Documente Academic

Documente Profesional

Documente Cultură

Din 2393-2

Încărcat de

Yalavarthi ChandrasekharTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Din 2393-2

Încărcat de

Yalavarthi ChandrasekharDrepturi de autor:

Formate disponibile

Global Marketing for Tube & Pipe www.TubeSolution.

com

DIN 2393-81 Part 2 WELDED PRECI SION STEEL TUBES

1.Field of application

This Standard defines the technical conditions of delivery for welded precision steel tubes in accordance with DIN 2393 Part 1 which are made from the steel grades listed in

section 5.

Tubes in accordance with this Standard are mainly used where accuracy to dimension and in some cases also small wall thicknesses and good surface condition are required.

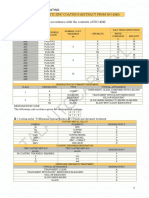

Chemical composition (%)

Grade Mfg. Process

C Si Mn P S Ni Cr Mo Others

!

"

St28

USt28

RSt28

W 0.13Max - - 0.50Max 0.50Max - - - -

#

!

"

St34.2

US34.2

RSt34.2

W 0.15Max - - 0.50Max 0.50Max - - - -

#

!

"

St37.2

USt37.2

RSt37.2

W 0.17Max - - 0.50Max 0.50Max - - - -

#

!

"

St44.2 W 0.21Max - - 0.50Max 0.50Max - - - -

#

!

"

St52.3 W 0.22Max 0.55Max 1.60Min 0.040Max 0.040Max - - - -

#

Cold-finished/hard !Cold-finished/soft "Annealed #Normalized

Global Marketing for Tube & Pipe www.TubeSolution.com

Tensile Test MPa or N/mm

2

Grade Material number

Min Yield point Tensile Strength

Remarks (Similar to J IS)

- 400Min

- 325Min

- 265Min

St28

USt28

RSt28

-

1.0357

1.0326

175 275~380

(STKM11)

(STAM80G)

- 410Min

- 350Min

- 305Min

St34-2

US34-2

RSt34-2

-

1.0028

1.0034

205 315~410

-

- 440Min

- 370Min

- 315Min

St37-2

USt37-2

RSt37-2

1.0037

1.0036

1.0038

235 340~470

(STKM12)

- 570Min

- 450Min

- 390Min

St44-2 1.0044

255 410~540

(STKM13)

(STAM40G)

- 590Min

- 540Min

- 490Min

St52-3 1.0570

350 490~630

(STKM19)

Table 1. Steel grades

Steel grade

Quality grade

Code number Material number

A and B

St 28

USt 28

-

1.0357

Global Marketing for Tube & Pipe www.TubeSolution.com

RSt 28

St 34-2

USt 34-2

RSt 34-2

St 37-2

USt 37-2

RSt 37-2

St 44-3

St 52-3

1.0326

-

1.0028

1.0034

1.0037

1.0036

1.0038

1.0044

1.0570

All steel grades IN accordance with quality grade A and B or other weldable steels, example to

C

DIN 1614

DIN 1623

DIN 1624

DI N 1651

DI N 17200

DI N 17 210

6. Chemical composition

6.1. Information on the chemical composition of the steels is given in table 2. Small departures from these data which apply to the ladle analysis are permissible provided the

properties of the steel in use are not thereby impaired.

6.2. When subsequent testing is carried out on the finished tube, additions to the figures given for the ladle analysis in table 2 must be allowed for the maximum permissible

contents in terms of carbon, phosphorus and sulfur :

of the particular maximum content.

Table 2. Steel grades and chemical composition of the steels (ladle analysis) 1)

Steel grade Chemical composition %

Symbol Material number

C

max

P

max

S

max

St 28 -

- ifor deviations due to sampling and method of analysis + 5 %

- ifor deviations due to segregation

in the case of rimming steels + 20%

in the case of killed steels + 5 %

Global Marketing for Tube & Pipe www.TubeSolution.com

USt 28 1.0357

RSt 28 1.0326

St 34-2 -

USt 34-2 1.0028

RSt 34-2 1.0034

0.15 0.050 0.050

St 37-2 1.0037

USt 37-2 1.0036

RSt 37-2 1.0038

0.17 0.050 0.050

St 44-2 1.0044 0.21 0.050 0.050

St 52-3 2) 1.0570 0.22 0.040 0.040

1) See Explanations

2) Si content 0.55%. max. Mn content 1.60% max.

7. Condition on delivery

The tubes are supplied in one of the conditions listed in table 3. Other conditions on delivery see table 9 (quality grade C).

Table 3. Conditions on delivery

Term Symbol Explanation

Cold-finished/hard

(cold-finished as-drawn)

BK

No heat treatment after the last cold-forming process. for this reason, the tubes therefore have only low

deformability.

Cold-finished/soft

(lightly cold-worked)

BKW

After the last heat treatment there is a light finishing pass (cold drawing). if subsequent working is carried out

properly, the tube can be cold-formed (e.g. bent, expanded) within certain limits.

Annealed GBK After the final cold-forming process, the tubes are annealed in a controlled atmosphere or under vacuum.

Normalized NBK The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum.

8. Mechanical and technological properties

Condition on delivery

Steel grade

Cold-finished/soft (BK) 3) Cold-finished/soft (BKM) 3) Annealed (GBK) 3) Normalized (NBK)

Global Marketing for Tube & Pipe www.TubeSolution.com

Code

number

Material

number

Tensile

strength

Rm

N/

min

Elongation at

repture

A5

%

min

Tensile

strength

Rm

N/

min

Elongation at

repture

A5

%

min

Tensile

strength

Rm

N/

min

Elongation

at repture

A5

%

min

Tensile

strength

Rm

N/

Upper

yield point

ReH

N/

min

Elongation

at repture

A5

%

min

St 28 -

USt 28 1.0357

RSt 28 1.0326

400 8 320 12 260 32 270 to 380 180 32

St 34-2 -

USt 34-2 1.0028

RSt 34-2 1.0034

410 6 350 12 300 28 310 to 410 205 28

St37-2 1.0037

USt37-2 1.0036

RSt 37-2 1.0038

440 6 370 10 315 25 340 to 470 235 25

St 44-2 1.0044 520 5 450 8 390 21 410 to 540 255 21

St 52-3 1.0570 590 4 540 6 490 22 490 to 630 355 22

3) The yield point for the annealed GBK condition on delivery is at least 50% of the tensile strength.

According to the degree of deformation, the drawing process, the yield point of tubes delivered in the cold finished/hare (BK) and cold-finished/soft (BKW) condition may

be increased to a level close to the tensile strength. The following value are recommended for calculating the yield pint : condition on delivery cold-finished/hard :$ 80%

of the tensile strength, cold-finished/soft: $ 70% of the tensile strength.

4) In the case of tubes of outside diameter % 30 mm, the wall thickness of which is % 3mm, the minimumvalue for the yield point is 10 N / lower.

S-ar putea să vă placă și

- Shahs System of Astrology Book 1Document575 paginiShahs System of Astrology Book 1Centre for Traditional Education100% (3)

- Unit-I Economic Operation: TOPICS: Optimal Operation of Generators in Thermal Power Stations, - HeatDocument32 paginiUnit-I Economic Operation: TOPICS: Optimal Operation of Generators in Thermal Power Stations, - Heatnadeem100% (5)

- Material Specification: Specification: Revision Date: Revision LevelDocument2 paginiMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- QB 11920999Document41 paginiQB 11920999matej princesÎncă nu există evaluări

- Modeling 6 Story RC Building Etabs 2013 Tutorial PDFDocument26 paginiModeling 6 Story RC Building Etabs 2013 Tutorial PDFRaul Araca100% (1)

- Geological of QatarDocument110 paginiGeological of Qatarayesha arshad0% (1)

- 9.57405-Eng - Plating Std.Document20 pagini9.57405-Eng - Plating Std.Baravkar Auto Parts100% (1)

- Astm A228Document2 paginiAstm A228Rakesh S IndiaÎncă nu există evaluări

- Iso 228 1 2000Document9 paginiIso 228 1 2000Ulvi NebiyevÎncă nu există evaluări

- CS-11000Document17 paginiCS-11000Engenharia APedro100% (1)

- IS 1079 Hot Rolled Carbon Steel SheetsDocument12 paginiIS 1079 Hot Rolled Carbon Steel Sheetssdmel75% (8)

- Iso 08764-1-2004Document28 paginiIso 08764-1-2004rtsultanÎncă nu există evaluări

- Sfa-5 8 PDFDocument24 paginiSfa-5 8 PDFgst ajahÎncă nu există evaluări

- Abaqus Analysis User's Manual, 32.15 (User Elements)Document22 paginiAbaqus Analysis User's Manual, 32.15 (User Elements)Elias BuÎncă nu există evaluări

- Statistics For Business and Economics: Continuous Random Variables and Probability DistributionsDocument68 paginiStatistics For Business and Economics: Continuous Random Variables and Probability Distributionsfour threepioÎncă nu există evaluări

- Hexalubulour BoltDocument20 paginiHexalubulour BoltMitesh MakvanaÎncă nu există evaluări

- Astm A263 (1999)Document8 paginiAstm A263 (1999)Yalavarthi ChandrasekharÎncă nu există evaluări

- Din 6930 Octobre 2011Document18 paginiDin 6930 Octobre 2011Franck Savignard100% (1)

- Jsa Jis G 0321Document16 paginiJsa Jis G 0321farhad pashaeimehrÎncă nu există evaluări

- En GJS 600 3Document2 paginiEn GJS 600 3abhiÎncă nu există evaluări

- FCA - PS.50009 (2014) - Ex PS.5570Document7 paginiFCA - PS.50009 (2014) - Ex PS.5570FeliceÎncă nu există evaluări

- TSH7702GDocument8 paginiTSH7702GEmir AkçayÎncă nu există evaluări

- Asme B18.16.6Document1 paginăAsme B18.16.6Mario FonsecaÎncă nu există evaluări

- 40NiCrMo7 PDFDocument2 pagini40NiCrMo7 PDFAmy GriffinÎncă nu există evaluări

- Conducting Temperature Uniformity Surveys of Furnaces Used To Heat Treat Steel ProductsDocument4 paginiConducting Temperature Uniformity Surveys of Furnaces Used To Heat Treat Steel Productssaran saranÎncă nu există evaluări

- ISO#TR 14638 1995 (E) - Image 600 PDF DocumentDocument5 paginiISO#TR 14638 1995 (E) - Image 600 PDF DocumentCamila QuidorneÎncă nu există evaluări

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 paginăJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáÎncă nu există evaluări

- TL 256 en 2022Document8 paginiTL 256 en 2022Michal BílekÎncă nu există evaluări

- Equivalent MaterialDocument1 paginăEquivalent MaterialRajput PratiksinghÎncă nu există evaluări

- Copper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForDocument7 paginiCopper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForgoggerÎncă nu există evaluări

- HN20037 - 2021 06 01Document9 paginiHN20037 - 2021 06 01giuseppe giudiceÎncă nu există evaluări

- European Standard Norme Européenne Europäische NormDocument21 paginiEuropean Standard Norme Européenne Europäische NormCentravis100% (2)

- Din1688 1 PDFDocument4 paginiDin1688 1 PDFFelipe FernandesÎncă nu există evaluări

- Design 3-Phase Core Type of Transformer and Modification of Symmetrical Star Shaped Core-IJAERDV04I0183936Document8 paginiDesign 3-Phase Core Type of Transformer and Modification of Symmetrical Star Shaped Core-IJAERDV04I0183936Editor IJAERDÎncă nu există evaluări

- Hollow Bars (ISO2938)Document8 paginiHollow Bars (ISO2938)suku maranÎncă nu există evaluări

- 13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Publication Date OrderDocument21 pagini13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Publication Date OrderGabriel RoqueÎncă nu există evaluări

- DIN EN 10277: ICS 77.140.60 Supersedes: See BelowDocument55 paginiDIN EN 10277: ICS 77.140.60 Supersedes: See BelowEmersonÎncă nu există evaluări

- Iso 10511 Nut Dimensions - RefDocument2 paginiIso 10511 Nut Dimensions - Refkumarkk1969Încă nu există evaluări

- Din 2393-1Document6 paginiDin 2393-1alextentwentyÎncă nu există evaluări

- 2430 & TB2448 ComarisionDocument6 pagini2430 & TB2448 ComarisionpiyushÎncă nu există evaluări

- DIN 55633 Recubrimiento AnclajesDocument29 paginiDIN 55633 Recubrimiento Anclajesdeybi resarteÎncă nu există evaluări

- Ejot - Delta PTDocument2 paginiEjot - Delta PTLucas VeronaÎncă nu există evaluări

- General Tolerances - DIN - IsO - 2768Document2 paginiGeneral Tolerances - DIN - IsO - 2768Pasca GheorgheÎncă nu există evaluări

- CuZn39pb3 - DIN 12164Document1 paginăCuZn39pb3 - DIN 12164Bruno FaveroÎncă nu există evaluări

- International Standard: Stainless Steels For Springs - WireDocument8 paginiInternational Standard: Stainless Steels For Springs - WireAfzal ImamÎncă nu există evaluări

- Iso AnnealingDocument2 paginiIso AnnealingPurushottam Sutar100% (1)

- Parallel Pin Din 6325-2.5X12 PDFDocument1 paginăParallel Pin Din 6325-2.5X12 PDFFer VFÎncă nu există evaluări

- Ifi 536Document2 paginiIfi 536Bomb20001Încă nu există evaluări

- Din 929 PDFDocument1 paginăDin 929 PDFprathmesh238Încă nu există evaluări

- General Dimensional Tolerances For Sheet Metal Formed Parts. (Unless Otherwise Specified)Document1 paginăGeneral Dimensional Tolerances For Sheet Metal Formed Parts. (Unless Otherwise Specified)murali036Încă nu există evaluări

- Bosch Norm 4 497 037 031 - N67F - CM-ZN-2Document18 paginiBosch Norm 4 497 037 031 - N67F - CM-ZN-2davi mooreÎncă nu există evaluări

- Mpaps G-20Document6 paginiMpaps G-20PANKAJ CHAUHANÎncă nu există evaluări

- Fittings Din11852 Din11850Document14 paginiFittings Din11852 Din11850dingobk1Încă nu există evaluări

- Normazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesDocument5 paginiNormazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesRizwanAliÎncă nu există evaluări

- M6x1.0x23 Long HHS Control PlanDocument2 paginiM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsÎncă nu există evaluări

- ISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsDocument4 paginiISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsViswanathan SrkÎncă nu există evaluări

- Jfe Cold Rolled Steel SheetDocument26 paginiJfe Cold Rolled Steel SheetaayopercivalÎncă nu există evaluări

- 2370 Ed1 ENDocument5 pagini2370 Ed1 ENanhthoÎncă nu există evaluări

- Vdocuments - MX Din 405 Universo For Knuckle Thread Din 405Document7 paginiVdocuments - MX Din 405 Universo For Knuckle Thread Din 405wauwio1906Încă nu există evaluări

- DIN580 Eye BoltDocument7 paginiDIN580 Eye BoltReda El-AwadyÎncă nu există evaluări

- M 3031 (2013-06)Document16 paginiM 3031 (2013-06)Hatada FelipeÎncă nu există evaluări

- Din Etg 100Document1 paginăDin Etg 100durgeshdesignÎncă nu există evaluări

- ISO 4020 ExtractDocument2 paginiISO 4020 ExtractBartek HajaÎncă nu există evaluări

- VW01155 en 2005-02-01Document8 paginiVW01155 en 2005-02-01koalaboi0% (1)

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De la EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonÎncă nu există evaluări

- Din 17100Document0 paginiDin 17100df_campos3353Încă nu există evaluări

- Welding Related Points To RecallDocument3 paginiWelding Related Points To RecallThulasi RamÎncă nu există evaluări

- Mahindra StandardDocument6 paginiMahindra StandardSuresh Shinde67% (3)

- Astm A254 (1997)Document4 paginiAstm A254 (1997)Yalavarthi ChandrasekharÎncă nu există evaluări

- Is Code CivilDocument10 paginiIs Code CivilgwaliorwalaÎncă nu există evaluări

- Revision (UNIT 4 & 5)Document10 paginiRevision (UNIT 4 & 5)WKQÎncă nu există evaluări

- Dss - Question BankDocument10 paginiDss - Question Bankapi-306484475Încă nu există evaluări

- The Phase Rule and Phase Diagrams-T and CDocument31 paginiThe Phase Rule and Phase Diagrams-T and CKunwarPawanSinghBhatiÎncă nu există evaluări

- Rahul Kasat IECResDocument12 paginiRahul Kasat IECResShaik RuksanaÎncă nu există evaluări

- Assignment 8 SolutionDocument8 paginiAssignment 8 SolutionSrinivas ShareÎncă nu există evaluări

- Pipe Bend ExperimentDocument9 paginiPipe Bend ExperimentNaga Manohar UmmadiÎncă nu există evaluări

- Ijert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerDocument8 paginiIjert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerguganesannnÎncă nu există evaluări

- Design of Multi Storied Building ReportDocument19 paginiDesign of Multi Storied Building ReportKevin HuangÎncă nu există evaluări

- Al971 LW FSC - S2045NP-BG45WH PDFDocument2 paginiAl971 LW FSC - S2045NP-BG45WH PDFAhmad HaririÎncă nu există evaluări

- Performance Analysis of Parabolic Trough Collector in Hot ClimateDocument21 paginiPerformance Analysis of Parabolic Trough Collector in Hot ClimateirfanajaiÎncă nu există evaluări

- Group A5 - EXP 9 Activated Carbon Adsorption Isotherm & KineticsDocument16 paginiGroup A5 - EXP 9 Activated Carbon Adsorption Isotherm & KineticsKabilashini Mana Mohan100% (2)

- ++ Drift-Velocity Closure Relationships For Slug Two-Phase High-Viscosity Oil Flow in PipesDocument9 pagini++ Drift-Velocity Closure Relationships For Slug Two-Phase High-Viscosity Oil Flow in PipesAnonymous H9n5g3aaCEÎncă nu există evaluări

- Casing DesignDocument12 paginiCasing DesignRisTy FrogGiesaa AmaNeeÎncă nu există evaluări

- L-9 Pure Substance Ideal Gases-IDocument25 paginiL-9 Pure Substance Ideal Gases-IShailin SequeiraÎncă nu există evaluări

- Sample Question Paper Mechanical Engineering MeasurementsDocument4 paginiSample Question Paper Mechanical Engineering MeasurementsAbhishek SakatÎncă nu există evaluări

- KX SM 06 Error PDFDocument65 paginiKX SM 06 Error PDFNavin kumarÎncă nu există evaluări

- Gantrex Non-Shrink Grout (Pre-Mix) : DescriptionDocument3 paginiGantrex Non-Shrink Grout (Pre-Mix) : DescriptionRuiÎncă nu există evaluări

- Synthesis of FlavanoneDocument5 paginiSynthesis of FlavanonefikarisvitaÎncă nu există evaluări

- Niels Henrik David BohrDocument4 paginiNiels Henrik David BohrValerie Ann FranciscoÎncă nu există evaluări

- (Paper) - Portal Frame PierDocument23 pagini(Paper) - Portal Frame PierShaileshRastogiÎncă nu există evaluări

- HS Model PresentationDocument58 paginiHS Model Presentationgeologist84100% (2)

- Water Cycle SEDocument3 paginiWater Cycle SEAlexÎncă nu există evaluări

- Horizontal CurveDocument2 paginiHorizontal CurveAmar DanialÎncă nu există evaluări