Documente Academic

Documente Profesional

Documente Cultură

fp50 fp100 fp200

Încărcat de

ducmanh83Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

fp50 fp100 fp200

Încărcat de

ducmanh83Drepturi de autor:

Formate disponibile

R RR R

Reliability and Innovation in directional controlR valves

Solenoid Valve

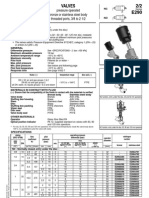

Model FP50, 100 & 200

up to 345 bar, 200 litres per minute

Superior performance throughout the full operational range

Features:

Worldwide solenoid approvals ATEX, CSA, SAA, INMETRO & GOST EExd, EExia and EExemb 316L Stainless steel Arctic Service options to -50oC Solenoid rotates through 360o NACE MR-01-75 option

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

R R R

CONTENTS

ORDERING CODE FLOW PERFORMANCE GRAPH 2/2, 3/2, DV & SV BODY & SUBBASE 4/2 & 4/3 BODY ASSEMBLY (CODE 42 & 43) SOLENOID TABLES LOW, HIGH PRESSURE SOLENOID OPERATORS OPTIONS

Reliability and Innovation in directional control valves

2 3-4 4 5 6 7 8 9

TECHNICAL SPECIFICATIONS AND INSTALLATION REQUIREMENTS

TECHNIC AL SPECIFIC ATIONS TECHNICAL SPECIFICA

MA TERIALS OF CONSTRUC TION MATERIALS CONSTRUCTION

All valve bodies:Internal components:Fasteners:Springs:Seals:stainless steel 316L stainless steel 316L/316, CA104 Aluminium Bronze, Ceramic, stainless steel AISI 440C (according to valve type), PEEK (according to valve type) A4 18/10 316 grade stainless steel Chrome Vanadium Steel SAE 6150, painted and wax coated Nitrile (standard). Alternative elastomers available for extreme conditions

MEDIA:

Mineral oils, water glycol mixtures, sea water (filtered), some chemicals (mainstage & high pressure pilot stages). Air, natural gas, bottled gases (low pressure pilot stages only). Mineral Oils, water glycol mixtures (low pressure pilot stages, solenoid types 87C, 87D, 92 92A only).

WORKING PRES SURE: PRESSURE: Up to 345 Bar. Maximum working pressure varies according to valve model. Refer to ordering code. TEMPERA TURE RANGE: TEMPERATURE

See solenoid and elastomer options. All high pressure, pilot stage solenoid valves, with the exception of type 97D, are limited to -36oC minimum operating temperature on account of restricted flow path and fluid viscsoity considerations:Examples FP50/SH1/M/32/SA-24VDC/97CA9 Operating temperature -36oC to + 40oC FP15/SH1/M/32/SA-24VDC/97CA2 Operating temperature -36oC to + 90oC FP15/SH1/M/32/A-24VDC/97DA4 Operating temperature -50oC to + 55oC

SOUR GAS SERVICE (REFER TO ORDERING CODE):

All internal wetted and body metal materials conforming to NACE MR-01-75. Solenoid options 97D, 87C & 87D only.

LAST CHANCE FIL TRA TION: FILTRA TRATION:

A 40 micron, sintered stainless steel, filter disc is fitted as standard on all high pressure, pilot stage solenoid valve operators

INST ALLA TION REQUIREMENTS INSTALLA ALLATION

345 300 System Pressure (bar) 200 100 0

INST ALLA TION: INSTALLA ALLATION: Valves can be mounted in any attitude. Solenoids can be rotated relative to the pilot stage valve body to suit cable entry. Systems should be flushed clean to ISO 4406 Class 18/15 or better. Bifold Fluidpower FP50/100/200 valves afford excellent sealing characteristics provided high standards of cleanliness are maintained. Where this cannot be assured we recommend the use of valves from the extensive range of Bifold Fluidpower Slide Valves which are . Weights detailed in this catalogue are approximate only more tolerant to fluid borne contaminants.

0.1

0.2

0.3

0.4

IMPORT ANT NO TE: Fluidpower FP50, 100 & 200 IMPORTANT NOTE: Series valves have an open centre change over. This means that whilst the valve is changing position, fluid will flow from the pressure supply to the return/tank port. The volume of fluid lost will depend on the system pressure and valve response time. See curves for typical valve response.

Fluid Loss (litres)

Graph illustrating typical fluid loss on SLx operators

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

R RR R

SELEC TION CHART SELECTION

FP50 FP100 FP200 50 lpm 100 lpm 200 lpm

Reliability and Innovation in directional control valves

Model Code & nominal flow rating Pilot Pressure Range - bar X 0 0A 1 1A 2 2A 3 3A 4 1 FP50 30-60 45-85 60-120 75-150 120-250 145-290 170-345 240-490 300-610 4.5 - 8.5 FP100/200 32-70 43-115 60-138 80-170 110-235 130-280 150-345 190-415 235-520 4.5 - 8.5 Connections Max working pressure - bar FP50 345 FP100/200 250 207 (-30 C (-20oC (-50oC (-46oC

o

SH X Solenoid valve operator (two stage) Refer to pilot pressure ranges

Standard operators (Other pressure ranges on request)

SL X X M

Subbase mounting - 32, DV & SV valves. Subbases ordered seperately. See page 5.

08 1/2 NPT ported subbase assembly 12 3/4 NPT ported subbase assembly (FP 100/200 only) 32 42 43 DV SV 3 - way, 2 - position 4 - way, 2 - position 4 - way, 3 - position Diverter Valve Selecter Valve S V A SA Nitrile (standard) Viton Silicone/Fluorosilicone Low temperature Nitrile XXX XXX A G I S U A A G A A 1 2 3 4 5 6 7 8 9 to to to to +130 C) +180oC) +40oC) +130oC)

o

Configuration

Refer to valve operating temperature range on page 2

O-ring material Voltage Solenoid

(refer to solenoid options on page 7) (refer to solenoid options on page 7) ATEX Ex II 2 GD (standard) GOST 1 Exd IIC T6 (T5,T4) INMETRO Br-Exd IIC T6 (T5) SAA Exd IIC T6 (T5,T4) CSA Exd IIC (Canada) CSA AExd IIC (USA) ATEX Ex II 1 GD T75oC (T110oC) ATEX Ex II 1 GD T65oC GOST 0 Exia IIC T6 ATEX Ex II 2 GDc T120oC ATEX Ex II 2 G T4 IIA T4 IIB T4 IIC T5 IIA T5 IIB T5 IIC T6 IIA T6 IIB T6 IIC H2S K6 K85 ML M MOR WS (standard) (standard) 87C, 87D, 97C, 97D, 97F, 97G, 87C, 87D 98C 981 94C 991

87C, 87D, 97C, 97D, 97F, 97G, As above +98C 87C, 87D, 97C, 97D, 97F, 97G, As above +98C

Solenoid Approvals

T-Rating & Gas Group

NACE MR-01-75 - (solenoid options 97D, 87C & 87D only) BSPP Ported 1/2 NPT cable entry Manual reset Solenoid operators Manual override spring return SHX only Manual override rotary stayput Weather seal solenoid core tube (90J only)

Options

FP50/ SH1/ M / 32 / S -24VDC/97C

Standard Test Fluid: Marston Bentley HW540.

9 / ML

Ordering Example

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

R R R

Reliability and Innovation in directional control valves TW O ST AGE V AL VE INST ALLA TION TWO STA VAL ALVE INSTALLA ALLATION

3/2 Valves

Series

Option 2

mounted valves

Option 1 Supply Return Pilot return must be tubed downstream of any mainline restrictions or direct to resevoir for SV and DV configurations

Valve Limits

In some situations due to cross flow leakage the system pressure local to the valve may fall below the required minimum operating pressure. This will result in the mainstage valve stalling in the mid position. To eliminate the possibility of this problem occuring we offer three alternative solutions. OPTION 1. Install a variable orifice in the supply line e: This should be down stream of the pilot take-off. Not Note: sized and set to maintain sufficient pilot pressure when the valve changes position. OPTION 2. Install an accumulator and non-return valve. This option must be applied when an accumulated supply is not used. (Preferred option) OPTION 3. Connect the pilot supply to a point in the system which is not influenced by the operation of the control valve.

NO TES:NOTES:For 4 way, 2 position two stage valves, the above 3/2 installation requirements apply. For 4 way, 3 position two stage valves, refer to series mounted valve installation details. At no time during operation of the valve to the piloted position should the supply pressure be allowed to fall below the minimum pilot pressure quoted for the operator fitted. Refer to ordering code, operator SHX.

FL OW PERF ORMANCE FLO PERFORMANCE

15

FP50 1/2 SUBBASE FP100 1/2 SUBBASE FP100 3/4 SUBBASE FP200 3/4 SUBBASE

10

p(bar)

5

10 20 230

30

40

50

60

70

80

90

100 110 120 130 140 150 160 170 180 190 200 210 220

Flow Rate (lpm)

Test fluid mineral oil @ 40 to 46 cSt

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

R RR R

2/2, 3/2, D V & SV Body & Subbase DV

Reliability and Innovation in directional control valves

MODEL

FP50 FP100/200

c1

41 70

c2

35 38

c3

35 45

c4

60 94

h1

82.6 101.6

h2

31.8 38.1

h3

16.5 17.5

h4

22 28

l1

124 183

l2

127.1 178.5

l3

76.2 110

w1

50.8 63.5

w2

60 63.5

w3

45 48.5

MODEL

FP50 FP100/200

Size

M6 X 50 M8 x 70

Valve Fixings Torque (Nm)

7.3 17.7

O-ring Engagement

10 13 BS0101-16 BS0191-16

Mounting holes

M6 x 1.0p x 10DP M8 x 1.25p x 10DP

Weight (kg)

2.0 4.65

ALL DIMENSIONS IN MILLIMETRES

FP50 (Singl e St ation Manif old) (Single Station Manifold)

Code P orting Porting W eight Weight

FP100 & 200 (Singl e St ation Manif old) (Single Station Manifold)

Code P orting Porting W eight Weight

2 Way

M164/02 M159/02 M165/02 M160/02

3 Way

M162/02 M147/02 M163/02 M158/02 3/8 NPT 1/2 NPT 3/8 BSPP 1/2 BSPP

kg

1.0 1.0 1.0 1.0

2 Way

M143/02 M157/02 M156/02 M155/02

3 Way

M141/02 M140/02 M152/02 M154/02 1/2 NPT 3/4 NPT 1/2 BSPP 3/4 BSPP

kg

2.0 2.0 2.0 2.0

For special multipurpose subbases consult Fluidpower

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

R R R

Reliability and Innovation in directional control valves 4/2 Body Assemby (Code 42) direct acting operators

l5

l2

h1 h2

FIXING HOLES IN 2 PLACES ON OPPOSITE SIDE

OPERATOR DATUM

h3

w2

w2

S1 & S2

w4

P

w3

S1

w1

S2 FIXINGS M8 x 15 DP M8 x 15 DP M10 x 15 DP M10 x 15 DP

OPERATOR DATUM

T P

l4

l3 l1 4/2 ASSEMBLY DIRECT ACTING 4/2 ASSEMBLY DIRECT OPERATORS ACTING OPERATORS FOR TWO STAGE OPERATORS

EQUIPMENT LIMITS

MODEL FP50 FP50 FP100/200 FP100/200

OPERA TOR OPERAT HX L1 & SL1 HX L1 & SL1

h1 89 89 100 100

h2 38 38 36 36

h3 17 17 18 18

l1 155 180 175 199

l2 105 130 135 159

l3 55 80 66 90

l4 50 50 54.5 54.5

l5 25 25 20 20

w1 76.2 76.2 110 110

w2 20.5 20.5 35 35

w3 124 124 183 183

w4 127 127 178.5 178.5

CONNEC TIONS CONNECTIONS 1/2 1/2 1/2 OR 3/4 1/2 OR 3/4

WEIGHT k g kg 7.5 8.1 14.7 15.4

OPERATOR WEIGHT NOT INCLUDED

4/3 Body Assemby (Code 43) direct acting operators

15 12 h1 h2 h3

w2

w2

w3

w4

w1

S1

S1 & S2

S2

123 112312 12

T P

l4

l3 l1

4/3 ASSEMBLY DIRECT ACTING OPERATORS FOR TWO STAGE OPERATORS CONSULT FLUIDPOWER

EQUIPMENT LIMITS EQUIPMENT LIMITS

MODEL FP50 FP50 FP50 FP100/200 FP100/200 FP100/200

OPERA TOR OPERAT HX L1 & SL1 SHX HX L1 & SL1 SHX

h1 89 89 89 100 100 100

h2 38 38 38 36 36 36

h3 17 17 17 18 18 18

l1 155 180 210 175 229 219

l2 105 130 160 135 189 179

l3 55 80 110 66 120 110

l4 50 50 50 54.5 54.5 54.5

l5 25 25 25 20 20 20

w1 76.2 76.2 76.2 110 110 110

w2 20.5 20.5 20.5 35 35 35

w3 124 124 124 183 183 183

w4 127 127 127 178.5 178.5 178.5

CONNEC TIONS CONNECTIONS 1/2 1/2 1/2 1/2 OR 3/4 1/2 OR 3/4 1/2 OR 3/4

WEIGHT k g kg 7.5 8.1 9.0 14.7 16.3 16.0

FIXINGS M8 x 15 DP M8 x 15 DP M8 x 15 DP M10 x 15 DP M10 x 15 DP M10 x 15 DP

OPERATOR WEIGHT NOT INCLUDED

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

R RR R

SOLENOID OPTIONS

HIGH PRESSURE PILOT STAGE SOLENOID VALVES

Order Code Apparatus Code Power Consumption Standard Voltage Voltage Tolerance

Reliability and Innovation in directional control valves

Temperature Range* Media Ambient Protection Cable Connection Materials of Construction Glass filled

90J

General Purpose

3 Watts

-20oC to +60oC

IP65 applies to connector

Hirschmann Connector

nylon moulded coil

94C 97C (std) 97F 97G 97D 98C

EExemb II T3 T120 C

o

3.7 Watts 3 Watts 1.5 Watts 1.0 Watt 5.7 Watts

12, 24, 48 & 110 VDC 110, 240 VAC 50 or 60 Hz + / - 10 %

-20oC to +40oC -20oC to +40oC (T6) (std) -60oC to +40oC (T6) -20oC to +55oC (T5) -60oC to +55oC (T5) -20oC to +90oC (T4) -60oC to +90oC (T4) -20oC to +60oC (T6) (std) -60oC to +60oC (T6) -20oC to +95oC (T4) -60oC to +95oC (T4)

*Refer to operating temperature range on page 2

EExd IIC T85 or T100 or T135

IP66

M20 x1.5

316 stainless steel

EExia IIC T6 or T4

refer to solenoid drivers table on the next page

UL / CSA approved solenoids available upon request. Consult Bifold Fluidpower for details

LOW PRESSURE PILOT STAGE SOLENOID VALVES

Order Code Apparatus Code Power Consumption Standard Voltage Voltage Tolerance Temperature Range Media Ambient Protection Cable Connection Materials of Construction

24VDC System, 12VDC @ solenoid 981 EExia IIC T6 370 OHMS (Typical barrier MTL728) 12, 24, 110 VDC 991 EExme II T3 5.7 Watts 110, 240 VAC 50 or 60 Hz -20oC to +40oC (T6) (std) -60oC to +40oC (T6) 87C 87D EExd IIC T85 or T100 or T135 92 92A Class I Div1 Gp C&D Class I Div2 Gp A&B Class II Div1 Gp E,F,G 5.6 - 7.2 Watts +/- 10% -20oC to +60oC NEMA 4, 4X 1/2 NPT Nickel plated steel enc. 3.5 Watts 5.7 Watts 24, 110 VDC 110, 240 VAC 50 or 60 Hz +/- 10% -20oC to +55oC (T5) -60oC to +55oC (T5) -20oC to +90oC (T4) -60oC to +90oC (T4) 316 stainless steel +10% / -15% -209C to +40oC IP66 M20 x 1.5 316 stainless steel -20oC to +40oC

INTRINSICALLY SAFE SOLENOID DRIVERS * (solenoid type 98C)

Interface Unit Manufacturer & Model Number Apparatus Code Solenoid Base model no. 24VDC/98C MTL 779+ EExia IIB & 24VDC/A98C TURCK MK72S13-Ex0 PEPERL & FUCHS KFD2-SD-Exl.36 ELCON HiD 2881-YA1 STAHL 9351/10/14/10 24VDC/98C EExia IIC & 24VDC/A98C 24VDC/98C EExia IIB & 24VDC/A98C 24VDC/98C EExia IIB EExia EExib IIB & IIC

CONSULT MANUFACTURER

Interface Unit Typical Input Characteristics Voltage (V) 28 24 20 30 24 20 30.0 24.0 20.0 28.0 24.0 21.0 30.0 24.0 20.0 Current (mA) 85.9 73.7 61.4 88 107 125 85.5 105.1 125.4 98.6 96 83.4 89.8 115.6 149.6 Power (W) 2.41 1.77 1.23 2.63 2.56 2.50 2.57 2.52 2.51 2.76 2.30 1.75 2.69 2.77 2.99 11.71 11.45 10.00 12.26 12.18 12.08 11.81 11.81 Voltage (V) 13.48 11.57 9.65

Typical Output Characteristics Measured At Solenoid Current (mA) 85.9 73.7 61.4 74.3 Power (W) 1.16 0.85 0.59 0.86

76.0 77.5 76.0 66.3 80.6 80.0 79.3

0.90 0.91 0.87 0.66 0.99 0.97 0.96

& 24VDC/A98C 24VDC/98C & 24VDC/A98C

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

* The solenoid drivers detailed are suggested models only and do not constitute an approved I.S. system. Consult Bifold Fluidpower proir to using alternative drivers.

R R R

Reliability and Innovation in directional control valves

High Pressure Pilot Stage Solenoid Valves

Solenoid EExd (97C,97F,97G), EExia (98C) and EExemb (94C)

203.0 FP50 IIA a b c d e f g 138 154 24.5 68.6 89.8 65.1 104 IIB 144.4 160.4 24.5 68.6 89.8 65.1 110.4 IIC 157 173 24.5 68.6 89.8 65.1 123 IIA 148 164 27.5 74.1 92.8 78.8 114 FP100/200 Gas Group IIB 167 183 IIC 176.3 192.3

M20 x 1.5 Cable Entry

27.5 27.5 74.1 74.1 92.8 92.8 78.8 78.8 133 142.3

AC

a g f

DC

31.5

CONNECTOR UNMARKED CONNECTOR UNMARKED

d e

Example code :- FP50/SH1/M/32/S-24VDC/97CA9

Low Pressure Pilot Stage Solenoid Valve Operators

Codes EExia (981) & EExme (991) - Pneumatic Pilot Only

155 DIMENSION DATUM

110

PLV VALVE CENTRE LINE

31

PL

M20 x 1.5 cable entry

CONNECTIONS:

PL - PILOT SUPLLY CONNECTION 1/8 NPT PLV - PILOT VENT CONNECTION 1/8 NPT

WEIGHT 2.2 Kg

For operating parameters and associated pilot operator dimensions, refer to option L1 (See page 7)

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

R RR R

Reliability and Innovation in directional control valves Codes 97D, (EExd)

192.5 65.3 102.4 16.5 86.5

2

224.2 193.4 38.1

M20 x 1.5 Cable Entry

1

41.0

3

17.6

PL

20.2 33.0

T1

84.2

31.1

Example code :- FP50/SH1/M/32/S-24VDC/97DA9

Manifold Options

Bifold Fluidpower has the technical capability to manifold many circuit requirements.

Reduced leak paths - eliminate fittings Simple maintenance Integral check valves, gauge port, needle valves - reduce system cost Manifold assembly fully tested 3D model drawings available to incorporate into customer circuits

Contact Bifold Fluidpower with circuit requirements.

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

Model Shown is a 3 station FP15 with 97C solenoid

R R R

Reliability and Innovation in directional control valves

UK Office

Greenside Way, Middleton, Manchester, M24 1SW Tel:+44 (0)161 345 4777 Fax:+44 (0)161 345 4780 EMail:sales@bifold-fluidpower.co.uk Web:www.bifold-fluidpower.co.uk

USA Office

11490 Westheimer, Suite 900, Houston, Texas , 77077 Tel:+1 713 783 4253 Fax:+1 713 783 0067 Email:sales@bifold-fluidpower.com Web:www.bifold-fluidpower.com

UK Office Asia Pacific Office Manchester, M24 1SW Greenside Way, Middleton,

424 Balestier+44 Road #02-08, Tel:(0)161 345 Giffard 4777 Mansion, Singapore 329810 Tel:+65 (0)161 6735 1323 Fax:+44 345 4780 Fax:+65 6735 1367 EMail:sales@bifold-fluidpower.co.uk EMail:bifold@singnet.com.sg Web:www.bifold-fluidpower.co.uk Web:www.bifold-fluidpower.co.uk

11490 Westheimer, Suite 900, Houston, Texas, 77077 Tel:+1 713 783 4253 Quality Assurance Fax:+1 713 783 0067 All Bifold Fluidpower products are manufactured to a most stringent QA programme. Every care is taken at all stages Email:sales@bifold-fluidpower.com of manufacture to ensure that every product will give optimum performance and reliability. We are recognised to EN Web:www.bifold-fluidpower.com

ISO 9001:2000. Functional test certificate, letter of conformity and copies of original mill certificates, providing total traceability are available on request, to BSEN 10204 3.1.B where available. The manufacturer reserves the right to make changes to the specifications and design etc., without prior notice

USA Office

Asia Pacific Office

360 Orchard Road, #10-02 International Building, Singapore 238869 We take care to ensure that product information in this catalogue is reasonably accurate and up-to-date. However, Tel:+65 6735 1323 our products and services are continually updated so to ensure accurate and up-to-date information please refer to Fax:+65 6735 1367 the issue list on the web site or contact a member of our sales team. EMail:bifold@singnet.com.sg Web:www.bifold-fluidpower.co.uk

FP50/100/200 Solenoids - Issue 4 - 23/02/05 Bifold Fluidpower Limited Middleton, Manchester, UK. tel:- +44(0)161 345 4777 fax:- +44(0)161 345 4780 sales@bifold-fluidpower.co.uk www.bifold-fluidpower.co.uk

Accuracy of information

Bifold Fluidpower Ltd 2005

10

S-ar putea să vă placă și

- Slide Valve SV and SV1 Series (U)Document9 paginiSlide Valve SV and SV1 Series (U)Enis LoureiroÎncă nu există evaluări

- 2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StyleDocument2 pagini2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StylemaarwaanÎncă nu există evaluări

- Walvoil Cartridge Ventielen HICDocument20 paginiWalvoil Cartridge Ventielen HICddÎncă nu există evaluări

- SM TM 1.5-4 Guardsman (G) Series02002Document4 paginiSM TM 1.5-4 Guardsman (G) Series02002Paola Arevalo RinconÎncă nu există evaluări

- HR E576qDocument12 paginiHR E576qIsanka SathsaraneeÎncă nu există evaluări

- Check ValvesDocument8 paginiCheck ValvesNilesh MistryÎncă nu există evaluări

- Vickers DG4V-3 DG4V-3S 6xDocument32 paginiVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroÎncă nu există evaluări

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 paginiValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuÎncă nu există evaluări

- HYD. PumpDocument40 paginiHYD. Pumprohitbhat2345Încă nu există evaluări

- About Axial Displacement Pump A4VSoDocument68 paginiAbout Axial Displacement Pump A4VSomrkadu_61Încă nu există evaluări

- Carrrier Manual 38ckc-c5pdDocument20 paginiCarrrier Manual 38ckc-c5pdAaron LeveyÎncă nu există evaluări

- 520 - MPC Plate Chiller BulletinDocument4 pagini520 - MPC Plate Chiller BulletinThanh Van LeÎncă nu există evaluări

- Optimex Prei RangeDocument12 paginiOptimex Prei RangeThomas DamonÎncă nu există evaluări

- Ael6 PDFDocument9 paginiAel6 PDFCarlos Rafael Pereyra SegoviaÎncă nu există evaluări

- DeaeratorDocument8 paginiDeaeratorfjoesandiÎncă nu există evaluări

- Relay AP Suat DanfossDocument16 paginiRelay AP Suat DanfossVo Ngoc DucÎncă nu există evaluări

- Valve and Actuator CatalogueDocument60 paginiValve and Actuator Catalogueashfaq-matte-79930% (1)

- GVO SeriesDocument20 paginiGVO SeriesHamed GeramiÎncă nu există evaluări

- Grundfos MTS Screw Spindle PumpDocument68 paginiGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Buchholz RelayDocument18 paginiBuchholz RelaysvismaelÎncă nu există evaluări

- Fluid Components Full CatalogDocument464 paginiFluid Components Full Catalognegg 348Încă nu există evaluări

- SUNTEC Pompa AL Fisa-TehnicaDocument2 paginiSUNTEC Pompa AL Fisa-TehnicaStroia Constantin MariusÎncă nu există evaluări

- Carrier38CKC 50HzDocument20 paginiCarrier38CKC 50HzAaron LeveyÎncă nu există evaluări

- E Smartlink MRV M Specs InstructionsDocument84 paginiE Smartlink MRV M Specs InstructionsAnthonyÎncă nu există evaluări

- Bom A4VG - REXROTHDocument44 paginiBom A4VG - REXROTHnamduong368100% (4)

- H25 Incremental EncoderDocument4 paginiH25 Incremental EncoderEdgar AllamÎncă nu există evaluări

- SDM 102 eDocument24 paginiSDM 102 eseaqu3stÎncă nu există evaluări

- Buchholz Relays PRINCIPLESDocument9 paginiBuchholz Relays PRINCIPLESBui VanluongÎncă nu există evaluări

- HVAC+Valves+and+Actuators+Catalogue+07 2011Document64 paginiHVAC+Valves+and+Actuators+Catalogue+07 2011Jafar JalladÎncă nu există evaluări

- ALISON HIDRAULIC - Catalogue PDFDocument250 paginiALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- SDM140EDocument36 paginiSDM140Eseaqu3stÎncă nu există evaluări

- Solenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06Document4 paginiSolenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06RFIGUEROACÎncă nu există evaluări

- Electro ValvulasDocument89 paginiElectro ValvulasJuan Domingo OrlandiniÎncă nu există evaluări

- Expansion Valve Emerson AlcoDocument4 paginiExpansion Valve Emerson AlcoCoolequipment Cee100% (1)

- Traxoil OM3 - OM4Document5 paginiTraxoil OM3 - OM4IonutCiobanuÎncă nu există evaluări

- Series D1VW Characteristics: Directional Control ValveDocument9 paginiSeries D1VW Characteristics: Directional Control ValvejuanÎncă nu există evaluări

- Elec Grs Pumps 203seriesDocument5 paginiElec Grs Pumps 203serieschand_yelÎncă nu există evaluări

- Features: How To Order (AOC-08 Models Only)Document4 paginiFeatures: How To Order (AOC-08 Models Only)CarmenLinoBedoyaÎncă nu există evaluări

- Series R5U Characteristics: Pilot Operated Pressure Unloading ValveDocument5 paginiSeries R5U Characteristics: Pilot Operated Pressure Unloading ValveHarinderÎncă nu există evaluări

- Catálogo General de McdonellsDocument139 paginiCatálogo General de McdonellsJuan Carlos Palomino JesusiÎncă nu există evaluări

- Catalogo General McdonellmillerDocument141 paginiCatalogo General McdonellmillerJesus CovarrubiasÎncă nu există evaluări

- Reg RedQ Specialy Regulators PDFDocument20 paginiReg RedQ Specialy Regulators PDFDavid SaldarriagaÎncă nu există evaluări

- Solenoid Select ChartDocument47 paginiSolenoid Select Chartسامح الجاسمÎncă nu există evaluări

- Catalogo ASCODocument4 paginiCatalogo ASCOIkaro MatosÎncă nu există evaluări

- Model 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentDocument4 paginiModel 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentMohd HassanudinÎncă nu există evaluări

- Valves ActuatorsCAT0408Document60 paginiValves ActuatorsCAT0408Rami ReddyÎncă nu există evaluări

- Axial Piston Pump CatalougeDocument36 paginiAxial Piston Pump Catalougemrkadu_61Încă nu există evaluări

- 38CKC Product DataDocument26 pagini38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- Model 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesDocument4 paginiModel 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesFaull JackmanÎncă nu există evaluări

- Valvulas SporlanDocument24 paginiValvulas SporlanCesar VillarÎncă nu există evaluări

- Yukenmodularvalves Yuken CatDocument140 paginiYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- 'C' Series Control ValvesDocument12 pagini'C' Series Control Valvesابزار دقیق100% (1)

- SD 25 eDocument20 paginiSD 25 eseaqu3stÎncă nu există evaluări

- Electrical Tech SpecificationDocument62 paginiElectrical Tech SpecificationNipun KohliÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe la EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGÎncă nu există evaluări

- RE14092021Document2 paginiRE14092021francis puthuserilÎncă nu există evaluări

- Design and Analysis of Piping System With Supports Using CAESAR IIDocument5 paginiDesign and Analysis of Piping System With Supports Using CAESAR IIangelufc99Încă nu există evaluări

- Find Serial Number of Computer in Windows 10Document2 paginiFind Serial Number of Computer in Windows 10GabbarÎncă nu există evaluări

- Ohm's Law and Kirchhoff's LawsDocument22 paginiOhm's Law and Kirchhoff's LawsTiarra MojelÎncă nu există evaluări

- Projects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationDocument2 paginiProjects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationAjay DuranÎncă nu există evaluări

- Classification Matter Flow ChartDocument1 paginăClassification Matter Flow ChartKiera CeelyÎncă nu există evaluări

- Chapter 10 ExamDocument10 paginiChapter 10 ExamOngHongTeckÎncă nu există evaluări

- Chemical BondingDocument27 paginiChemical BondingSachin Kumar50% (2)

- Pacom S72724+PDR32-RMT-HYB+ManualDocument130 paginiPacom S72724+PDR32-RMT-HYB+ManualDavidChisholmÎncă nu există evaluări

- Sony Cdx-G3100ue G3100uv G3150up G3150uv Ver.1.1 PDFDocument38 paginiSony Cdx-G3100ue G3100uv G3150up G3150uv Ver.1.1 PDFLisandroPeñateÎncă nu există evaluări

- E2186 Certif Conformidad - TomasDocument6 paginiE2186 Certif Conformidad - TomasFRANCISCOÎncă nu există evaluări

- Fiber Optic CablesDocument24 paginiFiber Optic CablesARCC2030Încă nu există evaluări

- HTML Meta TagsDocument4 paginiHTML Meta Tagsmamcapiral25Încă nu există evaluări

- HPSIM Command Line InterfaceDocument107 paginiHPSIM Command Line Interfacegverma80Încă nu există evaluări

- Lysaght SmartrussDocument2 paginiLysaght Smartrussiker880% (1)

- Delphi Informant Magazine Issue 3 Volume 6 2000Document36 paginiDelphi Informant Magazine Issue 3 Volume 6 2000Raimo JankaÎncă nu există evaluări

- Info - Iec61340-5-1 (Ed2 0 RLV) enDocument23 paginiInfo - Iec61340-5-1 (Ed2 0 RLV) enArhamÎncă nu există evaluări

- Argus Dual System Pi enDocument2 paginiArgus Dual System Pi enfahmi1987Încă nu există evaluări

- Propeller (PRELIMS LESSON)Document34 paginiPropeller (PRELIMS LESSON)Aidrian AidÎncă nu există evaluări

- Carbon Regeneration KilnsDocument3 paginiCarbon Regeneration KilnsLuis LabradorÎncă nu există evaluări

- Maps and Damos ID For EDC16 VAG ECUDocument7 paginiMaps and Damos ID For EDC16 VAG ECUGuler RahimÎncă nu există evaluări

- 5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop SchematicsDocument46 pagini5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop Schematicsamier jrs100% (1)

- Drag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Document2 paginiDrag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Arthur Saw Sher-QenÎncă nu există evaluări

- Wave Load Calculation in Transitional Water (Prototype)Document1 paginăWave Load Calculation in Transitional Water (Prototype)pradewoÎncă nu există evaluări

- HexWorks ManualDocument162 paginiHexWorks ManualIguodala OwieÎncă nu există evaluări

- SDFC AdminDocument8 paginiSDFC AdminYashpal SinghÎncă nu există evaluări

- Base Plate and Anchor Rod DesignDocument2 paginiBase Plate and Anchor Rod DesignKannan MurugesanÎncă nu există evaluări

- Spring Support Used in PipingDocument7 paginiSpring Support Used in Pipingashish.mathur1Încă nu există evaluări

- Reinforced Concrete Design BS 8110Document15 paginiReinforced Concrete Design BS 8110Kutty Mansoor75% (4)