Documente Academic

Documente Profesional

Documente Cultură

3.heat Flow Character in Welding

Încărcat de

Santhosh KumarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

3.heat Flow Character in Welding

Încărcat de

Santhosh KumarDrepturi de autor:

Formate disponibile

3.

HEAT FLOW CHARACTER IN WELDING

3.1 INTRODUCTION

Scope of this report is to discuss heat flow character in welding and the different timetemperature relations in detail.

3.2 THE EQUATION OF HEAT FLOW

The familiar Fouriers heat flow equation is the starting point for the discussion of heat flow in a fusion weld. It has been modified and presented below d2/dx2 d2/d!2 d2/d"2 #2d/dt

$here #temperature o%er ambient& is half of the thermal diffusi%it!. This equation has been deri%ed for a stationar! heat source. In fusion welding &heat source& whether it is an arc or a gas torch is in motion. Therefore equation must be modified b! introducing a parameter defined b! #x-%t where is a rectangular coordinate in the direction of tra%el of the point source& % is the %elocit! and t is the time. Figure ' shows the relation

fig '

The equation in &! and " co-ordinates is

The form of equation ( suggests that a solution ma! be found of the form

In this equation ) is proportional to amount of heat input. This is related to the watts of the arc& is a function of &! and " and must be determined. This function must satisf! an equation that is the result of substituting * into (.

+quation , must be sol%ed to find the function in terms of &! and ". The actual solution would depend on the boundar! conditions.

3.2.1 B OUNDARY C ONDITION

) solution has been obtained for equation , for the following boundar! condition '.It is assumed that there is no heat transfer across the surface of plate. This requirement ma! be expressed mathematics as d/d"#- where "#-&h where h is the thic.ness of the plate. This boundar! condition is not exactl! fulfilled since there is some heat loss through the bottom of the plate. 2.It is necessar! to use the fact that at %er! large distance from the heat source there is no heating up. This means that TT- or - as / where /#02 !2 "21'/2 (.$e assume that all the heat enters the plate at a true mo%ing point. This we .now is not so because a flame ob%iousl! has width. The cathode point of an arc is %er! nearl! a true point source& but it tends to wander as the weld progresses. )s the distance from the centre line increases the error rapidl! becomes negligible.

3.2.2 T HIN , T HICK AND S EMI - INFINITE PLATES

The plate thic.ness ma! be regarded as a .ind of boundar! condition and secondl! the complexit! of the answer depends upon plate thic.ness. )ll the plates are considered to be infinitel! wide. The three classes of plate thic.ness are readil! %isuali"ed in terms of the temperature pattern on the bac. of the plate while the arc is passing o%erhead. Thus if the plate is thin the bottom of the plate will be 2ust as hot as the top of the plate.

) plate that is thic. enough so that isotherms across a cross-section show a bend. Such a thic. plate is shown in figure (.the isotherms are crowded slightl! closer than the! were in the thin plate. This is a result of the fact that more mass is beneath the heat source to absorb the heat. The bottom of the thic. plate heats up but not as much as the top and the pea. temperature on the bottom is reached after the arc passes b!.

Finall! a plate so thic. that the bottom ne%er heats up to an! appreciable extent is called a semi-infinite plate. For steels such a plate is thic.er that about *inch.)luminium must be somewhat thic.er to be considered a semi-infinite plate.

3.2.3 T HE E QUATION FOR T EMPERATURE D ISTRIBUTION IN THE T HICK P LATE

The temperature distribution in a thic. plate that is infinitel! wide is gi%en b!

3.2.3 T HE E QUATION FOR T EMPERATURE D ISTRIBUTION IN THE T HICK P LATE

The temperature distribution in a thic. plate that is infinitel! wide is gi%en b!

The complexit! of this equation ma.es the actual calculation of the temperature distribution in a plate during welding quite tedious. The terms within the summation are referred to as reflection terms. The entire series summation could be omitted if the plate being welded was so thic. that the bottom of the plate did not heat up.

3.2.4 T HE EQUATION FOR TEMPERATURE DISTRIBUTION IN THE SEMI - INFINITE PLATE

$hen the reflection terms are omitted the resulting equation for the temp distribution in the semi-infinite plate is T#T- )+ $here +#e-%.e- %/// /#02 !2 "21'/2 )#3p/2.

3.2.5 T HE EQUATION FOR HEATING AND COOLING RATES

IN THICK PLATES

4etallurgists are often interested in the heating and cooling rates of metals. These rates can be found anal!ticall! b! differentiating the equation for temperature with respect to time. $hen this is done the expression for rate of temp change in thic. plate is

3.2.

C ALCULATED TEMPERATURE DISTRIBUTION IN

ALUMINIUM

+quation 5 gi%es the temperature distribution about a fusion weld in a thic. plate that is infinitel! wide. The equation has been sol%ed for t!pical welding conditions utili"ed in the welding of 6'S aluminium allo! and mild steel 7 inch thic.. In fig , the isothermal temperature distribution is gi%en for a plate of 6'S being machine-welded. The heat source& an arc is tra%eling 8 inch per min and is drawing **, amp at (( %olts. These %alues are t!pical for the machine arc welding of 7 in )l plate. The isothermal lines ha%e been computed for a plane l!ing -.2 cm below the surface.

S-ar putea să vă placă și

- BA Graville-Chapter 3Document36 paginiBA Graville-Chapter 3Bhavana ValetiÎncă nu există evaluări

- Unsteady State Heat TransferDocument4 paginiUnsteady State Heat Transfernaser hasan fauziÎncă nu există evaluări

- Assignment 3Document4 paginiAssignment 3abhijeetÎncă nu există evaluări

- Six-Figure Tables of Trigonometric Functions: Mathematical Tables SeriesDe la EverandSix-Figure Tables of Trigonometric Functions: Mathematical Tables SeriesEvaluare: 5 din 5 stele5/5 (1)

- Heat Flow During GTA Welding of PipesDocument7 paginiHeat Flow During GTA Welding of Pipesabraham silva hernandezÎncă nu există evaluări

- Cieec 2017 8388490Document5 paginiCieec 2017 8388490MatejComelÎncă nu există evaluări

- Wellbore Heat Losses and Casing Temperatures During Steam Injection - API-66-025Document8 paginiWellbore Heat Losses and Casing Temperatures During Steam Injection - API-66-025nicessg@gmail.comÎncă nu există evaluări

- Constant Area Fin: Q=Ua ΔtDocument11 paginiConstant Area Fin: Q=Ua ΔtMuyambo SàmsøñÎncă nu există evaluări

- Scha1301 - 033251 66 130Document65 paginiScha1301 - 033251 66 130danifexÎncă nu există evaluări

- Tutorial - 3 Conduction With Heat Generation and Extended SurfacesDocument1 paginăTutorial - 3 Conduction With Heat Generation and Extended SurfacesDr. Santosh BopcheÎncă nu există evaluări

- 1995 BHR Design PHEDocument11 pagini1995 BHR Design PHEMohsenÎncă nu există evaluări

- 00000096Document9 pagini00000096Javi PedrazaÎncă nu există evaluări

- Heating and Cooling of Circular Saws: K KT KTTDocument8 paginiHeating and Cooling of Circular Saws: K KT KTTte2makanza5279Încă nu există evaluări

- Heat Conduction EquationDocument45 paginiHeat Conduction EquationOmar EzzatÎncă nu există evaluări

- Heat Transfer CoefficientDocument3 paginiHeat Transfer CoefficientFrank DempsyÎncă nu există evaluări

- Tuga 2 Perpan PDFDocument4 paginiTuga 2 Perpan PDFKurniawan ChaniagoÎncă nu există evaluări

- ChE 154Document16 paginiChE 154DennisShinÎncă nu există evaluări

- Department of Mechanical Engineering Heat and Mass Transfer-2251 Unit-I (Two Marks Questions)Document9 paginiDepartment of Mechanical Engineering Heat and Mass Transfer-2251 Unit-I (Two Marks Questions)xljleninjudesÎncă nu există evaluări

- Heat Transfer in Natural ConvectionDocument6 paginiHeat Transfer in Natural ConvectionAbhishek AnandÎncă nu există evaluări

- CHEE 3369 Sample Exam 2 ProblemsDocument2 paginiCHEE 3369 Sample Exam 2 ProblemsChris HieuÎncă nu există evaluări

- Transport Phenomena ProblemsDocument10 paginiTransport Phenomena ProblemsbeningÎncă nu există evaluări

- Steady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodDocument5 paginiSteady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodAnonymous sAmJfcVÎncă nu există evaluări

- Erf A: Thermal ConductionDocument9 paginiErf A: Thermal ConductionAbdul Sami RajputÎncă nu există evaluări

- ConductionDocument159 paginiConductionNugi100% (1)

- SPE 133428 Modeling Thermal Effects On Wellbore StabilityDocument23 paginiSPE 133428 Modeling Thermal Effects On Wellbore StabilityMaria Fernanda LopezÎncă nu există evaluări

- Shell-and-Tube Heat Exchangers R. Shankar Subramanian: AdvantagesDocument10 paginiShell-and-Tube Heat Exchangers R. Shankar Subramanian: AdvantagesCherry May SerionÎncă nu există evaluări

- Three-Dimensional Simulation of The Temperature FieldDocument4 paginiThree-Dimensional Simulation of The Temperature FieldTasha AnaÎncă nu există evaluări

- Experiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural ConvectionDocument6 paginiExperiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural Convectionpriya3939Încă nu există evaluări

- PerpanDocument7 paginiPerpanT Bagus Tri LusmonoÎncă nu există evaluări

- 1.c Heat Flow and Temperature Distribution in Welding PDFDocument45 pagini1.c Heat Flow and Temperature Distribution in Welding PDFMukhlis Adam0% (1)

- Thermocouple InhomogeneityDocument6 paginiThermocouple InhomogeneityArmando_84Încă nu există evaluări

- Ramey PDFDocument10 paginiRamey PDFvitaxnÎncă nu există evaluări

- Storage-Tank Heat TransferDocument57 paginiStorage-Tank Heat Transfervitcon87100% (12)

- Experimental and Three Dimensional Finite Element Analysis of Thermal History of Oxy-Acetylene Line Heating ProcessDocument6 paginiExperimental and Three Dimensional Finite Element Analysis of Thermal History of Oxy-Acetylene Line Heating Processalvaromviegas_191514Încă nu există evaluări

- Multidimensional Heat TransferDocument6 paginiMultidimensional Heat TransferehdfhdhdfhdhÎncă nu există evaluări

- Solution A2 CHE 312ADocument12 paginiSolution A2 CHE 312AMukul ParasharÎncă nu există evaluări

- Finned Tube Heat ExchangerDocument15 paginiFinned Tube Heat ExchangerAna Quintana0% (1)

- Heat Transfer and Heat - ExchangersDocument6 paginiHeat Transfer and Heat - ExchangersVinh Do ThanhÎncă nu există evaluări

- Heat Transfer EquipmentDocument105 paginiHeat Transfer EquipmentBernard BaluyotÎncă nu există evaluări

- Thermal Analysis of Heat Pipe Shell-Fin Structures With Selective Coatings Under RadiationDocument7 paginiThermal Analysis of Heat Pipe Shell-Fin Structures With Selective Coatings Under RadiationLuis ReyesÎncă nu există evaluări

- 2.2 Conduction Heat Transfer Part IIDocument31 pagini2.2 Conduction Heat Transfer Part IIMukhzin RashidÎncă nu există evaluări

- Heattransfermanualsolution MatlabDocument23 paginiHeattransfermanualsolution Matlabdodydody25689Încă nu există evaluări

- 3 Heat Transfer 2021Document30 pagini3 Heat Transfer 2021Ahmed KingÎncă nu există evaluări

- Direq/CorDocument64 paginiDireq/CorMohamed Ben MansourÎncă nu există evaluări

- Welding FormulaDocument6 paginiWelding FormulachirpynikÎncă nu există evaluări

- Final Exam Review ProblemsDocument9 paginiFinal Exam Review ProblemsalvinchuanÎncă nu există evaluări

- Analisis de Transferencia de Calor en Un EvaporadorDocument9 paginiAnalisis de Transferencia de Calor en Un EvaporadorMaria Alejandra RamirezÎncă nu există evaluări

- Air EvaporatorDocument8 paginiAir Evaporatordoni.ekosaputroÎncă nu există evaluări

- 24th August HEAT GENERATION IN A SOLIDDocument11 pagini24th August HEAT GENERATION IN A SOLIDSaloni.Dhawale Btech2018Încă nu există evaluări

- HEDocument10 paginiHEMohamed BelallÎncă nu există evaluări

- Bau Sadhal Buried Pipe IJHMTDocument10 paginiBau Sadhal Buried Pipe IJHMTSurjit DuttaÎncă nu există evaluări

- Heat Transfer CylindricalDocument25 paginiHeat Transfer CylindricalPaul Williams MaravillasÎncă nu există evaluări

- Heat Transfer Tutorial For Heat ExchangersDocument0 paginiHeat Transfer Tutorial For Heat ExchangersvicopipÎncă nu există evaluări

- 2006 Part IPaper 1Document9 pagini2006 Part IPaper 1Oliver IyerÎncă nu există evaluări

- Modelling and Simulation Techniques For Forced Convection Heat Transfer in Heat Sinks With Rectangular FinsDocument26 paginiModelling and Simulation Techniques For Forced Convection Heat Transfer in Heat Sinks With Rectangular FinsFunda DurmazÎncă nu există evaluări

- Cheat Sheet 244Document2 paginiCheat Sheet 244torance44Încă nu există evaluări

- ChatGPT Prompts Article PDFDocument17 paginiChatGPT Prompts Article PDFSanthosh Kumar100% (2)

- Grills and RegistersDocument11 paginiGrills and RegistersSanthosh KumarÎncă nu există evaluări

- A8ZUYZ9tReL58evU5E2S EXCEL Stock Analysis Spreadsheet 10YR 2021 Vers 3.1Document13 paginiA8ZUYZ9tReL58evU5E2S EXCEL Stock Analysis Spreadsheet 10YR 2021 Vers 3.1Santhosh KumarÎncă nu există evaluări

- IIM Mumbai Campus Work Volume IDocument77 paginiIIM Mumbai Campus Work Volume ISanthosh KumarÎncă nu există evaluări

- Layer Chicken Business Planning Calculator - Final VersionDocument51 paginiLayer Chicken Business Planning Calculator - Final VersionSanthosh KumarÎncă nu există evaluări

- CBD Business Banking GeneraltermsDocument43 paginiCBD Business Banking GeneraltermsSanthosh KumarÎncă nu există evaluări

- Fundamental Accounting Principles Vol 1 Chapters 1 12 With Working Papers 20th Edition by John Wild Ken Shaw Barbara ChiappettaDocument8 paginiFundamental Accounting Principles Vol 1 Chapters 1 12 With Working Papers 20th Edition by John Wild Ken Shaw Barbara ChiappettaSanthosh KumarÎncă nu există evaluări

- Preface: Base HandbookDocument8 paginiPreface: Base HandbookSanthosh KumarÎncă nu există evaluări

- BH5001 IntroductionToBaseDocument40 paginiBH5001 IntroductionToBaseSanthosh KumarÎncă nu există evaluări

- Creating A Database: Base HandbookDocument28 paginiCreating A Database: Base HandbookSanthosh KumarÎncă nu există evaluări

- ABC Company Inc.: Purchase OrderDocument1 paginăABC Company Inc.: Purchase OrderSanthosh KumarÎncă nu există evaluări

- IC Business Financial Plan 10876 - PDFDocument7 paginiIC Business Financial Plan 10876 - PDFSanthosh KumarÎncă nu există evaluări

- BG4201 IntroducingBaseDocument45 paginiBG4201 IntroducingBaseSanthosh KumarÎncă nu există evaluări

- BH5003 TablesDocument45 paginiBH5003 TablesSanthosh KumarÎncă nu există evaluări

- Database Maintenance: Base HandbookDocument8 paginiDatabase Maintenance: Base HandbookSanthosh KumarÎncă nu există evaluări

- 1.profile Aimi DuctingDocument8 pagini1.profile Aimi DuctingSanthosh KumarÎncă nu există evaluări

- Automatic Invoice KaloiconDocument4 paginiAutomatic Invoice KaloiconSanthosh KumarÎncă nu există evaluări

- BH5004 FormsDocument78 paginiBH5004 FormsSanthosh KumarÎncă nu există evaluări

- Checklist Finding Employment PCC PDFDocument1 paginăChecklist Finding Employment PCC PDFSanthosh KumarÎncă nu există evaluări

- Acevac Catalogue VCD - R3Document6 paginiAcevac Catalogue VCD - R3Santhosh KumarÎncă nu există evaluări

- ABB Contractor Catalogue May 2013Document113 paginiABB Contractor Catalogue May 2013Santhosh KumarÎncă nu există evaluări

- Fittings & Valves Equivalent LengthsDocument2 paginiFittings & Valves Equivalent LengthsSanthosh Kumar33% (3)

- Mep Material Submittals LogDocument1 paginăMep Material Submittals LogSanthosh KumarÎncă nu există evaluări

- PolistirenDocument15 paginiPolistirenMaria TnsÎncă nu există evaluări

- Appendix GDR 00.1 001 CDocument81 paginiAppendix GDR 00.1 001 Cluce gianniÎncă nu există evaluări

- Radphysics 1Document5 paginiRadphysics 1Angelica BastesÎncă nu există evaluări

- Tutorial Sheet4Document4 paginiTutorial Sheet4Lê Anh QuangÎncă nu există evaluări

- NaphthaleneDocument3 paginiNaphthaleneNur Hafeza75% (4)

- Optical Communications4Document19 paginiOptical Communications4keane1Încă nu există evaluări

- Comparison Between Single and Double Anchored Sheet Piles With Simplified Approaches To Solve The Statically Indeterminate SystemsDocument16 paginiComparison Between Single and Double Anchored Sheet Piles With Simplified Approaches To Solve The Statically Indeterminate SystemsHipow87Încă nu există evaluări

- Assignment1 Group10 Report 1 1Document33 paginiAssignment1 Group10 Report 1 1api-531433079Încă nu există evaluări

- The History of The Atom - Theories and ModelsDocument1 paginăThe History of The Atom - Theories and Modelsabbychee100% (1)

- Tutorial 6Document4 paginiTutorial 6ArvinÎncă nu există evaluări

- Rubber Products in Automotive Applications: Standard Classification System ForDocument53 paginiRubber Products in Automotive Applications: Standard Classification System ForKhimeshÎncă nu există evaluări

- Classification of Elements Notes 3Document3 paginiClassification of Elements Notes 3Krishiv RajkumarÎncă nu există evaluări

- Insulated Glass Unit: Why Window Techs Insulated BlindDocument2 paginiInsulated Glass Unit: Why Window Techs Insulated BlindSuruthi DasanÎncă nu există evaluări

- PSL Rheotek Catalogue 2015 Lowres - 2Document28 paginiPSL Rheotek Catalogue 2015 Lowres - 2sohaib mughalÎncă nu există evaluări

- CBR OptikDocument8 paginiCBR OptikNuriyaniÎncă nu există evaluări

- WTP (Water Treatment Plant) DesignDocument3 paginiWTP (Water Treatment Plant) DesignPratiksha Pawar100% (1)

- WORKSHOPDocument9 paginiWORKSHOPManjunatha EikilaÎncă nu există evaluări

- Photography - Depth of FieldDocument3 paginiPhotography - Depth of FieldmirnafarahatÎncă nu există evaluări

- 0405 PDFDocument6 pagini0405 PDFCris CristyÎncă nu există evaluări

- Damping Dissipation AbsorbtionDocument3 paginiDamping Dissipation AbsorbtionLia MatiasÎncă nu există evaluări

- Formulation and Calculation of Isoparametric Finite Element MatrixDocument27 paginiFormulation and Calculation of Isoparametric Finite Element MatrixSanjib RaiÎncă nu există evaluări

- EEE-ETI 3208 ELECTROMAGNETICS III ExamDocument3 paginiEEE-ETI 3208 ELECTROMAGNETICS III ExamHenry Kabasa100% (1)

- Air Cooled Condenser (Acc) and Air Evacuation SystemDocument4 paginiAir Cooled Condenser (Acc) and Air Evacuation SystemCo-gen ManagerÎncă nu există evaluări

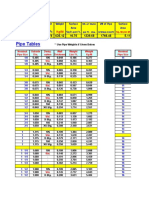

- Pipe Table For Smart EngineersDocument12 paginiPipe Table For Smart EngineersJade ClemenoÎncă nu există evaluări

- Operation and Calibration of UV-VIS SpectrophotometerDocument8 paginiOperation and Calibration of UV-VIS SpectrophotometerMaruthi K100% (1)

- sm1 014Document2 paginism1 014Paulo Henrique D. FavarettoÎncă nu există evaluări

- Silvaco TCAD Athena User ManualDocument438 paginiSilvaco TCAD Athena User Manualindrajit_0804Încă nu există evaluări

- 20121208094353783Document354 pagini20121208094353783WilDan RoFiqqÎncă nu există evaluări

- Fabiola Cruz Lesson 4.1 - Electrons in Atoms - Light and Quantized EnergyDocument6 paginiFabiola Cruz Lesson 4.1 - Electrons in Atoms - Light and Quantized EnergyFabiola Cruz0% (1)

- CAPE Physics Unit 1 Paper 2 2008Document11 paginiCAPE Physics Unit 1 Paper 2 2008GillÎncă nu există evaluări

- Laws of UX: Using Psychology to Design Better Products & ServicesDe la EverandLaws of UX: Using Psychology to Design Better Products & ServicesEvaluare: 5 din 5 stele5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneDe la EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneEvaluare: 4.5 din 5 stele4.5/5 (5)

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDe la EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsÎncă nu există evaluări

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDe la EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureEvaluare: 4.5 din 5 stele4.5/5 (2)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDe la EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionEvaluare: 3 din 5 stele3/5 (1)

- The Cyanide Canary: A True Story of InjusticeDe la EverandThe Cyanide Canary: A True Story of InjusticeEvaluare: 4 din 5 stele4/5 (52)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessDe la EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessÎncă nu există evaluări

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe la EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tEvaluare: 4.5 din 5 stele4.5/5 (27)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionDe la EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionÎncă nu există evaluări

- Waste: One Woman’s Fight Against America’s Dirty SecretDe la EverandWaste: One Woman’s Fight Against America’s Dirty SecretEvaluare: 5 din 5 stele5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDe la EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchEvaluare: 4 din 5 stele4/5 (10)

- Benchmarking Best Practices in Maintenance ManagementDe la EverandBenchmarking Best Practices in Maintenance ManagementÎncă nu există evaluări

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableDe la EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableÎncă nu există evaluări

- 507 Mechanical Movements: Mechanisms and DevicesDe la Everand507 Mechanical Movements: Mechanisms and DevicesEvaluare: 4 din 5 stele4/5 (28)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsDe la EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsEvaluare: 5 din 5 stele5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontDe la EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontEvaluare: 4.5 din 5 stele4.5/5 (18)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesDe la EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesÎncă nu există evaluări

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsDe la EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsÎncă nu există evaluări