Documente Academic

Documente Profesional

Documente Cultură

Modeling Two-Phase Flow in Pipe

Încărcat de

rahuldbajaj2011Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Modeling Two-Phase Flow in Pipe

Încărcat de

rahuldbajaj2011Drepturi de autor:

Formate disponibile

Savalaxs Supa-Amornkul

Department of Chemical Engineering, University of New Brunswick Fredericton, N.B. E3B5A3, Canada e-mail: h796e@unb.ca

Modeling Two-Phase Flow in Pipe Bends

In order to have a better understanding of the interaction between the two-phase steamwater coolant in the outlet feeder pipes of the primary heat transport system of some CANDU reactors and the piping material, themalhydraulic modelling is being performed with a commercial computational uid dynamics (CFD) codeFLUENT 6.1. The modeling has attempted to describe the results of ow visualization experiments performed in a transparent feeder pipe with air-water mixtures at temperatures below 55 C. The CFD code solves two sets of transport equationsone for each phase. Both phases are rst treated separately as homogeneous. Coupling is achieved through pressure and interphase exchange coefcients. A symmetric drag model is employed to describe the interaction between the phases. The geometry and ow regime of interest are a 73 deg bend in a 5.9 cm diameter pipe containing water with a Reynolds number of 1E5-1E6. The modeling predicted single-phase pressure drop and ow accurately. For two-phase ow with an air voidage of 550%, the pressure drop measurements were less well predicted. Furthermore, the observation that an air-water mixture tended to ow toward the outside of the bend while a single-phase liquid layer developed at the inside of the bend was not predicted. The CFD modeling requires further development for this type of geometry with two-phase ow of high voidage. DOI: 10.1115/1.1904063 Keywords: Two-Phase Flow Experiment, CFD Modeling, Film Inversion

Frank R. Steward

Centre for Nuclear Energy Research, Enterprise UNB Building, University of New Brunswick, Fredericton, N.B. E3B6C2, Canada e-mail: fsteward@unb.ca

Derek H. Lister

Department of Chemical Engineering, University of New Brunswick Fredericton, N.B. E3B5A3, Canada e-mail: dlister@unb.ca

Introduction

There have been a number of studies of vertical and horizontal two-phase ow in straight pipes as well as single-phase ow in curved pipes. In two-phase ow, the curved pipe geometry tends to give rise to inhomogeneous phase distribution, ow reversal, ooding, secondary ow, and lm inversion. These phenomena can cause problem such as burn-out, corrosion, and tube failure in industrial components, resulting in costly outages, repairs, and early replacement affecting plant reliability and safety. This project began with the discovery of unexpectedly high corrosion rates of several carbon steel feeder pipes at the reactor outlet in the primary coolant system of a CANDU reactor in 1996as high as 120 m / year. It should be noted that the anticipated corrosion rate of carbon steel obtained from laboratory studies 1 was 10 m / year. A program of in situ monitoring of feeders has since been carried out. Results of a program of laboratory experiments and modeling have indicated that the phenomenon is ow-accelerated corrosion FAC. In general, FAC of carbon steel can be described by processes in series, magnetite lm dissolution and erosion, and mass transport of dissolved iron into the bulk coolant. The last two processes are enhanced by the relative movement between the liquid and the surface. High turbulence areas such as sharp bends, elbows and entrances are susceptible to high FAC rates 24. It is therefore desirable to understand the hydrodynamics of the coolant in the complex geometry and aggressive conditions at the reactor outlets. The feeders are primarily 2.5 nominal size 2.3 inner diameter 5.9 cm connected to a horizontal reactor fuel channel with a Grayloc tting. The fuel channel has an annular geometry at that point and the feeders have single or double bends just after the Grayloc connector see Fig. 1. The coolant is heavy water at 310 C with Re of 1E5-1E6 and steam quality up to 4%. In this paper, the results of modeling the hydrodynamics of an

Contributed by the Pressure Vessels and Piping Division for publication in the JOURNAL OF PRESSURE VESSEL TECHNOLOGY. Paper presented at the 2004 ASME Pressure Vessels and Piping Division Conference PVP2004, July 25, 2004-July 29, 2004, San Diego, California, USA. Manuscript received November 4, 2004; Final manuscript received December 8, 2004. Review conducted by: Sam Zamrik.

experimental mock-up of an outlet feeder operating with air-water mixtures at room temperature are described. The modeling was carried out with the FLUENT 6.1 computational uid dynamics code. The model describes three-dimensional turbulent ow in the end tting and feeder pipe. The results are compared with measured pressure distributions. Phase distributions predicted from the modelling were compared with observations from ow visualization. Particular attention was paid to the two-phase ow characteristics in the bend since there have been few studies 5 in this area. Discrepancies between the predictions and observations occurred for two-phase ow.

Modeling the Experiments

The mock-up was a full-scale fuel-channel end tting connected to an acrylic feeder pipe that had a single bend. The endtting geometry was an annulus that was supplied with air-water mixtures at temperatures up to 55 C, ow rates up to 0.047 m3 / s liquid and void fractions up to 0.6. Pressure taps were xed at eight positions along the bend extrados and eight positions along the intrados. Two additional taps were positioned at the connector to the end tting. Flow patterns were visualized during several runs with a video camera and a high-speed movie camera and during other runs with the observation of the pattern in a previously applied viscous oil lm. The modeling used FLUENT version 6.1, which incorporates an Eulerian treatment of three-dimensional, two-phase ows singlephase ows are treated similarly but with a simplied approach. The following concepts and assumptions were made: 1 a single pressure is shared by both phases; 2 momentum and continuity equations are solved for each phase; 3 the secondary phase consists of uniform and unchanging bubbles dispersed in a continuous phase; 4 the bubble size is assumed to be 0.1 mm; 5 the turbulent ow is everywhere isotropic; 6 a two-equation turbulent model is solved for the mixture; and 7 physical properties are uniform throughout. The following conservation equations are the basis for the modeling: Transactions of the ASME

204 / Vol. 127, MAY 2005

Copyright 2005 by ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 04/08/2013 Terms of Use: http://asme.org/terms

A three-dimensional domain of the end tting and the feeder pipe was constructed for the modeling. The mesh was made to describe a large aspect ratio. The domain consisted of 360,714 elements. Several cells were placed close to the wall within the region y + 30 to account for wall functions. The hydraulic diameter DH of the annulus was 2.8 cm and its length from the inlet to the centerline of the feeder pipe was approximately 50 times DH. The feeder pipe diameter was 5.9 cm. The ratio of the bend radius of curvature R to the pipe cross section diameter D, R / D, was 1.61. The straight section after the bend was 30 cm. Independence of the modeling results from the chosen mesh could not be proven because of computing limitations. Instead, the results of single-phase ow modeling with the chosen mesh were validated by experiment.

Results and Discussions

Single-Phase. Figure 2 presents the pressure measurements and modeling predictions for a single-phase ow experiment. The pressure distribution is presented in terms of the pressure coef1 cient, C p, which is dened as p pref / 2 2 ave . The local static pressure is p and pref is an upstream reference pressure located at 56 cm from the centerline of the feeder pipe in this experiment. The average Reynolds number for the pipe bend in this experiment was 370,000. The circumferential position at 0 deg represents the data along the intrados of the bend whereas 180 deg represents the data along the extrados of the bend. At the connector zero on the abscissa the additional two measurements were made. The 1 position supplies the reference pressure. The overall pressure drop across the bend shows good agreement between the experiment and the predictions except at the location ahead of the bend. The RSM did not make a signicant difference on the pressure distribution prediction. The RSM was able to predict circular motions after the pipe bend; however, such a result can not be measured from the experiment at this time. When the ow follows a bend the static pressure and velocity distributions change; thus secondary ows are generated and turbulence structure is affected by the curvature. The static pressure increases with the radius of curvature to balance the centrifugal force. Centrifugal and pressure forces acting on the faster uid in the core cause the core to shift towards the extrados of the bend. Low energy uid near the wall tends to move around the wall towards the low static pressure region at the intrados of the bend. This tends to separate the low energy uid from the core ow and cause it to accumulate at the intrados. Figure 3 presents the Fluent representation of this phenomenon. Two counter-rotating recirculation ows of the uid at the entrance to the feeder pipe were predicted by the modeling Fig. 3; they are due to the adverse pressure gradient and the abrupt change in area ratio. The entrainment of recirculating uid induces a ow reattachment downstream 7. This recirculating uid was observed in the ow visualization experiments. Thus, two counter-rotating vortices over the intrados portion of the feeder inlet downstream from the recirculation region were generated. The line where these two ow systems meet can be seen in the oil ow visualization patterns Fig. 4. Two-Phase Flow Pressure Distribution. The average Reynolds number in the feeder pipe for these two-phase experiments varies from 7E5 to 1E6using a volume-weighted average to estimate physical properties and a homogeneous model to estimate the average velocity of the mixture. Since there is no universal model 8,9 that can represent properties of two-phase ow at the bend, the pressure measurements are presented as absolute pressure values. Pressure data at 16 points along the feeder pipe are shown in Figs. 5 and 6 for both the experiment and the predictions. Figure 5 shows the pressure data for 14% volume fraction air at average Reynolds number across the pipe bend of 780,000. The agreement is good for the extrados portion of the pipe except for a single MAY 2005, Vol. 127 / 205

Fig. 1 a End tting and feeder pipe geometry, b end view of end tting and feeder pipe, showing actual orientation, and c grid system

Mass:

k + ku k = 0 t

Momentum:

ku k u + ku k k = T + kg t

= p I where, T k + k Equations of jump conditions to ensure that mass and momentum are conserved at the phase interface are included. The interface force which is caused by the relative motion between phases is represented by the symmetric drag model 6. The Reynolds stress terms are averaged using Boussinesqs assumption. The standard k model was used to solve for the turbulent viscosity,t, using the properties of the mixture. The Reynolds stress model RSM 6 was also used for single-phase ow modeling.

Journal of Pressure Vessel Technology

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 04/08/2013 Terms of Use: http://asme.org/terms

Fig. 2 Pressure distribution along tube bend, experiment, and prediction single-phase, ow rate= 0.019 m3 / s, temperature = 25 C

Fig. 4 Oil pattern from ow visualization experiment Fig. 3 Predicted velocity distribution along the pipe bend

Fig. 5 Pressure distribution along tube bend, experiment, and prediction volume fraction of air= 14%, liquid ow rate = 0.0312 m3 / s, temperature= 25 C

206 / Vol. 127, MAY 2005

Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 04/08/2013 Terms of Use: http://asme.org/terms

Fig. 6 Pressure distribution along tube bend, experiment and prediction volume fraction of air= 49%, liquid ow rate = 0.0224 m3 / s, temperature= 25 C

point at 6 cm from the connection. However, numerical modeling tends to overpredict the pressure values at the intrados portion of the feeder pipe. Experimental conditions in Fig. 6 are 49% volume fraction of air with a Reynolds number of 930,000 in the feeder pipe. The agreement for the extrados again is good except for a single point at 6 cm from the connector, where the experimental value is substantially lower, and downstream of the bend midpoint. The values for the intrados of the feeder pipe are consistently higher for the simulation than for the experiment. The difference is less than that for the lower void fraction Fig. 5. Phase Distribution. The ow pattern is considered to depend on the ow rate of each phase, the interaction of the phases, the transport properties and the geometry of the bend. Figure 7 presents photographs of the phase distribution for a void fraction of 15%. The bubbles are smaller than the recording resolution of the high-speed movie camera of about 0.1 mm. The ow regime was difcult to determine in the two-phase region near the intrados. While there is generally an accumulation of air towards the intrados, there also appears to be an accumulation of a slower liquid lm underneath the faster core. This originates from the start of the bend and extends to 0.5 diameters downstream from the bend before the core ow reattaches. This could be caused by a radial pressure gradient generated by the faster core of the lower density mixture causing the slow-moving liquid phase near the wall to move toward the intrados. Other workers 1016 observed a similar phenomenon at high gas ow rates; most of them offer the same explanation and invoke the ratio of centrifugal force to gravity force. The criterion which is used to predict the accumulation of liquidthe Froude number 16failed to predict these experimental conditions. A similar concept using slip velocity ratio 10, which was based purely on centrifugal force and gravity force, does not apply here because the slip velocity was observed to be too low. From the ow visualization, it was deduced that the secondary ow vortices that originated from the inlet portion of the feeder pipe could be an important factor in this type of ow 15. As found in the single phase experiment, the secondary ow normally originated in a pair of counter-rotating vortices at the intrados portion of the feeder inlet. These vortices leave the intrados and contact the extrados immediately downstream of the bend. The vortices then merge downstream of the bend intrados see Fig. 8a. Journal of Pressure Vessel Technology

Fig. 7 a,b Phase distribution at the bend volume fraction of air= 15%, Re= 7.0E5, temperature= 25 C

MAY 2005, Vol. 127 / 207

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 04/08/2013 Terms of Use: http://asme.org/terms

Fig. 8 a,b Phase distribution at the bend volume fraction of air= 52%, Re= 12.0E5, temperature= 40 C

Fig. 9 a Air distribution at the middle plane of the feeder pipe volume fraction of air= 49%, Re= 9.3E5, temperature= 25 C, and b water distribution around the wall volume fraction of air= 49%, Re= 9.3E5, temperature= 25 C

stream. In the experiment this liquid lm was found earlier at the intrados of the bend.

The apparent layer of slow moving liquid at the intrados of the bend is larger at higher void fractions compare Figs. 7a and 8b and becomes less stable as the void fraction increases. Subsequent measurements have shown that these liquid lms are thinner than they appear. Quantitative measurements are needed to conrm the layer thickness. The phase distribution predicted by FLUENT for similar conditions fails to represent this development of a liquid lm at the intrados of the bend. Figure 9a shows the prediction of an accumulation of air at the intrados of the bend. FLUENT predicts the movement of the high density uid to the extrados of the bend due to the centrifugal force. The inability of FLUENT to predict the pressure distribution measured for two-phase ow may then be related to these discrepancies in predicting lm development at the bend. The inconsistency implies that the current two-uid model and/or above assumptions need to be improved, in particular, surface tension effects on the nature of two-phase ow should be considered. Bubble size and velocity and spatial variations in volume fraction would inuence the drag coefcient term in the model, which may account for the discrepancy. On the other hand, the predominantly liquid layer predicted by FLUENT to develop at the bend extrados and to extend downstream and around the wall see Figs. 9a and 9b was observed in the ow tests. Figure 9a shows a liquid lm at one diameter downstream from the intrados of the bend which extends further down208 / Vol. 127, MAY 2005

Conclusions

1. The simulation with the CFD code, FLUENT, for single phase ow gives a representation of the pressure distribution along a feeder pipe test section that is in reasonable agreement with the experimental data. 2. The simulation by FLUENT for two-phase ow was signicantly different from the experimental data. The predicted pressures along the intrados of the bend were higher than the experimental values. The overall pressure drop across the test section was signicantly less for the simulation than for the experimental data. 3. The chosen models within FLUENT predicted an accumulation of air at the intrados of the bend in general agreement with ow observations but did not predict the development of the liquid lm near the intrados that was observed. This may be related to the inability of FLUENT to predict pressure drop in two-phase ow accurately, possibly because it does not consider bubble evolution in any detail.

Acknowledgments

The authors would like to acknowledge the CANDU Owners Group and thank Atomic Energy of Canada Limited for conducting the experiments and providing the experimental data and photographs. In particular, Bruce Smith and John Pietralik are Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 04/08/2013 Terms of Use: http://asme.org/terms

thanked for their assistance and valuable discussions. The Natural Sciences and Engineering Research Council of Canada is thanked for providing nancial support.

Nomenclature

y+ g ui Re pk I u

k

dimensionless distance from the wall gravitational acceleration, m / s2 interface velocity, m/s Reynolds number thermodynamic pressure, Pa unit tensor velocity of phase k, m/s

Greek Symbols density, kg/ m3 k stress tensor of phase k, kg/ s2 Subscript k liquid or gas phase in governing equations

References

1 Videm, K., and Aas, S., 1963, Mild Steel in Primary Circuits in Water Cooled Power Reactors, Institutt for Atomernergi Kjeller Research Establishment, Kjeller, Norway. 2 Chexal, B., Mahini, R., Munson, D., Horowitz, J., Randall, G., and Shevde, V., 1993 Strategic Plan for Successful Flow-Accelerated Corrosion Program, Proceedings of the 1993 Pressure Vessels and Piping Conference, ASME, PVP-Vol. 259, pp 201208. 3 Chandra, S., Klisiewicz, J. W., Schonenberg, R. Y., and Habicht, P. R., 1994, The Examination of Pipe Components Degraded Due to the Erosion/ Corrosion Phenomenon, Proceedings of the 1994 Pressure Vessels and Piping

Conference, Part 16 of 19, ASME, PVP- Vol. 285, pp 1724. 4 Lister, D. H., Slade, J., and Arbeau, N., 1997, The Accelerated Corrosion of CANDU Outlet Feeders-Observations, Possible Mechanisms and Potential Remedies, Proceedings of the Canadian Nuclear Society Annual Conference, Toronto. 5 Xin, R. C, Dong, Z. F, and Ebadian, M. A, 1996, Three-Dimensional Numerical Modeling of Turbulent Single-Phase and Two-Phase Flow in curved Pipes, National Heat Transfer Conference, ASME, Vol. 4, pp 227233. 6 Fluent. Inc., 2003, FLUENT 6.1 Users Guide. 7 Miller, D. S., 1978 Internal Flow Systems, Bedford, BHRA Fluid Engineering Series Vol. 5, pp. 6167. 8 Azzi, A., Friedel, L., and Balaadi, S., 2000, Two-Phase Gas/Liquid Flow Pressure Loss in Bends, Forsch. im Ingenieurwes., 6510, pp 309318. 9 Azzi, A., Friedel, L., Kibboua, R., and Shannak, B., 2002, Reproductive Accuracy of Two-Phase Flow Pressure Loss Correlations for Vertical 90 Bends, Forschung. im Ingenieurwesen, 6710, pp 109116. 10 Banerjee, S., Rhodes, E., and Scott, D. S., 1967, Film Inversion of Cocurrent Two-Phase Flow in Helical Coils, AIChE J., 131, pp. 189191. 11 Farukhi, Nayeem, M., and Parker, J. D., 1974, A Visual Study of Air-Water Mixtures Flowing Inside Serpentine Tubes, Proceeding of The Fifth International Heat Transfer Conference, JSME, Tokyo, B5.5, pp. 205209. 12 Maddock, C., Lacey, P. M. C., and Patrick, M. A., 1974, The Structure of Two-Phase Flow in a Curved Pipe, I. Chem. E. Symp. Series 38. II, Chem. E. Services, London, pp 122. 13 Oshinowo, T., and Charles, M. E., 1974, Vertical Two-Phase Flow. Part I Flow Pattern Correlation, Can. J. Chem. Eng., 52, pp. 2535. 14 Usui, K., Aoki, S., and Inoue, A., 1980, Flow Behavior and Phase Distribution in Two-Phase Flow Through C-Shaped Bend in Vertical Plane, I, J. Nucl. Sci. Technol., 1712, pp. 113. 15 Usui, K., Aoki, S., and Inoue, A., 1983, Flow Behavior and Phase Distribution in Two-Phase Flow Around Inverted U-Bend, J. Nucl. Sci. Technol., 2011, pp. 3346. 16 Gardner, G. C., and Neller, P. H., 19691970, Phase Distributions in Flow of An Air-Water Mixture Round Bends and Past Obstructions at The Wall of A 76-mm Bore Tube, Paper 12 at Symposium on Fluid Mechanics and Measurements in Two- Phase Flow System, Proc. Inst. Mech. Eng., 1843C, pp. 93101.

Journal of Pressure Vessel Technology

MAY 2005, Vol. 127 / 209

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 04/08/2013 Terms of Use: http://asme.org/terms

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Document 1Document1 paginăDocument 1rahuldbajaj2011Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- PUMPS, VALVES & FITTINGS 2015 (Mumbai) - Hydraulics & Pneumatics - Mechanical ComponentsDocument2 paginiPUMPS, VALVES & FITTINGS 2015 (Mumbai) - Hydraulics & Pneumatics - Mechanical Componentsrahuldbajaj2011Încă nu există evaluări

- Print ReceiptDocument1 paginăPrint ReceiptAnonymous 0BYsFuVÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Syllabus Waste Heat Recovery: Classification, Advantages and Applications, CommerciallyDocument18 paginiSyllabus Waste Heat Recovery: Classification, Advantages and Applications, Commerciallyalzewam152100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Prof.: Day Mon Tue Wed Thu Fri Sat TotalDocument1 paginăProf.: Day Mon Tue Wed Thu Fri Sat Totalrahuldbajaj2011Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Pune Uni - Engg.catalouge 150114124058Document9 paginiPune Uni - Engg.catalouge 150114124058rahuldbajaj2011Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- STTP On Industrial Engineering TechniquesDocument2 paginiSTTP On Industrial Engineering Techniquesrahuldbajaj2011Încă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- QualificationDocument1 paginăQualificationrahuldbajaj2011Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Online Prepaid Recharge - Online Recharge - Prepaid Mobile Recharge Online - Tata DOCOMODocument4 paginiOnline Prepaid Recharge - Online Recharge - Prepaid Mobile Recharge Online - Tata DOCOMOrahuldbajaj2011Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Authorization LetterDocument1 paginăAuthorization LetteracaylarveronicayahooÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Yashwantrao Chavan Maharashtra Open University (Ycmou) : Programme StructureDocument3 paginiYashwantrao Chavan Maharashtra Open University (Ycmou) : Programme Structurerahuldbajaj20110% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Salary Request Letter - Sample LettersDocument3 paginiSalary Request Letter - Sample Lettersrahuldbajaj2011Încă nu există evaluări

- Educational Loan Scheme - Term Loan, InterestDocument3 paginiEducational Loan Scheme - Term Loan, Interestrahuldbajaj2011Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Fls Scheme LetterDocument2 paginiFls Scheme Letterrahuldbajaj2011Încă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- PaperDocument1 paginăPaperrahuldbajaj2011Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Resume (M-Tech Hydro Power Engg and BE Mechanical Engg)Document3 paginiResume (M-Tech Hydro Power Engg and BE Mechanical Engg)rahuldbajaj2011Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Adiabatic Two-Phase Frictional Pressure Drops in MicrochannelsDocument13 paginiAdiabatic Two-Phase Frictional Pressure Drops in Microchannelsrahuldbajaj2011Încă nu există evaluări

- Brochure MASUM 2014 1Document2 paginiBrochure MASUM 2014 1rahuldbajaj2011Încă nu există evaluări

- Coep FDP BrochureDocument2 paginiCoep FDP Brochurerahuldbajaj2011Încă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- An Sfile 292Document26 paginiAn Sfile 292rahuldbajaj2011Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

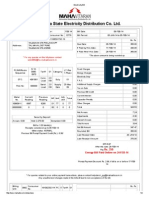

- Electricity BillDocument2 paginiElectricity Billrahuldbajaj2011Încă nu există evaluări

- M.E.Mech. HEAT POWERDocument37 paginiM.E.Mech. HEAT POWERKapil KotangaleÎncă nu există evaluări

- Performance Characteristics of A Pelton TurbineDocument2 paginiPerformance Characteristics of A Pelton Turbinerahuldbajaj2011Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Chervolet Spark: Brio E MTDocument4 paginiChervolet Spark: Brio E MTrahuldbajaj2011Încă nu există evaluări

- Khandelwal Autowheels Pvt. LTD: Tirupati Chambers, Convent Road Akola Akola 4440050724 - 2426373 0724 - 2421681 2420758Document2 paginiKhandelwal Autowheels Pvt. LTD: Tirupati Chambers, Convent Road Akola Akola 4440050724 - 2426373 0724 - 2421681 2420758rahuldbajaj2011Încă nu există evaluări

- Two-Phase Flow Pressure Drop inDocument8 paginiTwo-Phase Flow Pressure Drop inrahuldbajaj2011Încă nu există evaluări

- Flow Characteristics of Water in Straight and SerpentineDocument8 paginiFlow Characteristics of Water in Straight and Serpentinerahuldbajaj2011Încă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Prediction and Simulation of Two-Phase Pressure Drop inDocument8 paginiPrediction and Simulation of Two-Phase Pressure Drop inrahuldbajaj2011Încă nu există evaluări

- How Newtons Cradle WorksDocument3 paginiHow Newtons Cradle WorksIli AtallaÎncă nu există evaluări

- Relativity of Superluminal Observers, Dragan - 2023 - Class. - Quantum - Grav. - 40 - 025013Document16 paginiRelativity of Superluminal Observers, Dragan - 2023 - Class. - Quantum - Grav. - 40 - 025013ADRIAN TURCUÎncă nu există evaluări

- CBSE Class 11 Physics Study Material All ChaptersDocument44 paginiCBSE Class 11 Physics Study Material All Chapterssnehalaya710Încă nu există evaluări

- COSMIC LAWS As Given by Cosmic AwarenessDocument41 paginiCOSMIC LAWS As Given by Cosmic AwarenessImmalightÎncă nu există evaluări

- Linear MomentumDocument4 paginiLinear MomentumJunLi CaiÎncă nu există evaluări

- 2 DCollisions SEDocument7 pagini2 DCollisions SEVijay VishalÎncă nu există evaluări

- ch4 - 1d MomentumDocument8 paginich4 - 1d Momentumapi-301275445Încă nu există evaluări

- Crash Course 12 Hour Session - Part 1, 2 and 5Document131 paginiCrash Course 12 Hour Session - Part 1, 2 and 5Mrs MendezÎncă nu există evaluări

- Reduce XI SyllabusDocument82 paginiReduce XI SyllabusJawwad IqbalÎncă nu există evaluări

- BSC Maths & StatisticsDocument58 paginiBSC Maths & StatisticsAkash MalhotraÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- PHYS 101 - General Physics I Final Exam Solution (17.05.2022)Document5 paginiPHYS 101 - General Physics I Final Exam Solution (17.05.2022)Tuğba AydemirÎncă nu există evaluări

- Bernoulli EquationDocument12 paginiBernoulli EquationMuneeb Imran BhaniaÎncă nu există evaluări

- Video ListDocument94 paginiVideo ListElias Sevenstar100% (3)

- Lab Report About The Conservation of Mechanical EnergyDocument5 paginiLab Report About The Conservation of Mechanical EnergyFer Tamez0% (1)

- Amin N Ed Titanium Alloys Towards Achieving Enhanced Propert PDFDocument238 paginiAmin N Ed Titanium Alloys Towards Achieving Enhanced Propert PDFArkhatNurakhmetovÎncă nu există evaluări

- An Introduction To Flow Acoustics PDFDocument184 paginiAn Introduction To Flow Acoustics PDFMats Åbom0% (1)

- Physical Science 1 1Document58 paginiPhysical Science 1 1Anonymous N0FZEkrSaeÎncă nu există evaluări

- Solid Mechanics: Lecture NotesDocument45 paginiSolid Mechanics: Lecture Notessumith85100% (1)

- Impulse Worksheet and AnswerDocument5 paginiImpulse Worksheet and AnswerdarwishmajidÎncă nu există evaluări

- 11 Exampler PhysicsDocument206 pagini11 Exampler PhysicsOm SharmaÎncă nu există evaluări

- Chapter 12 Study Guide Physical ScienceDocument4 paginiChapter 12 Study Guide Physical Sciencekso20Încă nu există evaluări

- PHYC2121 General Physics 1 PHYSICS EXAM (1stquarter)Document18 paginiPHYC2121 General Physics 1 PHYSICS EXAM (1stquarter)Andrea NombreÎncă nu există evaluări

- Chapter 7 HW Packet: N×s N×sDocument29 paginiChapter 7 HW Packet: N×s N×sYoojin KimÎncă nu există evaluări

- Solutions To Problems in Goldstein, Classical Mechanics, Second EditionDocument18 paginiSolutions To Problems in Goldstein, Classical Mechanics, Second EditiondedrÎncă nu există evaluări

- G8-Week1-2 WorksheetDocument6 paginiG8-Week1-2 WorksheetTeacher MelÎncă nu există evaluări

- Inspire Physics Pacing GuideDocument19 paginiInspire Physics Pacing Guidejsencion977Încă nu există evaluări

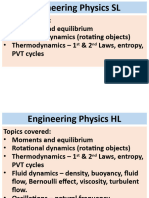

- Engineering PhysicsDocument177 paginiEngineering PhysicsReally RileyÎncă nu există evaluări

- Unit 3 Forensic PhysicsDocument93 paginiUnit 3 Forensic PhysicsJamu PanduÎncă nu există evaluări

- Annotated Physics Data Booklet 2016Document17 paginiAnnotated Physics Data Booklet 2016okiknkjkbiÎncă nu există evaluări

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDe la EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsÎncă nu există evaluări

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDe la EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchEvaluare: 4 din 5 stele4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsDe la EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsEvaluare: 4 din 5 stele4/5 (2)