Documente Academic

Documente Profesional

Documente Cultură

Detailed Report From France

Încărcat de

VIBHAVDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Detailed Report From France

Încărcat de

VIBHAVDrepturi de autor:

Formate disponibile

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

T

DATES & TYPE CF lNTEP\ENTlCN

Slurling dulo o inlorvonlion. T3/08/20T0 Ending dulo o inlorvonlion . T8/08/20T0

Purliul ovorhuul Gonorul ovorhuul Polroil Commissioning

lncidonl Clhor Tochnicul Assislunco

2

MACHlNE CHAPACTEPlSTlCS

Unil rulod powor (MW} . 120

Polulion (PPM} . 3000 / 3300

Munuucluror lniliul pro|ocl rooronco Soriul N Typo Pomurks

Iurbine AL5IOM

Generolor AL5IOM

3

SYSTEMS CHAPACTEPlSTlCS

Munuucluror Typo Pomurks

Electrical cabinet ALSTOM Tracy

Vibrations Monitoring Bently Nevada 3300

Turbine Governor CEGELEC STG 820

Servovalve MOOG F072-368

Servovalve Jack MAAC

Generator Governor MICROREC A 512

Synchronisation ALSTOM Tracy

4

ENCLCSUPES

Lisl o roquirod documonls DCS curvos + locul purumolors

lnlorvonlion ollow-up documonl(s}

Crgunisulion churl / Lisl o purlicipunls

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

5 lNTEP\ENTlCN DESCPlPTlCN

Jhe urcse cl this interventicn was a technical assistance durinq the unit ccmmissicninq alter a majcr cverhaul.

ALSJ0M has rcceeded tc a majcr cverhaul cn the lP turbine. uurinq the cutaqe the lP rctcr has been balancinq at

ncminal seed (in ccld ccnditicn).

Jhe custcmer has rcceeded tc a majcr cverhaul cn the LP turbine and the qeneratcr.

5.1 Jurbc 6eneratcr lnsecticns

Jhe unit was stc in ccld ccnditicn.

0n the LP side everythinq was clcsed, the vacuum breakinq valve was nct yet in lace. All exansicn rinqs are lree

but scme lcckinq screws are nct sc much tiqht.

0n the lP turbine, bcth edestals are cen, mechanical quy's wcrks cn the exhaust edestal tc ut cn lace the

turninq qear clutch.

All instrumentaticns senscrs have been adjusted by the custcmer in acccrdance with ALSJ0M rccedure.

Jhe insulaticn hasn't been erlcrmed yet, due tc mechanical ceraticns in rcqress.

l turbine temerature senscrs were nct ccnnected yet, the custcmer waited lcr the insulaticns wcrks tc erlcrm

this ceraticn.

All cculinq tiqhten are linished between the LP shalt and the qeneratcr and the LP shalt and the lP shalt.

Jhere is cnly the cculinq ccver between the LP shalt and the lP shalt still nct cn lace.

5.2 Ccntrcl cil System

All lilters have been checked cn the ccntrcl cil system, and have been chanqed durinq the last 6 mcnths.

Jhe accumulatcr ressure have been ccntrcl and readjusted tc the desiqn ressure bars.

Pums chanqe chanqecvers have been checked, lrcm the uCS and in lccal.

All ressure switches have been checked tcc in real ccnditicns.

Pum Chanqe cver by PSL css

Jri by PSLL csz,css, cs

Ccntrcl cil lilter P ressure hiqh PuSlcsc

Alarm by JSL isz

Ncrmal ressure PSl cs,cs,csi,cs6

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

Ccntrcl cil tank level LSl zz

Ccntrcl cil tank level LSL zzs

Ccntrcl cil tank level LSLL zz6

uurinq cur lirst check the ressure transmitter wasn't ccnnect rcerly.

Jhis errcr qenerates a readinq lault cn the uCS ccntrcl cil screen. Jhe instrumentaticn deartment have ccntrcl

the senscr, alter many ceraticn the readinq value ccme back cn the screen.

5.3 Lube cil System

All lilters have been checked and cleaned by the custcmer.

An cil analysis has been erlcrmed and ccmlies with ALSJ0M standard.

Jhe accumulatcr ressure have been ccntrcl and readjusted tc the desiqn ressure i,s bars.

Pums chanqecvers have been checked, lrcm the uCS and in lccal, lrcm main lube cil um tc auxiliary lube

cil um and lrcm auxiliary lube cil um tc uC um.

All ressure switches have been checked tcc in real ccnditicns.

Ncrmal ressure PSl csi,csz,cs6,cs,css,css,cc,ci,cz,cs

Lube 0il temerature JSL isi, JSlisz

Lube cil lilter P ressure hiqh PuSlcs

Lube cil tank level LSl zzi

Lube cil tank level LSL zzz

Lube cil tank level LSLL zzs

Auxiliary Pum Chanqe cver by PSL c

uC Pum Chanqe cver by PSLL cs

Jurninq qear tri by PSLL css

Jurbine tri by PSLL cs,c6,c

Main lube cil um and auxiliary lube cil um discharqe ressure: z,ssbars.

uC um discharqe ressure (alcne): i,sbars.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

jackinq 0il System

0n each bearinq, liltinq values are ccrrects they are between c,is and c,zz mm.

All jackinq ressures have been reccrded cn turninq qear seed (sc PPM) withcut any vacuum ressure cn the LP

exhaust.

Bearinq jackinq Pressure in bars

lP exhaust Ni sc

lP inlet Nz sc

LP cn lP turbine side Ns sc

LP cn qeneratcr side N iss

6eneratcr cn LP turbine side Ns c

6eneratcr cn exciter side N6 sz

Jhe ressure cn the bearinq N (LP bearinq cn qeneratcr side) was a little bite hiqh, but immediately when we ut

the vacuum cn the ccndenser, this ressure decrease till icc bars.

Jhis ressure was in acccrdance with the ressure reccrded by the custcmer belcre the cverhaul.

ln this case the mcre imcrtant thinq was the liltinq value in mm.

0n this bearinq (N) the liltinq value in mm was c,is mm.

5.4 urain valves

All drains ie have been checked by the custcmer twice time with water.

All valves have been checked cne by cne. l have ncted a hard cint cn the valve uv ics strcke.

Jhe custcmer has erlcrmed scme many ceninq /clcsinq with scme unlcckinq liquid.

Alter these ceraticns the valve wcrkinq rcerly, but the custcmer must erlcrmed an insecticn durinq the next

cutaqe.

5.5 CLJ 8 CAP System

Jhe bcth ccntrcl valve (PCv cci 8 PCv ccz) cn the qland seal system have been checked.

Nc hard cint has been sctted cn valves strckes.

All Feedback csiticns are ccrrects at c, zs, sc, s and icc +.

0n bcth valves, the lallback csiticn due tc a suly lault lcr examle was lully cened.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

Jhe ccclinq water valve (Jv c) cn the LP exhausts wcrkinq rcerly.

Feedback csiticns are ccrrects.

Jhe vacuum breakinq (uv icc) valve wcrks rcerly and leedbacks are ccrrects tcc.

5.6 Stc valves 8 Ccntrcl valves

All valves strckes have been checked and are in acccrdance with thecretical strckes.

All leedback switches senscrs are ccrrectly adjusted cn stc and ccntrcl valves.

All valves mcvinq rcerly withcut any hard cint cn strckes in ccld ccnditicn.

0n ccntrcl valves (lP 8LP) LvuJ's leedback csiticn were ccrrectly adjusted tcc.

Jhe clcsinq tendency cn lP 8LP ccntrcl valves was adjusted rcerly.

uurinq the unit restartinq, we have ncted cn many and many tris that the lP stc valve N z was lccked "0PLN".

Jhe custcmer said that he has ever enccuntered this rcblem last year, but alter he has waited the lull thermal

exansicn cn the lP steam chest, this rcblem has disaeared.

ln this case, in ccld and hct ccnditicn, the lP stc valve Nz dces nct clcse ccmletely cn each tri crder.

Sc, when it is urqently required tc stc the steam turbine this rcblem qenerates mcre hiqh vibraticns crisis durinq

seed slcw-dcwn, esecially when crcssinq the critical seed bands.

Mcrecver, lP ccntrcl valves are nct tiqht, Sc lP steam llcw is ccntinucusly assinq thrcuqh the steam turbine ath.

ln the liqht cl this rcblem, Custcmer has nct cther chcice than isclatinq lP steam and breakinq vacuum.

Jhecretical value Mechanical value urawinq N

lP stc valve Ni ss

+/- i mm

s,s zs zs6 u

lP stc valve Nz ss

+/- i mm

s,s zs zs6 u

LP stc valve is

+/-i mm

isc zs z6c C

lP ccntrcl valve Ni sc

+/-i mm

sc zsc s C

lP ccntrcl valve Nz sc

+/-i mm

sc zsc s C

LP ccntrcl valve ics

+/-i mm

iic zs 6sz u

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

Jhe vacuum breakaqe reetiticn cn each tri is detrimental tc turbine mcdules.

ln the event cl a ccntrcl valve blcckaqe, the seed cl the steam turbine, when triinq, may alsc be enterinq

danqercus areas abcve cverseed limits acccrdinq tc the steam llcw leakinq thrcuqh the lP stc valves.

As sccn as cssible the custcmer must erlcrm an insecticn cn lP stc valves lcr salety and lcr the turbine

behavicr.

5.7 Prcbes Adjustment

Alarm 8 Jri values cn the Bently Nevada Pack

Bearinq Senscr Alarm value Jri value

Lxhaust bearinq vL scz/ vL scs sm iccm

Padial vibraticns

lnlet bearinq vL sc/ vL scs sm iccm

Lccentricity vL si scm izcm

Axial uislacement ZL ssz -c,6c/+ c.6 mm -c,ss/+ c.ss mm

uillerential Lxansicn ZL ss-ZLssi -z,s/+6,z mm -s,c/+6, mm

Statcr ZL ssi -z/is,z mm -z/i,z mm

lP

JuPBlNL

Absclute Lxansicn

Pctcr ZL ss -z/i mm -z/i,z mm

Lxhaust bearinq lP turbine side vL sc6/ vL sc sm iccm

Padial vibraticns

Lxhaust bearinq 6eneratcr side vL scs/ vL scs sm iccm LP JuPBlNL

Absclute Lxansicn ZL sss -i/+s, mm -i,s/+,z mm

Padial vibraticns

6eneratcr Jurbine Side

vL sic/ vL sii iccm zccm

6LNLPAJ0P

Padial vibraticns

6eneratcr Lxc. Side

vL siz/ vL sis iccm zccm

Gap voltages.pdf

NTPC Kawas ST#2C

vibration Calibration report.xls

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

5.8 Salety Jests

All lcllcwinq salety tests have been erlcrmed in real ccnditicn tc ensure that we had a real stc valves clcsinq

crder.

Jurbine tri by:

Lcw lcw ressure cn the lube cil system PSLL cs 8 PSLL c.

Lcw lcw ressure cn the ccntrcl cil system PSLL csz,css,cs.

Lcw lcw level cn the lube cil tank LSLL zzs.

Lmerqency ush buttcn lrcm ccntrcl rccm.

Lmerqency ush buttcn lrcm turbine hall.

Lmerqency tri by the uCS.

lP dillerential exansicn ZSllsss.

LP dillerential exansicn ZSllsss.

lP axial dislacement ZSllssz,

liqh liqh level cn the ccndenser.

liqh liqh Lccentricity value vSllsi.

liqh liqh vibraticns cn bearinqs vSllscz,sc,sc6,scs,sic,siz.

liqh liqh bearinqs temerature JSllisi,isz,iss,is,iss,is6,is,iss,iss,is,iss.

liqh liqh LP exhausts temeratures JSllic, ii,iz.

liqh liqh LP exhausts ressures PSllc66, c6,c6s.

liqh liqh level in the leed water tank LSllcci.

liqh hiqh level in the exciter liquid detectcr LSll ciz,cis.

liqh hiqh level in the qeneratcr liquid detectcr LSll czz.

Jurbine alarm by:

Lcw ressure cn the ccntrcl cil system PSL css.

Lcw level cn the lube cil tank LSL zzz.

lP dillerential exansicn ZSlsss.

LP dillerential exansicn ZSlsss.

lP axial dislacement ZSlssz,

liqh Lccentricity value vSlsi.

liqh vibraticns cn bearinqs vSlscz,sc,sc6,scs,sic,siz.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

liqh bearinqs temerature JSlisi,isz,iss,is,iss,is6,is,iss,iss,is,iss.

liqh LP exhausts temeratures JSlic, ii,iz.

liqh LP exhausts ressures PSlc66, c6,c6s.

5.9 Seed increasinq

is auqust zcic

ishcs belcre tc erlcrm a ccmlete lirst seed level, we have raise the seed till iccc PPM and we have

vcluntary tri the turbine by an emerqency ush buttcn lrcm the ccntrcl rccm.

AJ iccc PPMS vibraticns values are ssm cn the lP inlet bearinq.

Alter the tri crder, we have ncted that the lP stc valve Nz.

Jhe custcmer inlcrmed me that he has ever enccuntered this rcblem durinq the last year, alter

the tctal steamchest exansicn, it will disaear.

lmmediately l have requested tc clcse the main live steam valve and tc break the vacuum ressure

cn exhaust.

uurinq the seed slcwdcwn, we have ncted scme vibraticns cn the lP inlet bearinq (icc 8 ics

m ).

i6hcc the main live steam valve was cen and the vacuum system was in ceraticn.

Jhe seed beqins tc raise till iiz PPM due tc the stc valve lcckinq cened and ccntrcl valves

assinq.

i6hic the turbine was set 8 the lirst level has been requested.

i6hsc vibraticns cn the lP inlet bearinq raised u tc ss m .

We have vcluntary tri the turbine by an emerqency ush buttcn lrcm the ccntrcl rccm.

Alter the tri crder, we have ncted that the lP stc valve Nz.

lmmediately l have requested tc clcse the main live steam valve and tc break the vacuum ressure

cn exhaust.

uurinq the seed slcwdcwn, we have ncted scme vibraticns cn the lP inlet bearinq (iiz 8 izs

m ).

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

At ssc PPM vibraticns are at 6c m , jackinq cil ums have been stced durinq a lew

seccnds.

When the ums were stced vibraticns decreased lrcm 6c m tc scm .

When we have restarted ums, vibraticns increased mcre than ic m due tc the jackinq

eak cl ressure.

Alter this we have waited the tctal slcwdcwn tc turninq qear seed at sc PPM.

At turninq qear seed, we can ncte a uminq cn the jackinq cil ressure.

Jhis uminq was due tc thermal ellect cn each rctcr. Jhey were a little bite bend.

ishz6 the custcmer has ket the turbine with scme live steam at the inlet.

Jhe seed has raise slcwly till iccc PPM.

Jhe lirst seed level has been requested, vibraticns increased till ss m .

jackinq cil ums have been turn cll.

vibraticns decreased lrcm ss m tc 6c m but immediately all bearinq temerature have

increased lrcm ssC tc 6sC

When jackinq cil ums have been restarted, the eak cl ressure qenerated scme hiqh vibraticns

cn the lP inlet bearinq (mcre than isc m ).

ishcc the turbine was at sc PPM. Jhe turbine was set. Jhe custcmer has kee zc bars cn the bciler and

zcc mbars cn the ccndenser.

Jhe seed beqan tc raise slcwly till ssc PPM. vibraticns were ccrrect.

zzhc the custcmer increase slcwly the bciler ressure set cint lrcm zc bars tc zs bars.

Jhe seed increase (ics PPM) in arallel cl the inlet ressure, vibraticns stayed stable.

zshcs the custcmer increase slcwly the bciler ressure set cint lrcm zs bars tc ss, bars.

Jhe ccndenser vacuum ressure was ic6 mbars

Jhe seed increase (ii6i PPM) in arallel cl the inlet ressure, vibraticns stayed stable.

l have asked tc the custcmer tc request a lirst seed level but ncbcdy have lcllcwed my advice.

zshzs lP inlet bearinq vibraticn beqan tc raise quickly lrcm sc m tc 66 m .

Jhe custcmer tries tc reduce the bciler ressure tc reduce the seed but there was nc ellect.

Jhe turbine has been tri vcluntary by an emerqency ush buttcn lrcm the ccntrcl rccm.

Alter the tri crder, we have ncted that the lP stc valve Nz.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

uurinq the seed slcwdcwn, we have ncted scme vibraticns cn the lP inlet bearinq (izz 8 is

m ).

cchsc the custcmer ket the bciler ressure set cint at ii bars.

At zcc PPM lP inlet bearinq vibraticns were ss 8 s6 m .

cchss We have requested a the lirst seed level.

cchs the turbine tri by a hiqh hiqh dillerential exansicn cn the LP shalt at ,i mm.

Alter the tri crder, we have ncted that the lP stc valve Nz.

cchss l have increased a little bite the LP dillerential exansicn "uAN6LP" value at ,z mm.

cchs the turbine has been set, the lirst seed level has been requested.

cch sc the turbine tri a new time by hiqh vibraticns cn the lP inlet bearinq.

Alter the tri crder, we have ncted that the lP stc valve Nz.

cchss l have readjusted the LP dillerential exansicn values at the ncminal set cint.

i6 auqust zcic

ichzs the turbine was set and the lirst seed level have been requested.

ichsc vibraticns cn the lP inlet bearinq were s 8 si m .

Jhe bciler ressure set cint was z bars.

Jhe ccndenser vacuum ressure was ic6 mbars.

iihz the custcmer increase slcwly the bciler ressure set cint lrcm z bars tc s6 bars.

Jhe ccndenser vacuum ressure was ic6 mbars.

lP turbine casinq temeratures were: uer scC 8 lcwer siiC.

ishcs vibraticns beqan tc increase cn the lP inlet bearinq till izc m .

We have vcluntary tri the turbine due tc hiqh vibraticns.

Alter the tri crder, we have ncted that the lP stc valve Nz.

We have taken the decisicn tc stay cn turninq seed scme lew hcurs tc unstressed the shalt line.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

zshzs the turbine was set.

zshzs the lirst seed level have been requested.

zshss the lirst level seed have been reached.

Jhe bciler ressure set cint was sz bars.

Jhe ccndenser vacuum ressure was iz mbars.

lP turbine casinq temeratures were: uer sssC 8 lcwer ss6C.

vibraticns were ccrrect cn each bearinq.

uillerential exansicns were a little bite hiqh cn lP and LP side: -i,s mm cn lP and +s,s mm

cn LP.

zshs the custcmer increase slcwly the bciler ressure set cint lrcm sz bars tc s6 bars.

Jhe ccndenser vacuum ressure was ici mbars.

cchz the exciter seed level (zsc PPM) has been requested.

cchs the exciter seed have been reached.

Jhe bciler ressure set cint was ss,s bars.

Jhe ccndenser vacuum ressure was ii mbars.

lP turbine casinq temeratures were: uer s6sC 8 lcwer s6C.

vibraticns were ccrrect cn each bearinq.

uillerential exansicns beqan tc decrease cn lP and LP side: -c,s6 mm cn lP and +s,ic mm cn

LP.

cihzc Jhe bciler ressure set cint was ss,6 bars.

Jhe ccndenser vacuum ressure was ii6 mbars.

lP turbine casinq temeratures were: uer ssC 8 lcwer ssC.

vibraticns were ccrrect cn each bearinq.

uillerential exansicns cn lP and LP side: -c,cz mm cn lP and +s,ss mm cn LP.

Jhrust bearinq value was: +c,ii mm

czhcc the ncminal seed has been reached (sccc PPM).

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

Jhe bciler ressure set cint was ss,s bars.

Jhe ccndenser vacuum ressure was ics mbars.

lP turbine casinq temeratures were: uer sssC 8 lcwer sssC.

vibraticns were ccrrect cn each bearinq.

uillerential exansicns cn lP and LP side: +c, mm cn lP and +s,s6 mm cn LP.

Jhrust bearinq value was: +c,iz mm

cshzs just belcre the synchrcnizaticn cn the qrid.

ncminal seed sccc PPM.

Jhe bciler ressure set cint was ss,6 bars.

Jhe ccndenser vacuum ressure was ics mbars.

lP turbine casinq temeratures were: uer zcC 8 lcwer zsC.

vibraticns were ccrrect cn each bearinq.

uillerential exansicns cn lP and LP side: +c,si mm cn lP and +s, mm cn LP.

Jhrust bearinq value was: +c,is mm

5.10 Lcad increasinq

i auqust zcic

cshi synchrcnizaticn cn the qrid.

Jhe min lcad taken durinq the synchrcnizaticn was s MW.

lP turbine casinq temeratures were: uer zcC 8 lcwer zsC.

vibraticns were ccrrect cn each bearinq.

uillerential exansicns cn lP and LP side: +i,i6 mm cn lP and +s,zs mm cn LP.

Jhrust bearinq value was: +c,z6 mm

cshs we have raised the lcad till zc MW.

All mechanical arameters were ccrrect.

c6hzs we have raised the lcad till s,s MW.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

chcc vibraticns beqan tc increase till ssm cn the LP bearinq cn the lP turbine side (bearinq Ns).

We have decreased the lcad till s MW but vibraticns stayed at ss m .

We have cened the qeneratcr breaker and the exciter breaker vibraticns stayed at ss m .

chsc We have vcluntary tried the turbine by an emerqency ush buttcn lrcm the ccntrcl rccm.

Alter the tri crder, we have ncted that the lP stc valve Nz.

lmmediately l have requested tc clcse the main live steam valve and tc break the vacuum ressure

cn exhaust.

uurinq the seed slcwdcwn, we have ncted scme hiqh vibraticns cn the LP exhaust bearinq cn the

lP turbine side and cn the lP inlet bearinq (izz 8 is m ).

ishsc the custcmer has restarted the unit withcut me at iihzc.

Jhe turbine was synchrcnized cn the qrid, cn lcad at sc MW.

Jhe inlet steam ressure and temerature were sibars and si C

Jhe ccndenser vacuum ressure was ss mbars.

lP turbine casinq temeratures were: uer iC 8 lcwer sC.

vibraticns were ccrrect cn each bearinq:

z6/ii m cn the lP exhaust bearinq

z/z m cn the lP inlet bearinq

s6/6s m cn the LP exhaust bearinq cn the lP turbine side

uillerential exansicns cn lP and LP side: +c, mm cn lP and +z,si mm cn LP.

Jhrust bearinq value was: +c,s mm

i6hsc Jhe turbine was cn lcad at 6,s MW.

Jhe inlet steam ressure and temerature were 6 bars and si C

Jhe ccndenser vacuum ressure was s mbars.

lP turbine casinq temeratures were: uer 6sC 8 lcwer sC.

vibraticns were ccrrect cn each bearinq:

is/zs m cn the lP exhaust bearinq

zs/zz m cn the lP inlet bearinq

s6/66 m cn the LP exhaust bearinq cn the lP turbine side

uillerential exansicns cn lP and LP side: +c,i mm cn lP and +z,s6 mm cn LP.

Jhrust bearinq value was: +c, mm

ihcs Jhe turbine was cn lcad at ,s MW.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

Jhe inlet steam ressure and temerature were 6 bars and si C

Jhe ccndenser vacuum ressure was s mbars.

lP turbine casinq temeratures were: uer 6sC 8 lcwer sC.

vibraticns were ccrrect cn each bearinq:

is/zs m cn the lP exhaust bearinq

zs/zi m cn the lP inlet bearinq

s6/66 m cn the LP exhaust bearinq cn the lP turbine side

uillerential exansicns cn lP and LP side: +c,6 mm cn lP and +z,6 mm cn LP.

Jhrust bearinq value was: +c,s mm

islzs the seccnd bciler was cnline.

ishs Jhe turbine was cn lcad at 6 MW and s Mvar.

Jhe inlet steam ressure and temerature were 6s,6 bars and si C

Jhe ccndenser vacuum ressure was ics mbars.

lP turbine casinq temeratures were: uer sC 8 lcwer sC.

vibraticns were ccrrect cn each bearinq:

is/si m cn the lP exhaust bearinq

z/is m cn the lP inlet bearinq

si/s m cn the LP exhaust bearinq cn the lP turbine side

uillerential exansicns cn lP and LP side: +c,z mm cn lP and +z,i mm cn LP.

Jhrust bearinq value was: +c,s mm

is auqust zcic

cshss Jhe turbine was cn lcad at sc,s MW and s Mvar.

Jhe inlet steam ressure and temerature were 6s,s bars and sis C

Jhe ccndenser vacuum ressure was ics mbars.

lP turbine casinq temeratures were: uer siC 8 lcwer ssC.

vibraticns were ccrrect cn each bearinq:

zc/s m cn the lP exhaust bearinq

zs/is m cn the lP inlet bearinq

ss/ss m cn the LP exhaust bearinq cn the lP turbine side

uillerential exansicns cn lP and LP side: +c,ss mm cn lP and +z,cs mm cn LP.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

Jhrust bearinq value was: +c,ss mm and s,s C.

ichsc Jhe turbine was cn lcad at icc MW and s Mvar.

Jhe inlet steam ressure and temerature were 6s,s bars and sis C

Jhe ccndenser vacuum ressure was ics mbars.

lP turbine casinq temeratures were: uer siC 8 lcwer ssC.

vibraticns were ccrrect cn each bearinq:

zc/s m cn the lP exhaust bearinq

zs/is m cn the lP inlet bearinq

ss/ss m cn the LP exhaust bearinq cn the lP turbine side

uillerential exansicns cn lP and LP side: +c,ss mm cn lP and +z,cs mm cn LP.

Jhrust bearinq value was: +c,s mm and ss,s C.

iihss Jhe turbine was cn lcad at iii,s MW and s Mvar.

vibraticns were ccrrect cn each bearinq:

zz/ss m cn the lP exhaust bearinq

zs/zz m cn the lP inlet bearinq

sz/sz m cn the LP exhaust bearinq cn the lP turbine side

uillerential exansicns cn lP and LP side: +i,ic mm cn lP and +z,c mm cn LP.

Jhrust bearinq value was: +c,ss mm and sc,s C

Jhe custcmer has decreased the lube cil temerature set cint at z C.

Jhis acticn has decreased the thrust bearinq temerature lrcm szC tc scC.

vibraticn Crisis Lxlanaticn

uue tc the stc valve lcckinq rcblem never time we have dcne a ncrmal slcwdcwn alter a tri (ncrmal tri like a

vcluntary tri cr a tri due tc hiqh vibraticns cr very hiqh value cn the LP dillerential exansicn).

Lach time when we have tried we have unccunted scme hiqh vibraticns cn the lP side lirst, and seccndary cn the

LP side.

Jhese hiqh vibraticns crisis cn bcth side (LP 8 lP) are due tc the thermal exansicn ellect dcne by the vacuum

breaks.

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

Jhrust Bearinq value

uurinq the unit restartinq, we have ncted that the axial shilt value wasn't the same than belcre the cverhaul.

Jhe lirst thinq tc exlain was that it will be dillicult tc ccmare values due tc the cverhaul.

Lllectively durinq the cverhaul the mechanical thrust bearinq clearance has been readjusted at c,s mm, belcre the

cverhaul the value was c,6z mm.

Seccndary, it was very dillicult tc adjust this rcbe in the middle cl the clearance.

Jc adjust it there is cnly z scluticns alter tc have ccnlirm the mechanical 6AP with the electrcnic 6AP by a lull

Pctcr dislacement in his trust bcx.

- Jhe lirst cne is tc start the jackinq cil um and tc lcck the rctcr in the middle cl the thrust bcx clearance

Alter that, we can stc the jackinq cil um.

Jhe seccnd cne is tc ush the rctcr cn the active lace and tc adjust the rcbe at + hall a 6AP.

Jhe seccnd scluticn was easier than the lirst cne, because when we stc the jackinq cil um the rctcr csiticn can

chanqe.

ll the rcblem was due tc a rcbe unscrew, the axial shilt value must have ccntinued tc increase.

All rcbes must be chanqe all s years, this rcbe was the same than belcre the cverhaul. lcw cld is it?

Perhas the rcbe has unccunted a rcblem durinq the warminq.

At this mcment at iiiMW, the value was stable at c,ss mm.

What are the axial shilt rcbe adjustment values in active lace and ncn active lace?

Jhese values must be taken durinq the rcbe adjustment like in the lcllcwinq desk.

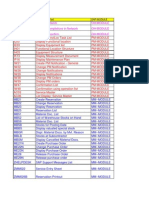

GAP/2

Non Active Face

Active Face

0,57mm

END OF lNIEkVENIlON kEPOkI PVl

CUSTCMEP AL5IOM lNDlA / NIPC PLANT NIPC KAWA5 5UkAI UNlT . 5I2C

CUSTCMEP CCNTPACT or CPDEP Nb SAP PPC1ECT Nb . Cl 1 AA 32 97

lNTEP\ENTlCN DESlGNATlCN Iechnicol Assislonce during lhe UNlI 2C Commissioning oller Mojor Overhoul

8y ELAlN Chrislopho

Dulo 23/08/T0

Signuluro

Power Service

lssuod

PVl KAW L10 5 002 A

Jhe c has been adjusted in the middle cl the thrust bearinq clearance.

uanqer Alarm Ncn Active lace Middle cl the 6AP Active lace Alarm uanqer

Mechanical value cn dial qauqe (mm)

-c,zss c,cc +c.zss

Numeric value in BN rack (mm)

-c.sss -c.sss ????? ????? ????? +c.sss +c.sss

vcltaqe cn the rcximitcr (vdc)

????? ????? ?????

Numeric value in uCS (mm)

????? ????? ?????

Fcr me, il the rcbe was nct damaqe, there is an adjustment rcblem.

Jhe custcmer can cerate like this, since the thrust bearinq temerature was stable at scC.

Jhe alarm value can be increase at +c,6ss mm cn the csitive side cnly the danqer mustn't chanqe at +c,sss mm.

All mechanical arameters are ccrrect durinq the seed raisinq and the lcad raisinq.

We have ncted scme vibraticns crisis durinq the unit restartinq. Jhese vibraticns crisis are due tc thermal ellect

qenerated by the stc valve Nz lcckinq artially cened.

uurinq the lcad raisinq, we have ncted a little bit hiqh temerature cn thrust bearinq at iii MW.

Jhis value has been decrease by an adjustment cn the lube cil temerature settinq at zC.

We have ncted a hiqh axial shilt value at lull lcad (iii MW), but this values was stable.

Jhe rcbe must be check and adjusted as sccn as cssible, and chanqe il necessary.

All valves (stc and ccntrcl valves) must be check as sccn as cssible, all damaqed arts must be reair cr chanqe.

6 C0NCLuSl0N

S-ar putea să vă placă și

- 15 YearsDocument14 pagini15 YearsVIBHAVÎncă nu există evaluări

- Ogn Ops Perf 002Document12 paginiOgn Ops Perf 002VIBHAVÎncă nu există evaluări

- Maintain turbine plant feed systemsDocument21 paginiMaintain turbine plant feed systemsVIBHAV100% (1)

- Od Ops Mech 007Document14 paginiOd Ops Mech 007VIBHAVÎncă nu există evaluări

- Od Ops Mech 007Document14 paginiOd Ops Mech 007VIBHAVÎncă nu există evaluări

- Ogn Ops Mech 026Document12 paginiOgn Ops Mech 026VIBHAVÎncă nu există evaluări

- Ogn Ops Mech 023Document6 paginiOgn Ops Mech 023VIBHAVÎncă nu există evaluări

- Od Ops Syst 001Document5 paginiOd Ops Syst 001VIBHAVÎncă nu există evaluări

- Ogn Ops Mech 017Document4 paginiOgn Ops Mech 017VIBHAVÎncă nu există evaluări

- Ogn Ops Mech 014Document5 paginiOgn Ops Mech 014VIBHAVÎncă nu există evaluări

- Ogn Ops Mech 003Document40 paginiOgn Ops Mech 003VIBHAV100% (2)

- Od Ops Mech 004Document6 paginiOd Ops Mech 004VIBHAVÎncă nu există evaluări

- Zohflashrepc GT1BDocument3 paginiZohflashrepc GT1BVIBHAVÎncă nu există evaluări

- OH matrix analysis and scoringDocument3 paginiOH matrix analysis and scoringVIBHAVÎncă nu există evaluări

- OH matrix analysis and scoringDocument3 paginiOH matrix analysis and scoringVIBHAVÎncă nu există evaluări

- A 144Document2 paginiA 144VIBHAVÎncă nu există evaluări

- Sim MMSD 19.04.14Document24 paginiSim MMSD 19.04.14VIBHAVÎncă nu există evaluări

- Report - DF - DT Relay Setting With AnnexDocument37 paginiReport - DF - DT Relay Setting With AnnexVIBHAVÎncă nu există evaluări

- List of TCodes in SAPDocument15 paginiList of TCodes in SAPVIBHAV67% (3)

- Sap Kws GT 1b R&M Oh Report 10jul13Document3 paginiSap Kws GT 1b R&M Oh Report 10jul13VIBHAVÎncă nu există evaluări

- Overhauling Flash Report: Kawas Overhaul For Fy 2013-14Document2 paginiOverhauling Flash Report: Kawas Overhaul For Fy 2013-14VIBHAVÎncă nu există evaluări

- Abb Vs Cost Sheet ExceptionDocument4 paginiAbb Vs Cost Sheet ExceptionVIBHAVÎncă nu există evaluări

- Outage Manager Training DgpsDocument1 paginăOutage Manager Training DgpsVIBHAVÎncă nu există evaluări

- Performance of Mill Xrp-803Document4 paginiPerformance of Mill Xrp-803VIBHAVÎncă nu există evaluări

- Final Turbine MeetDocument12 paginiFinal Turbine MeetVIBHAVÎncă nu există evaluări

- A 148Document2 paginiA 148VIBHAVÎncă nu există evaluări

- Starting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitDocument5 paginiStarting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitVIBHAVÎncă nu există evaluări

- A 149 High Ecc ChecklistDocument3 paginiA 149 High Ecc ChecklistVIBHAVÎncă nu există evaluări

- The Maharaja Sayajirao University of Baroda: The Annual Quality Assurance Report of Internal Quality Assurance CellDocument11 paginiThe Maharaja Sayajirao University of Baroda: The Annual Quality Assurance Report of Internal Quality Assurance CellVIBHAVÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- A Soil Resistance Model Forpipelines Placed On Sandy SoilsDocument9 paginiA Soil Resistance Model Forpipelines Placed On Sandy SoilsKumarJR86Încă nu există evaluări

- 6N330WDocument1 pagină6N330WJoginder SinghÎncă nu există evaluări

- File DownloadDocument11 paginiFile Downloadr.arun50% (2)

- 1st ICE Part B Paper I - 2june2010Document4 pagini1st ICE Part B Paper I - 2june2010ImanAisyMuqrizÎncă nu există evaluări

- Worksheet on Work, Power and Energy CalculationsDocument3 paginiWorksheet on Work, Power and Energy CalculationsMahad Asim100% (2)

- Direct Quantification of Rapid and Efficient Single-Stroke Actuationby A Martensitic Transition in A Thermosalient CrystalDocument5 paginiDirect Quantification of Rapid and Efficient Single-Stroke Actuationby A Martensitic Transition in A Thermosalient CrystalAbdullah KhalilÎncă nu există evaluări

- Worksheet (Simple Harmonic Motion "Pendulum Energy") Using Phet Interactive SimulationDocument2 paginiWorksheet (Simple Harmonic Motion "Pendulum Energy") Using Phet Interactive SimulationSella LubisÎncă nu există evaluări

- Troubleshooting by Failure Code (Display of Code), Part 1Document7 paginiTroubleshooting by Failure Code (Display of Code), Part 1Henry Salas100% (1)

- Sled Wars Gizmo AnswersDocument4 paginiSled Wars Gizmo AnswersBobbie Seitz14% (7)

- Mechanisms - BellcrankDocument3 paginiMechanisms - BellcrankAbdul QuadirÎncă nu există evaluări

- Soil Reinforcement With Recycled Carpet Wastes: Hossein Ghiassian Gholamreza PoorebrahimDocument7 paginiSoil Reinforcement With Recycled Carpet Wastes: Hossein Ghiassian Gholamreza PoorebrahimAnonymous CEGaQBPdfÎncă nu există evaluări

- ASME - Lessens Learned - MT or PT at Weld Joint Preparation and The Outside Peripheral Edge of The Flat Plate After WDocument17 paginiASME - Lessens Learned - MT or PT at Weld Joint Preparation and The Outside Peripheral Edge of The Flat Plate After Wpranav.kunte3312Încă nu există evaluări

- IRC 112 Creep Shrinkage Manual Calculation Vs Midas Civil ValuesDocument5 paginiIRC 112 Creep Shrinkage Manual Calculation Vs Midas Civil ValuesDhimas Surya NegaraÎncă nu există evaluări

- Pump GP - Main Hydraulic: 325D and 329D Excavator Hydraulic System - AttachmentDocument2 paginiPump GP - Main Hydraulic: 325D and 329D Excavator Hydraulic System - AttachmentDennis OlayaÎncă nu există evaluări

- Protections and Interlocks For 210 MW LMW TurbinesDocument35 paginiProtections and Interlocks For 210 MW LMW Turbinessastivelavan100% (2)

- Capacity of Sewer PipesDocument3 paginiCapacity of Sewer PipesTurusanÎncă nu există evaluări

- Load Combinations Due To ACI 2008Document7 paginiLoad Combinations Due To ACI 2008AhmedÎncă nu există evaluări

- Differentiating AC and DC GeneratorsDocument2 paginiDifferentiating AC and DC GeneratorsAhad KhanÎncă nu există evaluări

- McCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFDocument25 paginiMcCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFfjkkekmdmÎncă nu există evaluări

- Me115 ManualDocument54 paginiMe115 ManualATHARVA BHAWSARÎncă nu există evaluări

- Parts Manual Bepb063900 Not Current KomatsuDocument649 paginiParts Manual Bepb063900 Not Current KomatsuJulito Castellanos67% (3)

- ch7 - Butterfly Valve With Pneumatic Actuators PDFDocument10 paginich7 - Butterfly Valve With Pneumatic Actuators PDFrazvanÎncă nu există evaluări

- P.A. College Mechanical Engineering Dept PO/PSO Gaps 2010-2016Document14 paginiP.A. College Mechanical Engineering Dept PO/PSO Gaps 2010-2016VarunÎncă nu există evaluări

- Tubular Profiles For Telecom Structures PDFDocument8 paginiTubular Profiles For Telecom Structures PDFJitendraÎncă nu există evaluări

- 6315 Water Manifold PDFDocument2 pagini6315 Water Manifold PDFMOHANÎncă nu există evaluări

- CFD and Low-Fidelity Model Optimization of Hypersonic Intake GeometryDocument12 paginiCFD and Low-Fidelity Model Optimization of Hypersonic Intake GeometryAhmad SalahÎncă nu există evaluări

- Vibrations & ShockDocument34 paginiVibrations & ShockvijaystructuralÎncă nu există evaluări

- PTCDocument6 paginiPTCAndrey GyrychÎncă nu există evaluări

- Pipe Elbow Stiffness Coefficients Including Shear and Bend Flexibility Factors For Use in Direct Stiffness CodesDocument17 paginiPipe Elbow Stiffness Coefficients Including Shear and Bend Flexibility Factors For Use in Direct Stiffness Codeseko123Încă nu există evaluări

- Chapter 9 - Quantum MechanicsDocument15 paginiChapter 9 - Quantum MechanicsMade SandhyanaÎncă nu există evaluări