Documente Academic

Documente Profesional

Documente Cultură

Structural Robustness of Steel Framed Buildings

Încărcat de

Cristina VlaicuDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Structural Robustness of Steel Framed Buildings

Încărcat de

Cristina VlaicuDrepturi de autor:

Formate disponibile

Structural

robuStneSS of Steel

framed buildingS

Structural

robuStneSS of Steel

framed buildingS

iii

A G J WayMEngCEngMICE

Structural

robuStneSS of Steel

framed buildingS

In accordance with Eurocodes and UK National Annexes

SCI PublICatIon P391

iv

2011 SCI. All rights reserved.

Publication Number: SCI P391

ISBN: 978-1-85942-198-7

Published by:

SCI, Silwood Park, Ascot,

Berkshire. SL5 7QN UK

T: +44 (0)1344 636525

F:

+44 (0)1344 636570

E: reception@steel-sci.com

www.steelsci.com

To report any errors, contact:

publications@steel-sci.com

SCI (The Steel Construction Institute) is the leading, independent provider of technical expertise

and disseminator of best practice to the steel construction sector. We work in partnership with

clients, members and industry peers to help build businesses and provide competitive advantage

through the commercial application of our knowledge. We are committed to offering and promoting

sustainable and environmentally responsible solutions.

Our service spans the following five areas:

Membership

Individual & corporate membership

Advice

Members advisory service

Information

Publications

Education

Events & training

Consultancy

Development

Product development

Engineering support

Sustainability

Assessment

SCI Assessment

Specification

Websites

Engineering software

Apart from any fair dealing for the purposes of

research or private study or criticism or review,

as permitted under the Copyright Designs and

Patents Act, 1988, this publication may not be

reproduced, stored or transmitted, in any form

or by any means, without the prior permission

in writing of the publishers, or in the case of

reprographic reproduction only in accordance

with the terms of the licences issued by the UK

Copyright Licensing Agency, or in accordance

with the terms of licences issued by the

appropriate Reproduction Rights Organisation

outside the UK. Enquiries concerning

reproduction outside the terms stated here

should be sent to the publishers, SCI.

Although care has been taken to ensure, to

the best of our knowledge, that all data and

information contained herein are accurate to

the extent that they relate to either matters of

fact or accepted practice or matters of opinion

at the time of publication, SCI, the authors and

the reviewers assume no responsibility for any

errors in or misinterpretations of such data and/or

information or any loss or damage arising from or

related to their use.

Publications supplied to the members of the

Institute at a discount are not for resale by them.

British Library Cataloguing-in-Publication Data.

A catalogue record for this book is available from

the British Library.

The text paper in this publication is totally

chlorine free. The paper manufacturer and

the printers have been independently certified

in accordance with the rules of the Forest

Stewardship Council.

v

IntheUK,thedesignofhot-rolledsteel-framedbuildingsforavoidanceofdisproportionate

collapseandrobustnesshas,since1990,generallybeeninaccordancewiththeBritish

StandardBS5950-1.However,thatStandardwaswithdrawninMarch2010andreplaced

bythecorrespondingPartsoftheEurocodes.ThemainEurocodePartthatwillneedto

beconsultedfordesigntoresistaccidentalactionsandstrategiestoachievestructural

robustnessisBSEN1991-1-7anditsNationalAnnex.

Thisguidewaspreparedtodescribethedesignofhot-rolledsteelbuildingsforstructural

robustnessinaccordancewiththeEurocodes.ItsscopeissimilartothatofSCIpublication

P341,Guidance on meeting the Robustness Requirements in Approved Document A,

whichfocussedontheUKRegulationsandofferedguidanceinrelationtoBS5950-1.

Thispublicationdoesnotspecifcallydealwithaccidentalactionscausedbyexternal

explosions,warfareandterroristactivities,ortheresidualstabilityofbuildingsorother

civilengineeringworksdamagedbyseismicactionorfre.

ThispublicationwaspreparedbyAndrewWayofSCI.Theauthorwouldliketothank

thefollowingindividualsfortheircontributionsandthecommentsreceivedduringthe

preparationofthisguide:

StuartAlexander WSPGroup

MikeBanf Arup

JohnCarpenter SCOSS

RogerDavies Gifford

ChrisDolling BCSA

GeoffHarding FormerlyofCLG

AllanMann JacobsEngineeringGroupInc

DavidMoore BCSA

RogerPope Consultant

WalterSwann BCSA

ThepreparationofthisguidewasfundedbyBCSAandTataSteel;theirsupportis

gratefullyacknowledged.

foreword

vii

contentS

Foreword v

Contents vii

summary ix

IntroduCtIon 11

1.1 Scope 11

1.2 Eurocodes 11

1.3 Robustness 12

BuIldIng regulatIons 15

2.1 The Requirement 15

2.2 Guidance documents 15

2.3 Approved Document A 16

euroCode roBustness

requIrements 19

3.1 BS EN 1990 19

3.2 BS EN 199311 22

3.3 BS EN 199117 22

3.4 Robustness strategies 26

BuIldIng ClassIFICatIon 29

4.1 Consequences classes 29

4.2 Practical cases 29

4.3 Conversions, alterations and extensions 35

BuIldIngs In ConsequenCes

Class 1 37

5.1 Structural requirements 37

5.2 Minimum horizontal tying 37

5.3 Practical application of design rules 38

BuIldIngs In ConsequenCes

Class 2a 41

6.1 Structural requirements 41

6.2 Horizontal ties 42

6.3 Practical application of design rules 45

BuIldIngs In ConsequenCes

Class 2B 55

7.1 Structural requirements 55

7.2 Horizontal ties 56

7.3 Vertical ties 56

7.4 Vertical bracing 57

7.5 Anchorage of heavy floor units 58

7.6 Notional removal design strategy 59

7.7 Key element design 63

7.8 Practical application of design rules 64

BuIldIngs In ConsequenCes

Class 3 79

8.1 Structural requirements 79

8.2 Risk assessment 80

transFer Beams 91

9.1 General 91

9.2 Class 1 buildings 91

9.3 Class 2a buildings 92

9.4 Class 2b buildings 92

9.5 Class 3 buildings 93

summary oF roBustness

requIrements 95

reFerenCes 97

appendIx a 101

ix

Thispublicationprovidesdesignguidanceforhot-rolledsteel-framedbuildingson

theEurocodestrategiesforstructuralrobustnessanddesigningfortheavoidanceof

disproportionatecollapseasrequiredbytheUKBuildingRegulations.

DesignguidanceinaccordancewiththeEurocodesispresentedforthefourbuilding

classesintheEurocodesandtheUKRegulations.Guidanceonrecommendedgood

practiceispresentedwheretheEurocodesdonotgiverequirementsorwheretheyare

notspecifcandareopentointerpretation.Thescopeofthispublicationislimitedto

applicationintheUKandreferenceismadetotheUKNationalAnnexesasappropriate.

Inadditiontothedesignguidance,sixworkedexamplesareincludedtodemonstrate

theapplicationofrobustnessstrategiestodifferentclassesofbuilding.Detailed

guidanceonthebuildingclassifcationprocessisalsopresented.

Summary

11

introduction

1.1 Scope

ThispublicationprovidesdesignguidanceontheEurocodeandUKBuildingRegulation

requirementsforprovidingrobustnessandtheavoidanceofdisproportionatecollapse

inhot-rolledsteelframedbuildings.Guidanceisprovidedonhowtherequirements

relatetocommonstructuralsolutions.Recommendedpracticeispresentedwherethe

Eurocodesdonotgiverequirementsorwheretherequirementsarenotspecifcorare

opentointerpretation.

ThemajorityoftherobustnessrelatedclausesaregiveninBSEN1991

[1]

andinparticular

Part1-7.However,referenceisalsomadetoBSEN1993

[2]

andBSEN1990

[3]

,asappropriate.

ThescopeofthispublicationislimitedtoapplicationintheUK.Referenceismadetothe

UKNationalAnnexesasappropriate.

Thispublicationdoesnotaddresstheotherlegalobligationsthatarerelatedtorobustness.

However,designersshouldbeawareofsuchobligationsandtheimplicationsfordesign.The

relevantreferencesinclude;BuildingAct

[4]

,HealthandSafetyatWorkAct

[5]

,Construction

(DesignandManagementRegulations)

[6]

andWorkplace(Health,SafetyandWelfare)

Regulations

[7]

.GuidanceontheseisprovidedinReference24.

1.2 Eurocodes

TherearetenEurocodes,whichtogetherprovideacomprehensivesetofStandards

coveringallaspectsofstructuraldesignusingthenormalconstructionmaterials.

ThetenEurocodesare:

BSEN1990-Eurocode:Basisofstructuraldesign;

BSEN1991-Eurocode1:Actionsonstructures;

BSEN1992-Eurocode2:Designofconcretestructures;

BSEN1993-Eurocode3:Designofsteelstructures;

BSEN1994-Eurocode4:Designofcompositesteelandconcretestructures;

BSEN1995-Eurocode5:Designoftimberstructures;

BSEN1996-Eurocode6:Designofmasonrystructures;

BSEN1997-Eurocode7:Geotechnicaldesign;

BSEN1998-Eurocode8:Designofstructuresforearthquakeresistance;

BSEN1999-Eurocode9:DesignofAluminiumStructures.

12

IntroduCtIon

EachEurocodeiscomprisedofanumberofParts,whicharepublishedasseparate

documents.ForageneralintroductiontotheEurocodesinrelationtothedesignof

steelbuildings,seeSCIpublicationP361

[8]

.

National Annexes

WithinthefulltextofaEurocode,nationalchoiceisallowedinthesettingofsome

factorsandinthechoiceofsomedesignmethods.Thechoicesaregenerallyreferred

toasNationallyDeterminedParameters(NDP)andthesearepublishedinaNational

Annex.EachpartoftheEurocodeshasaseparateNationalAnnex.

TheguidancegiveninaNationalAnnexappliestostructuresthataretobeconstructed

withinthatcountry.NationalAnnexesarelikelytodifferbetweencountrieswithin

Europe.TheNationalAnnexforthecountrywherethestructureistobeconstructed

shouldalwaysbeconsultedinthedesignofastructure.

Withinthispublication,thevaluesandchoicesrecommendedintheUKNational

Annexesareused.

1.3 Robustness

Thetermrobustnessisoftenusedgenericallytoinferpropertiessuchassturdiness,

strength,solidityanddurability.However,inEurocodes,robustnesshasaprecise

defnitionanditisinthecontextoftheEurocodedefnitionthatthetermrobustness

isusedinthispublication.RobustnessisdefnedinBSEN1991-1-7Actions on

structures. General actions. Accidental actions,asfollows:

Robustness is the ability of a structure to withstand events like fre, explosions,

impact or the consequences of human error, without being damaged to an extent

disproportionate to the original cause.

Fromthisdefnitionitcanbeconcludedthatastructuredesignedandconstructedtohave

robustnesswillnotsufferfromdisproportionatecollapse.Designforavoidanceofdispro-

portionatecollapseisarequirementofBuildingRegulationsintheUK(seeSection2).

AccidentaldesignsituationsaredefnedinBSEN1990,reproducedbelow;fromthisit

canbeseenthattheeventsreferredtointheBSEN1991-1-7defnitionofrobustness

areaccidentaldesignsituations.

Accidental design situations are design situations involving exceptional conditions of

the structure or its exposure, including fre, explosion, impact or local failure.

Inessence,theobjectiveistoensurethatbuildingsdonotsufferdisproportionate

collapseunderaccidentalloading.Largely,thisisassuredinsteelframedbuildingsby

designingconnectionsappropriately.

13

Thetermsdisproportionatecollapseandprogressivecollapseareoftenused

interchangeablybutitispossibletomakeadistinction.Progressivecollapseis

thespreadofstructuralcollapsefromtheinitialfailureofoneorafewlocalised

structuralelements.Ifprogressivecollapseoccursitdoesnotnecessarilyresult

indisproportionatecollapse.However,theRonanPointcollapseillustratesacase

whereprogressivecollapsedidresultindisproportionatecollapse(seeFigure1.1).

TheRonanPointcollapsewasthemotivationforintroducingdisproportionate

collapseregulationsintheUKandiswelldocumented;forfurtherinformationsee

References9and10.

Figure 1.1

Ronan Point 1968

- Partial collapse of

a concrete structure

due to a gas explosion

15

building

regulationS

2.1 The Requirement

IntheUK,therearethreedifferentsetsofBuildingRegulations,oneforeachofthe

followingjurisdictions:

1. EnglandandWales;

2. Scotland;

3. NorthernIreland.

Althoughthewordingvariesslightly,theRequirementconcerningdisproportionate

collapseisessentiallythesameinallthreejurisdictions.

RequirementA3fromPartAoftheEnglandandWalesBuildingRegulations

[11]

isgivenbelow.

The building shall be constructed so that in the event of an accident the building

will not suffer collapse to an extent disproportionate to the cause.

Thephrasein the event of an accidentfromtherequirementgivenabove,ties

upneatlywiththephraseconsequences of human errorfromthedefnitionof

robustnessgiveninBSEN1991-1-7.Bothofthesephraseshelptoemphasizethatwe

arenotdealingwithdeliberateactsintendedtocausedamageorcollapse.However,

allbuildingsshouldberobustandtheengineerhasaresponsibilitytoconsiderall

loadsincludingthoseduetomaliciousaction.Inmostcases,maliciousactshavea

verylowriskofoccurrenceandcanreasonablybediscounted.However,theremightbe

occasionswheretheirconsiderationiswarranted.Thismatterwillbepartoftheoverall

considerationofhazardandriskandshouldbediscussedwiththeclient.

Atthetimeofwriting,theavoidanceofdisproportionatecollapserequirementunder

theBuildingRegulationsisapplicableasfollows:

1. InEnglandandWales-Applicabletoallbuildings.

2. InScotland-Applicabletoallbuildings.

3. InNorthernIreland-Applicabletoallbuildingswithfveormorestoreys.

2.2 Guidance documents

Ineachofthethreejurisdictionslistedabove,offcialguidancedocumentsarepublished

toexplainhowcompliancewiththeregulatoryrequirementsmaybeachieved.

16

buIldIng regulatIonS

InEnglandandWales,theguidancedocumentsaretermedApprovedDocuments

andthereisoneforeachpartoftheRegulations.ApprovedDocumentA

[12]

includes

guidanceonhowthekeyrobustnessrequirementA3shouldbeappliedtodifferent

typesandsizesofbuilding.

InScotland,guidanceonsatisfyingtheregulationsisgiveninTheScottishBuilding

StandardsAgency(SBSA)TechnicalHandbooks

[13]

.

InNorthernIreland,guidanceonsatisfyingtheregulationsisgiveninTheBuilding

Regulations(NorthernIreland),TechnicalBookletD

[14]

.

Induecourse,theseoffcialguidancedocumentswillbeupdatedtoreference

theEurocodes,whereguidanceondesigningsteelframedstructurestoavoid

disproportionatecollapseisgiven(seeSection3).

2.3 Approved DocumentA

2.3.1 Building classes

ApprovedDocumentA(2004Edition)

[12]

setsoutdifferentrequiredlevelsofrobustness

fordifferenttypesandsizesofbuildings.Therearefourclassesofbuilding;Class1,

Class2A,Class2BandClass3.ThebuildingclassifcationpresentedinApproved

DocumentAisthesameasthatpresentedintheSBSATechnicalHandbooks

[13]

andthereisonlyasmalldifferencefromthatpresentedinBSEN1991-1-7.The

classifcationofbuildingsisdescribedindetailinSection4.

TherobustnessrequirementsspecifedinApprovedDocumentAforeachclassof

buildingaresummarisedbelow.Detailedguidanceandexplanationsofthestructural

provisionsthatshouldbeprovidedforeachofthebuildingclassesaregivenin

Sections5,6,7and8.

For Class1 buildings

Providedthatthebuildinghasbeendesignedandconstructedinaccordancewiththe

rulesgiveninApprovedDocumentAfornormaluse,noadditionalmeasuresarelikely

tobenecessary.

For Class2A buildings

Effectivehorizontaltiesshouldbeprovidedforframedconstruction.

For Class2B buildings:

Therearethreemethodsbywhichtherobustnessrequirementsmaybesatisfedfor

Class2Bbuildings.

1. Provideeffectivehorizontalties,togetherwitheffectiveverticaltiesinall

supportingcolumns.

2. Checkthatuponthenotionalremovalofasupportingcolumnorabeam

supportingoneormorecolumns(oneatatimeineachstoreyofthebuilding)

17

thatthebuildingremainsstableandthattheareaoffooratanystoreyatriskof

collapsedoesnotexceed15%ofthefoorareaofthatstoreyor70m

2

,whichever

issmaller,anddoesnotextendfurtherthantheimmediateadjacentstoreys.(Note:

Thelimitis100m

2

inBSEN1991-1-7anditisexpectedthatatitsnextrevision

thelimitinApprovedDocumentAwillberevisedtoagreewithBSEN1991-1-7.)

3. Wherethenotionalremovalofsuchcolumns(orbeamssupportingoneormore

columns)wouldresultindamageinexcessoftheabovelimit,thensuchelements

shouldbedesignedaskeyelements.

Note:Atthetimeofwriting,thereisongoingdebateaboutwhetherApproved

DocumentAshouldbeamendedsuchthattheprovisionofhorizontaltiesis

recommendedinallcasesofClass2Bbuildingsirrespectiveofwhichmethodis

adoptedtosatisfytherobustnessrequirements.Reference24makesthepointthat

thenotionalremovalandkeyelementmethodsareprincipallyconcernedwithvertical

structureorelementssupportingverticalstructure.Therefore,whenapplyingthe

notionalremovalorkeyelementmethods,thedesignermuststillensurethatthe

structureisrobustinorthogonalhorizontaldirections,whichisgenerallyachievedby

providinghorizontalties.

For Class 3 buildings

Asystematicriskassessmentofthebuildingshouldbeundertaken,takinginto

accountallthenormalhazardsthatcanreasonablybeforeseen,togetherwithany

abnormalhazards.Criticalsituationsfordesignshouldbeselectedthatrefectthe

conditionsthatcanreasonablybeforeseenaspossibleduringthelifeofthebuilding.

2.3.2 Eurocodes and Approved DocumentA

ApprovedDocumentApermitsanymethodofdesigntobeused,providingitsatisfes

thefunctionalrequirementsoftheBuildingRegulations.

Thecurrent2004versionofApprovedDocumentAreferstonationaldesignstandards,

i.e.BS5950,forthedesignofsteelframedbuildingsanddoesnotrefertoEurocodes.

ApprovedDocumentAisscheduledforrevisionin2013,atwhichpointitwillinclude

referencetotheEurocodes.

InJanuary2010,CLG(DepartmentofCommunitiesandLocalGovernment)issueda

circularletterthatconfrmedthesuitabilityoftheEurocodestomeettherequirements

oftheBuildingRegulations.

Thefollowingsectionsofthispublicationexplainhowsteelframedbuildingscanbe

designedforstructuralrobustnessinaccordancewiththeEurocodes.Whereitis

deemedappropriate,additionalstructuralprovisionshavebeenrecommended.

19

3.1 BSEN 1990

BSEN1990canbeconsideredasthecoredocumentofthestructuralEurocode

system,asitestablishestheprinciplesandrequirementsforthesafety,serviceabilityand

durabilityofstructures.Italsodescribesthebasisforstructuraldesignandverifcation.

ThemainsectionsofBSEN1990include:

Requirements.

Principlesoflimitstatedesign.

Basicvariables.

Structuralanalysisanddesignassistedbytesting.

Verifcationbythepartialsafetyfactormethod.

3.1.1 Basic requirements

BSEN1990,2.1(1)Pand(2)Psetsoutseveralbasicrequirementsforthedesignof

structures,including:thestructureshallsustain all actions and infuences likely to

occur during execution and use;thestructureshallbe designed to have adequate

structural resistance, serviceability and durability.

TheprinciplegiveninBSEN1990,2.1(4)Phasparticularrelevancetostructural

robustness;itstatesthat:

A structure shall be designed and executed in such a way that it will not be

damaged by events such as: explosion, impact, and the consequences of

human errors, to an extent disproportionate to the original cause.

Note 1 - The events to be taken into account are those agreed for an individual

project with the client and the relevant authority.

Note 2 - Further information is given in EN 1991-1-7.

ThewordinginBSEN1990,2.1(4)Pisverysimilartothedefnitionofrobustness

giveninBSEN1991-1-7.Inessence,theprinciplesetsouttheoverridingrequirement

toprovideabuildingthatisdesignedandexecutedtohaverobustness.

eurocode

robuStneSS

requirementS

20

euroCode requIrementS

TheprinciplegiveninBSEN1990,2.1(5)Palsohasparticularrelevancetostructural

robustnessandstatesthat:

Potential damage shall be avoided or limited by appropriate choice of one or more

of the following:

avoiding, eliminating or reducing the hazards to which the structure

can be subjected;

selecting a structural form which has low sensitivity to the hazards considered;

selecting a structural form and design that can survive adequately the

accidental removal of an individual member or a limited part of the structure,

or the occurrence of acceptable localised damage;

avoiding as far as possible structural systems that can collapse

without warning;

tying the structural members together.

Thesemethodsarestructuralphilosophiesratherthandetaileddesignguidance.

DetailedguidanceisprovidedinBSEN1991-1-7.

3.1.2 Design situations

ThedesignsituationsthatshouldbeconsideredaregiveninBSEN1990,3.2.

Theconsiderationofaccidentalactionsasaseparatedesignsituationisshownin

BSEN1990,3.2(2)P,whichgivesthefollowingdesignsituations:

Persistent duringnormaluseofthestructure.

Transient temporaryconditionse.g.duringexecutionorrepair.

Accidental exceptionaleventse.g.exposuretofre,impact,explosionor

consequencesoflocalisedfailure.

Seismic conditionsduetoseismicevents.

Informationonspecifcdesignsituationswithineachoftheseclassesisgivenin

theotherPartsoftheEurocodes.Structuralrobustnessisconsideredaspartofthe

Accidentaldesignsituation.

FromBSEN1990,3.2(1)Pand(3)P,itisclearthatallrelevantdesignsituations

shouldbeselectedandtheseshouldbesuffcientlyseveretoincludeallreasonably

foreseeableconditionsduringtheintendeduseofthestructure.Therefore,accidental

designsituationsshouldbeconsideredforallbuildingsdesignedinaccordancewith

theEurocodes.

3.1.3 Ultimate limit states

BSEN1990givesdetailsoftheultimatelimitstatesthatmustbeverifedandhow

designvaluesoftheeffectsoftheactionsshouldbecombined.Detailedexplanationof

thelimitstatesandloadcombinationsforgeneralapplicationtosteelbuildingdesign

isgiveninSCIpublicationP362

[15]

.

21

FromBSEN1990,6.4.3.3,Eq.(6.11b)andTableNA.A1.3oftheUKNationalAnnex,

thecombinationofactionsforaccidentaldesignsituationscanbeexpressedas:

G A Q Q

j

j

i i

i

k,

1

d 1, k,1 2, k,

1

+ + + " " " " " "

1

where:

+ impliestobecombinedwith

impliesthecombinedeffectof

G

k,j

arethecharacteristicvaluesofthepermanentactions

A

d

isthedesignvalueofanaccidentalaction

Q

k,1

isthecharacteristicvalueoftheleadingvariableactions

Q

k,i

arethecharacteristicvaluesoftheothervariableactions

y

1,1

isthefactorforthefrequentvalueoftheleadingvariableaction Q

k,1

(seeTable3.1)

y

2,i

isthefactorforthequasi-permanentvalueofthei-thvariableactionQ

k,i

(seeTable3.1).

Thevaluesfory

1

andy

2

factorsforbuildingsaregiveninTable3.1.Thevalues

presentedaretakenfromTableNA.A1.1oftheUKNationalAnnextoBSEN1990.

Theaccidentalcombinationofactionsisusedwhenverifyingtherobustnessof

astructure,particularlywiththenotionalremovalandkeyelementmethods.The

yfactorsareusedinthecalculationoftherequiredtyingresistanceofconnectionsfor

effectivehorizontalties,seeSection6.2.Theapplicationofthecombinationofactions

fortheaccidentaldesignsituationisexplainedinSection7.

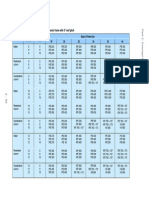

Table 3.1

Values of y

1

and y

2

factors for buildings

(from the UK NA to

BS EN 1990)

aCtIon y

1

y

2

Imposed loads in buildings (see bS en 199111)

Category A: domestic, residential areas 0.5 0.3

Category B: office areas 0.5 0.3

Category C: congregation areas 0.7 0.6

Category D: shopping areas 0.7 0.6

Category E: storage areas 0.9 0.8

Category H: roofs* 0 0

Snow loads on buildings (see en 19913)

For sites located at altitude H > 1000 m a.s.l. 0.5 0.2

For sites located at altitude H 1000 m a.s.l. 0.2 0

Wind loads on buildings (see en 199114) 0.2 0

temperature (nonfire) in buildings (see en 199115) 0.2 0

*Onroofs,imposedloadsshouldnotbecombinedwitheitherwindloadsorsnowloads.

22

euroCode requIrementS

3.2 BSEN 1993-1-1

BSEN1993istheEurocodefordesignofsteelstructures:BSEN1993-1-1givesgeneric

designrulesforsteelstructuresandspecifcguidanceforstructuralsteelworkusedin

buildings.BSEN1993-1-1givesnospecifcguidanceforthedesignofsteelbuildings

forstructuralrobustness.AlthoughBSEN1993-1-1,2.1.3isentitledDesignworking

life,durabilityandrobustnessandstatesthatsteelstructuresshallbedesignedfor

accidentalactions,itsimplyrefersthereadertoBSEN1991-1-7

[1]

.

Theabsenceofdirectusefulguidancecontrastswiththemoredetailedprovisionsin

BS5950-1.Eurocodesaregenerallylessspecifcandgivegeneralprinciples.

3.3 BSEN 1991-1-7

Therequirementtodesignandconstructbuildingstohaverobustnessandavoid

disproportionatecollapseunderaccidentaldesignsituationsisestablishedfrom

BSEN1990(asdescribedinSection3.1).Detailsofhowtherequirementshouldbemet

aregiveninBSEN1991-1-7.

3.3.1 Scope

BSEN1991-1-7providesstrategiesandrulesforsafeguardingbuildingsandothercivil

engineeringworksagainstaccidentalactions.However,thescopeofthispublicationis

limitedtobuildings.

Localisedfailureduetoaccidentalactionscanbeacceptableprovidedthat:itwillnot

endangerthestabilityofthewholestructure;theoverallload-bearingresistanceofthe

structureismaintained;thenecessaryemergencymeasuresareabletohappen.

Theminimumperiodthatmostbuildingsneedtosurvivefollowinganaccidentshould

bethatperiodneededtofacilitatethesafeevacuationandrescueofpersonnelfromthe

buildinganditssurroundings(i.e.theemergencymeasures).Longerperiodsofsurvival

mightberequiredforbuildingsusedforhandlinghazardousmaterials,provisionof

essentialservices,orfornationalsecurityreasons.

BSEN1991-1-7doesnotspecifcallydealwithaccidentalactionscausedbyexternal

explosionsandterroristactivities,ortheresidualstabilityofbuildingsorothercivil

engineeringworksdamagedbyseismicactionorfre.

Ifbuildingsarerequiredtobedesignedtoresistexternalexplosions,warfareactivitiesor

terroristactivitiestheseareadditionaldesignrequirementsoutsidethescopeof

BSEN1991-1-7andofthispublication.SCIPublicationP244

[16]

Protection of buildings

against explosionsprovidesgeneralguidanceontheprotectionofcommercialpropertyand

personnelfromtheeffectsofexplosionscausedbythedetonationofhighexplosives.

Part1ofBSEN1998

[17]

Design of structures for earthquake resistanceprovidesgeneral

rulesonseismicactionsandrulesforbuildings.BSEN1993-1-2

[18]

Eurocode 3, Design

23

of steel structures, General rules, Structural fre designprovidesgeneralrulesfor

structuralfredesignofsteelbuildings.

3.3.2 Design strategies

Twogenerictypesofstrategyfordesigningstructuresforaccidentalactionsare

providedinBSEN1991-1-7:

a. Strategiesbasedonidentifedaccidentalactions.

b. Strategiesbasedonunidentifedaccidentalactions.

ThesestrategiesareillustratedinFigure3.1ofBSEN1991-1-7,reproducedhere

inFigure3.1.

BSEN1991-1-7,3.2and3.3outlinethestrategiesforidentifedaccidentalactions

andforlimitingtheextentoflocalisedfailure,respectively.

Strategiesbasedonunidentifedaccidentalactionscoverawiderangeofpossible

eventsandarerelatedtostrategiesbasedonlimitingtheextentoflocalisedfailure.

Theadoptionofstrategiesforlimitingtheextentoflocalisedfailuremightprovide

adequaterobustnessagainstthoseaccidentalactionsnotspecifcallycoveredby

BSEN1991-1-7suchasexternalexplosionsandterroristactivities,oranyotheraction

resultingfromanunspecifedcause.However,theadequacyoftherobustnesswillbe

greatlydependantontheaccidentalactionthatisexperienced.

Strategiesbasedonidentifedaccidentalactionsarenaturallymorespecifc.However,

dependingontheexactnatureofthestrategy,thestructuremightalsopossess

adequaterobustnessagainstsomeunidentifedactions.

Forthemajorityofsteelframedbuildings,thepotentialaccidentalactionswillremain

unidentifedandthereforetheapproachoflimitingtheextentoflocalisedfailureis

likelytobethegeneralstrategyadopted.

Figure 3.1

Strategies for

accidental design

situations

Accidental Design Situations

robustness accidental

action

Strategies based on identifed

accidental actions

Strategies based on limiting

extent of localised failure

Design for

sufcient

minimum

Prevent or

reduce

action

Design to

sustain

action

Enhanced

redundancy

Design to

resist

notional

Prescriptive

rules e.g.

tying

24

euroCode requIrementS

Strategies for identifed accidental actions

ThestrategyforidentifedaccidentalactionsissetoutinBSEN1991-1-7,3.2.The

mainfeaturesare:

A localised failure due to accidental actions may be acceptable, provided it will

not endanger the stability of the whole structure and that the overall load-bearing

capacity of the structure is maintained and allows the necessary emergency

measures to be taken.

Measures should be taken to mitigate the risk of accidental actions and

these measures should include, as appropriate, one or more of the

following strategies:

preventing the action from occurring

protecting the structure against the effects of the accidental action

ensuring that the structure has suffcient robustness, by adopting one or more

of the following approaches:

by designing certain components of the structure upon which stability

depends as key elements

designing structural members, and selecting materials, to have suffcient

ductility, capable of absorbing signifcant strain energy without rupture.

incorporating suffcient redundancy in the structure to facilitate the

transfer of actions to alternative load paths following an accidental event.

Strategies for limiting the extent of localised failure

Whereaccidentalactionsareunidentifed,strategiesforlimitingtheextentoflocalised

failuremaybeapplied.BSEN1991-1-7,3.3(1)Psetsoutthefollowingprinciple:

In the design, the potential failure of the structure arising from an unspecifed

cause shall be mitigated.

The mitigation should be reached by adopting one or more of the following

approaches:

Designing key elements, on which the stability of the structure depends, to

sustain the effects of a model of accidental action Ad;

Designing the structure so that in the event of a localised failure

(e.g. failure of a single member) the stability of the whole structure or

of a signifcant part of it would not be endangered;

Applying prescriptive design/detailing rules that provide acceptable robustness

for the structure (e.g. three dimensional tying for

additional integrity, or a minimum level of ductility of structural

members subject to impact).

ExamplesrelatingtotheuseoftheapproachesforbuildingsaregiveninAnnexAof

BSEN1991-1-7(seeSection3.3.3).

25

Consequences classes

BSEN1991-1-7,3.4permitsthestrategiesforaccidentaldesignsituationstobe

basedonconsequencesclassessetoutinBSEN1990.Theguidancegivenis

summarisedinTable3.2.

TheclassifcationofbuildingsisdescribedindetailinSection4.

Table 3.2

Consequences class

design strategies

3.3.3 AnnexA

AnnexAofBSEN1991-1-7presentsmoredetailedguidancethanthatgivenin

Section3ofBSEN1991-1-7.AnnexAisaninformativeannexratherthannormative

meaningthatitisforinformationandtheguidancedoesnothavetobefollowed.

However,theUKNationalAnnexdecisiononthestatusoftheinformativeAnnexAisto

recommendtheapplicationofAnnexAbystatingthat:

Guidance in Annex A of BS EN 1991-1-7:2006 should be used in the absence

of specifc requirements in BS EN 1992-1-1 to BS EN 1996-1-1 and

BS EN 1999-1-1 and their National Annexes.

TherearenospecifcrequirementsgiveninBSEN1993-1-1.Therefore,itis

recommendedthattheguidanceinAnnexAofBSEN1991-1-7shouldbefollowedfor

steelframedbuildings.

CompliancewithBSEN1991-1-7,AnnexAcanbeusedtodemonstratecompliance

withtherequirementtoensuretheavoidanceofdisproportionatecollapseintheUK

BuildingRegulations.

ThescopeofBSEN1991-1-7,AnnexAistogiverulesandmethodsfordesigning

buildingstosustainanextentoflocalisedfailurefromanunspecifedcausewithout

disproportionatecollapse.Whileotherapproachesmightbeequallyvalid,adoptionof

theAnnexAstrategyislikelytoensurethatabuildingissuffcientlyrobusttosustaina

limitedextentofdamageorfailurewithoutexcessivecollapse.

ConSequenCeS

ClaSS

ConSIderatIonS for aCCIdental deSIgn SItuatIonS

CC1

No specific consideration is necessary for accidental actions except

to ensure that the robustness and stability rules given in EN 1990 to

EN 1999, as applicable, are met.

CC2

Depending upon the specific circumstances of the structure,

a simplified analysis by static equivalent action models may be

adopted or prescriptive design/detailing rules may be applied.

CC3

An examination of the specific case should be carried out to

determine the level of reliability and the depth of structural analyses

required. This might require a risk analysis to be carried out and the

use of refined methods such as dynamic analyses, non-linear models

and interaction between the load and the structure.

26

euroCode requIrementS

ThemaintopicsforwhichAnnexAprovidesguidanceare:

Consequencesclassesforbuildings.

Recommendedstrategies.

Effectivehorizontalties.

Effectiveverticalties.

Keyelements.

ExplanationandapplicationoftheguidanceofAnnexAtohot-rolledsteelframed

buildingsisprovidedinthefollowingSectionsofthispublication.

ItisimportanttounderstandthattherulesinAnnexAarebestconsideredas

prescriptiverulesintendedtostrikeabalancebetweencostandsafetyandwhich

experiencesuggestsproducestructuresthatgenerallyperformadequatelyinextreme

circumstances.Therulesarenotmeanttobefullydescribedsystemsofstructural

mechanics.Itisimportantthatdesignersarenotexcessivelytheoreticalabout

providingasolutiontorobustnessdesign.

3.4 Robustness strategies

Therecommendedstrategiestoprovideanacceptablelevelofrobustnessforeach

consequencesclassarepresentedinBSEN1991-1-7,AnnexA,A.4.Thestructural

requirementsareprogressivelymorestringentfromClass1throughtoClass3,which

refectstheincreaseinconsequencesifcollapseweretooccur.

AdoptionoftherecommendedstrategiesgiveninBSEN1991-1-7,A.4(1)isintended

toprovideabuildingwithanacceptablelevelofrobustnesstosustainlocalisedfailure

withoutadisproportionatelevelofcollapse.

Sections5to8ofthispublicationdescribethestructuralrequirementsofthe

BSEN1991-1-7recommendedrobustnessstrategiesforeachconsequencesclass.

Sections5to8alsoadviseofadditionalstructuralprovisionsthatcanbeapplied

togetherwiththerecommendationsofBSEN1991-1-7.

27

29

4.1 Consequences classes

TableA.1inAnnexAofBSEN1991-1-7providesamethodtocategorisebuildingsin

fourconsequencesclasses.Thebuildingcategorisationconsidersthebuildingtype,

occupancyandsize.

ThemethodofbuildingclassifcationgiveninAnnexAofBSEN1991-1-7isverysimilar

tothatgiveninApprovedDocumentAguidancefortheEnglandandWalesBuilding

Regulations,exceptthatAnnexAusesClasses2aand2bwhereasthenotation2Aand

2BisusedinApprovedDocumentA.

InBSEN1990andBSEN1991-1-7,3.4therearethreeconsequencesclasses.In

AnnexAofBSEN1991-1-7consequencesclass2hasbeensubdividedintoCC2a

(Lowerriskgroup)andCC2b(Upperriskgroup),creatingatotaloffourclasses.The

categorisationfromAnnexAofBSEN1991-1-7isshowninTable4.1.

Thebuildingclassifcationisasimplifcationofacomplexrisk-basedbuilding

classifcationsystem.Theclassesareonlypartlyrelatedtothebuildingsize,theother

mainfactoristhebuildingusewhichtakesaccountofsocio-economicfactors.Hence,

hospitalsandschools,forexample,generallyhaveahigherclassifcationthanother

buildingsofasimilarsize.Therisk-basedapproachcalculatesariskfactorforeach

typeofbuildingbasedonthefollowingvariables:

Thenumberofpeopleatrisk.

Thelocationofthestructureanditsheight.

Theperceptioninsocietyofdamagetothestructure.

Thetypeofloadandlikelihoodthattheloadwilloccuratthesametimeasalarge

numberofpeoplebeingpresentwithinornearthestructure.

Thestructuraltypeandnatureofthematerial.

FurtherinformationontheclassifcationprocessisprovidedinReference19.

4.2 Practical cases

Inpractice,manybuildingswillnotfallsimplyintooneofthedescriptionsgivenin

Table4.1.Therearemanyreasonswhythiscouldbethecase,forexamplemixeduse,

basementsandvaryingnumberofstoreys.

building

claSSification

30

buIldIng ClaSSIfICatIon

ConSequenCeS

ClaSS

buIldIng tyPe and oCCuPanCy

1

Low consequences

of failure

Single occupancy houses not exceeding 4 storeys.

Agricultural buildings.

Buildings into which people rarely go, provided no part of the

building is closer to another building, or area where people do go,

than a distance of 1.5 times the building height.

2a

(Lower risk group)

Medium

consequences of

failure

5 storey single occupancy houses.

Hotels not exceeding 4 storeys.

Flats, apartments and other residential buildings not exceeding

4 storeys.

Offices not exceeding 4 storeys.

Industrial buildings not exceeding 3 storeys.

Retailing premises not exceeding 3 storeys of less than 1000 m

2

floor

area in each storey.

Single storey educational buildings.

All buildings not exceeding two storeys to which the public are

admitted and which contain floor areas not exceeding 2000 m

2

at

each storey.

2b

(Upper risk group)

Medium

consequences of

failure

Hotels, flats, apartments and other residential buildings greater than

4 storeys but not exceeding 15 storeys.

Educational buildings greater than single storey but not exceeding

15 storeys.

Retailing premises greater than 3 storeys but not exceeding

15 storeys.

Hospitals not exceeding 3 storeys.

Offices greater than 4 storeys but not exceeding 15 storeys.

All buildings to which the public are admitted and which contain floor

areas exceeding 2000 m

2

but not exceeding 5000 m

2

at each storey.

Car parking not exceeding 6 storeys.

3

High consequences

of failure

All buildings defined above as Class 2 Lower and Upper

Consequences Class that exceed the limits on area and number

of storeys.

All buildings to which members of the public are admitted in

significant numbers.

Stadia accommodating more than 5000 spectators.

Buildings containing hazardous substances and /or processes.

Notes:

1. Forbuildingsintendedformorethanonetypeofuse,theconsequencesclassshouldbethatrelating

tothemostoneroustype.

2. Indeterminingthenumberofstoreys,basementstoreysmaybeexcluded,providedthatsuch

basementstoreysfulfltherequirementsofConsequencesClass2bUpperRiskGroup.

Table 4.1

Categorisation

of consequences

classes

AdditionalguidanceonclassifcationofbuildingshasbeenpublishedinReferences20,

21and24.TheadditionalguidancewasoriginallyproducedforusewithApproved

DocumentA,butsincetheclassifcationsysteminAnnexAofBSEN1991-1-7is

31

almostexactlythesameasinApprovedDocumentAtheadditionalguidanceisequally

applicableforusewithBSEN1991-1-7.

TheonlydifferencebetweenthebuildingclassifcationsysteminApprovedDocumentA

andinBSEN1991-1-7isthefoorarealimitforClass2aretailingpremises.In

ApprovedDocumentA,thedefnitionofClass2aretailingpremisesispremises

not exceeding 3 storeys of less than 2000 m

2

foor area in each storeywhereas

inBSEN1991-1-7thedefnitionispremises not exceeding 3 storeys of less than

1000 m

2

foor area in each storey.

GuidanceonbuildingclassifcationissuesisgiveninSections4.2.1to4.2.6.Itis

importantthatguidanceisnotfollowedwithoutalsojudgingeachcaseonitsmerits.

4.2.1 Mezzanine foors

TheclassifcationinAnnexAofBSEN1991-1-7requiresthenumberofstoreysinthe

buildingtobecounted;whetheramezzaninefoorshouldbecountedasastoreyor

notdependsonitssizeanditsuse.Eachsituationneedstobejudgedonitsmerits.

However,asanapproximateguide,amezzaninefoorshouldbeconsideredasa

storeyifitisgreaterthan20%ofthebuildingfootprint.Ifpersonnelarenotaccessing

themezzaninefoordailythenitmightbereasonabletoincreasethelimit.Guidance

onthedesignofmezzaninefoorsforlateralstabilityisprovidedinAdvisoryDesk

NoteAD267

[22]

.

4.2.2 Habitable roof spaces

Habitableareasofroofspaceshouldgenerallybecountedasastorey,irrespectiveof

theslopeoftheroof.Roofspacesinresidentialbuildingsthatareusedtohouseonly

plantandwatertanksneednotbeconsideredasastorey.

Forloftconversions,acasecanbedevelopedfornotcountingtheloftaccommodation

asanadditionalstoreyincircumstanceswhere:

Theoccupancyofthebuildinghasnotincreasedsignifcantly(e.g.wheretheloft

conversionprovidesadditionalspaceforthecurrentinhabitantsratherthanasa

self-containedapartment).

Theexistinglineoftheroofismaintained,exceptperhapsfortheadditionofdormer

windowsononeelevation.

Thesecircumstancesshouldbeconfrmedwiththebuildingcontrolauthority.

4.2.3 Buildings with a varying number of storeys

Buildingswithavaryingnumbersofstoreysthatfallintomorethanoneconsequences

classshouldbeclassifedasthemoreonerousclass.Therobustnessmeasuresfor

themoreonerousclassshouldcontinueuntilastructuraldiscontinuity(suchasa

movementjoint)isreached,providedthatthebuildingeithersideofthemovement

jointisstructurallyindependentandrobustinitsownright.

32

buIldIng ClaSSIfICatIon

Example

Figure4.1showsablockoffatspartlyof4storeysandpartlyof5storeys.Class2b

robustnessstrategiesshouldbeappliedtothe5storeyareasandextendingtoa

suitablestructuraldiscontinuityinthe4storeyareaandClass2arobustnessstrategies

maybeappliedtotheremaining4storeyarea.

4.2.4 Mixed use buildings

Forbuildingsintendedformorethanonetypeofusetheclassshouldbethat

pertainingtothemostoneroustype.Wheredifferentoccupanciesareinhorizontally

adjacentpartsofthesamebuilding,thesameapproachtoconsequencesclassesmay

beadoptedasdescribedinSection4.2.3forbuildingswithvaryingnumbersofstoreys,

i.e.theconsequencesclassforthemoreonerousclassshouldcontinuehorizontally

untilastructuraldiscontinuity(suchasamovementjoint)isreached.

Thefollowingexamplesillustratetheclassifcationofmixedusebuildings.

Examples

Figure4.2shows2storeysoffatsover1storeyofretailingpremises.Thiscaseshould

beconsideredas3storeysofretailingpremises.Therefore,applyClass2arobustness

strategiestothewholebuilding,orapplyClass2brobustnessmeasurestothewhole

buildingiffoorareaofretailingpremisesis1000mormore(perstorey).

(Note:The1000m

2

limitusedhereistakenfromBSEN1991-1-7,AnnexA,the

equivalentlimitinApprovedDocumentAis2000m

2

.)

Figure 4.1

Classifcation of 4

and 5 storey fats

Figure 4.2

Classifcation of

2 storey fats over

1 storey retail

2a, or 2b if retail

premises > 1,000 m

Shop

Flats

Flats Flats

2b 2a

Movement joint

33

Figure4.3shows2storeysoffatsover2storeysofretailingpremises.Thiscase

shouldbetakenas4storeysofretailingpremises.Therefore,applyClass2b

robustnessstrategiestothewholebuilding.

Figure4.4shows4storeysoffatsadjacentto5storeysofoffces.Class2brobustness

strategiesshouldbeappliedtothe5storeyoffceareaandextendingtoasuitable

structuraldiscontinuityinthe4storeyresidentialareaandClass2arobustness

strategiesshouldbeappliedtotheremaining4storeyresidentialarea.

4.2.5 Buildings with basements

Toqualifyasabasementstoreyforthepurposeofbuildingclassifcation,theexternal

groundlevelshouldbeatleast1.2mabovethetopsurfaceofthebasementfoorfora

minimumof50%oftheplanareaofthebuilding(seeReference20).

Therobustnessstrategiesthatarerequiredtobeappliedtothepartofthebuilding

abovethebasementdependonthetotalnumberofstoreysandtherobustness

strategiesappliedtothebasementstorey.

Indeterminingthenumberofstoreysforclassifcation,basementstoreysmaybe

excludediftheyfulfltherobustnessrequirementsofClass2bbuildings.Otherwise,

thebasementstoreysmustbeincludedindeterminingthenumberofstoreysfor

buildingclassifcation.

Thebasementcanbeforhabitableaccommodationorparking.Thefollowingexamples

illustratetheappropriateclassifcationtobeapplied.

Shop

Flats

2b

Shop

Figure 4.3

Classifcation of

2 storey fats over

2 storey retail

Figure 4.4

Classifcation of

4 storey fats attached

to 5 storey offces

Ofces Flats

2b 2a

Movement joint

34

buIldIng ClaSSIfICatIon

Examples

Figure4.5showsbuildingswithstoreysoffatsabovebasementsandtheclassof

robustnessstrategytobeapplied.

4.2.6 Ground foor storey

Indeterminingthenumberofstoreysforclassifcation,thegroundfoorstoreymay

generallybeexcludedifallthestructuralelementsofthegroundfoorstorey,and

theirconnections,aredesignedaskeyelements(seeReference20).Section7.7gives

guidanceonthedesignofkeyelements.

Whereusedforparking,thegroundfoorstoreymayonlybeexcluded(asdescribed

above)ifallofthefollowingconditionsapply:

i. Parkingisexclusivelyforusersofthebuilding.

ii. Thegroundfoorstoreymustnotbeaccessibletoorcontainarightofwayforthe

generalpublic.

iii. Allthestructuralelementsofthegroundfoorstorey,andtheirconnections,are

designedaskeyelements.

Thefollowingexamplesillustratetheappropriateclassifcationtobeapplied.

Examples

Figure4.6showsblocksoffatsandtheclassofrobustnessstrategytobeapplied

fromusingtheoptiontodesignthegroundfoorstoreymembersaskeyelements.

Figure 4.5

Classifcation of fats

over basements

4 storey over

basement

Flats Flats

5 storey over

basement

Flats

15 storey over

basement

Flats

16 storey over

basement

2b

2a 2b

2b

3

35

Figure4.7showsblocksoffatsaboveagroundfoorstoreyusedasacarparkandthe

consequencesclasstobeappliedforrobustnessfromusingtheoptiontodesignthe

groundfoorstoreymembersaskeyelements.Inthisexampleitisassumedthatthe

parkingisexclusivelyforusersofthebuildingandthatthegroundfoorstoreyisnotbe

accessibletoanddoesnotcontainarightofwayforthegeneralpublic.

Reference24providesadditionalguidanceontheclassifcationofbuildingswherea

mixofstructuralmaterialshasbeenused,particularlywhereagroundfoorpodium

hasbeenused.

4.3 Conversions, alterations and extensions

Buildingsthatundergoconversions,alterationsorextensions(oracombinationof

these)canhavechangedconsequencesclassasaresultofthework.Wherethe

workhascausedthebuildingtobecategorisedintoamoreonerousclass(e.g.due

toarooftopextension)thepotentialrequirementtoapplytherobustnessstrategy

appropriatetothemoreonerousclassthroughoutthebuildingmaybeeconomically

prohibitive.Thestructuralrequirementsinsuchcasesshouldbeclarifedandagreed

withthelocalbuildingcontrolbody.OnesolutionmightbetousetheCamdenRuling,

whichhasbeenusedinthepastintheUK

[23]

.TheCamdenRulingallowsthedesigner

toadoptasolutionthatdemonstratesthatanydamageoccurringwithinthestoreys

ofarooftopextensionwouldbecontainedbythefoorformingtheroofoftheoriginal

buildingi.e.theroofoftheoriginalbuildingcansupportthedebrisloadingofthe

rooftopextension.Ifthiscanbeachieved,thealterationappearsnottochangethe

risktotheoccupantsoftheoriginallowerfoors.However,theCamdenRulingmethod

isnotuniversallyacceptedandcanbeconsideredascontroversialbecauseadditional

storeyswillalmostcertainlyincreasetheriskonthelowerstoreys.Furtherdiscussion

onthemethodisgiveninReference24.

Figure 4.6

Classifcation

options for fats

Figure 4.7

Classifcation of

fats with ground

foor car park

Flats

2a

2a

Flats

Flats

Flats

Flats

Flats

Key

element

Key

element

2b 2b 2b

Flats

2a

Car park

Flats

Car park

Flats

Car park

Key

element

2b

2b

Key

element

2b

2a

Key

element

2b

37

5.1 Structural requirements

5.1.1 Robustness strategy

TherecommendedstrategyinBSEN1991-1-7,AnnexA,A.4forConsequencesClass1

buildingsstates:

Provided a building has been designed and constructed in accordance with the

rules given in EN 1990 to EN 1999 for satisfying stability in normal use, no

further specifc consideration is necessary with regard to accidental actions from

unidentifed causes.

Hence,forsteel-framedbuildingsdesignedinaccordancewiththerulesgiven

inBSEN1993noadditionalrulesneedtobeappliedforcompliancewith

BSEN1991-1-7fortheconsiderationofavoidanceofdisproportionatecollapse.

5.1.2 Additional structural provisions

Inadditiontoadoptingtheabovestrategy,itisrecommendedthataminimumlevel

ofhorizontaltyingisprovidedwithintheframe.Therecommendedminimumlevel

ofhorizontaltyingisthatallfoorbeam-to-columnconnectionsaredesignedtobe

capableofsustainingadesigntensileforceof75kN.

5.2 Minimum horizontal tying

5.2.1 Benefts of providing a minimum level of horizontal tying

Thepurposeofprovidingaminimumlevelofhorizontaltyingistoensurethatbeam-to-

columnconnectionsarenotimpairedbyrelativelysmallhorizontalorupwardactions

appliedtothebeamsthatcouldcausebeamstocollapseontofoorsbelow.

Ifonlygravityandhorizontalactionsweretobeconsidered,itwouldbetheoretically

possibletodesignbeam-to-columnconnectionswithinabracedframethatonlyhave

averticalshearresistance,e.g.abeamseatedonabearingblockweldedtoacolumn.

ThesetypesofconnectionarenotnormallyusedintheUK,sincethebeamcould

easilybedislodged.Itisgoodengineeringpractisetodetailallconnectionstohavea

minimumlevelofhorizontalresistance.

buildingS in

conSequenceS

claSS 1

38

ConSequenCeS ClaSS 1

5.2.2 Design rules

Foraminimumlevelofhorizontaltyingthefollowingdesignrulesarerecommended:

a. Allfoorbeam-to-columnconnectionsshouldbedesignedtobecapableof

sustainingadesigntensileforceof75kN.

b. The75kNtieforceneednotbecombinedwiththeeffectsofanyotheractions.

Therecommendationshouldalsobeappliedatrooflevel,exceptwherethesteelwork

onlysupportsroofcladdingthatweighsnotmorethan0.7kN/m

2

andcarriesonly

imposedroofloadsandwindloads.

Itisnotnecessarythatbeam-to-beamconnectionsaredesignedforaspecifctying

forceinordertosatisfyarobustnessstrategyforClass1buildingsastheminimum

tyingrecommendationappliesonlytobeam-to-columnconnections.Hence,itisnot

necessarytodesignsecondarybeamsasties,asshowninFigure5.1.

Figure 5.1

Ties recommended in

Class 1 buildings

5.3 Practical application of design rules

Inordertodesigncolumnsasrestrainedinpositionforeachaxisateachfoorand

rooflevel,thecolumnsshouldgenerallybeconnectedtobeams,approximatelyatright

angles,ateachprincipalfoorlevel.

Providingresistancetothe75kNtyingforcewillgenerallynotbeanonerous

requirementforconnectionsinhot-rolledsteelframes.Allstandardbeam-to-column

connectionsforsimplysupportedbeamshaveatyingresistancethatexceeds75kN.

Designtablesforstandardsimpleconnectiontypes(seeFigure5.2)areprovidedinSCI

publicationP358

[25]

.

Secondary beams

are not ties

Beams between

columns are ties

39

a.

b.

c.

Partial depth end plate

Flush end plate

Fin plate

Tying resistance with:

3 rows of 2 bolts = 296 kN

4 rows of 2 bolts = 426 kN

Tying resistance with:

3 rows of 2 bolts = 436 kN

4 rows of 2 bolts = 564 kN

Tying resistance with:

3 bolts = 308 kN

4 bolts = 428 kN

Note: Values for 3 rows of bolts are for a 356 x 171 x 67 S275 UKB

Values for 3 rows of bolts are for a 356 x 171 x 67 S275 UKB

BSEN1993-1-8

[26]

doesnotgiveanyguidanceonthetyingresistanceofconnections.

Largestrainsandlargedeformationsareacceptableintheaccidentaldesignsituation.

Therefore,forthecalculationofconnectiontyingresistance,SN015

[27]

recommends

thatultimatetensilestrengths(f

u

)beusedandthepartialfactorfortying

M,u

betaken

as1.1.ExamplesshowingthecalculationofconnectionresistancesareincludedinSCI

publicationP364

[28]

.

DesignresistancesforM16andM20class8.8boltsinS275steelaregivenin

Table5.1.Anyreasonableconnectionwithatleasttwoboltswillprovideatying

resistanceinexcessofthe75kNrequirement.

Figure 5.2

Types of simple

connection with typical

tying resistance

bolt dIameter

tenSIon

reSIStanCe

SIngle Shear

reSIStanCe

bearIng

reSIStanCe

(8 mm Plate)

M16 90.4 kN 60.3 kN 54.5 kN

M20 141 kN 94.1 kN 67.4 kN

Note: TheabovevalueshavebeencalculatedinaccordancewithBSEN1993-1-8

[26]

.

Table 5.1

Design resistances

for class 8.8 bolts in

S275 steel

41

6.1 Structural requirements

6.1.1 Robustness strategy

TherecommendedstrategyinBSEN1991-1-7,AnnexA,A.4forConsequences

Class2abuildingsstates:

In addition to the recommended strategies for Consequences Class 1, the provision

of effective horizontal ties, or effective anchorage of suspended foors to walls,

as defned in A.5.1 and A.5.2 respectively for framed and load-bearing wall

construction should be provided.

Note 1: Details of effective anchorage may be given in the National Annex.

Load-bearingwallconstructionisoutsidethescopeofthispublicationandthe

requirementforeffectiveanchorageisnotdiscussed.Therequirementsofeffective

horizontaltiesforframedstructuresassetoutinA.5.1ofBSEN1991-1-7,are

describedinSection6.2.

Approved Document A

Thewordingoftherecommendedstrategyissimilartotheguidancegivenin

ApprovedDocumentA(2004)forClass2Abuildings.However,itshouldbenotedthat

interpretationofwhatconstituteseffectivehorizontaltiesisconsiderablydifferentin

magnitude.TheApprovedDocumentA(2004)interpretationisthat75kNconstitutesan

effectivehorizontaltieforhot-rolledsteelframeconstruction.InBSEN1991-1-7,75kN

isaminimumtensileloadthatthetieshouldsustain.Theactualtieforceiscalculated

andinmanycaseswillbesignifcantlygreaterthan75kN(seeSection6.3.8).

6.1.2 Additional structural provisions

InadditiontotherobustnessstrategyfromBSEN1991-1-7,bearingdetailsforfoor,

roofandstairunitsshouldconformtoBSEN1992andmakedueallowancefor

construction,fabricationandmanufacturingtolerances.

buildingS in

conSequenceS

claSS 2a

42

ConSequenCeS ClaSS 2a

6.2 Horizontal ties

6.2.1 Benefts of providing horizontal ties

Horizontaltyingcanbebenefcialtoastructureinanaccidentalactionsituationby:

enablingcatenaryactiontodevelop;

holdingcolumnsinplace.

Thesetwopotentialrolesofhorizontaltyingarediscussedbelow.

Catenary action

Theprincipleofprovidinghorizontaltiesnotionallyallowsforbeammemberstosupport

loadsbyformingcatenariesoverdamagedareasofstructure.Theprovisionofhorizontal

ties,designedtotheEurocoderules,hasnocomplementaryrequirementsrelating

tojointductilityorjointrotationcapacity.Therobustnessrulesarenotmeanttofully

describesystemsofstructuralmechanicsbutareconsideredasrulesintendedto

producestructuresthatperformadequatelyinaccidentalcircumstances.Nonetheless,

applyingtherulescontributestowardssupportoverdamagedareasofstructurewhere

thesupportprovidedbyacolumnhasbeenlost,asshowninFigure6.1.

Figure6.1showsforcesredistributedverticallyaswellashorizontally.However,

forConsequencesClass2abuildings,verticaltyingisnotarequirementof

BSEN1991-1-7orApprovedDocumentA

[12]

.Therefore,Figure6.1doesnotshow

forcesbeingredistributedverticallypastthefrstcolumnspliceabovethedamaged

columnsection.Columnmembersaregenerallysplicedeverysecondorthirdstoreyso,

dependingonthelocationofthedamage,therewillusuallybesomeupwardtransferof

forcesatleastasfarasthefrstcolumnsplice.

Figure 6.1

Catenary action with

horizontal ties

Splice

Holding columns in place

Accidentalactionscancausehorizontalforcestoactoncolumnsections:ensuringthat

beam-to-columnconnectionshavetyingresistancehelpstoholdthecolumninplace

andthereforethatitcancontinuetosupportverticalloads,asshowninFigure6.2.The

accidentalactionshowninFigure6.2isdepictedasaninternalblastbuttheprinciple

appliestoanyaccidentalactionthatcancausehorizontalforces.Holdingcolumnsin

43

placealso,importantly,helpstopreventfoorunitsfallingduetothespreadofbeams

thatcouldoccurifcolumnswerenotheldinposition.

6.2.2 Design forces

Therequirementsforeffectivehorizontalties,asdefnedinA.5.1ofBSEN1991-1-7,

aregivenbelow.

Eachtiemember,includingitsendconnections,shouldbecapableofsustaininga

designtensileloadofT

i

fortheaccidentallimitstateinthecaseofinternalties,andT

p

,

inthecaseofperimeterties.ThemagnitudesofT

i

andT

p

arecalculatedaccordingto

equationsA.1andA.2fromBSEN1991-1-7,A.5.1,reproducedbelow:

T

i

=0.8(g

k

+y q

k

)s L or75kN,whicheveristhegreater

T

p

=0.4(g

k

+y q

k

)s L or75kN,whicheveristhegreater

where:

g

k

isthepermanentaction

q

k

isthevariableaction

s isthespacingoftheties

L isthespanofthetie

y istherelevantfactorintheexpressionforcombinationofactioneffectsfor

theaccidentaldesignsituation(i.e.y

1

ory

2

inaccordancewithexpression

(6.11b)ofEN1990).

Note:Thereferencetoexpression(6.11b)ofEN1990inthedefnitionofyisspecifc

totheyfactor.Expression(6.11b)ofEN1990isnotusedtodeterminethetieforce.

Notethatthepermanentactionofcladdingloadsdoesnotneedtobeincludedinthe

expressionforT

p

asthecladdingloadwouldnolongerbepresentonthememberin

thisdesignsituation.

Internal blast

Blowing out of columns

resisted by tie forces at

foor levels T

Figure 6.2

Columns held

in position with

horizontal ties

44

ConSequenCeS ClaSS 2a

TheUKNationalAnnextoBSEN1990specifesthaty

1

shouldbeusedfor

combinationswithaccidentalactions(see3.1.3).Valuesfory

1

,takenfrom

TableNA.1.1,aregiveninTable3.1.Valuesofy

1

forfoorloadsinbuildingsvaryfrom

zeroforroofsto0.9forstorageareas.Forthecommonsituationsofoffceareasand

residentialareas,y

1

shouldbetakenas0.5.

Itisnotnecessaryforthetieforcetobecombinedwithanyotherloads.Therefore,the

connectiondoesnotneedtobedesignedtoresistashearloadandatensileloadfrom

thetiessimultaneously.

6.2.3 Provision of ties

Thehorizontaltiesshouldbe:

a. Providedaroundtheperimeterofeachfoor.

b. Providedaroundtheperimeteroftherooflevel.

c. Providedinternallyintworightangledirectionstotiethecolumnssecurelytothe

structureofthebuilding.

d. Incontinuouslines.

e. Forperimeterties,arrangedascloselyaspracticabletotheedgesoffoors.

f. Fortiesintendedtobeoncolumnlines,arrangedascloselyaspracticabletothe

linesofcolumns.

g. Arrangedsothatatleast30%ofthetiesarelocatedwithintheclosevicinityofthe

gridlinesofthecolumns.

Figure6.3showsthelocationofhorizontaltiesinafoorofaClass2abuilding.

Thehorizontaltiescancomprisethefollowingelementsoracombinationofthem:

a. Rolledsteelsections(i.e.foorbeammembers).

b. Steelbarreinforcementincompositesteel/concretefoors.

c. Steelfabric(mesh)reinforcementincompositesteel/concretefoors.

d. Profledsteelsheetingincompositesteel/concretefoors.

e. Precastunits,ifeffectivelytiedtothesteelbeams.

Figure 6.3

Location of

horizontal ties in

Class 2a buildings

Internal tie All beams

designed to

act as ties

Perimeter tie

Tie anchored

to column

45

Note:Items(b),(c)and(d)mayonlybeutilisedastiesifthecompositesteel/concrete

foorsareconnecteddirectlytothesteelbeamswithshearconnectors.Item(d)may

onlybeutilisedastiesactinginthesamedirectionofthespanoftheprofledsteel

sheetingandwherethesheetingisdirectlyfxedtothesupportingsteelbeam.

6.3 Practical application of design rules

6.3.1 Chasing loads

ThereisnorequirementinbuildingregulationsorBSEN1991-1-7tochasethetie

forcesaroundthestructure.Therequirementisonlytodesignthememberanditsend

connectionforthetieforce;thedesignerisnotrequiredtoconsidertheconsequences

ofthetieforcesanyfurther.ThispointisillustratedbyreferencetoFigure6.4which

showsahorizontaltieforceactingonanexternalcolumn.Theexternalcolumnsection

ABdoesnotneedtobedesignedforalateralforce.

Figure 6.4

Tie force on

external column

A

B

Tie force

Unequal tie

forces due to

unequal spans

Theoretical

catenary

Figure 6.5

Tie force with

unequal spans

Forabeamconnectedtoacolumnwebwithanendplateconnection,thecolumnweb

shouldbecheckedtoensurethatitcansustainthetyingforce(largedeformationsare

acceptable)butthecolumnsectionasamemberdoesnotneedtobechecked.

6.3.2 Unequal spans

Asstatedpreviously,providinghorizontaltiesnotionallyallowsforbeammembers

tosupportloadsbyformingcatenaries.Wherealineoftiesconsistsofbeamswith

differentspans(asshowninFigure6.5)thedesigntieforceswillbedifferentalong

thelineofties.Thisisatoddswiththetheoreticaltensileforceinacatenarywhich

46

ConSequenCeS ClaSS 2a

isconstantthroughoutitslength.However,whenconsideringunidentifedaccidental

actions,thedesignerisnotrequiredtoconsiderthistheoreticalinconsistencyandno

rationalisationofdesigntieforcesalongalineoftiesisrequired.Thesametheoretical

inconsistencycanoccurwhenbeamsaresupportingdifferentlevelsofload.

6.3.3 Continuous lines

BSEN1991-1-7,A.5.1statesthatthehorizontaltiesshouldbearrangedincontinuous

lines.Wherethereareirregularcolumngridsorbeamarrangementsresultinginan

offsetbetweenlinesofties(asshowninFigure6.6),thebeamsarenotincontinuous

lines.Thedesignerneedstobesatisfedthatthetieforcecanbetransferredfromone

beamtothenext.Alternativeelementssuchasthefoorslabmaybeused,orinextreme

cases,anadditionalmembercanbeaddedtotransferthetieforce.Dependingonthe

sizeofthetieforce,andiftheoffsetordiscontinuityissmall,itispossibletojustifythat

thetieforcecanbetransferredthroughbendingandshearofconnectedmembers.

6.3.4 Voids

Anothersituationwhereitcouldbearguedthatthetiesarenotcontinuousiswhere

alineoftiesisinterruptedduetoavoidinabuildingsuchasanatrium.Inthiscase

thereisnorequirementtomakeadditionalallowanceforthevoidinthefoor.The

voidoratriumshouldbetreatedinthesamewayasanyotherfoororroofedgeinthe

building.Hence,horizontaltiesshouldbeprovidedaroundtheperimeterofeachfoor

androoflevel,whichincludestheperimeteradjacenttovoidsinthefoorsuchasatria.

6.3.5 Beams not on column lines

BSEN1991-1-7isambiguousaboutwhetherbeamsthatarenotoncolumnlines

shouldbedesignedastiesornot.BSEN1991-1-7A.5.1(1)statesthathorizontalties

shouldbeprovidedascloselyaspracticabletolinesofcolumnsandatleast30%of

thetiesshouldbelocatedwithinclosevicinityofthegridlinesofcolumns.Incontrast,

Beam designed as tie

Ofset

Figure 6.6

Discontinuity in

line of ties

47

L /4 L /4 L /4 L /4 L /4 L /4

L L

A B C

T

1

T

1

T

2

T

2

T

3

T

3

T

4

T

4

T

5

T

5

T

6

T

6

T

7

T

7

T

8

T

8

T

9

T

9

At least 30% of tie

capacity in this zone

At least 30% of tie

capacity in this zone

At least 30% of tie

capacity in this zone

Figure 6.7

Distribution of

horizontal tie forces

label(b)ofFigureA.2indicatesthatallbeamsshouldbedesignedtoactasties.

Therefore,itisconcludedthatequationsA.1(orA.2)shouldbeappliedtoallbeams

whetherornottheyareonthecolumnlines.Theexpression30%ofthetiesisthen

interpretedtomean30%ofthetotalrequiredtieresistance.Hence,thedesignermust

alsocheckthatatleast30%oftherequiredtieresistanceisinclosevicinitytothe

columnline.NoguidanceisprovidedinBSEN1991-1-7astothedefnitionofclose

vicinity.Forthepurposesofthispublication,closevicinityistakentomeanaquarterof

thecolumnspacing.

Figure6.7showsanarrangementofinternalfoorbeams.EquationA.1of

BSEN1991-1-7A.5.1shouldbeappliedtoeachbeaminFigure6.7todetermine

therequiredminimumtyingresistance(T

i

)ofthebeamanditsendconnections.

Dependingontheloadingandbeamspacing,eachbeamcanhaveadifferent

minimumtyingresistance.Inadditiontoverifyingthatthememberanditsend

connectionscanresistthecalculatedtyingload,thedesignermustalsoverifythatat

least30%ofthetieresistanceiswithinadistanceofaquarterofthecolumnspacing

eithersideofthecolumnline.Therefore,consideringthebeamoncolumnlineBin

Figure6.7,thefollowingrequirementshouldbesatisfed:

T

5

0.3(T

4

+T

5

+T

6

)

EquivalentexpressionsshouldalsobesatisfedforbeamsoncolumnlinesAandC.

6.3.6 Tie resistance provided by slab components

AsdiscussedinSection6.2.2,BSEN1991-1-7,A.5.1allowstherequiredtying

resistancetobeprovidedbycompositeslabcomponentssuchassteelreinforcement

orsteelsheeting.

48

ConSequenCeS ClaSS 2a

Itisimportanttonotethatthepurposeofprovidingthehorizontaltiesspecifedin

BSEN1991-1-7,A.5.1istoholdtheverticalmembersoftheframeinplaceandto

enablethebeamstoactincatenary.Thehorizontaltyingisnotprovidedtoholdthe

foorslabsinplaceonthesupportingstructure,althoughtheywillinmanycaseshave

thiseffect.Thepurposeofthehorizontaltiesisemphasisedbytheconditiongivenin

BSEN1991-1-7,A.5.1(2)thatslabcomponentsshouldonlybeusedtoprovidetying

resistanceifthecompositesteel/concretefoorsaredirectlyconnectedtothesteel

beamswithshearconnectors(asshowninFigure6.8).Thetiesmusttiethestructural

frametogether,notjusttiefoorslabstoadjacentfoorslabs.Forthearrangement

showninFigure6.8,thetransversereinforcement,fabricreinforcementandprofled

steeldeckingmayallbeusedtocontributetotherequiredtieforceresistance.General

guidanceoncompositeslabsandbeamsisprovidedinSCIpublicationP300

[29]

.

Whenthetyingresistanceisprovided,entirelyorinpart,bycompositeslab

componentsthereisscopeforthetieforceresistancetobedistributedacrossthe

widthoftheslabandnotlocatedoncolumnlines.

6.3.7 Beam-to-beam connections

Asexplainedin6.3.1,BSEN1991-1-7andApprovedDocumentAonlyrequirea

tiememberanditsendconnectionstobedesignedfortherequiredtieforce.This

requirementcanbediffculttointerpretwhentwotiemembers(beams)connectto

thewebofatransversesupportingbeamfromoppositesides,asshowninFigure6.9.

Inthissituation,thesupportingbeamwebispartoftheconnectionandshouldbe

designedtoresistthetieforces.Dependingonthebeamspansandloading,thetie

forcesoneachsideofthesupportingbeamcanbeofdifferentmagnitudes.However,

thetieforcesarenotadditivebecauseitisnotnecessarytoconsiderbothtieforces

actingsimultaneously.Hence,thebeamwebneedonlybedesignedforthelargerof

Profled steel

decking

Shear stud

connector

Transverse

reinforcement

In-situ concrete

Figure 6.8

Tying with slab

components

49

thetwotieforces,asshouldtheothercommoncomponentsofeachconnectione.g.

theboltsshouldalsobedesignedforthelargertieforce.AsdiscussedinSection6.3.1,

thebeammemberdoesnotneedtobedesignedtoresistlateralbendingduetothe

tieforce.TheconnectionshowninFigure6.9isanendplateconnectionbutthesame

principleswouldapplytofnplateordoubleanglecleatconnections.

SCIpublicationP358

[25]

givesdetaileddesignchecksforeachcomponentof

nominallypinnedconnections,includingthoserequiredtocalculatetheconnection

tyingresistance.

6.3.8 Beam arrangements

ThetieforceequationsgiveninBSEN1991-1-7,A.5.1onlyneedtobeappliedto

horizontalmembersthatcarryfoorloads.Membersalongwiththeirendconnections

thatdonot,intheory,carryanyfoorloadonlyneedtobedesignedforatieforceof

75kN.Therefore,differentbeamarrangementscanresultindifferenttyingresistance

requirements,eventhoughthecolumngridmightbeverysimilar.

Genericexpressionsfortyingresistancerequirements,basedonthetieforceequations

giveninBSEN1991-1-7,A.5.1,fordifferentbeamarrangementsareshowninFigure6.10

andFigure6.11.Figure6.10showstieforceexpressionsforabeamarrangementthat

couldbeusedwithlongspanslabsolutionssuchasdeepcompositedeckingorprecast

units.Figure6.11showstieforceexpressionsforabeamarrangementthatcouldbe

usedwithshortspanslabsolutionssuchasshallowcompositedecking.

Table6.1givestyingrequirementsbasedontheexpressionsgiveninFigure6.10.The

maximumtieforcecalculatedforthetwoscenariosconsideredinTable6.1is270kN.

Tie force Tie force

Figure 6.9

Tie force on

beam web

loadIng tIe forCe requIrementS

g

k

kN/m

2

q

k

kN/m

2

T

1

kN

T

2

kN

T

3

kN

3.0 2.5 75 191 96

4.0 4.0 75 270 270

Note: is taken as 0.5, L and B are taken as 7.5 m.

Table 6.1

Tie forces for beam

arrangement shown

in Figure 6.10

50

ConSequenCeS ClaSS 2a

B B B

L

L

L

T

3

T

3

T

3

T

3

T

3

T

3

T

1

T

1

T

1

T

1

T

3

T

3

T

3

T

3

T

3

T

3

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

3

T

1

T

2

T

2

T

2

T

2

T

2

T

2

T

2

T

2

T

3

T

3

T

3

T

3

T

3

T

3

T

3

T

3

T

1

T

1

T

1

T

1

T

1

T

1

T

1

= 75 kN

T

2

= 0.8(g

k

+ q

k

) LB but 75 kN

T

3

= 0.4(g

k

+ q

k

) LB but 75 kN

where:

g

k

characteristic dead load

combination factor for accidental loading

q

k

characteristic imposed load.

Figure 6.10

Generic tie forces

for a long span slab

beam arrangement

51

B B B

L

L

L

T

5

T

5

T

5

T

5

T

5

T

5

T

4

T

4

T

4

T

4

T

3

T

3

T

3

T

3

T

3

T

3

T

2

T

2

T

2

T

2

T

2

T

2

T

2

T

2

T

2

T

2

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

5

T

5

T

5

T

5

T

5

T

5

T

5

T

5

T

4

T

4

T

4

T

4

T

4

T

4

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

T

1

= 0.8(g

k

+ q

k

) LB/2 but 75 kN

T

2

= 0.8(g

k

+ q

k

) LB but 75 kN

T

3

= 0.8(g

k

+ q

k

)3LB/4 but 75 kN

T

4

= 0.4(g

k

+ q

k

) LB but 75 kN

T

5

= 0.4(g

k

+ q

k

) LB/2 but 75 kN

where:

g

k

q

k

characteristic dead load

combination factor for accidental loading

characteristic imposed load.

Figure 6.11

Generic tie forces

for a short span slab

beam arrangement

52

ConSequenCeS ClaSS 2a

a.

b.

c.

Partial depth end plate

Flush end plate

Fin plate

Tying resistance with:

3 rows of 2 bolts = 296 to 281 kN

4 rows of 2 bolts = 563 to 374 kN

5 rows of 2 bolts = 699 to 384 kN

Tying resistance with:

3 rows of 2 bolts = 436 to 421 kN

4 rows of 2 bolts = 741 to 515 kN

5 rows of 2 bolts = 836 to 602 kN

Tying resistance with:

3 bolts = 308 to 197 kN

4 bolts = 428 to 289 kN

5 bolts = 535 to 429 kN

Note: Tying resistances are for standard connection details with S275 beams, taken from SCI-P358

[25]

loadIng tIe forCe requIrementS

g

k

kN/m

2

q

k

kN/m

2

T

1

kN

T

2

kN

T

3

kN

T

4

kN

T

5

kN

3.0 2.5 96 191 143 96 75

4.0 4.0 135 270 203 135 75

Note: is taken as 0.5, L and B are taken as 7.5 m

Table 6.2

Tie forces for beam

arrangement shown

in Figure 6.11

Figure 6.12

Types of simple

connection with typical

tying resistances

Table6.2givestyingrequirementsbasedontheexpressionsgiveninFigure6.11.The

maximumtieforcecalculatedforthetwoscenariosconsideredinTable6.2is270kN.

TyingresistancesforstandardconnectionsaregiveninFigure6.12;itcanbeseenthat

thetieforceof270kNcaneasilybesatisfedbystandardconnectiondetails.

53

55

7.1 Structural requirements

7.1.1 Robustness strategy

TherecommendedstrategyinBSEN1991-1-7,AnnexA,A.4forConsequences

Class2bbuildingsstates:

In addition to the recommended strategies for Consequences Class 1, the provision of:

Horizontal ties, as defned in A.5.1 and A.5.2 respectively for framed and load-

bearing wall construction (see 1.5.11), together with vertical ties, as defned in

A.6, in all supporting columns and walls should be provided.

Or, alternatively:

The building should be checked to ensure that upon the notional removal of

each supporting column and each beam supporting a column, or any nominal

section of load-bearing wall as defned in A.7 (one at a time in each storey of

the building) the building remains stable and that any local damage does not

exceed a certain limit.