Documente Academic

Documente Profesional

Documente Cultură

6089-6090 Alarm List Fanuc

Încărcat de

Ricardo Jose PirelaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

6089-6090 Alarm List Fanuc

Încărcat de

Ricardo Jose PirelaDrepturi de autor:

Formate disponibile

B65195EN/01

TROUBLESHOOTING AND RECOVERY

3. TROUBLESHOOTING AND RECOVERY PROCEDURES

3.1

SERVO AMPLIFIER UNIT 3.1.1

LED Indications and Meanings

Type Over-voltage alarm (HV) Low control power voltage alarm (LV) Low DC link voltage alarm (LVDC) Regenerative discharge control circuit failure alarm (DCSW) Over-regenerative discharge alarm (DCOH) Dynamic brake circuit failure alarm (DBRLY) L-axis over-current alarm (HCL) M-axis over-current alarm (HCM) L-and M-axis over-current alarm (HCM) L-axis IPM alarm (IPML) M-axis IPM alarm (IPML) L-and M-axis IPM alarm (IPMLM) Circuit breaker Trips LED indication

If an alarm condition related to the servo amplifier unit occurs, the 7-segment LED indicator on the amplifier front panel behaves as listed below.

Description This alarm occurs if the DC voltage of the main circuit power supply is abnormally high. This alarm occurs if the control power voltage is abnormally low.

This alarm occurs if the DC voltage of the main circuit power supply is abnormally low or the circuit breaker trips. This alarm occurs if : The short-time regenerative discharge energy is too high. The regenerative discharge circuit is abnormal. This alarm occurs if : The average regenerative discharge energy is too high (too frequent acceleration/deacceleration). The transformer overheats. This alarm occurs if the relay contacts of the dynamic brake welds together. This alarm occurs if an abnormally high current flows in the L-axis motor.

This alarm occurs if an abnormally high current flows in the M-axis motor.

This alarm occurs if an abnormally high current flows in the L-and M-axes motor. This alarm is detected by the IPM (intelligent power module) of the L-axis. (Note 1) This alarm is detected by the IPM (intelligent power module) of the M- axis. (Note 1) This alarm is detected by the IPM (intelligent power module) of the L-and Maxes. (Note 1) The circuit breaker trips if an abnormally high current (exceeding the working current of the circuit breaker) flows through it. Note 2)

43

3. TROUBLESHOOTING AND RECOVERY PROCEDURES

TROUBLESHOOTING AND RECOVERY

B65195EN/01

Notes 1 The IPM can detect the following alarms. Over-current Over-heat Drop in IPM control power voltage 2 When the control power is separated from the main power, if the circuit breaker of the servo amplifier is off, low DC link voltage alarm (LVDC) is detected.

3.1.2

Actions to be Taken on Each Alarm

Type Over-voltage alarm (HV) LED Action (1) The three-phase input voltage is probably higher than the rating. Check the voltage and correct it as required. (2) The connection of the separate regenerative discharge unit is probably incor rect. Check the connection. (3) The resistor of the separate regenerative discharge unit is probably defec tive.Disconnect the wiring of the regenerative discharge unit and check the resistance. If it is not within +20% of the rating (described in Section 3. 5), replace the regenerative discharge unit. If any of the above three items does not fit the case,replace the servo amplifier. Low control power voltage alarm (LV) (1) The single-phase input voltage (for control circuit) is probably lower than the rating. Check the voltage and correct it as required. (2) The emergency stop input signal is probably short- circuited. Remove the CX4 connector from the amplifier. If the alarm condition disap pears,check the connection of the external cable. (3) For the type B interface,the pulse coder is probably short- circuited. Remove the JF* connector from the amplifier. If the alarm condition disap pears,check the connection of the external cable. If any of the above three items does not fit the case,replace the servo amplifier. Low DC link voltage alarm (LVDC) (1) The circuit breaker is probably off. Check the circuit breaker. (2) The three-phase input voltage is probably lower than the rating. Check the volt age and correct it as required. If either of the above two items does not fit the case, replace the servo am plifier Regenerative discharge control circuit failure alarm (DCSW) (1) The connection of the separate regenerative discharge unit is probably incor rect. Check the connection. (2) The resistor of the separate regenerative discharge unit is probably defec tive.Disconnect the wiring of the regenerative discharge unit and check the resistance. If it is not within +20% of the rating (described in Section 3. 5), replace the regenerative discharge unit. If either of the above two items does not fit the case, replace the servo amplifier

44

B65195EN/01

TROUBLESHOOTING AND RECOVERY

3. TROUBLESHOOTING AND RECOVERY PROCEDURES

Type Over-regenerative discharge alarm (DCOH)

LED

Action (1) The average regenerative discharge energy is probably too high. Reduce the frequency of acceleration/deceleration. (2) The connection of the thermostat line to the separate regenerative discharge unit is probably incorrect. Check the connection. (3) The thermostat of the separate regenerative discharge unit is probably defec tive.Disconnect the wiring of the regenerative discharge unit, and check the thermostat. If the thermostat is open when the regenerative discharge unit is not hot, replace the regenerative discharge unit. (4) The transformer has probably overheated. Check the ambient temperature, motor output, and transform rating. If any of the above four items does not fit the case,replace the servo amplifier.

Dynamic brake circuit failure alarm (DBRLY)

The connection between the NC and servo amplifier is probably incorrect. Check the connection. If the above items does not fit the case,replace the servo amplifier.

45

3. TROUBLESHOOTING AND RECOVERY PROCEDURES

TROUBLESHOOTING AND RECOVERY

B65195EN/01

Type L-axis overcurrent alarm (HCL)

LED

Type M-axis overcurrent alarm (HCM)

LED

Type L-and M-axes over-current alarm (HCL)

LED

Action

(1) Check that following parameters are set to standard values. If they are not, normal current control is impossible.

No. 1809 No. 2004 No. 8X04

No. 1884 No. 2006 No. 8X06

No. 1954 (15-A), 1955 (15-B) No. 2011 No. 8X10

No. 1852 No. 2040 No. 8X40

No. 1853 No. 2041 No. 8X41

No. 1967 No. 2074 No. 8X74

No. 1991 No. 2098 No. 8X98

(2) Disconnect the power wires from the amplifier terminals,and release the emergency stop condition. If an overcurrent alarm is issued, replace the amplifier. If an overcurrent alarm is not issued,go to (3). (3) Disconnect the power wires from the amplifier terminals, and check the U, V, and W wires for isolation from the grounding wire sequentially. If they are isolated from the grounding wire, go to (4) and (5). If any of the power wires is short-circuited to the grounding wire, disconnect the power wires from the motor connector, and check the U, V, and W terminals of the motor for isolation from the ground terminal sequentially. If the U,V,or W terminal of the motor is short- circuited to the ground terminal,replace the motor. If they are isolated from the ground terminal,replace the power wires. (4) Connect the wires again,and observe the motor current(IR,IS)waveforms when the motor is accelerating or decelerating. (See Subsec. 4.2.2 in Part I for how to measure) If the motor current waveforms are abnormal,replace the amplifier. (5) Check that noise is induced on the motor current (IR, IS) waveforms. If there is noise,shield the wires and ground the shielding. If there is no noise,replace the amplifier. (6) If any of the above five items does not fit the case,the pulse coder,command cable or the hardware inside the CNC is probably defective.

46

B65195EN/01

TROUBLESHOOTING AND RECOVERY

3. TROUBLESHOOTING AND RECOVERY PROCEDURES

Type L-axis IPM alarm (IPML)

LED

Type M-axis IPM alarm (IPMM)

LED

Type L-and M-axes IPM alarm (IPMLM)

LED

Remarks Both figure and period appear simultaneously.

Action

(1) Only the SVU1- 20(A06B- 6089- H102)has a built- in fan. If this fan stops,an IPM alarm (8. in the LED indicator) is issued. So, if this alarm is issued on the SVU1- 20, first check that the fan is rotating. A spare of the fan motor can be ordered using the spare list code A06P- 6089- H102. (2) After keeping the amplifier switched off for about ten minutes, release the emergency stop condition. If the alarm was due to IPM overheat, it will not be issued this time because the IPM is not hot any longer. The probable causes of IPM overheat include high ambient temperature and excessively strict operating condition for the motor.Check for these conditions. If the IPM alarm is still issued, go to (3). (3) Disconnect the power wires from the amplifier terminals, and release the emergency stop condition. If the IPM alarm is still issued, the probable cause is the operation of the IPM protection function (overcurrent or power supply failure). Replace the IPM or amplifier. If the IPM alarm is not issued, go to (4). (4) Disconnect the power wires from the amplifier terminals, and check the U, V, and W wires for isolation from the grounding wire sequentially. If they are isolated from the grounding wire, go to (5) and (6). If any of the power wires is short- circuited to the grounding wire, disconnect the power wires from the motor connector, and check the U, V, and W terminals of the motor for isolation from the ground terminal sequentially. If the U, V, or W terminal of the motor is short-circuited to the ground terminal, replace the motor. If they are isolated from the ground terminal, replace the power wires. (5) Connect the wires again,and observe the motor current (IR, IS) waveforms when the motor is accelerating or decelerating. (See Section 4.2.2 for how to measure.) If the motor current waveforms are abnormal, replace the amplifier. (6) Check to see if noise is induced on the motor current (IR, IS) waveforms. If there is noise, shield the wires and ground the shielding. If there is no noise, replace the amplifier. (7) Any of the above six items does not fit the case,the pulse coder, command cable or the hardware inside the CNC is probably defective.

47

3. TROUBLESHOOTING AND RECOVERY PROCEDURES

TROUBLESHOOTING AND RECOVERY

B65195EN/01

3.2

CURRENT CONVERSION FAILURE ALARM

(1) Exchange the command cables as shown in the example below. Turn on CNC in an emergency stage. If the alarm is issued on the same axis, go to (2). If the alarm is issued now on the axis that was normal, go to (3). (2) The module for current conversion in the CNC is defective. (3) Disconnect the command cable from the axis on which the alarm was issued, and connect it to a normal axis. If the alarm is issued on the same axis, go to (4) If the alarm is issued now on the axis that was normal, go to (5). (4) The servo amplifier is defective. (5) The command cable is defective. Replace it.

CNC Defective Axis (L) M-axis command cable Servo Amplifier L-axis Cable M-axis

Exchange Normal Axis (M)

L-axis command cable

48

S-ar putea să vă placă și

- SerialSpindle AlarmDocument11 paginiSerialSpindle AlarmserkandmÎncă nu există evaluări

- Fanuc Drive AlramDocument4 paginiFanuc Drive AlrammntcepplÎncă nu există evaluări

- Fanuc Alpha-I Series Spindle Amplifier Module Troubleshooting and ActionDocument24 paginiFanuc Alpha-I Series Spindle Amplifier Module Troubleshooting and ActionMD WAQAR KHANÎncă nu există evaluări

- Alpha-I SPM Alarm CodesDocument20 paginiAlpha-I SPM Alarm CodesjoydeepÎncă nu există evaluări

- Fanuc 30i Data Input OutputDocument10 paginiFanuc 30i Data Input OutputShahzad AnwarÎncă nu există evaluări

- Fanuc 0 Series Controller Spindle Amplifier AlarmsDocument17 paginiFanuc 0 Series Controller Spindle Amplifier AlarmsHoangvinh DuongÎncă nu există evaluări

- 802Dsl AlarmesDocument438 pagini802Dsl AlarmesWagner Rodolfo da SilvaÎncă nu există evaluări

- Fanuc 11m v70Document3 paginiFanuc 11m v70slaven67Încă nu există evaluări

- CNC SERVO ADJUSTMENT GUIDEDocument120 paginiCNC SERVO ADJUSTMENT GUIDEAlisson cruzÎncă nu există evaluări

- Fanuc 10 Fanuc 11 Memory Backup ProceduresDocument1 paginăFanuc 10 Fanuc 11 Memory Backup Procedures2RtiÎncă nu există evaluări

- EP3 Use ManualDocument321 paginiEP3 Use Manualalejandro becerraÎncă nu există evaluări

- Add Info B-65285EN 04Document86 paginiAdd Info B-65285EN 04clausÎncă nu există evaluări

- List of Alarm Codes for CNC MachinesDocument78 paginiList of Alarm Codes for CNC Machinessssf-doboj100% (2)

- 61393e OModelCD (107 197)Document91 pagini61393e OModelCD (107 197)25 HanhaÎncă nu există evaluări

- Clear NC and PLC dataDocument2 paginiClear NC and PLC dataAntonio de la TorreÎncă nu există evaluări

- The Caution of Rate Feed Function in FANUC Power Mate-MODEL E OPERATOR’S MANUALDocument183 paginiThe Caution of Rate Feed Function in FANUC Power Mate-MODEL E OPERATOR’S MANUALCONG TRAN NGOCÎncă nu există evaluări

- Borrado de Todos Los Datos de NC y PLC Gildemeister 6017Document2 paginiBorrado de Todos Los Datos de NC y PLC Gildemeister 6017Antonio de la TorreÎncă nu există evaluări

- Parameter Manual: Fanuc Ac Spindle Motor @ Series Fanuc Ac Spindle Motor # SeriesDocument939 paginiParameter Manual: Fanuc Ac Spindle Motor @ Series Fanuc Ac Spindle Motor # SeriesTony AntonyÎncă nu există evaluări

- Fanuc MD Alarms ListDocument7 paginiFanuc MD Alarms Listrattan singhÎncă nu există evaluări

- Fan Uc Manuals 1790Document213 paginiFan Uc Manuals 1790Somchai SompongpuangÎncă nu există evaluări

- VAC Motor CheckDocument3 paginiVAC Motor CheckAnders-Pehr GidlundÎncă nu există evaluări

- Fanuc-Page-7 (Pluse @i64)Document13 paginiFanuc-Page-7 (Pluse @i64)Hoangvinh DuongÎncă nu există evaluări

- Mori Dura AlarmDocument4 paginiMori Dura AlarmNGUYEN HUU DAOÎncă nu există evaluări

- 62543en1 PDFDocument519 pagini62543en1 PDFroshan lal100% (1)

- Inverter Sumitomo Af3100Document20 paginiInverter Sumitomo Af3100FarizÎncă nu există evaluări

- 伺服参数 PDFDocument688 pagini伺服参数 PDFIrving HardenzenÎncă nu există evaluări

- BNP B2202Document10 paginiBNP B2202hanhvannguyentranÎncă nu există evaluări

- CACR-SR Alarm TroubleshootingDocument2 paginiCACR-SR Alarm TroubleshootingMladen Vujicic100% (1)

- Modulos y Servos FanucDocument14 paginiModulos y Servos FanucIrving LopezÎncă nu există evaluări

- Baldor - Spindle Drive Instructions, 7500 WD Tuning v11-4Document7 paginiBaldor - Spindle Drive Instructions, 7500 WD Tuning v11-4Asif JamilÎncă nu există evaluări

- Fanuc SPM PDFDocument2 paginiFanuc SPM PDFBrianÎncă nu există evaluări

- FS16/18-MC/TC and FS16i/18i/21i-MA/TA external touch panel interface specificationsDocument7 paginiFS16/18-MC/TC and FS16i/18i/21i-MA/TA external touch panel interface specificationsmahdi elmayÎncă nu există evaluări

- 0 401 PDFDocument2 pagini0 401 PDFarturonaupa4302100% (1)

- Adittional Axis Robot MitsubishiDocument111 paginiAdittional Axis Robot MitsubishiParIs MoRanÎncă nu există evaluări

- MCV1020A - 2600 Operation and Maintenance Manual V2 - 0 PDFDocument366 paginiMCV1020A - 2600 Operation and Maintenance Manual V2 - 0 PDFcesar aldapeÎncă nu există evaluări

- Sanyo Denki TapeReader Model 2702 Instruction ManualDocument18 paginiSanyo Denki TapeReader Model 2702 Instruction ManualcoronaqcÎncă nu există evaluări

- Cnctrain Fanuc0M: CNC Simulation Systems 1995 2010Document51 paginiCnctrain Fanuc0M: CNC Simulation Systems 1995 2010Siti Idah TawhidÎncă nu există evaluări

- 64113EN1Document1.224 pagini64113EN1João Paulo Moreira Santos BarbosaÎncă nu există evaluări

- 9513 OptoDocument18 pagini9513 OptoCatalina MuneraÎncă nu există evaluări

- CNC MitshibushiDocument394 paginiCNC MitshibushiMathi AlaganÎncă nu există evaluări

- Wire EDM Alarm Message GuideDocument263 paginiWire EDM Alarm Message Guideorhan kızmaz100% (1)

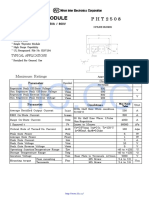

- PHT2508CFDocument5 paginiPHT2508CFArnulfo Muñoz FraustoÎncă nu există evaluări

- Fanuc Series 15i Maint Alarm WarmingsDocument414 paginiFanuc Series 15i Maint Alarm WarmingsstephenawoodruffÎncă nu există evaluări

- FADAL ERRORES Sect - 10 - Error - MessagesDocument36 paginiFADAL ERRORES Sect - 10 - Error - MessagesArnulfo Muñoz FraustoÎncă nu există evaluări

- Okuma OSP-U100M Special FunctionDocument350 paginiOkuma OSP-U100M Special FunctionJean_vzlaÎncă nu există evaluări

- Toshiba Machine Co., LTD.: User's Manual Product SHAN5 Version 1.12Document39 paginiToshiba Machine Co., LTD.: User's Manual Product SHAN5 Version 1.12杨建华Încă nu există evaluări

- Fanuc 16i 210i Ts AlarmsDocument109 paginiFanuc 16i 210i Ts AlarmstugskulÎncă nu există evaluări

- Fagor 800T Manual 2 PDFDocument224 paginiFagor 800T Manual 2 PDFniksa77Încă nu există evaluări

- MR-J2S-S099 - Specifications and Instruction Manual BCN-B11127-478 (01.02) PDFDocument84 paginiMR-J2S-S099 - Specifications and Instruction Manual BCN-B11127-478 (01.02) PDFDoDuyBacÎncă nu există evaluări

- Manual FanucDocument6 paginiManual FanucWermeson SousaÎncă nu există evaluări

- Servo/Spindle's Troubleshooting: 9.1.3.1 Troubleshooting at Power ONDocument26 paginiServo/Spindle's Troubleshooting: 9.1.3.1 Troubleshooting at Power ONjaganksÎncă nu există evaluări

- 63003en-1 01Document1.417 pagini63003en-1 01Bobert HÎncă nu există evaluări

- B-85444EN-3_03_Custom PMC FunctionDocument392 paginiB-85444EN-3_03_Custom PMC FunctionKonrad WolnyÎncă nu există evaluări

- Variable Lead Thread Cutting Initialization Flow For FS-0iDocument20 paginiVariable Lead Thread Cutting Initialization Flow For FS-0iS.DharanipathyÎncă nu există evaluări

- PMC Supplemental Programming ManualDocument88 paginiPMC Supplemental Programming ManualTien Nguyen VanÎncă nu există evaluări

- Medoc DosDocument16 paginiMedoc DosGUSZ_GUSZÎncă nu există evaluări

- Fanuc 31i-BM Standard Features and Options PDFDocument10 paginiFanuc 31i-BM Standard Features and Options PDFdanielstancu883296Încă nu există evaluări

- 6089-6090_Alarm_listDocument6 pagini6089-6090_Alarm_listMohammad MahmodiÎncă nu există evaluări

- Servo Amplifier Unit 3.1.1: LED Indications and MeaningsDocument6 paginiServo Amplifier Unit 3.1.1: LED Indications and MeaningsPhuc PhamÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Shipping Document ChecklistDocument4 paginiShipping Document ChecklistRicardo Jose PirelaÎncă nu există evaluări

- Gerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Document2 paginiGerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Ricardo Jose PirelaÎncă nu există evaluări

- Application: Name:Plate-Shaped RF Power Ceramic Capacitor Item#.: CCG81 SeriesDocument3 paginiApplication: Name:Plate-Shaped RF Power Ceramic Capacitor Item#.: CCG81 SeriesRicardo Jose PirelaÎncă nu există evaluări

- HF PVC WeldingDocument7 paginiHF PVC WeldingRicardo Jose PirelaÎncă nu există evaluări

- Container DimensionsDocument6 paginiContainer Dimensionspajipitar100% (1)

- Tríodos de Electrofusion 3CX20000H3Document6 paginiTríodos de Electrofusion 3CX20000H3Ricardo Jose PirelaÎncă nu există evaluări

- Gerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Document2 paginiGerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Ricardo Jose PirelaÎncă nu există evaluări

- Thread Consumption MethodsDocument13 paginiThread Consumption MethodsSaravanan Arasu100% (1)

- Application: Name:Plate-Shaped RF Power Ceramic Capacitor Item#.: CCG81 SeriesDocument3 paginiApplication: Name:Plate-Shaped RF Power Ceramic Capacitor Item#.: CCG81 SeriesRicardo Jose PirelaÎncă nu există evaluări

- Application: Name:Plate-Shaped RF Power Ceramic Capacitor Item#.: CCG81 SeriesDocument3 paginiApplication: Name:Plate-Shaped RF Power Ceramic Capacitor Item#.: CCG81 SeriesRicardo Jose PirelaÎncă nu există evaluări

- Gerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Document2 paginiGerneral Characteristics Maximum Ratings: Electron Tube FU-612F and FU-613F (Equivalent To 3CX2500F3 and 3CX2500H3)Ricardo Jose PirelaÎncă nu există evaluări

- Quincy QGB Series Rotary Screw Air Compressors 20 - 60 HPDocument10 paginiQuincy QGB Series Rotary Screw Air Compressors 20 - 60 HPRicardo Jose PirelaÎncă nu există evaluări

- HF PVC WeldingDocument7 paginiHF PVC WeldingRicardo Jose PirelaÎncă nu există evaluări

- Manual Pfaff 335 HDocument10 paginiManual Pfaff 335 HJulianaÎncă nu există evaluări

- Container DimensionsDocument6 paginiContainer Dimensionspajipitar100% (1)

- US-Quick Operation Guide of DS-9500 NVR (V1.3.1)Document18 paginiUS-Quick Operation Guide of DS-9500 NVR (V1.3.1)Ricardo Jose PirelaÎncă nu există evaluări

- Container DimensionsDocument6 paginiContainer Dimensionspajipitar100% (1)

- Egner FluteMethodDocument108 paginiEgner FluteMethodRicardo Jose PirelaÎncă nu există evaluări

- Power Transmission CatalogDocument273 paginiPower Transmission CatalogRicardo Jose PirelaÎncă nu există evaluări

- Teileliste Parts List Liste de Pièces Lista de Piezas: 296-12-18 284 Dtsch./engl./franz./span. 06.05Document52 paginiTeileliste Parts List Liste de Pièces Lista de Piezas: 296-12-18 284 Dtsch./engl./franz./span. 06.05Ricardo Jose PirelaÎncă nu există evaluări

- Manual EnergizadorDocument19 paginiManual EnergizadorRicardo Jose PirelaÎncă nu există evaluări

- Hans Sitt Practical Viola MethodDocument16 paginiHans Sitt Practical Viola MethodRicardo Jose Pirela100% (2)

- Data Types (Transact-SQL) - Microsoft DocsDocument124 paginiData Types (Transact-SQL) - Microsoft DocsRicardo Jose PirelaÎncă nu există evaluări

- Incoterms 2010 Incoterms 2010: February, 2012Document34 paginiIncoterms 2010 Incoterms 2010: February, 2012Ricardo Jose PirelaÎncă nu există evaluări

- Single Axis Servo Controller: LEDC 2009A/B 8808D User ManualDocument10 paginiSingle Axis Servo Controller: LEDC 2009A/B 8808D User ManualRicardo Jose PirelaÎncă nu există evaluări

- Incoterms 2010 en v2Document2 paginiIncoterms 2010 en v2Candace JonesÎncă nu există evaluări

- Tube TopicsDocument31 paginiTube TopicsRicardo Jose PirelaÎncă nu există evaluări

- Incoterms 2015: An OverviewDocument5 paginiIncoterms 2015: An OverviewAbdul SattarÎncă nu există evaluări

- Sekonda UputstvoDocument2 paginiSekonda Uputstvohellios81Încă nu există evaluări

- Chapter 10: Performance Measurement, Monitoring, and Program EvaluationDocument20 paginiChapter 10: Performance Measurement, Monitoring, and Program EvaluationShauntina SorrellsÎncă nu există evaluări

- Data Integrity Issues and SolutionsDocument4 paginiData Integrity Issues and SolutionsApphia MendozaÎncă nu există evaluări

- 12 Volt Relay Wiring DiagramDocument1 pagină12 Volt Relay Wiring Diagramgoshhub100% (1)

- Strategic Mine Planning With COMET SoftwareDocument4 paginiStrategic Mine Planning With COMET SoftwareALfian Bangngabua'Încă nu există evaluări

- Transformer Repair PresDocument20 paginiTransformer Repair PrestapasÎncă nu există evaluări

- Cpu 260 PDFDocument70 paginiCpu 260 PDFFernandoCamargoÎncă nu există evaluări

- Wireless Compilation 19122014wir CompDocument21 paginiWireless Compilation 19122014wir CompPankaj Singh RawatÎncă nu există evaluări

- Polymetron 9125 (EngDocument4 paginiPolymetron 9125 (EngYounes ArabiÎncă nu există evaluări

- Volar Sobre El Pantano Carlos Cuauhtemoc Sanchez PDF CompletoDocument4 paginiVolar Sobre El Pantano Carlos Cuauhtemoc Sanchez PDF CompletoCarlos Alberto30% (10)

- DCDB Board CatalogueDocument4 paginiDCDB Board CatalogueMtel LogisticÎncă nu există evaluări

- STS Activity 1Document3 paginiSTS Activity 1SHARAINE PRINCESS CASTILLOÎncă nu există evaluări

- Model Predictive Control For Mining: Process Optimization SolutionDocument14 paginiModel Predictive Control For Mining: Process Optimization SolutionJRaulk PalomaresÎncă nu există evaluări

- Ajuste Del Freno Estacionamiento ProbarDocument2 paginiAjuste Del Freno Estacionamiento ProbarVictor NunezÎncă nu există evaluări

- Project SynopsisDocument23 paginiProject SynopsisRahul Raj SinghÎncă nu există evaluări

- Assembly-Power Distribution Center C6: Connector DetailsDocument3 paginiAssembly-Power Distribution Center C6: Connector DetailsEnrique Arevalo LeyvaÎncă nu există evaluări

- OOS Confidence LevelDocument14 paginiOOS Confidence Levelpinnacle qaÎncă nu există evaluări

- Interscan Web Security Virtual Appliance: Trend MicroDocument4 paginiInterscan Web Security Virtual Appliance: Trend MicroriyasathsafranÎncă nu există evaluări

- Siemens Mag 6000Document12 paginiSiemens Mag 6000Richard VizcarraÎncă nu există evaluări

- 1 2 Short Circuit Current Calculation at Various Point of Electrical Circuits (Isc)Document18 pagini1 2 Short Circuit Current Calculation at Various Point of Electrical Circuits (Isc)Mark Tristan VallesterosÎncă nu există evaluări

- Loom OMEGA6 Guide EngDocument54 paginiLoom OMEGA6 Guide EngPhúc Vũ Viết Phúc83% (6)

- VERTIV Liebert EXS 10kVA-20kVA - V1.0Document108 paginiVERTIV Liebert EXS 10kVA-20kVA - V1.0Jayz JDKÎncă nu există evaluări

- Policies - ICT Systems and Services SOPDocument52 paginiPolicies - ICT Systems and Services SOPAteeq Haider Baig100% (2)

- E-283 (2) Gondi 930K PDFDocument1 paginăE-283 (2) Gondi 930K PDFLuis Manuel CastilloÎncă nu există evaluări

- Elite Flyer Arabic 3Document2 paginiElite Flyer Arabic 3Hakeem AdDarÎncă nu există evaluări

- Microcontroller MCQ Quiz: Test Your Knowledge of Microcontrollers with 20 Multiple Choice QuestionsDocument5 paginiMicrocontroller MCQ Quiz: Test Your Knowledge of Microcontrollers with 20 Multiple Choice QuestionsDeepika SharmaÎncă nu există evaluări

- FiretideDocument187 paginiFiretideAnil JiandaniÎncă nu există evaluări

- LTE KPI OptimizationDocument13 paginiLTE KPI Optimizationsonuvikas775Încă nu există evaluări

- Parts Manual: Belt Drive Air CompressorDocument57 paginiParts Manual: Belt Drive Air CompressorestebanÎncă nu există evaluări

- Poclain Hydraulics Selection GuideDocument44 paginiPoclain Hydraulics Selection GuideM S GokulÎncă nu există evaluări