Documente Academic

Documente Profesional

Documente Cultură

SchuF Diverter Valve Brochure

Încărcat de

Gohilakrishnan ThiagarajanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SchuF Diverter Valve Brochure

Încărcat de

Gohilakrishnan ThiagarajanDrepturi de autor:

Formate disponibile

Fetterolf Corporation, Inc.

phone: +1 610 584-1500

fax: +1 610 584-5904

info@fetterolfvalves.com

SchuF (USA) Inc.

phone: +1 843 8813345

fax: +1 843 8816121

sales@schuf.us

U

S

A

SchuF Valve Technology GmbH

phone: +353 (0)21 4837000

fax: +353 (0)21 4837030

sales@schuf.ie

I

R

E

L

A

N

D

SchuF Chemieventile Vertriebs GmbH

phone: +49 (0)6198 571100

fax: +49 (0)6198 571200

verkauf@schuf.de

G

E

R

M

A

N

Y

Fetterolf SchuF do Brazil Ltda

phone: +55 19 3936 9090

fax: +55 19 39353215

fbvendas@fetterolf.com.br

B

R

A

Z

I

L

Your Local Agent :

SchuF Speciality Valves India Pvt. Ltd.

phone: +91 421 2264600

fax: +91 421 2362018

sales@schuf-india.com

I

N

D

I

A

Worl dwi de

www. s c huf . c om www. s c huf . de

Diverter Valves

VE R T E I L E R VE NT I L E

Diverter Valve Configuration Options

Operating Principles

In its simplest form a diverter valve has one

inlet and two outlets or vice versa.

When the medium flows through the inlet it

can either be routed to 1) outlet A only,

2) outlet B only, or 3) to both outlet A and B

simultaneously. This is achieved by two pistons

(or discs) that move into the valve body and

cover all or part of the outlets from either side.

This action results in a completely dead space

free valve.

Alternatively, the valve can have multiple inlets

and outlets. This allows for different substan-

ces to be brought together as required and

routed to one or multiple lines or vessels.

4 Way R type Diverter Valve

3 2

The Diverter valve was invented by SchuF in

1965. The first diverter valves were the simple

combination of two or more piston or disc valves.

Over the past 45 years, SchuF Fetterolf developed

this original idea into a valve category in its own

right. The name comes about as a result of the

fact that the construction enables a process

flow to be diverted (or routed) into two or more

directions. Diverter valves are sometimes called

switch valves, multi-way, or combination valves.

Diverter Valve Applications

Diverter valves have the primary purpose of

splitting or combining process media into one

or more streams. They can be widely found in

the chemical, polymer, and refining industries

and are used in a broad variety of applications:

To split one large process line into

many smaller lines

To replace several isolation valves

and T-pieces in order to eliminate

back flushing of dead spaces

To keep one line in service whilst

maintaining another

Switching between filters, without

downtime or pressure and flow

variations

To switch between control valves or

pumps

For high viscosity media, where dead

or slow spaces lead to poor product

quality

To combine a process isolation and

a start up dump valve in one valve

body

Where space does not permit larger

valves or extensive piping

To integrate multiple valve process

functions into one valve

Key Features & Options

Modular design

2, 3, 4, or multiple inlets / outlets

Dead space free, unimpeded flow

Slow space avoidance

Metal to metal bubble tight seal

Stuffing box seal to atmosphere

Rotating and contoured pistons / discs

Control functionality option

Repairable in place

Customised design

Diverter Valves General Overview

1. T Type Diverter Valves with 90 inlet / outlet angle

2. T Type Diverter valves with 45 or 60 inlet / outlet angle

3. R Type Diverter Valves with outlet at right angle to inlet

4. Diverter Valve with multiple

bi-directional inlets or outlets

5. Multi-way Star Design Diverter Valve

Diverter Valve Configuration Options

Operating Principles

In its simplest form a diverter valve has one

inlet and two outlets or vice versa.

When the medium flows through the inlet it

can either be routed to 1) outlet A only,

2) outlet B only, or 3) to both outlet A and B

simultaneously. This is achieved by two pistons

(or discs) that move into the valve body and

cover all or part of the outlets from either side.

This action results in a completely dead space

free valve.

Alternatively, the valve can have multiple inlets

and outlets. This allows for different substan-

ces to be brought together as required and

routed to one or multiple lines or vessels.

4 Way R type Diverter Valve

3 2

The Diverter valve was invented by SchuF in

1965. The first diverter valves were the simple

combination of two or more piston or disc valves.

Over the past 45 years, SchuF Fetterolf developed

this original idea into a valve category in its own

right. The name comes about as a result of the

fact that the construction enables a process

flow to be diverted (or routed) into two or more

directions. Diverter valves are sometimes called

switch valves, multi-way, or combination valves.

Diverter Valve Applications

Diverter valves have the primary purpose of

splitting or combining process media into one

or more streams. They can be widely found in

the chemical, polymer, and refining industries

and are used in a broad variety of applications:

To split one large process line into

many smaller lines

To replace several isolation valves

and T-pieces in order to eliminate

back flushing of dead spaces

To keep one line in service whilst

maintaining another

Switching between filters, without

downtime or pressure and flow

variations

To switch between control valves or

pumps

For high viscosity media, where dead

or slow spaces lead to poor product

quality

To combine a process isolation and

a start up dump valve in one valve

body

Where space does not permit larger

valves or extensive piping

To integrate multiple valve process

functions into one valve

Key Features & Options

Modular design

2, 3, 4, or multiple inlets / outlets

Dead space free, unimpeded flow

Slow space avoidance

Metal to metal bubble tight seal

Stuffing box seal to atmosphere

Rotating and contoured pistons / discs

Control functionality option

Repairable in place

Customised design

Diverter Valves General Overview

1. T Type Diverter Valves with 90 inlet / outlet angle

2. T Type Diverter valves with 45 or 60 inlet / outlet angle

3. R Type Diverter Valves with outlet at right angle to inlet

4. Diverter Valve with multiple

bi-directional inlets or outlets

5. Multi-way Star Design Diverter Valve

Valve and Process Efficiency

SchuFs attention to quality and ensuring

optimal valve efficiency is reflected in our use

of finite element simulation analysis.

These simulations enable us to advise the best

valve design for a specific process.

The example below shows the results of a valve

simulation for a polymer like medium.

Each flow line is colour coded to show how far

the polymer will have travelled in a given time.

Deep blue shows how far the polymer would

travel in the first 2 seconds, light blue in six

seconds, green in 9 seconds, yellow in 13

seconds and so on. The simulation shows that

there are variances in residence time between

the flow in the centre and the flow through the

corners. The pressure drop is less than 1 bar.

For many applications this level of performance

is superior to existing valve solutions. However,

certain media (such as polyester) necessitate

the elimination of even the slightest slow

spaces. Without this consistent high quality

end product cannot be assured.

SchuF has been able to successfully produce

valves for these slow and dead space appli-

cations. In fact it has also led to other SchuF

"process customised" designs and in turn to

improved customer end product and more

efficient processes.

The valve consists of several key parts an

enclosed cast, forged or welded body, two or

more pistons or discs (depending on the num-

ber of inlets and outlets required), a stuffing

box, packing rings, gearing, a hand wheel and

electric, hydraulic, or pneumatic actuation.

Design Options

A standard Y type diverter valve with one inlet

and two outlets is illustrated in the picture

below:

The process flow enters the top connection and

the outlet flow is to either or both of the outlet

lines existing in parallel below the valve body.

The R type diverter valve (illustrated on page 6)

is similar to the Y type except that the outlets

are at right angles to the inlet flow. This design

frequently utilises rotating, contoured

pistons/rams on one or both sides to assure

smooth, unobstructed flow. This is a particularly

useful feature for highly viscose media such as

polymer or heavy gas oil with high solids

content.

SchuF Fetterolf also provides a T type and an

S Type (short for Star configuration with multi-

ple inlets and outlets) diverter valves. In all

designs the angular relationship of the outlet

ports may be changed to meet the requirements

of the installation. Special designs are also avai-

lable for large size valves or high flow rates.

Full heat jacketing is available in all designs and

may be zoned so that only the flowing side is

heated.

Flexible and Efficient Design

Diverter Valve FE simulation

3 Way Y type Diverter Valve

I N L E T

OU T L E T

Process Dead Space Problems

Dead space can lead to many

unwelcome consequences.

In plastic and polymer pro-

duction, the medium can be

contaminated by trapped

particles, rendering it

worthless. In the refinery,

dead space can lead to

accumulation of coke like

particles, catalyst fines or

clumps which necessitates

back flushing and thereby

reduces line capacity.

Traditional Isolation

Approach

Traditionally, isolation valves

interconnected with T-piece

piping are used to isolate the process flow in

one direction. This is achieved by using two ball

valves and a T-piece as shown above.

When one of the ball valves is closed and

the medium contains solid particles or highly

viscose liquid, a Dead

Space is created by the

medium in and around the

ball, between the ball and

the valve body, and in the

left section of the T-piece.

The dead space area is

shown in black in the

second drawing. When this

ball valve is opened, part of

the residue that filled the

dead spaces will either stick

to the piping reducing the

full through bore and over

time require the valve to be

removed for maintenance.

Alternatively the residue will

form clumps that over time

break away to damage other equipment down-

stream or contaminate other media in the

batches that follow.

Dead and Slow Space The Process Killers

The clean and modern alternative is a SchuF

Fetterolf Diverter valve as illustrated above.

The piston seals flush to the inlet body in the

closed position and flush with the outlet

take off point in the open position.

The media can flow freely through the valve

and there are no cavities, spaces or areas where

sediment can stick or accumulate. For all

intents and purposes, the SchuF Diverter valve

becomes a full bore extension of the pipeline.

Dead space is eliminated!

The Modern Alternative

5 4

3 Way T type Diverter Valve Dead Space Free, unimpeded flow

2. Cross sectional drawing of 1.

1. Ball Valve and T-piece arrangement

Valve and Process Efficiency

SchuFs attention to quality and ensuring

optimal valve efficiency is reflected in our use

of finite element simulation analysis.

These simulations enable us to advise the best

valve design for a specific process.

The example below shows the results of a valve

simulation for a polymer like medium.

Each flow line is colour coded to show how far

the polymer will have travelled in a given time.

Deep blue shows how far the polymer would

travel in the first 2 seconds, light blue in six

seconds, green in 9 seconds, yellow in 13

seconds and so on. The simulation shows that

there are variances in residence time between

the flow in the centre and the flow through the

corners. The pressure drop is less than 1 bar.

For many applications this level of performance

is superior to existing valve solutions. However,

certain media (such as polyester) necessitate

the elimination of even the slightest slow

spaces. Without this consistent high quality

end product cannot be assured.

SchuF has been able to successfully produce

valves for these slow and dead space appli-

cations. In fact it has also led to other SchuF

"process customised" designs and in turn to

improved customer end product and more

efficient processes.

The valve consists of several key parts an

enclosed cast, forged or welded body, two or

more pistons or discs (depending on the num-

ber of inlets and outlets required), a stuffing

box, packing rings, gearing, a hand wheel and

electric, hydraulic, or pneumatic actuation.

Design Options

A standard Y type diverter valve with one inlet

and two outlets is illustrated in the picture

below:

The process flow enters the top connection and

the outlet flow is to either or both of the outlet

lines existing in parallel below the valve body.

The R type diverter valve (illustrated on page 6)

is similar to the Y type except that the outlets

are at right angles to the inlet flow. This design

frequently utilises rotating, contoured

pistons/rams on one or both sides to assure

smooth, unobstructed flow. This is a particularly

useful feature for highly viscose media such as

polymer or heavy gas oil with high solids

content.

SchuF Fetterolf also provides a T type and an

S Type (short for Star configuration with multi-

ple inlets and outlets) diverter valves. In all

designs the angular relationship of the outlet

ports may be changed to meet the requirements

of the installation. Special designs are also avai-

lable for large size valves or high flow rates.

Full heat jacketing is available in all designs and

may be zoned so that only the flowing side is

heated.

Flexible and Efficient Design

Diverter Valve FE simulation

3 Way Y type Diverter Valve

I N L E T

OU T L E T

Process Dead Space Problems

Dead space can lead to many

unwelcome consequences.

In plastic and polymer pro-

duction, the medium can be

contaminated by trapped

particles, rendering it

worthless. In the refinery,

dead space can lead to

accumulation of coke like

particles, catalyst fines or

clumps which necessitates

back flushing and thereby

reduces line capacity.

Traditional Isolation

Approach

Traditionally, isolation valves

interconnected with T-piece

piping are used to isolate the process flow in

one direction. This is achieved by using two ball

valves and a T-piece as shown above.

When one of the ball valves is closed and

the medium contains solid particles or highly

viscose liquid, a Dead

Space is created by the

medium in and around the

ball, between the ball and

the valve body, and in the

left section of the T-piece.

The dead space area is

shown in black in the

second drawing. When this

ball valve is opened, part of

the residue that filled the

dead spaces will either stick

to the piping reducing the

full through bore and over

time require the valve to be

removed for maintenance.

Alternatively the residue will

form clumps that over time

break away to damage other equipment down-

stream or contaminate other media in the

batches that follow.

Dead and Slow Space The Process Killers

The clean and modern alternative is a SchuF

Fetterolf Diverter valve as illustrated above.

The piston seals flush to the inlet body in the

closed position and flush with the outlet

take off point in the open position.

The media can flow freely through the valve

and there are no cavities, spaces or areas where

sediment can stick or accumulate. For all

intents and purposes, the SchuF Diverter valve

becomes a full bore extension of the pipeline.

Dead space is eliminated!

The Modern Alternative

5 4

3 Way T type Diverter Valve Dead Space Free, unimpeded flow

2. Cross sectional drawing of 1.

1. Ball Valve and T-piece arrangement

Standard and Customised Diverter Valve Designs

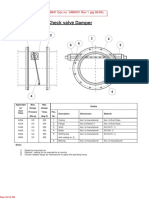

3 Way T type Diverter Valve with Disc Model 43TT

3 Way Y type Diverter Valve with Piston Model 40YK

7 6

3 Way R type Diverter Valve Piston with jacketing Model 45RK

The drawings shown on this

page illustrate 3 basic

Diverter Valve designs:

Y Type

T Type

R Type

The drawings opposite show

several customised designs.

5 Way Double T Diverter Valve with

integral flushing Model 49VS

6 Way Diverter Valve Model 42FK

High Vacuum Diverter Valve Model 44YB

4 Way Tangential Star Diverter

Model 47DK

10 Way Diverter Valve- Model 42ZK

Multiway and Customised Diverter Valve Standard Y type, T type and R type Diverter Valve

Choice of valve configu-

ration or type depends on a

number of factors including:

flow characteristics of the

medium, available space,

piping layout and process or

application requirements.

Standard and Customised Diverter Valve Designs

3 Way T type Diverter Valve with Disc Model 43TT

3 Way Y type Diverter Valve with Piston Model 40YK

7 6

3 Way R type Diverter Valve Piston with jacketing Model 45RK

The drawings shown on this

page illustrate 3 basic

Diverter Valve designs:

Y Type

T Type

R Type

The drawings opposite show

several customised designs.

5 Way Double T Diverter Valve with

integral flushing Model 49VS

6 Way Diverter Valve Model 42FK

High Vacuum Diverter Valve Model 44YB

4 Way Tangential Star Diverter

Model 47DK

10 Way Diverter Valve- Model 42ZK

Multiway and Customised Diverter Valve Standard Y type, T type and R type Diverter Valve

Choice of valve configu-

ration or type depends on a

number of factors including:

flow characteristics of the

medium, available space,

piping layout and process or

application requirements.

9 8

Product Range and Technical Data The m-Factory Diverter Valve

Size 1" to 18" as standard Larger as per requirement

Body Stainless steel 1.4408 (CF-8M) Carbon Steel, 304, 316L, Duplex,

or 1.4571 (316Ti) Hastelloy, Monel, Titanium, Nickel,

Inconel, Incoloy, etc.

Valve Lining n/a PTFE, glass, ceramic or rubber

Inlet Perpendicular to body Inlet larger than outlet; same size

inlet/outlet; off-set to body;

bi-directional inlet/outlet etc.

Outlet 45, 60 or 90 Angle per customer requirement

Piston Stainless steel 1.4571 (316 Ti) 17- 4PH, hard faced, PTFE and all

or 1.4541 (321) materials under "Body - Optional"

Disc Stainless steel 1.4571 (316 Ti) As piston above

Spindle Stainless steel 1.4122 (420) Others are possible on request

Seat Integrated seat (hard faced) Replaceable seat, sleeve or ring

Sealing to atmosphere Stuffing box Fully enclosed yoke

Temperature minus 100 to 500 C Higher or lower on request

Process sealing Metal to metal Radial seal; vacuum yoke

Pressure range All up to ASME 2500 (PN 320) Higher on request

Connection types Butt weld end or flanged Clamp type

Actuators Manual, hydraulic or electric Pneumatic

Fire safe n/a Fire safe design to BS 6755 Pt. 2*

Heating jacket n/a Full or semi jacketing

Surface coating n/a Anodising, Canadizing, Titanium

Nitriding, Ceramic and Tungsten

Control Characteristics On/off Linear, equal %, or SchuF gap control

(straight or contoured piston) (patented control contour)

Add ons Flushing ports Integral drain valve, sampling valves,

mechanical lock

* European safety standard similar to API 607

Item Standard Optional

Standard Diverter Valves From 1 inch (DN 25) to 18 inch (DN 450) and up to ASME 2500#

(PN 320) pressure class

High Pressure Diverter High Pressure Diverter valves from 1 inch (DN 25) to 14 inches

Valves (DN 350) and up to ASME 4500# pressure class

Maritime & Offshore Maritime & Offshore Diverter valves with special body and trim

Valves material

Customised Custom designed diverter valves

Product Range Description

Diverter Valve Product Portfolio Challenges for new plant or plant redesign

The Diverter valve is an ideal tool to reconstruct,

replace or redesign a process or plant layout. It is

also an essential ingredient in new plant design

where capital cost and space are primary concerns.

The picture below shows the piping, valve

and space requirements for part of a refinery

process. This part of the refinery includes

equipment for isolation, steam injection,

quenching, condensate, and draining.

In addition to the equipment, a significant

length of piping is required. This in turn has to

be kept clean and regularly maintained.

All in all the initial capital outlay and ongoing

operating costs are high.

mini-Factory Diverter Valve Solution

In response to these problems, SchuF has

developed special new diverter valve assemblies.

They incorporate many valve functions in one,

including all of the piping and valves shown

above. The critical switching valve can also be

included. In addition, the required floor space, the

initial capital outlay and the on-going maintenance

is significantly reduced. Moreover dead space and

consequentially back flushing is eliminated.

An added extra benefit is that sealing performance

and thereby plant safety is improved.

The mini-Factory diverter valve is the SchuF

Fetterolf answer to the ever increasing need to

reduce operating costs without sacrificing technical

performance. It shows the Diverter valve to be one

of the most versatile, reliable and innovative valve

designs available to industry today.

Diverter Valve Technical Data

Isolation

valve

Isolation

valve

Steam

injection valve

Steam

injection

valve

Condensate gate

valve

Quench

water

inlet valve

Drain

valve

9 8

Product Range and Technical Data The m-Factory Diverter Valve

Size 1" to 18" as standard Larger as per requirement

Body Stainless steel 1.4408 (CF-8M) Carbon Steel, 304, 316L, Duplex,

or 1.4571 (316Ti) Hastelloy, Monel, Titanium, Nickel,

Inconel, Incoloy, etc.

Valve Lining n/a PTFE, glass, ceramic or rubber

Inlet Perpendicular to body Inlet larger than outlet; same size

inlet/outlet; off-set to body;

bi-directional inlet/outlet etc.

Outlet 45, 60 or 90 Angle per customer requirement

Piston Stainless steel 1.4571 (316 Ti) 17- 4PH, hard faced, PTFE and all

or 1.4541 (321) materials under "Body - Optional"

Disc Stainless steel 1.4571 (316 Ti) As piston above

Spindle Stainless steel 1.4122 (420) Others are possible on request

Seat Integrated seat (hard faced) Replaceable seat, sleeve or ring

Sealing to atmosphere Stuffing box Fully enclosed yoke

Temperature minus 100 to 500 C Higher or lower on request

Process sealing Metal to metal Radial seal; vacuum yoke

Pressure range All up to ASME 2500 (PN 320) Higher on request

Connection types Butt weld end or flanged Clamp type

Actuators Manual, hydraulic or electric Pneumatic

Fire safe n/a Fire safe design to BS 6755 Pt. 2*

Heating jacket n/a Full or semi jacketing

Surface coating n/a Anodising, Canadizing, Titanium

Nitriding, Ceramic and Tungsten

Control Characteristics On/off Linear, equal %, or SchuF gap control

(straight or contoured piston) (patented control contour)

Add ons Flushing ports Integral drain valve, sampling valves,

mechanical lock

* European safety standard similar to API 607

Item Standard Optional

Standard Diverter Valves From 1 inch (DN 25) to 18 inch (DN 450) and up to ASME 2500#

(PN 320) pressure class

High Pressure Diverter High Pressure Diverter valves from 1 inch (DN 25) to 14 inches

Valves (DN 350) and up to ASME 4500# pressure class

Maritime & Offshore Maritime & Offshore Diverter valves with special body and trim

Valves material

Customised Custom designed diverter valves

Product Range Description

Diverter Valve Product Portfolio Challenges for new plant or plant redesign

The Diverter valve is an ideal tool to reconstruct,

replace or redesign a process or plant layout. It is

also an essential ingredient in new plant design

where capital cost and space are primary concerns.

The picture below shows the piping, valve

and space requirements for part of a refinery

process. This part of the refinery includes

equipment for isolation, steam injection,

quenching, condensate, and draining.

In addition to the equipment, a significant

length of piping is required. This in turn has to

be kept clean and regularly maintained.

All in all the initial capital outlay and ongoing

operating costs are high.

mini-Factory Diverter Valve Solution

In response to these problems, SchuF has

developed special new diverter valve assemblies.

They incorporate many valve functions in one,

including all of the piping and valves shown

above. The critical switching valve can also be

included. In addition, the required floor space, the

initial capital outlay and the on-going maintenance

is significantly reduced. Moreover dead space and

consequentially back flushing is eliminated.

An added extra benefit is that sealing performance

and thereby plant safety is improved.

The mini-Factory diverter valve is the SchuF

Fetterolf answer to the ever increasing need to

reduce operating costs without sacrificing technical

performance. It shows the Diverter valve to be one

of the most versatile, reliable and innovative valve

designs available to industry today.

Diverter Valve Technical Data

Isolation

valve

Isolation

valve

Steam

injection valve

Steam

injection

valve

Condensate gate

valve

Quench

water

inlet valve

Drain

valve

In December 2008, a major coal producer

launched the first full scale commercial trial for

a coal to liquid refinery based on the Bergius

process. The plant was designed to produce

900,000 tons of gasoline, diesel and kerosene

per annum. The Bergius process uses ground

coal as feed, which is then processed under

temperatures up to 500C and high pressure

(to 240 bar). These operating conditions create

a series of problems for equipment and in

particular for valves. The control valves have to

handle pressure drops of up to 200 bar with a

high solids content and high temperature.

Original Design

The original design foresaw four pressure

let down valves installed in paralllel, and the

associated extensive piping, T-pieces, and

double block isolation valves, running from the

HHPS (Hot High Pressure Separator) to the

HMPS (Hot Medium Pressure Separator). The

dead space created from the inlet take off point

of the T-piece to the ball valve necessitated

constant and significant back flushing. This

reduced capacity in the open line. A second

alternative had all four control valves operating

partially open, which resulted in unacceptably

high erosion rates.

New SchuF Diverter Approach

SchuF Fetterolf proposed a completely new

design based on a star type Diverter valve. In

this solution the effluent exiting the HHPS

Alok Industries

Aker Solutions

BASF

BP

China Petrol & Chemical

Dow Chemical

Du Pont

Eastman

E.on / VEBA

Far Eastern OPC

Formosa Petrochemichals

Fuji Filter

Indorama

Invista

Lonza

Reliance Industries

Sabic

Samnam

Samsung

Shell Oil

Shenhua

Sasol

Tuntex

Yizheng

SchuF Fetterolf Valve Portfolio

11 10

Other

Products

Y-Globe

Valve

Line Sampling

Valve

Angle Control

Valve

Pistom / Ram

Bottom Outlet

Multiport

Diverter Valve

Lift Plug

Bypass

Special Gate

Valve

Line Blinds

Cam-Set

& Stacey

Lift Plug

On-Off Isolation

Screw-In

Sampling Valve

Globe Control

Valve

Disc lowering

Bottom Outlet

Lift Plug

Diverter Valve

Spray Rinse

Valve

Lift Plug

Switching

Coker

IsoPlug

Coker

SwitchPlug

Coker

ControlPlug

Coker

Quench Valve

Submersed

Sampling Valve

Wafer Control

Valve

Disc rising

Bottom Outlet

Changeover

Valve

High Pressure

Angle Valve

Wafer

Sampling Valve

Sampling

Systems

Backpressure

Control Valve

Automatic

Recirculation

Valve

Changeover

Combination

Valve

Tank Storage

Valve

Steam Injection

Valve

In-lying Disc

Valve

In-Line

Valves

Sampling

Valves

Control

Valves

Bottom

Outlet

Valves

Diverter &

Changeover

Valves

Coker

Valves

SchuF Fetterolf has delivered over one million valves

during its almost 100 year history to a wide variety

of industries in over 50 countries worldwide.

Headquartered near Frankfurt in Germany, the

company has additional design and manufacturing

centres in Brazil, India, Ireland and the United States.

The SchuF group has sales and agent offices

covering almost every country in the world.

We manufacture valve products that control,

isolate, divert, and sample liquids, gases,

powders, and slurries. Our product range of

engineered, customised valves includes:

Case Study - The Worlds Most Advanced Diverter Valve

6 Way Star Diverter Valve

Sample Diverter Valve Client List:

V

E

R

S

A

T

I

L

E

EFFICIENT &

enters a star shaped diverter valve from above

and is directed to one of the four outlets,

whilst the other three remain closed.

Once the initial process run is complete, the

first outlet is closed and another is opened.

There are many advantages to this approach:

SchuF Fetterolf Design Benefits

Back flushing was eliminated and

full line capacity usage was achieved.

Switching time from one line to the

next is minimised.

Significant piping and space has been

saved.

The associated control valves (also

delivered by SchuF) showed no signs

of erosion, and could be closed as and

when required.

Significant capital investment and

on-going maintenance cost savings

have been made.

In December 2008, a major coal producer

launched the first full scale commercial trial for

a coal to liquid refinery based on the Bergius

process. The plant was designed to produce

900,000 tons of gasoline, diesel and kerosene

per annum. The Bergius process uses ground

coal as feed, which is then processed under

temperatures up to 500C and high pressure

(to 240 bar). These operating conditions create

a series of problems for equipment and in

particular for valves. The control valves have to

handle pressure drops of up to 200 bar with a

high solids content and high temperature.

Original Design

The original design foresaw four pressure

let down valves installed in paralllel, and the

associated extensive piping, T-pieces, and

double block isolation valves, running from the

HHPS (Hot High Pressure Separator) to the

HMPS (Hot Medium Pressure Separator). The

dead space created from the inlet take off point

of the T-piece to the ball valve necessitated

constant and significant back flushing. This

reduced capacity in the open line. A second

alternative had all four control valves operating

partially open, which resulted in unacceptably

high erosion rates.

New SchuF Diverter Approach

SchuF Fetterolf proposed a completely new

design based on a star type Diverter valve. In

this solution the effluent exiting the HHPS

Alok Industries

Aker Solutions

BASF

BP

China Petrol & Chemical

Dow Chemical

Du Pont

Eastman

E.on / VEBA

Far Eastern OPC

Formosa Petrochemichals

Fuji Filter

Indorama

Invista

Lonza

Reliance Industries

Sabic

Samnam

Samsung

Shell Oil

Shenhua

Sasol

Tuntex

Yizheng

SchuF Fetterolf Valve Portfolio

11 10

Other

Products

Y-Globe

Valve

Line Sampling

Valve

Angle Control

Valve

Pistom / Ram

Bottom Outlet

Multiport

Diverter Valve

Lift Plug

Bypass

Special Gate

Valve

Line Blinds

Cam-Set

& Stacey

Lift Plug

On-Off Isolation

Screw-In

Sampling Valve

Globe Control

Valve

Disc lowering

Bottom Outlet

Lift Plug

Diverter Valve

Spray Rinse

Valve

Lift Plug

Switching

Coker

IsoPlug

Coker

SwitchPlug

Coker

ControlPlug

Coker

Quench Valve

Submersed

Sampling Valve

Wafer Control

Valve

Disc rising

Bottom Outlet

Changeover

Valve

High Pressure

Angle Valve

Wafer

Sampling Valve

Sampling

Systems

Backpressure

Control Valve

Automatic

Recirculation

Valve

Changeover

Combination

Valve

Tank Storage

Valve

Steam Injection

Valve

In-lying Disc

Valve

In-Line

Valves

Sampling

Valves

Control

Valves

Bottom

Outlet

Valves

Diverter &

Changeover

Valves

Coker

Valves

SchuF Fetterolf has delivered over one million valves

during its almost 100 year history to a wide variety

of industries in over 50 countries worldwide.

Headquartered near Frankfurt in Germany, the

company has additional design and manufacturing

centres in Brazil, India, Ireland and the United States.

The SchuF group has sales and agent offices

covering almost every country in the world.

We manufacture valve products that control,

isolate, divert, and sample liquids, gases,

powders, and slurries. Our product range of

engineered, customised valves includes:

Case Study - The Worlds Most Advanced Diverter Valve

6 Way Star Diverter Valve

Sample Diverter Valve Client List:

V

E

R

S

A

T

I

L

E

EFFICIENT &

enters a star shaped diverter valve from above

and is directed to one of the four outlets,

whilst the other three remain closed.

Once the initial process run is complete, the

first outlet is closed and another is opened.

There are many advantages to this approach:

SchuF Fetterolf Design Benefits

Back flushing was eliminated and

full line capacity usage was achieved.

Switching time from one line to the

next is minimised.

Significant piping and space has been

saved.

The associated control valves (also

delivered by SchuF) showed no signs

of erosion, and could be closed as and

when required.

Significant capital investment and

on-going maintenance cost savings

have been made.

Fetterolf Corporation, Inc.

phone: +1 610 584-1500

fax: +1 610 584-5904

info@fetterolfvalves.com

SchuF (USA) Inc.

phone: +1 843 8813345

fax: +1 843 8816121

sales@schuf.us

U

S

A

SchuF Valve Technology GmbH

phone: +353 (0)21 4837000

fax: +353 (0)21 4837030

sales@schuf.ie

I

R

E

L

A

N

D

SchuF Chemieventile Vertriebs GmbH

phone: +49 (0)6198 571100

fax: +49 (0)6198 571200

verkauf@schuf.de

G

E

R

M

A

N

Y

Fetterolf SchuF do Brazil Ltda

phone: +55 19 3936 9090

fax: +55 19 39353215

fbvendas@fetterolf.com.br

B

R

A

Z

I

L

Your Local Agent :

SchuF Speciality Valves India Pvt. Ltd.

phone: +91 421 2264600

fax: +91 421 2362018

sales@schuf-india.com

I

N

D

I

A

Worl dwi de

www. s c huf . c om www. s c huf . de

Diverter Valves

VE R T E I L E R VE NT I L E

S-ar putea să vă placă și

- Diverter Valves BrochureDocument12 paginiDiverter Valves Brochuredanny buiÎncă nu există evaluări

- p43 Formation Isolation ValveDocument1 paginăp43 Formation Isolation ValvePak RioÎncă nu există evaluări

- Three Way ValvesDocument8 paginiThree Way ValvesWalter JosephÎncă nu există evaluări

- Introduction To Gate Valves and Gate Valve TypesDocument16 paginiIntroduction To Gate Valves and Gate Valve TypesVinay Sharma100% (1)

- Technical PapersDocument4 paginiTechnical PapersKanishk PandeyÎncă nu există evaluări

- What Are The Different Types of Valves Used in Hvac?: RequestDocument6 paginiWhat Are The Different Types of Valves Used in Hvac?: RequestShihad BasheerÎncă nu există evaluări

- Pipeline Prover SpheresDocument2 paginiPipeline Prover SpheresandraÎncă nu există evaluări

- Process Valv HandbookDocument14 paginiProcess Valv Handbookdenim89Încă nu există evaluări

- Piping DesignDocument14 paginiPiping Designchinnak123Încă nu există evaluări

- 610e Varivent Valves 11 2010Document16 pagini610e Varivent Valves 11 2010José A. RamírezÎncă nu există evaluări

- PIPING DESIGN ENGINEER INTERVIEW QUESTIONS - PART-1 - Oilandgasclub PDFDocument5 paginiPIPING DESIGN ENGINEER INTERVIEW QUESTIONS - PART-1 - Oilandgasclub PDFGemailÎncă nu există evaluări

- Making of Most of ValvesDocument12 paginiMaking of Most of ValvesShaikh MateenÎncă nu există evaluări

- PDF ValveDocument13 paginiPDF ValveHyperFlickÎncă nu există evaluări

- Sohel Ffo ProjectDocument13 paginiSohel Ffo ProjectSANIKA TALATHIÎncă nu există evaluări

- Pressure Seal Valves-GateDocument24 paginiPressure Seal Valves-GateHieu NguyenÎncă nu există evaluări

- Training Valves FAINAL 2013 AugustDocument6 paginiTraining Valves FAINAL 2013 Augustwidada007Încă nu există evaluări

- ValvesDocument27 paginiValveswassliÎncă nu există evaluări

- 4 Guidance On Valve Type SelectionDocument86 pagini4 Guidance On Valve Type SelectionKrista OneillÎncă nu există evaluări

- List The Main Features of Globe ValveDocument3 paginiList The Main Features of Globe ValveArvin Rei SanquilosÎncă nu există evaluări

- Velan Y-Pattern Globe CAT BG 04 10Document12 paginiVelan Y-Pattern Globe CAT BG 04 10mfcramer0% (1)

- Large Size Quarter Turn Control Valves Can Improve Safety in PipelinesDocument19 paginiLarge Size Quarter Turn Control Valves Can Improve Safety in PipelinesgpuzoneÎncă nu există evaluări

- WH Is in Control?: Ising Stem Uarter TurnDocument4 paginiWH Is in Control?: Ising Stem Uarter TurnPeter Nai Ho100% (1)

- DAN-EX Brochure WebDocument12 paginiDAN-EX Brochure Webzakkyf6455Încă nu există evaluări

- Valves in The Oil and Gas IndustryDocument55 paginiValves in The Oil and Gas IndustryK LandryÎncă nu există evaluări

- Piping DesignersDocument60 paginiPiping DesignersKagira Drawing Soltuion100% (1)

- Sluice CatalogueDocument40 paginiSluice CatalogueLungisaniÎncă nu există evaluări

- Choke E Series MasterFloDocument14 paginiChoke E Series MasterFloianherzogÎncă nu există evaluări

- Design and Selection Criteria For Check ValvesDocument26 paginiDesign and Selection Criteria For Check Valvesmhopgood100% (3)

- Valves: Training Centre Monday, April 21, 2014Document77 paginiValves: Training Centre Monday, April 21, 2014Abdullah Sabry AzzamÎncă nu există evaluări

- Safety Relief ValvesDocument52 paginiSafety Relief ValvesHamza NoumanÎncă nu există evaluări

- Valves HandbookDocument51 paginiValves Handbookedhy_0367% (3)

- DBB CatalogueDocument28 paginiDBB CatalogueHeri SetyantoÎncă nu există evaluări

- Valves All TypesDocument77 paginiValves All TypesShyam Prasad K S100% (1)

- Valves AssignmentDocument16 paginiValves AssignmentAdil Jutt GÎncă nu există evaluări

- DSSV SDMDocument6 paginiDSSV SDMvishnunair27Încă nu există evaluări

- Crane Engineering Data 1Document56 paginiCrane Engineering Data 1jerry666aÎncă nu există evaluări

- Design and Use of Check ValvesDocument10 paginiDesign and Use of Check Valvesjenshid0% (1)

- ValvesDocument44 paginiValvesأحمد محمد قدريÎncă nu există evaluări

- VIP Red CatalogueIntroduction This catalogue will provide you with an idea of range, which now includes a huge selection of plumbing products and pumps to complement our already extensive engineering range. - our service is constantly reviewed and we aim to offer our customers excellence in all areas. About Us Formed in 1985, we have earned a reputation for setting standards in quality, service and reliability. We supply a wide range of industries including:Document28 paginiVIP Red CatalogueIntroduction This catalogue will provide you with an idea of range, which now includes a huge selection of plumbing products and pumps to complement our already extensive engineering range. - our service is constantly reviewed and we aim to offer our customers excellence in all areas. About Us Formed in 1985, we have earned a reputation for setting standards in quality, service and reliability. We supply a wide range of industries including:aco1970Încă nu există evaluări

- Valve Case StudyDocument10 paginiValve Case StudycynthiaÎncă nu există evaluări

- Design and Analysis of High Pressure Globe Valve Body With Two ElementsDocument6 paginiDesign and Analysis of High Pressure Globe Valve Body With Two ElementsCarlos HinostrozaÎncă nu există evaluări

- ValvesDocument108 paginiValvesGautam Wayse100% (1)

- Valve Types and ApplicationsDocument82 paginiValve Types and Applicationsrajeshn1Încă nu există evaluări

- Dome ValveDocument6 paginiDome Valvesaisssms9116Încă nu există evaluări

- Control ValveDocument98 paginiControl ValveUtku KepcenÎncă nu există evaluări

- Gate ValvesDocument13 paginiGate Valvesyessa gamuedaÎncă nu există evaluări

- Instrumentation Course 2.Document67 paginiInstrumentation Course 2.FACE BOOK100% (1)

- Valves Gate DamperDocument54 paginiValves Gate DamperLalit MeenaÎncă nu există evaluări

- Hunter PGV Valve ManualDocument16 paginiHunter PGV Valve Manualrodolfos_8Încă nu există evaluări

- Geovent CatalogDocument108 paginiGeovent CatalogadnanÎncă nu există evaluări

- Shut-Off ValvesDocument9 paginiShut-Off Valvesalec.cabanyolÎncă nu există evaluări

- Isolation Valves - Linear MovementDocument9 paginiIsolation Valves - Linear MovementEmad A.AhmadÎncă nu există evaluări

- ValvesDocument9 paginiValvesHarrabyy RÂwaaÎncă nu există evaluări

- Piping AuxiliariesDocument12 paginiPiping AuxiliariesarchitÎncă nu există evaluări

- Valves PresentationDocument36 paginiValves PresentationFareedee100% (1)

- Simple Plumbing Repairs for the Home and FarmsteadDe la EverandSimple Plumbing Repairs for the Home and FarmsteadÎncă nu există evaluări

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDe la EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingEvaluare: 5 din 5 stele5/5 (3)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- Prevention of Actuator Emissions in the Oil and Gas IndustryDe la EverandPrevention of Actuator Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- Is.1976.1976 Paddy Wheader ManualDocument13 paginiIs.1976.1976 Paddy Wheader ManualGohilakrishnan ThiagarajanÎncă nu există evaluări

- 2 Check Type Damper Drawing 1555074039Document1 pagină2 Check Type Damper Drawing 1555074039Gohilakrishnan ThiagarajanÎncă nu există evaluări

- Cotton Waste TenderDocument2 paginiCotton Waste TenderGohilakrishnan ThiagarajanÎncă nu există evaluări

- Bharat Heavy Electricals Limited: Tvenkat@bheltry - Co.inDocument14 paginiBharat Heavy Electricals Limited: Tvenkat@bheltry - Co.inGohilakrishnan ThiagarajanÎncă nu există evaluări

- Wps FormatDocument12 paginiWps FormatGohilakrishnan ThiagarajanÎncă nu există evaluări

- Valve Stds AllDocument11 paginiValve Stds AllGohilakrishnan ThiagarajanÎncă nu există evaluări

- Welding Process: SMAW WGS /WPS/ SMAW/0033 Dear Sir, We Are Sending The Following PlateDocument1 paginăWelding Process: SMAW WGS /WPS/ SMAW/0033 Dear Sir, We Are Sending The Following PlateGohilakrishnan ThiagarajanÎncă nu există evaluări

- Process Layout Status SheetDocument2 paginiProcess Layout Status SheetGohilakrishnan ThiagarajanÎncă nu există evaluări

- Ball Screw AssyDocument8 paginiBall Screw AssyGohilakrishnan ThiagarajanÎncă nu există evaluări

- Butterfly ValveDocument20 paginiButterfly Valvenazar750Încă nu există evaluări

- Inspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsDocument3 paginiInspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsGohilakrishnan ThiagarajanÎncă nu există evaluări

- Bharat Heavy Electricals LimitedDocument8 paginiBharat Heavy Electricals LimitedGohilakrishnan ThiagarajanÎncă nu există evaluări

- Valve Size & Class PO Reference:-: Qty: Drawing No: NBDN Ref:-: Description:Seat Ring:-: Invoice No. Job Code Report No Material (Base + Overlay)Document1 paginăValve Size & Class PO Reference:-: Qty: Drawing No: NBDN Ref:-: Description:Seat Ring:-: Invoice No. Job Code Report No Material (Base + Overlay)Gohilakrishnan ThiagarajanÎncă nu există evaluări

- Astrum BrochureDocument20 paginiAstrum BrochureGohilakrishnan ThiagarajanÎncă nu există evaluări

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 paginiTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanÎncă nu există evaluări

- TDC-10B Heat Treatment For C12A Steel CastingsDocument2 paginiTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanÎncă nu există evaluări

- SOP - 03C Rev 1 Weld Shop PDFDocument9 paginiSOP - 03C Rev 1 Weld Shop PDFGohilakrishnan Thiagarajan100% (1)

- Demographic Data of Bakalia DistrictDocument4 paginiDemographic Data of Bakalia DistrictJannatul FerdousÎncă nu există evaluări

- IS3370 (Part - I) 2009Document20 paginiIS3370 (Part - I) 2009amithcivil100% (1)

- CorrigendumtoNotificationNo15 2023dt26122023forAEE 25012024Document3 paginiCorrigendumtoNotificationNo15 2023dt26122023forAEE 25012024boyalakshmi212Încă nu există evaluări

- Extraction of Ce and TH From Monazite Using REE Tolerant Aspergillus NigerDocument10 paginiExtraction of Ce and TH From Monazite Using REE Tolerant Aspergillus Nigerjay9037Încă nu există evaluări

- NAHRIM's Experiencein Rainwater Utilisation System Research-SlidesDocument13 paginiNAHRIM's Experiencein Rainwater Utilisation System Research-SlideskaishiÎncă nu există evaluări

- Energy Conversion and Management: Salah-Eddine Amrani, Ahmed Alami Merrouni, Samir Touili, Hassane DekhissiDocument16 paginiEnergy Conversion and Management: Salah-Eddine Amrani, Ahmed Alami Merrouni, Samir Touili, Hassane DekhissisalahÎncă nu există evaluări

- Hydraulics Engineering Week 12: Dams and Reservoirs: Dr. M. Mubashir QureshiDocument88 paginiHydraulics Engineering Week 12: Dams and Reservoirs: Dr. M. Mubashir QureshiRana Asad AliÎncă nu există evaluări

- Executive MBA Project - Self Help Allowance - FinalDocument55 paginiExecutive MBA Project - Self Help Allowance - FinalKumar SourabhÎncă nu există evaluări

- Kikuyu: Isitasbadas Environmentalists Suggest?Document32 paginiKikuyu: Isitasbadas Environmentalists Suggest?CompleatGolferÎncă nu există evaluări

- Climate and Weather (Esquema)Document7 paginiClimate and Weather (Esquema)Janet Gallardo SerraÎncă nu există evaluări

- Stratigraphy, Exploration and EOR Potential of The TensleepCasper Formations, SE WyomingDocument15 paginiStratigraphy, Exploration and EOR Potential of The TensleepCasper Formations, SE WyomingWelsinsin Kevin SinÎncă nu există evaluări

- L14-Multiphase Pumping & Subsea Processing (Compatibility Mode)Document26 paginiL14-Multiphase Pumping & Subsea Processing (Compatibility Mode)Laxmi Kant Prasad100% (1)

- Civil Engineer Resume 0Document2 paginiCivil Engineer Resume 0Nazee 122333Încă nu există evaluări

- Evidence The Story of Bottled WaterDocument2 paginiEvidence The Story of Bottled WaterPaula MelissaÎncă nu există evaluări

- Technological Institute of The Philippines: Department of Environmental and Sanitary EngineeringDocument5 paginiTechnological Institute of The Philippines: Department of Environmental and Sanitary EngineeringAl RomanoÎncă nu există evaluări

- Habitat Centre ReportDocument87 paginiHabitat Centre Reportnc85% (13)

- 2017 Iceti Proceeding Book 1 - Part13Document25 pagini2017 Iceti Proceeding Book 1 - Part13KathirrveluSubramainanÎncă nu există evaluări

- Self Watering Planter PresentationDocument13 paginiSelf Watering Planter Presentationapi-500694538Încă nu există evaluări

- Starting Up and Operating An Electrical Submersible Pump (ESP)Document3 paginiStarting Up and Operating An Electrical Submersible Pump (ESP)Yougchu LuanÎncă nu există evaluări

- No. Category of Contribution RateDocument3 paginiNo. Category of Contribution RateFuadChiwaÎncă nu există evaluări

- AFB PPRC - 20 13-Proposal-for-Ethiopia PDFDocument209 paginiAFB PPRC - 20 13-Proposal-for-Ethiopia PDFdawitÎncă nu există evaluări

- Iceland - The Ultimate Road TripDocument15 paginiIceland - The Ultimate Road TripRMascilÎncă nu există evaluări

- Drawing Boiler PartsDocument1 paginăDrawing Boiler PartsAnonymous FZs3yBHh7Încă nu există evaluări

- Ship Building Offshore: From Applications To ProductsDocument36 paginiShip Building Offshore: From Applications To ProductsaminÎncă nu există evaluări

- Aquaculture Systems: Presented By: M.F.Sc. I YearDocument18 paginiAquaculture Systems: Presented By: M.F.Sc. I Yearshivani vermaÎncă nu există evaluări

- Approved Rates For Testing of Materials and Services: Effective From 1 January 2017 Rates Include 15% VATDocument4 paginiApproved Rates For Testing of Materials and Services: Effective From 1 January 2017 Rates Include 15% VATSaJedur RahmanÎncă nu există evaluări

- Trinidad Guardian - 07.10.22Document48 paginiTrinidad Guardian - 07.10.22D-TECH CONTRACTINGÎncă nu există evaluări

- Hoja de Seguridad Cintas PolykenDocument7 paginiHoja de Seguridad Cintas PolykenCarlos TarquinoÎncă nu există evaluări

- Amoco Cadiz Oil SpillDocument19 paginiAmoco Cadiz Oil SpillHemanth KrishnaÎncă nu există evaluări

- Brief Directions For The Use of Biodynamic Sprays 500, 501 and 508Document3 paginiBrief Directions For The Use of Biodynamic Sprays 500, 501 and 508budhistsluvcopyrightÎncă nu există evaluări