Documente Academic

Documente Profesional

Documente Cultură

Axle Type & Sub Type Major Sub Assly & Lowe Level Parts

Încărcat de

Amit GosaviDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Axle Type & Sub Type Major Sub Assly & Lowe Level Parts

Încărcat de

Amit GosaviDrepturi de autor:

Formate disponibile

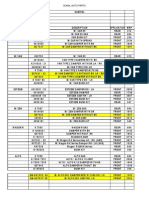

Axle Type & Sub Type Major Sub assly & lowe level parts Front Axle Salisbury

Center section Carrier

Ring Gear & Pinion Shim / Threaded adjuster Diffcase Assly (STD) Diffcase Side Gear Pinion met Diff Shaft Thrust Washer Diffcase Assly (TL) Clutch Pack Companion Flange assly Companion Flange Or Yoke Deflector Oil Seal Head & Tail Bearing Collapsible spacer Bearing Cap Diff Bearing Cover Assly Cover Plate Tube Assly Tube Yoke Brackets Shaft & joint assly (Cardan Joint) Or CVJ shaft Hub & Rotor assly Hub Rotor Brake Dust cover & Calliper Hub o Knuckle Brake assly Bush (Ball & Socket) Cam Shell (Independent) Center section

CV shaft Shaft assly Front axle disconnect ABS 4 Channel or 3 Channel Tonner ring Sensor Oil Volume Rear Axle Banjo Full Float

Semi Float Shaft assly Bearing Retainer plate Wedding ring Tone wheel

Salisbury Tube Assly Tube Brake mounting flange Brackets Spindle (Incase of full float)

Cam Shell (Independent)

Tandum

Other

Panhard rod / Track bar

Watt's linkage

Jaunce pad / Bump stop

Control arm brackets

Shock absorber bracket

Traction bar

Spring seat

trailing-arm suspension

Part description / Function / Working

Wall Thickness Min clearance with respect to moving parts & Fix parts Bearing Cap Mounting Trunion:Back lash, Contact pattern Above center design Threaded adjuster needs retainer clip to hold during driving

In case of TL type diffcase side gear hub has additional external spline to guide Clutch plate Has sperical back face

Oil seal types - Radial, axial Helicle ribs on seal Bearing backup & Bearing width are the imp dimensions

1) It has Stearing arm, King pin arm with bushing hole 1) Brake caliper & Dust cover is mounted on yoke

Two bearings mounted on spindle, No shaft assly

Unit bearing :- Tapper roller bearing with wedding ring On shaft bearing :- Cylindrical roller with C lock at side gear end

Dust cover & Brake assly mounted on it

is a component of a car suspension system that provides lateral location of the axle.[1] Originally invented by the Panhard automobile company of France in the early twentieth century, this device has been widely used ever since. While the purpose of the suspension of an automobile is to allow the wheels to move vertically with respect to the body, it is undesirable to allow them to move forward and backwards (longitudinally), or side to side (laterally). The Panhard rod is designed to prevent lateral movement This does not effectively locate the axle longitudinally, therefore it is usually used in conjunction with trailing arms which stabilize the axle in the longitudinal direction. This arrangement is not usually used with a leaf spring suspension, where the springs themselves supply enough lateral rigidity, but only with coil spring suspensions. The advantage of the Panhard rod is its simplicity. Its major disadvantage is that the axle must necessarily move in an arc relative to the body, with the radius equal to the length of the Panhard rod. If the rod is too short, there will be excessive sideways movement between the axle and the body at the ends of the spring travel. Therefore, the Panhard rod is less desirable on smaller cars than larger ones. A suspension design that is similar but used in automobile suspensions, allowing the axle of a vehicle to travel vertically while preventing sideways motion

Types of suspension

Instead of allowing the metal components of the suspension to hit the frame or body of the vehicle, a rubber or foam bumper is used to absorb and isolate the suspension from the frame or body. These bumpers are called bump stops, suspension bumpers, strike-out bumpers, or jounce bumpers. Jounce means jolt.

Traction bars were created to cancel the effects of axle wrap. Axle wrap can happen to leaf springs under hard acceleration. (When you drop the hammer...) The torque from the rear axle can try to twist the leaf spring into an 'S' shape. As the spring snaps back, it can cause wheel hop. One way to fix this is to use traction or 'slapper' bars. Another method is to use the 'Caltrac' style traction bars.

A trailing-arm suspension, sometimes referred as trailing-link is an automobile suspension design in which one or more arms (or "links") are connected between (and perpendicular to and forward of) the axle and the chassis. It is usually used on rear axles. A "leading arm", as used on aCitron 2CV, has an arm connected between (and perpendicular to, and to the rear of) the axle and the chassis. It is used on the front axle.

Trailing-arm designs in live axle setups often use just two or three links and a Panhard rod to locate the wheel laterally. A trailing arm design can also be used in an independent suspension arrangement. Each wheel hub is located only by a large, roughly triangular arm that pivots at one point, ahead of the wheel. Seen from the side, this arm is roughly parallel to the ground, with the angle changing based on road irregularities. A twist-beam rear suspension is very similar except that the arms are connected by a beam, used to locate the wheels and which twists and has an anti-roll effect. A semi-trailing arm suspension is a supple independent rear suspension system for automobiles where each wheel hub is located only by a large, roughly triangular arm that pivots at two points. Viewed from the top, the line formed by the two pivots is somewhere between parallel and perpendicularto the car's longitudinal axis; it is generally parallel to the ground. Trailing-arm and multilink suspension designs are much more commonly used for the rear wheels of a vehicle where they can allow for a flatter floor and more cargo room. Many small, front-wheel drive vehicles feature a MacPherson strutfront suspension and trailing-arm rear axle.

Query

REF PN

How to design oil Gallery

Drive Direction ? Hands of Sprial ? Study pinion spline design

Study EWO - 51375 What is torque to rotate? PTTR / PTR Study Spline design

What is significance of bearing preload ?

Semi-trailing arm suspension

Trailing arm rear suspension of FF cars

S-ar putea să vă placă și

- Big Export Price List 250504Document27 paginiBig Export Price List 250504Risto GeorgievÎncă nu există evaluări

- Indian CarDocument48 paginiIndian Carprashant pandeyÎncă nu există evaluări

- LeafletFayat2012EN PDFDocument32 paginiLeafletFayat2012EN PDFOlivier BariauÎncă nu există evaluări

- IATCO Catalog 07.2020Document24 paginiIATCO Catalog 07.2020Edwin KaNaÎncă nu există evaluări

- SWAG Catalogue Axle Steering BootsDocument238 paginiSWAG Catalogue Axle Steering BootsautoindustriesÎncă nu există evaluări

- Zhejiang Shifeng Machinery Co - LTD: Jinyun Industrial Park Jinyun, Zhejiang, P.R China FEX:+86-578-3218664Document1 paginăZhejiang Shifeng Machinery Co - LTD: Jinyun Industrial Park Jinyun, Zhejiang, P.R China FEX:+86-578-3218664shovaghoÎncă nu există evaluări

- Nissan Oil SealDocument133 paginiNissan Oil SealEvaristus ChukwukaÎncă nu există evaluări

- 2017 Purolator ListDocument9 pagini2017 Purolator ListNishant Sanghvi100% (4)

- Quick-Brake Catalogue 2010 2011Document325 paginiQuick-Brake Catalogue 2010 2011efgie100% (1)

- بضاعة صينية تويوتا EEBDocument55 paginiبضاعة صينية تويوتا EEBصلاح القدسيÎncă nu există evaluări

- Truck LightsDocument79 paginiTruck LightsarchychenÎncă nu există evaluări

- Automatic Transmission ProductsDocument108 paginiAutomatic Transmission ProductswaggcasÎncă nu există evaluări

- Water Pump Quotation From Cinaautoparts 2020.11.09 Email Cinaautoparts@Document6 paginiWater Pump Quotation From Cinaautoparts 2020.11.09 Email Cinaautoparts@Wang KathyÎncă nu există evaluări

- Ring Detail PriceDocument37 paginiRing Detail PriceKrishnanÎncă nu există evaluări

- Price List: Periodic Maintenance Charges - Honda CarsDocument1 paginăPrice List: Periodic Maintenance Charges - Honda CarsUtpal MondalÎncă nu există evaluări

- Corteco Cross Reference Nrs 201511 - Cassette - BrochureDocument7 paginiCorteco Cross Reference Nrs 201511 - Cassette - BrochureBOCHORIDISMEUROPARTSÎncă nu există evaluări

- Price List: CV Joint W/KitDocument2 paginiPrice List: CV Joint W/Kitandrew candraÎncă nu există evaluări

- Price List Mercedes BenzDocument1 paginăPrice List Mercedes BenzBuay BuayÎncă nu există evaluări

- Aplic (1) - Bandas Aut.Document25 paginiAplic (1) - Bandas Aut.Jorge Luis Amores Torres50% (2)

- 1829Document12 pagini1829Pavlova AsiaÎncă nu există evaluări

- Ltvs Price List - Oct 2017 PDFDocument4 paginiLtvs Price List - Oct 2017 PDFEr MuralidharanÎncă nu există evaluări

- Ingreso China Julio 2021 (2Document12 paginiIngreso China Julio 2021 (2Andres MoraÎncă nu există evaluări

- KbxPrice List W e F 1st July 2017Document17 paginiKbxPrice List W e F 1st July 2017Jaydeep KachchhavaÎncă nu există evaluări

- FP RviDocument29 paginiFP RviFulga AlexÎncă nu există evaluări

- 400cc (LT-A400F AK46K 2003-2006) Suzuki ATV Parts ListDocument71 pagini400cc (LT-A400F AK46K 2003-2006) Suzuki ATV Parts ListMarkÎncă nu există evaluări

- Lista Precios Repuestos 1605Document20 paginiLista Precios Repuestos 1605jdcastellanoÎncă nu există evaluări

- GSP Strut Mounting Protection Kit Catalogue 2020-2021-484-570Document87 paginiGSP Strut Mounting Protection Kit Catalogue 2020-2021-484-570Zorlac GreenÎncă nu există evaluări

- Volvo V40 Price ListDocument7 paginiVolvo V40 Price Listdavid1064Încă nu există evaluări

- Monroe Catalogue IndonesiaDocument43 paginiMonroe Catalogue Indonesiabilling mail100% (1)

- Delphi Lock Sleeve Spare PartsDocument52 paginiDelphi Lock Sleeve Spare Partskarthikeyan1992Încă nu există evaluări

- Sangsin Brake IndiaDocument2 paginiSangsin Brake IndiaGurjot Singh100% (1)

- Passenger Car Light Trucks 2015 PDFDocument364 paginiPassenger Car Light Trucks 2015 PDFAlbert DanicescuÎncă nu există evaluări

- Gabrielprice List W.E.F 01.6.2015Document8 paginiGabrielprice List W.E.F 01.6.2015Deepak SiwalÎncă nu există evaluări

- Equiv. FiltrosDocument61 paginiEquiv. FiltrosDaniel Ayala100% (1)

- BearingsDocument299 paginiBearingsktef_010417030Încă nu există evaluări

- Partmaster AmgDocument1.132 paginiPartmaster Amgashish kumarÎncă nu există evaluări

- Updated: January - 2015: Bosch Automotive Aftermarket: Braking ComponentsDocument17 paginiUpdated: January - 2015: Bosch Automotive Aftermarket: Braking ComponentsVenura VishwajithÎncă nu există evaluări

- 36 Interchange BearingDocument6 pagini36 Interchange Bearingmanoj_doshi_1Încă nu există evaluări

- Eaton Advantage Series Clutch Brochure Clsl1531 0617web enDocument4 paginiEaton Advantage Series Clutch Brochure Clsl1531 0617web enHenry O TelloÎncă nu există evaluări

- Oferta de Pret Rulmenti GenOparts GermaniaDocument10 paginiOferta de Pret Rulmenti GenOparts GermaniaPopa CatalinÎncă nu există evaluări

- Scania Catalogue - SpringsDocument9 paginiScania Catalogue - SpringsFilipposÎncă nu există evaluări

- Brembo CatalogueDocument37 paginiBrembo CatalogueJérémy ChevallereauÎncă nu există evaluări

- 2006 Brake Lining CatalogueDocument89 pagini2006 Brake Lining Cataloguea_khan35263398Încă nu există evaluări

- Part 01 ApplicationDocument560 paginiPart 01 ApplicationMichael AkhramovichÎncă nu există evaluări

- Price List Application WiseDocument1 paginăPrice List Application Wisemanojkhare7620Încă nu există evaluări

- CTR Catalogue 2009Document321 paginiCTR Catalogue 2009wan_yong_siangÎncă nu există evaluări

- Zndmotor Truck Flywheel ListDocument4 paginiZndmotor Truck Flywheel ListMarco WeiÎncă nu există evaluări

- John Deere BeltsDocument2 paginiJohn Deere BeltssenatÎncă nu există evaluări

- Harga Spert Part DmaxDocument4 paginiHarga Spert Part DmaxDwi SupriyantoÎncă nu există evaluări

- HH SparesDocument32 paginiHH SparesVimal Aathithan67% (3)

- R MB Freca AdvntreDocument1 paginăR MB Freca Advntrehijet84Încă nu există evaluări

- One Safe Source From DortmundDocument21 paginiOne Safe Source From DortmundMiguel RodriguezÎncă nu există evaluări

- Wagon RDocument241 paginiWagon RJorgeiro Peña0% (1)

- Automotive Suspension SystemDocument32 paginiAutomotive Suspension SystemMoniruzzaman Shuvo100% (2)

- 2131 CH16Document13 pagini2131 CH16Krishanlal GuinÎncă nu există evaluări

- Automotive Suspension SystemDocument83 paginiAutomotive Suspension SystemTanzim Rafat AyonÎncă nu există evaluări

- Independent Suspension System Full ReportDocument21 paginiIndependent Suspension System Full Reportmonikaneha12380% (5)

- Chapter No 3 Automobile Suspension SystemDocument36 paginiChapter No 3 Automobile Suspension SystemAmit BhatiaÎncă nu există evaluări

- Automotive (2) Lab: Suspension SystemDocument8 paginiAutomotive (2) Lab: Suspension SystemMohammad YahyaÎncă nu există evaluări

- Chapter - Suspension System - Chasis-1Document9 paginiChapter - Suspension System - Chasis-1karanragav12Încă nu există evaluări

- New Name FormDocument1 paginăNew Name FormManjeet GognaÎncă nu există evaluări

- Swara ChintamaniDocument50 paginiSwara Chintamaniluck00_85% (34)

- Shiva PuranaDocument812 paginiShiva PuranaVRFdocsÎncă nu există evaluări

- Juran Ideation I DFSSDocument35 paginiJuran Ideation I DFSSAmit GosaviÎncă nu există evaluări

- Kid CareDocument1 paginăKid CareAmit GosaviÎncă nu există evaluări

- Quotation For Making Flex FramesDocument1 paginăQuotation For Making Flex FramesAmit GosaviÎncă nu există evaluări

- Traffic Offences and Penal SectionDocument3 paginiTraffic Offences and Penal Sectionamitkumaramit7Încă nu există evaluări

- Chakra HealingDocument1 paginăChakra HealingAmit GosaviÎncă nu există evaluări

- MLSD SpeachDocument3 paginiMLSD SpeachAmit GosaviÎncă nu există evaluări

- 11 Bhariavji Batukaya MantraDocument1 pagină11 Bhariavji Batukaya MantraAmit GosaviÎncă nu există evaluări

- Traffic Offences and Penal SectionDocument3 paginiTraffic Offences and Penal Sectionamitkumaramit7Încă nu există evaluări

- Mecanical Locking LSD 3Document16 paginiMecanical Locking LSD 3Amit GosaviÎncă nu există evaluări

- How To - Changing Your Windows PasswordDocument2 paginiHow To - Changing Your Windows PasswordAmit GosaviÎncă nu există evaluări

- The Golden CrabDocument153 paginiThe Golden CrabAmit Gosavi100% (2)

- DFMEADocument13 paginiDFMEAmahaprabhu78Încă nu există evaluări

- Nokia PC Suite UG EngDocument28 paginiNokia PC Suite UG Engshelly_nataliaÎncă nu există evaluări

- Self S.W.O.T. Analysis Self S.W.O.T. Analysis: Trengths:-Internal Positive Aspects That Are Under Control and UponDocument3 paginiSelf S.W.O.T. Analysis Self S.W.O.T. Analysis: Trengths:-Internal Positive Aspects That Are Under Control and UponAmit GosaviÎncă nu există evaluări

- Electrical BoardDocument14 paginiElectrical BoardAmit GosaviÎncă nu există evaluări

- AR107 PEBeh CHG ArchDocument65 paginiAR107 PEBeh CHG ArchAmit GosaviÎncă nu există evaluări

- How To Make U'r Own Baby's BootiesDocument4 paginiHow To Make U'r Own Baby's Bootieslangit biruÎncă nu există evaluări

- Curriculum-Viate: Personal InformationDocument3 paginiCurriculum-Viate: Personal InformationAmit GosaviÎncă nu există evaluări

- Tors enDocument11 paginiTors enAmit GosaviÎncă nu există evaluări

- MBA Colleges in PuneDocument4 paginiMBA Colleges in PuneAmit GosaviÎncă nu există evaluări

- How To Make U'r Own Baby's BootiesDocument4 paginiHow To Make U'r Own Baby's Bootieslangit biruÎncă nu există evaluări

- Self S.W.O.T. Analysis Self S.W.O.T. Analysis: Trengths:-Internal Positive Aspects That Are Under Control and UponDocument3 paginiSelf S.W.O.T. Analysis Self S.W.O.T. Analysis: Trengths:-Internal Positive Aspects That Are Under Control and UponAmit GosaviÎncă nu există evaluări

- Basic of Locating and ClampingDocument36 paginiBasic of Locating and ClampingKaran HoodaÎncă nu există evaluări

- Banking Ombudsman SchemeDocument26 paginiBanking Ombudsman SchemeUjjwal SinghÎncă nu există evaluări

- Presentation 1Document1 paginăPresentation 1Amit GosaviÎncă nu există evaluări

- AC Vs Climate ControlDocument11 paginiAC Vs Climate ControlAmit GosaviÎncă nu există evaluări

- ETG Business ModelDocument9 paginiETG Business ModelSupreeth R KoundiniyaÎncă nu există evaluări

- Giant Bicycles Bike 999Document1 paginăGiant Bicycles Bike 999Santi StgoÎncă nu există evaluări

- Water Wash CouponDocument10 paginiWater Wash CouponCheck BoxÎncă nu există evaluări

- Anand Sardar - SMR MRP LIST 01.01.2021Document47 paginiAnand Sardar - SMR MRP LIST 01.01.2021sssakol1981Încă nu există evaluări

- Tesla Motors January 2014 Investor PresentationDocument33 paginiTesla Motors January 2014 Investor PresentationotteromÎncă nu există evaluări

- PB 001 - Innova VenturerDocument23 paginiPB 001 - Innova VenturerHary PrasetyoÎncă nu există evaluări

- EV WH RS010 Front PDFDocument1 paginăEV WH RS010 Front PDFtareq.sefatÎncă nu există evaluări

- QuestionnaireDocument5 paginiQuestionnairemaliniinilam100% (1)

- Manual Mangueras HidraulicasDocument44 paginiManual Mangueras HidraulicasemelysdegarciaÎncă nu există evaluări

- 700r4 Cable Adjustment InstructionsDocument3 pagini700r4 Cable Adjustment InstructionsTito Tales100% (1)

- Tacoma BrochureDocument31 paginiTacoma BrochureAsÎncă nu există evaluări

- Report Summary: 1997 Cadillac Seville STSDocument4 paginiReport Summary: 1997 Cadillac Seville STSJohn WhiteÎncă nu există evaluări

- 2017 Chevrolet Trailering and Towing GuideDocument17 pagini2017 Chevrolet Trailering and Towing GuideHéctor GodoyÎncă nu există evaluări

- 11 PDFDocument124 pagini11 PDFMarcinÎncă nu există evaluări

- B 05Document14 paginiB 05Jenniffer MartinezÎncă nu există evaluări

- DTC Chasis Fault CodesDocument5 paginiDTC Chasis Fault CodesSatish DevisettiÎncă nu există evaluări

- Carbrand: Name Description Brand Images Brand Logo Carmodel: Name Description Variants Body Type Model Images Year Carvariant: All The Specs PrixDocument5 paginiCarbrand: Name Description Brand Images Brand Logo Carmodel: Name Description Variants Body Type Model Images Year Carvariant: All The Specs Prixben haydarÎncă nu există evaluări

- B56 BrochureDocument2 paginiB56 BrochureRizkyy Rachmalya Zainal100% (1)

- Voltage RegulatorsDocument94 paginiVoltage Regulatorslasith50% (2)

- 4X2 Tractor: Build Your Own TruckDocument2 pagini4X2 Tractor: Build Your Own TruckBadrinath RaghavendranÎncă nu există evaluări

- Renault Kenya Duster Brochure - EmailDocument24 paginiRenault Kenya Duster Brochure - EmailMike LitoriesÎncă nu există evaluări

- BMW F650 CS Parts ListDocument15 paginiBMW F650 CS Parts ListRosa FreitagÎncă nu există evaluări

- MG6 BrochureDocument5 paginiMG6 Brochure615327Încă nu există evaluări

- BMW ETK InfoDocument2 paginiBMW ETK InfoKifah ZaidanÎncă nu există evaluări

- Ford Panel VansDocument18 paginiFord Panel Vansmichal123456987Încă nu există evaluări

- Manual Ix20 Hiunday.17Document1 paginăManual Ix20 Hiunday.17Ay cuanto leoÎncă nu există evaluări

- PM The All-New BMW X3 M and BMW X4 M With M Performance PartsDocument4 paginiPM The All-New BMW X3 M and BMW X4 M With M Performance PartsDanny StoÎncă nu există evaluări

- 510B Backhoe Loader: Engine PerformanceDocument5 pagini510B Backhoe Loader: Engine PerformancebalajimetturÎncă nu există evaluări

- Authomix CruzetasDocument10 paginiAuthomix CruzetasEzequiel ReisÎncă nu există evaluări