5.2. Strain-gauges Strain-gauges probes deals with analogical information deriving from the electrical resistance variation produced when the stylus touch the part to be measured. To use this technique as a digital switch, it is necessary an electrical signal conditioning and treatment, establishing the limits from which the trigger signal is generated.

Fig. 2. Kinematic Touch Trigger Probes working principle (Tooling & Production [2]).

spring action, restricting its degrees of freedom until the stylus is brought into contact with the workpiece. An electrical current normally ows through the three seats in series. When the probe tip moves away from its stable position, one or more of the seat contacts breaks and the increase in resistance is immediately detected electronically (Mayer et al. [8] and Reid [9]). After the measurement is done, when the probe tip moves back from the piece, the probe spring forces the mechanism back to the initial stable position, re-establishing the standard resistance. 5.1.1. System advantages From the main advantages presented by this system, it is distinguished: the simplicity of the system, robustness of the electro-mechanical assembly, widespread and studied principle. 5.1.2. System disadvantages Due to the electro-mechanical assembly, kinematic probes are susceptible to the consuming and corrosion of its electric contacts. Besides, the main typical characteristic of this kind of probe is related to the pre-travel variation. Since stylus bending prior to trigger is the major constituent of probe pre-travel, this characteristic varies according to changes in touch directions (Reid [10]). This behavior happens due to the fact that the internal mechanism seats in three V-Blocks separated by a 120 angle, causing the force necessary to generate the trigger signal to vary according to the approaching direction (Kim and Chung [11]). Miguel et al. [12] also say that the dynamic force necessary to open one of the electric contacts depends on the approaching velocity. According to Shen and Moon [7], same Touch Trigger Probes models may show different pre-travel variation behavior due to manufacture and small changes during the assembly process.

5.2.1. Advantages One of the main advantages of this technique is that the pre-travel variation is much lower than on kinematic probes because the stylus deformation itself is responsible for trigging the event. For this reason, this kind of probe is extremely accurate and makes possible the use of stylus as long as 200 mm (Fig. 3). The probe uses solid state electronics, providing long life and low wear. Based on analog signal calibration, these systems are able to detect contact forces of 0.2 N. 5.2.2. Disadvantages The disadvantages associated with these probes rely on the high acquisition cost, extremely advanced electronics that makes it very delicate equipment and the fact that there are very few literature and information specically approaching these systems. 5.3. Laser These probes operate with an optical switch as sensor. A lens system collimates the light generated from an LED and focuses it onto a differential photocell. When the stylus is deected, the differential photocell produces a trigger signal, (Dr. Johannes Heidenhain [13]). 5.3.1. Advantages One of the main advantages of these equipments is related to its cost, relatively low if compared to other equipments that provide similar performance. 5.3.2. Disadvantages To have a change on the differential photocell point where the collimated light happens and generates the trigger signal, rst of all, a force between the stylus tip and the part to be measured will be needed to deect the internal mechanism, similarly to what happens with kinematic probes regarding to the opening of its electrical contacts. For this reason, both systems present similar pre-travel variation characteristics, showing

120

M. Del Guerra, R.T. Coelho / Journal of Materials Processing Technology 179 (2006) 117123

Fig. 3. Pr e-travel variation: comparing the performance of kinematic probes (TP20) with strain-gauge probes (TP800) (Renishaw [1]).

accuracy dependence on direction approach to the part to be measured and both systems are not indicate to use stylus longer than 30 mm. 5.4. Piezoelectric sensor Piezoelectric probes are based on the principle for which an electric potential difference is generated between the two faces of a piezoelectric crystal when it is pressed. Using this physical principle, it was possible to design a probe able to generate the trigger signal from the electric potential generated at the moment the probe stylus reaches the part. 5.4.1. Advantages They are extremely accurate and repetitive systems. Like strain-gauge probes, pre-travel variation is much lower than on kinematic probes and it is possible to calibrate the system to be sensitive to forces in the order of 0.2 N. 5.4.2. Disadvantages They may be sensitive to some low frequency noises like collisions, start of motors, high spindle accelerations/decelerations, machine vibration, etc. 6. Proposal of a model based on a simple electric contact This work aims to use basic and well-known technologies to design and manufacture a low cost, robust and accurate Touch Trigger Probe able to measure external diameters on CNC Lathes. For that, precise mechanical machined parts and assembly were designed and applied to develop a system able to be used on the major Touch Trigger Probes applications. 6.1. The system The working principle of the proposed equipment consists on closing an electrical contact between the stylus (grounded) and the internal target (Positive Pole). At this particular moment, the

trigger signal is generated and sent by radio (wireless) to the probes interface that will be responsible for sending a 24 V dc to an appropriate input of the CNC. Due to the fact that the carriage will continue to move by inertia after the trigger signal happens, the target should have a drawback mechanism able to adsorb this movement, assuring its surface integrity (Fig. 4). Consequently, the repeatability of the developed Touch Trigger Probe is directly associated with the ability of the drawback system to precisely seats back to its original position after a trigger event occurs. If the drawback system does not work properly, there will be a change on the probes length preset after a measurement and the diameter of the next part measured will be showed as different than the real. For this reason, the development of the drawback system was done very carefully to guarantee a good performance for the system. The probe was designed to be used on VDI Toolholders, according to DIN 69880 and VDI 3425 standards. 6.2. System repeatability and reproducibility (R&R) The CNC Lathe used to test the Touch Trigger Probe was an INDEX-TRAUB, model GU600, 22 kW power. The CNC was

Fig. 4. Dynamic behavior of the drawback mechanism during the measurement process.

M. Del Guerra, R.T. Coelho / Journal of Materials Processing Technology 179 (2006) 117123

121

Fig. 5. Illustration of the experiment procedure used to determine the probe R&R and a photo of the probe inspecting the part.

a Siemens 810D, able to provide the measurement functions needed for the experiment. To determine the total system R&R (probe + machine tool), the experiment was accomplished taking a part of which diameter was previously machined and normalized. After that, a turning operation was made using a carbide cutting tool VBMT160404UC6010, cutting 0.010 mm from the part diameter, taking all the necessary care with the cutting parameters to reduce the tool wear during the process. The part was then inspected using the Touch Trigger Probe developed, probing 60 consecutive times at the same point. Also a manual measurement was made at that point using a regular micrometer. The data were saved on the CNC and downloaded to a PC. The turning operation and consecu-

tive measurements procedure was repeated ve times, obtaining ve data samples relative to each one of the diameters (Fig. 5). According to QS9000 [14], one of the most effective methods to statistically analyze process and equipments is the method for computing the repeatability and reproducibility (R&R). The range and average method to calculate R&R computes the total measurement system variability, and allows the total measurement system variability to be separated into repeatability, reproducibility and part variation. The repeatability of the measurement system may be estimated from the average of the means collected by the same operator, while the reproducibility may be estimated from the range of variation of the average results collected by different operators.

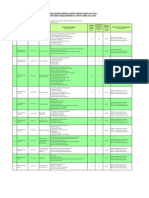

Table 1 Probe data collect to simulate the effect of three operators measuring ve different parts OP1 Measurement 1 Measurement 2 Measurement 3 Measurement 4 Measurement 5 R x/ OP2 Measurement 1 Measurement 2 Measurement 3 Measurement 4 Measurement 5 R x/ OP3 Measurement 1 Measurement 2 Measurement 3 Measurement 4 Measurement 5 R x/ Diameter 1 39.33162 39.33162 39.33162 39.33129 39.33129 0.000332 39.33148 Diameter 1 39.33129 39.33129 39.33129 39.33195 39.33129 0.000664 39.33142 Diameter 1 39.33162 39.33129 39.33256 39.33129 39.33129 0.00127 39.33161 Diameter 2 39.32545 39.32517 39.32574 39.32517 39.3249 0.00084 39.32529 Diameter 2 39.32545 39.32574 39.32574 39.32574 39.3249 0.00084 39.32551 Diameter 2 39.32574 39.32545 39.32605 39.3249 39.32517 0.01153 39.32546 Diameter 3 39.31334 39.31334 39.31357 39.31443 39.31443 0.001094 39.31382 Diameter 3 39.31334 39.31379 39.31334 39.314 39.31334 0.000664 39.31356 Diameter 3 39.31334 39.31379 39.31334 39.31334 39.31334 0.000449 39.31343 Diameter 4 39.30672 39.30744 39.30707 39.30638 39.30605 0.001387 39.30673 Diameter 4 39.30672 39.30744 39.30744 39.30783 39.30744 0.001113 39.30737 Diameter 4 39.30672 39.30707 39.30672 39.30638 39.30672 0.000683 39.30672 Diameter 5 39.29861 39.29783 39.29744 39.29783 39.29744 0.001171 39.29783 Diameter 5 39.29744 39.2982 39.29861 39.2982 39.29861 0.001171 39.29821 Diameter 5 39.2982 39.29744 39.2982 39.299 39.29783 0.001562 39.29813

122

M. Del Guerra, R.T. Coelho / Journal of Materials Processing Technology 179 (2006) 117123

To simulate the effect of different operators, the measurement routine was taken 3 consecutive times for each diameter (3 data set containing 60 measurements each were generated for each diameter). OP1 (Operator 1) represents the rst data set containing 60 measurements took for each one of the 5 diameters. OP2 (Operator 2) represents the second data set containing 60 measurements took for each one of the 5 diameters and OP3 (Operator 3) represents the third data set containing 60 measurements took for each one of the 5 diameters. Random samples containing ve measurements were taken from each of the sets, simulating the effect of three operators making ve measurements for each diameter. Table 1 presents the results. Using the mathematical relations to calculate the limits for graph, the following can be found: UCL = 39.3157 mm, the X CL = 39.3151 mm and LCL = 39.3146 mm. graph is present below, Fig. 6, Using these limits, the X showing the ability of system to distinguish between different dimensions measured. The graph shows its points out of the control limits, as desired. graphs limits are calculated According to Carpinetti [15], the X based on the variation of measurements on the same item, not considering the variation between items. For this reason, the fact that the points are out of the control limits shows the ability of the measurement system to recognize the difference between the ve diameters tested. Using the mathematical relations to calculate the limits for the R graph, the following can be found: UCL = 0.00203 mm, CL = 0.00096 mm and LCL = 0 mm. The R graph is present in Fig. 7, directly showing the variability due to the measurement system, evaluating the ability of the measurement process. The R graph shows the difference between measurements made on the same item, using the same measurement system, by the three different simulated operators. The range graph shows that the measurement process is under statistical control, indicating that the variability of the results is due to chronic causes.

Fig. 7. The range graph.

Calculating the repeatability of the measurement system, representing 99.73% of the results: repe = 6 Repeatability = 6 = 0.0026 mm Calculating the reproducibility: repro = 6 Reproducibility = 6 = 0.00046 mm Rx d2 R d2 =6 0.00096 2.236 (1)

2 repe

nr

(2)

The estimative of measurement system characteristics regarding R&R is given by: R&R = 6 %R&R =

2 2 repro repe + = 0.00264

(3) (4)

R&R 0.00264 100 = 100 = 3.51% total 6 6 0.01255

The present study shows that 3.51% of the total variability of the data set is responsibility of the uncertain of measurement process (probe + machine tool) and 96.49% of the variability is due to the real difference existent between the pieces. 7. Conclusions The use of Touch Trigger Probes for CNC Machine Tools has become a worldwide necessity. However, some barriers still need to be transposed, like the measurement routines programming difculties, low number of prepared technicians and technical literature about this subject and the high acquisition costs of these equipments. This scenario makes the use of the tool on small and medium size companies close to impossible and exactly for them, which deal with small and assorted batches, where the process control easily goes out of range. This work shows the viability of development of a wireless Touch Trigger Probe model based on an internal switch, with the needed characteristics and low cost, to be used in CNC Lathes. Despite the probe simplicity, the result of the tests in the

Fig. 6. Average graph.

M. Del Guerra, R.T. Coelho / Journal of Materials Processing Technology 179 (2006) 117123

123

laboratory shows a repeatability of 0.003 mm (3 s or 99.73% condence interval). Those characteristics are high compatible with the most of the needs for lathe applications in industries. The probe development will continue making it available in three directions of measurements and improvements in its wireless capability will be pursued. References

[1] Renishaw PLC, Metrology Division, New Mills, Wotton-under-Edge, Gloucestershire, UK, Technical Literature, available at <http://www. renishaw.com> (accessed on December 14th, 2005). [2] Tooling & Production, RF technology enhances touch probe, October 1999, available at <http://www.manufacturingcenter.com/tooling/ archives/1099/1099rf.asp> (accessed on December 14th, 2005). [3] Modern Machine Shop On Line, System simplies probing operations on VMCs, September 2001, available at <http://www.mmsonline.com/ articles/1002scan1.html> (accessed on December 14th, 2005). [4] E.P. Zhou, D.K. Harrison, D. Link, Effecting in-cycle measurement with preterit CNC machine tools, Comput. Ind. 28 (1996) 95102. [5] Modern Machine Shop On Line, Probing for process improvement, 2001, available at <http://www.mmsonline.com/articles/mtg0005.html> (accessed on December 14th, 2005).

[6] Modern Machine Shop On Line, CNC machine tool in-process inspection, 2001, available at <http://www.mmsonline.com/articles/1 10105.html> (accessed on December 14th, 2005). [7] Y. Shen, S. Moon, Error compensation of coordinate measurements in computer-integrated manufacturing using neural networks, J. Mater. Process. Technol. 61 (1996) 1217. [8] J.R. Mayer, A. Ghazzar, O. Rossy, 3D characterisation, modelling and compensation of the pre-travel of a kinematic touch trigger probe, Measurement 19 (2) (1996) 8394. [9] C. Reid, Performance characteristics of touch trigger probes, in: Quality Today. Buyers Guide, 1995, pp. 152155. [10] C. Reid, Probe technologybeyond accuracy, in: Proceedings of Applying Imaging and Sensoring Technology to CMM Applications, SME, Nashville, Tennessee, 1993. [11] K.D. Kim, S.C. Chung, Synthesis of the measurement system on the machine tool, Int. J. Prod. Res. 19 (11) (2001) 24752497. [12] P.C. Miguel, T. King, A. Abackerli, A review on methods for probe performance verication, Measurement 23 (1998) 1533. [13] Dr. Johannes Heidenhain, GmbH, Traunreut, Germany, available at <http://www.heidenhain.com> (accessed on December 14th, 2005). [14] QS 9000, Measurement System AnalysisReference Manual (1995). [15] L.R.C. Carpinetti, Process Quality Control, EESC-USP, Sao Carlos, 2000.

S-ar putea să vă placă și

- A Virtual Sensor For Online Fault Detection of Multitooth ToolsDocument24 paginiA Virtual Sensor For Online Fault Detection of Multitooth ToolsLibotÎncă nu există evaluări

- Introduction to N.C.M., a Non Contact Measurement ToolDe la EverandIntroduction to N.C.M., a Non Contact Measurement ToolÎncă nu există evaluări

- Research Paper On Coordinate Measuring MachineDocument4 paginiResearch Paper On Coordinate Measuring MachineafeaoebidÎncă nu există evaluări

- Application of Mechatronics in Manufacturing IndustriesDocument4 paginiApplication of Mechatronics in Manufacturing IndustriesThaneesh Kumar33% (3)

- Advancing Touch Point Corrosion Management White PaperDocument5 paginiAdvancing Touch Point Corrosion Management White PaperVivek PatilÎncă nu există evaluări

- Jumping Into Industry 4.0 With Predictive Maintenance SolutionsDocument26 paginiJumping Into Industry 4.0 With Predictive Maintenance SolutionsNantha Kumara PeriasamyÎncă nu există evaluări

- NonContactwhole Part Inspection FinalDocument10 paginiNonContactwhole Part Inspection Finalkranthi142434Încă nu există evaluări

- Machining Digital Twin Using Real-Time Model-BasedDocument16 paginiMachining Digital Twin Using Real-Time Model-BasedNg YaNyusÎncă nu există evaluări

- Robotic Non-Destructive InspectionDocument8 paginiRobotic Non-Destructive InspectionFadhli AzinnuddinÎncă nu există evaluări

- An Overview of Data Acquisition System For Cutting Force Measuring and Optimization in MillingDocument8 paginiAn Overview of Data Acquisition System For Cutting Force Measuring and Optimization in MillingM Vamshi KrrishnaÎncă nu există evaluări

- Advances in Engineering Software: Bulent Kaya, Cuneyt Oysu, Huseyin M. ErtuncDocument9 paginiAdvances in Engineering Software: Bulent Kaya, Cuneyt Oysu, Huseyin M. ErtuncannevenugopalÎncă nu există evaluări

- Condition-Based Maintenance: Model vs. Statistics A Performance ComparisonDocument7 paginiCondition-Based Maintenance: Model vs. Statistics A Performance ComparisonLourds Egúsquiza EscuderoÎncă nu există evaluări

- Ilovepdf Merged 2Document48 paginiIlovepdf Merged 221146387Încă nu există evaluări

- Calibration Service Provider Works Faster and Smarter To Create More RevenueDocument3 paginiCalibration Service Provider Works Faster and Smarter To Create More Revenuekamala nandulaÎncă nu există evaluări

- Yuanzhi Huang@ucd IeDocument22 paginiYuanzhi Huang@ucd Iehideki hidekiÎncă nu există evaluări

- Electronics 10 01462Document23 paginiElectronics 10 01462Koti ReddyÎncă nu există evaluări

- Research Paper On CNC MachineDocument6 paginiResearch Paper On CNC Machineafnhgewvmftbsm100% (1)

- Unit-I What Is "Mechatronics"?Document35 paginiUnit-I What Is "Mechatronics"?nagsanthosh3Încă nu există evaluări

- Xu 2005 Step Compliant NC Research The SearDocument42 paginiXu 2005 Step Compliant NC Research The Sear林北煎包侠Încă nu există evaluări

- Design of Multisensor Fusion-Based Tool Condition Monitoring System in End MillingDocument14 paginiDesign of Multisensor Fusion-Based Tool Condition Monitoring System in End Millinguamiranda3518Încă nu există evaluări

- An Investigation of Tool-Wear Monitoring in A High-SpeedDocument7 paginiAn Investigation of Tool-Wear Monitoring in A High-SpeedLuiz Andre Silva CorreaÎncă nu există evaluări

- IOT - Based Data Capturing System in Machining: Department of Mechanical EngineeringDocument1 paginăIOT - Based Data Capturing System in Machining: Department of Mechanical EngineeringShankar KÎncă nu există evaluări

- Elysium VLSI 2010Document21 paginiElysium VLSI 2010elysiumtechnologiesÎncă nu există evaluări

- Reliability Characteristics of Machining Systems and Some Queueing Theory Regarding The MachineDocument8 paginiReliability Characteristics of Machining Systems and Some Queueing Theory Regarding The MachineIJRASETPublicationsÎncă nu există evaluări

- Cutting Tool Condition Monitoring using AIDocument24 paginiCutting Tool Condition Monitoring using AISelva GanapathyÎncă nu există evaluări

- State-of-the-Art Predictive Maintenance TechniquesDocument13 paginiState-of-the-Art Predictive Maintenance TechniquesKleber VieiraÎncă nu există evaluări

- Laser-Based Inspection of Cutting Tools For Advanced Manufacturing SystemsDocument8 paginiLaser-Based Inspection of Cutting Tools For Advanced Manufacturing Systemslelag96085Încă nu există evaluări

- Automating Concrete and Mortar Elastic Modulus Test Reports Cpi 5 2010 Eng.Document2 paginiAutomating Concrete and Mortar Elastic Modulus Test Reports Cpi 5 2010 Eng.Asmir SofticÎncă nu există evaluări

- Off-Line Programming of CMMDocument42 paginiOff-Line Programming of CMMLucianÎncă nu există evaluări

- Application of Computers in TextileDocument4 paginiApplication of Computers in TextileMobin AkhandÎncă nu există evaluări

- In-Fixture Measurements Using Vector Network Analyzers: Keysight TechnologiesDocument33 paginiIn-Fixture Measurements Using Vector Network Analyzers: Keysight TechnologiesPaulo Tibúrcio PereiraÎncă nu există evaluări

- Comparison of Machine Learning Approaches For Time-Series-Based Quality Monitoring of Resistance Spot Welding (RSW)Document17 paginiComparison of Machine Learning Approaches For Time-Series-Based Quality Monitoring of Resistance Spot Welding (RSW)Ram PrakashÎncă nu există evaluări

- A Simple Real Time Fault Signature Monit PDFDocument12 paginiA Simple Real Time Fault Signature Monit PDFfares noureddineÎncă nu există evaluări

- Wear Testing RigDocument6 paginiWear Testing Rigibson045001256Încă nu există evaluări

- Benefits of Reverse Engineering For Ensuring Pipeline Integrity en 060502015Document12 paginiBenefits of Reverse Engineering For Ensuring Pipeline Integrity en 060502015Joaquin De Los RiosÎncă nu există evaluări

- Materials: Prediction of Tool Wear Using Artificial Neural Networks During Turning of Hardened SteelDocument15 paginiMaterials: Prediction of Tool Wear Using Artificial Neural Networks During Turning of Hardened Steelrub786Încă nu există evaluări

- Condition Monitoring, Fault Diagnosis and PredictiveDocument8 paginiCondition Monitoring, Fault Diagnosis and PredictiveChaitanya AbhishekÎncă nu există evaluări

- Vision Systems Fall Edition Cfe Media 32 2023Document32 paginiVision Systems Fall Edition Cfe Media 32 2023Jonas BarbosaÎncă nu există evaluări

- Shaft Alignment Measurement System Developed For IDocument13 paginiShaft Alignment Measurement System Developed For IEnerprec SASÎncă nu există evaluări

- Ijdmt: ©iaemeDocument13 paginiIjdmt: ©iaemeIAEME PublicationÎncă nu există evaluări

- Automatic In-Process Chatter Avoidance in The High-Speed Milling ProcessDocument14 paginiAutomatic In-Process Chatter Avoidance in The High-Speed Milling ProcessDeiby Caicedo LeonÎncă nu există evaluări

- Introduction to Sensors and TransducersDocument6 paginiIntroduction to Sensors and TransducersAbraham GmÎncă nu există evaluări

- Deep Learning For The Detection of Machining Vibration ChatterDocument28 paginiDeep Learning For The Detection of Machining Vibration Chatterxh yanÎncă nu există evaluări

- The Modular Compact Rheometer SeriesDocument20 paginiThe Modular Compact Rheometer SeriesSupriyo PÎncă nu există evaluări

- Vibration Signal Diagnosis and Analysis of Rotating Machine by Utilizing Cloud ComputingDocument10 paginiVibration Signal Diagnosis and Analysis of Rotating Machine by Utilizing Cloud ComputingDrRajeev ChauhanÎncă nu există evaluări

- Machine Condition Monitoring Project Final ReportDocument11 paginiMachine Condition Monitoring Project Final ReportSivasidharth EzhilÎncă nu există evaluări

- CNC ThesisDocument4 paginiCNC Thesisbkxk6fzf100% (2)

- Literature Review On CNC MachineDocument7 paginiLiterature Review On CNC Machineaflsnbfir100% (1)

- FstTracer enDocument12 paginiFstTracer enbinukumar100Încă nu există evaluări

- Strategies For High Quality Low Cost Optical Sensors - Automotive v7Document11 paginiStrategies For High Quality Low Cost Optical Sensors - Automotive v7Poovannan PrakashÎncă nu există evaluări

- (b1264b950ce44583bab73d6b965f7616)Document72 pagini(b1264b950ce44583bab73d6b965f7616)jgkothavadeÎncă nu există evaluări

- Innovative Techniques in Non-Destructive Testing and Industrial Applications On Pressure EquipmentDocument13 paginiInnovative Techniques in Non-Destructive Testing and Industrial Applications On Pressure EquipmentJavier Alejandro RodriguezÎncă nu există evaluări

- An Accelerometer Based Digital Pen: I J I R S E TDocument6 paginiAn Accelerometer Based Digital Pen: I J I R S E TmedhaÎncă nu există evaluări

- Aess 2011 SympDocument1 paginăAess 2011 SympSupreeth PrakashÎncă nu există evaluări

- 2019 TUGx Global Seminar Abstracts on Test StrategiesDocument15 pagini2019 TUGx Global Seminar Abstracts on Test StrategiesMahesh MahiÎncă nu există evaluări

- Overview On The Object Rejection and Counting Machine: July 2017Document4 paginiOverview On The Object Rejection and Counting Machine: July 2017dhanshri kolekarÎncă nu există evaluări

- Phase 2 ReportDocument20 paginiPhase 2 ReportSusheel PoonjaÎncă nu există evaluări

- Manufacturing Letters: Daniel Frank Hesser, Bernd MarkertDocument4 paginiManufacturing Letters: Daniel Frank Hesser, Bernd MarkertGijvf GbjjÎncă nu există evaluări

- Making CBM Effective: A Guide To Condition-Based Monitoring Programs, and in Particular, Ultrasound DetectionDocument2 paginiMaking CBM Effective: A Guide To Condition-Based Monitoring Programs, and in Particular, Ultrasound DetectionLuisAlbarranÎncă nu există evaluări

- Understanding & Using Dc-Ac Inverters: Electus Distribution Reference Data Sheet: INVERTER PDFDocument4 paginiUnderstanding & Using Dc-Ac Inverters: Electus Distribution Reference Data Sheet: INVERTER PDFragupathiindiaÎncă nu există evaluări

- Premia Panel Lights Guide with Specs and PricesDocument2 paginiPremia Panel Lights Guide with Specs and PricesNarayan ApteÎncă nu există evaluări

- OM 4 Sept 19Document2 paginiOM 4 Sept 19Narayan ApteÎncă nu există evaluări

- Rapid Brochure PDFDocument66 paginiRapid Brochure PDFankur100% (1)

- 2.2 Conventional Methods of Speed Control: Unit-Ii DC DrivesDocument47 pagini2.2 Conventional Methods of Speed Control: Unit-Ii DC DrivesrajeshÎncă nu există evaluări

- Reactive Power1Document8 paginiReactive Power1Tulika BhattacharjeeÎncă nu există evaluări

- Ultra Fast Switches for Future MV SwitchgearDocument7 paginiUltra Fast Switches for Future MV SwitchgearNarayan ApteÎncă nu există evaluări

- Maharashtra State Board of Technical EducationDocument1 paginăMaharashtra State Board of Technical EducationNarayan ApteÎncă nu există evaluări

- Tel: (592) 252-9530 (P. R. China) Email:: 2.6 5.5V Avdd DVDD Refp 0.1u Vout R3Document1 paginăTel: (592) 252-9530 (P. R. China) Email:: 2.6 5.5V Avdd DVDD Refp 0.1u Vout R3Narayan ApteÎncă nu există evaluări

- Prezi ShortcutsDocument1 paginăPrezi ShortcutsNarayan ApteÎncă nu există evaluări

- Vacuum Switching in Low VoltageDocument3 paginiVacuum Switching in Low Voltageandrei_filip_3Încă nu există evaluări

- CN0350Document7 paginiCN0350Narayan ApteÎncă nu există evaluări

- Biasing Internally Amplified Accelerometers: Bias RequirementsDocument4 paginiBiasing Internally Amplified Accelerometers: Bias RequirementsNarayan ApteÎncă nu există evaluări

- PcbsDocument4 paginiPcbsNarayan ApteÎncă nu există evaluări

- LCL - LC Comparison and DesignDocument5 paginiLCL - LC Comparison and DesignSimon ZhangÎncă nu există evaluări

- Tata Docomo Recharge Receipt 350 Rs SuccessfulDocument1 paginăTata Docomo Recharge Receipt 350 Rs SuccessfulNarayan ApteÎncă nu există evaluări

- TrialDocument1 paginăTrialNarayan ApteÎncă nu există evaluări

- Ascii ChartDocument6 paginiAscii ChartNarayan ApteÎncă nu există evaluări

- HNM BookDocument268 paginiHNM BookasnsashankÎncă nu există evaluări

- Varistores SIOV - Leaded - StandarD PDFDocument36 paginiVaristores SIOV - Leaded - StandarD PDFDavid RosalesÎncă nu există evaluări

- 5.5" PmoledDocument4 pagini5.5" PmoledNarayan ApteÎncă nu există evaluări

- 5.5" PmoledDocument4 pagini5.5" PmoledNarayan ApteÎncă nu există evaluări

- Ermaksan Fiber LaserDocument40 paginiErmaksan Fiber LaserJohan SneiderÎncă nu există evaluări

- ALARM 410 (Excessive Position Error Amount During Stop)Document1 paginăALARM 410 (Excessive Position Error Amount During Stop)Cicero MelloÎncă nu există evaluări

- Opticut V: Panel and Profile Cutting OptimizationDocument23 paginiOpticut V: Panel and Profile Cutting OptimizationLjuboVukadinÎncă nu există evaluări

- Mazak Fusion 640 Series How To Replace The HDDDocument7 paginiMazak Fusion 640 Series How To Replace The HDDElida Rodriguez Garcia100% (5)

- SBTET AP C-14 SYLLABUS DME VI SemesterDocument41 paginiSBTET AP C-14 SYLLABUS DME VI Semesterthirukumar100% (4)

- Incremental Sheet Metal Forming On CNC Milling Machine-Tool: J. Kopac, Z. KampusDocument7 paginiIncremental Sheet Metal Forming On CNC Milling Machine-Tool: J. Kopac, Z. KampusRhahli JamelÎncă nu există evaluări

- Long Foam Cutting Tools EPS Foam Milling Router Bits Ball End and Flat EndDocument3 paginiLong Foam Cutting Tools EPS Foam Milling Router Bits Ball End and Flat EndSalce SmithÎncă nu există evaluări

- Machine Tools-2011 PDFDocument28 paginiMachine Tools-2011 PDFRustaiderÎncă nu există evaluări

- X4 User ManualDocument78 paginiX4 User ManualJeff RyersonÎncă nu există evaluări

- PBB Da56 80 250Document114 paginiPBB Da56 80 250Paganini CombaÎncă nu există evaluări

- Proceso Cold RollingDocument7 paginiProceso Cold RollingFernando FiallosÎncă nu există evaluări

- Cosmos Imtex Die MouldDocument2 paginiCosmos Imtex Die MouldAbhishek Velaga100% (2)

- Visi Cad ManualDocument4 paginiVisi Cad ManualserdarÎncă nu există evaluări

- ACE - Vantage SeriesDocument4 paginiACE - Vantage SeriesTECH TALOSÎncă nu există evaluări

- OCTOBER 2018 Surplus Record Machinery & Equipment DirectoryDocument715 paginiOCTOBER 2018 Surplus Record Machinery & Equipment DirectorySurplus RecordÎncă nu există evaluări

- Plasma CamDocument20 paginiPlasma CamkairotdfÎncă nu există evaluări

- Cad, Cam, 3d PrintingDocument20 paginiCad, Cam, 3d Printingvanikv40Încă nu există evaluări

- 6000 I Tech ManualDocument944 pagini6000 I Tech ManualarslansarÎncă nu există evaluări

- Cycle Time Reduction Studies in Threading: K. Palaksha Reddy, Deepak Kumar, R. Venkatraman & V. VishweshvarDocument8 paginiCycle Time Reduction Studies in Threading: K. Palaksha Reddy, Deepak Kumar, R. Venkatraman & V. VishweshvarTJPRC PublicationsÎncă nu există evaluări

- Implementation 3-Axis CNC Router For Small Scale Industry: Telkom Applied Science School, Telkom University, IndonesiaDocument6 paginiImplementation 3-Axis CNC Router For Small Scale Industry: Telkom Applied Science School, Telkom University, IndonesiaAnonymous gzC9adeÎncă nu există evaluări

- Modern Steel Construction 2020-12 - 2020 PDFDocument70 paginiModern Steel Construction 2020-12 - 2020 PDFCaro AGÎncă nu există evaluări

- COFMOW CompendiumDocument22 paginiCOFMOW CompendiumRajiv Mahajan100% (1)

- En Ac-cnc2019-1d-Mega r1.x Diagram JogwheelDocument4 paginiEn Ac-cnc2019-1d-Mega r1.x Diagram JogwheelpeterÎncă nu există evaluări

- GE Fanuc CNC: Series 0/00/0-Mate Maintenance ManualDocument312 paginiGE Fanuc CNC: Series 0/00/0-Mate Maintenance ManualООО ЛантисÎncă nu există evaluări

- Short Term Courses Offered at Adtec Taiping 2014/2015Document2 paginiShort Term Courses Offered at Adtec Taiping 2014/2015Safar BrolyÎncă nu există evaluări

- Troubleshooting FSSB Alarm 926Document1 paginăTroubleshooting FSSB Alarm 926manuali-calogero0% (1)

- Durant InternetDocument56 paginiDurant Internettomjordan12321Încă nu există evaluări

- Laser CladdingDocument22 paginiLaser CladdingHabeebMohammedFarooq100% (1)

- Buyers Guide To CNC Machined PartsDocument16 paginiBuyers Guide To CNC Machined PartsnadoÎncă nu există evaluări