Documente Academic

Documente Profesional

Documente Cultură

Improving Structural Drawings

Încărcat de

Constantin DimitriuDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Improving Structural Drawings

Încărcat de

Constantin DimitriuDrepturi de autor:

Formate disponibile

STRUCTURE magazine May 2006

Communication and coordination

between the architect and engineer

are essential for improving structural

drawings for masonry construction.

Errors, omissions and conicts, which

can lead to additional costs, are often

caused by a lack of coordination

between the architectural plans and

specications and the structural

drawings. Structural steel framed

buildings with masonry cavity walls seem to

generate the most problems.

Structural drawings for masonry construction

have improved in recent years, thanks to increased

technical literature written and distributed from

masonry organizations. This article will review

the most important items that have emerged

from these communications, as well as those that

have come from actual review by International

Masonry Institute (IMI) staff.

1

Figure 2: Column penetrates wall cavity

Figure 3B: Column and spaces are protected by

membrane ashing

Figure 1: Steel Column within CMU backup

Communication and coordination between the architect and

engineer are essential for improving structural drawings for masonry

construction. Errors, omissions and conicts, which can lead to

additional costs, are often caused by a lack of coordination between

the architectural plans and specications and the structural drawings.

Structural steel framed buildings with masonry cavity walls seem to

generate the most problems.

Structural drawings for masonry construction have improved

in recent years, thanks to increased technical literature written and

distributed from masonry organizations. This article will review the

most important items that have emerged from these communications,

as well as those that have come from actual review by International

Masonry Institute (IMI) staff.

Structural Steel Frame Columns

Many times, the structural engineer does not consider the exterior

masonry wall conguration when designing and locating columns and

beams. The location of structural steel columns can interfere with

adjacent masonry wall construc-

tion. Failure to provide a water-

resistant or waterproof barrier

at columns that penetrate into

the masonry cavity is a common

problem. New energy codes that

require air and vapor barriers can

further complicate these situa-

tions. Developing the proper

details for these conditions re-

quires a special coordination

between the architect and the

structural engineer.

The detail shown in Figure 1

illustrates a successfully designed

column and masonry interface.

The CMU cavity wall backup

has a clearance of

3 to 4 inches in

front of the col-

umn. This allows

the backup wall to

be continuous and,

when dampproofed

or waterproofed,

forms a moisture-

resistant barrier as

required by build-

ing codes. A con-

trol joint is created

by the separation

of the masonry

and steel. Engi-

neers and architects

should always indi-

Improving

Structural

Drawings

for

Masonry

Construction

By Richard Filloramo

Figure 3A: Unprotected column

Fillers and sealant

are difcult to use

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

2

Figure 4: Do NOT penetrate ashing with ties and anchors at steel

columns when anchor spacing requirements are maintained

Figure 7: Columns with reproong or voids

A

Add rigid material

B

If needed, add metal

strips or anchors

cate when a separation space (usually 1 inch) is required between steel

columns and masonry. It is also important to indicate concrete ll

around the column base to support the CMU backup wall.

The detail shown in Figure 2 and the photos in Figure 3 illustrate

conditions where the column penetrates the masonry cavity by 1

inch. Although this can be remedied by installing full-height ash-

ing membrane over the exterior column, it does add cost to the

project. Without proper coordination between the architect and

structural engineer, this condition often goes unnoticed, leading to

water penetration into the building.

In Figure 2, the membrane is adhered to the column and onto the

adjacent CMU. This application protects the column, and the space

between the column and the CMU backup, from air leakage and water

penetration. Always specify the manufacturers recommendations for

wall preparation, primers, adhesives, and laps.

Locate adjustable veneer ties within 2 or 4 inches of the columns.

Do not specify and indicate ties on structural or architectural drawings

that pierce the ashing membrane with anchors from the steel column

(Figure 4). This only increases the potential for water penetration and

air leakage. Ties are not required at the column if the adjustable ties

are maintained at the required horizontal spacing. Although many

projects specify ties spaced 16 inches vertically and horizontally, the

MSJC code permits 16- x 24-inch spacing for masonry veneers. It

is best to leave the spacing at 16- x 16-inches to allow for tolerances

and eld conditions, but to accept 24-inch spacing at columns and

other locations if necessary. Always check local codes for anchor and

tie requirements. If the distance between adjustable ties exceeds 24

inches or the required design distance, additional detailing is required.

Contact IMI for information.

Insulation with a thickness of 1 or 1 inches can be installed over

the column membrane to provide a continuous layer of insulation

as a thermal break. This is an example of the versatility of the 16

inch drainage wall (Figures 5 and 6) with the 2:-inch air space and

4:-inch cavity. For the condition where the column projects 1 inch

into the cavity, the 1 inch insulation still ts and leaves a 2-inch air

space. Compressible llers or mineral wool can be placed between the

column and the CMU to further insulate the area. Engineers must be

familiar with these architectural masonry wall congurations. Steel

columns projecting greater than 1 inch into the cavity will require the

reduction of either the insulation or the air space, and will require

special detailing.

It should be noted that cavities can exceed the code maximum of

42 inches, and typically do, as long as calculations are performed for

the anchors. IMI has performed this study and the results are available

from IMI.

Figure 5: Drainage wall brick veneer/CMU back-up

Brick

Veneer

2 : Air

Space

2 Rigid

Insulation

CMU

Back-Up

Damp-

proofng

Eye & Joint

Reinforcing

Figure 6: 16-inch drainage wall brick veneer/CMU back-up

continued next page

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

3

Figure 10: Good Detail

Figure 8: Columns with reproong or voids

B

Add anchors

if required

A

Add studs and

exterior sheathing

If the open web of a steel column faces the cavity, or if a large

space remains, it must be in-lled with masonry, insulation or some

other rigid material to provide support for the vertical membrane

waterproong. This also applies to columns with reproong (Figures

7, 8 and 9). Once again, do not indicate ties on the steel column that

penetrate the ashing.

Column ties to CMU backup (shown in Figure 1) are only required if

the wall spans horizontally. Most exterior walls span vertically and are

attached to the structure above (Figure 10). These ties, if not required,

only interfere with column wraps, reproong, insulation and other

construction, making the detail difcult to build. Engineers and

architects should work together to eliminate these ties when not

required since substantial cost savings can be realized.

Structural Steel Beams

Structural engineers must consider the position, size, and location

of structural steel beams since they will affect the moisture-control

systems with adjacent masonry construction. Figures 11 and 12

illustrate how the lack of water-resistant protection can lead to

air leakage and water penetration within the building. It is best to

maintain a continuous wall plane of CMU backup at beams as shown

in Figure 10. There must be at least 4 inches of clear space from the

exterior face of the CMU backup units to the beam web to install

the CMU ller. Full 3-inch (actual size) solid units are available for

tight conditions since 2-inch soap units may not provide adequate

support for the veneer when required. If there is not sufcient beam

space to provide support for CMU backup, an alternate detail should

be used as shown in Figure 13.

To improve structural drawings, engineers need to consider masonry

coursing heights when indicating the location of bond beams. Bond

beams should not be located directly below a steel beam unless the

beam is offset to provide at least 4 inches of clear space on one side for

pouring the grout into the bond beam. Notice in Figures 14 and 15

that the bond beam is located one course below the beam, but there is

space to pour the grout. In most cases, the bond beam will be located

two courses below the beam, as shown in Figure 10 and Figure 16.

Since beam heights and depths will vary (Figure 17), it may be easier

for the structural drawings to include a notation for locating bond

beams a minimum of 4 inches below and a maximum of 12 inches

below beams, unless there is access for grouting.

In most CMU details, a clear space, usually about 1 inch, is left

open between the bottom of the steel beam and the top course of

CMU to provide for deection (Figure 18). If required, engineers

should indicate this on the drawings. The resulting space in all details

must be covered with a exible water-resistant barrier. A compressible

ller with a facing can be used if it is compatible with the CMU

dampproong. Mortar is sometimes used if the CMU extends beyond

the beam and does not contact the beam, and if movement can be

compensated within the beam.

Figure 11: Poor Detail

The lack of

water resistant

protection

leads to water

penetration

Figure 9: Columns with reproong or voids

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

4

Figure 12: Moisture protection at steel beams. Poor Detail - the lack

of water resistant protection leads to water penetration

Figure 13: Good Detail

Figure 14: Locate bond beam directly under steel beam only if there is

room to grout from the exterior side. Maintain 1-inch space and use

slotted angles or bolts

Other Items of Importance

Engineers should highlight plans by cross hatching the exact location

and length of shear walls. The elevation and section for these walls

should be clearly indicated on the plan and be differentiated from non-

structural masonry walls. A good example is shown in Figure 19. In

this actual project, Glastonbury Elementary School, Macchi Engineers

clearly indicates reinforcing requirements and has coordinated with

Moser Pilon Nelson Architects on the architectural drawings.

A common mistake, usually found on the masonry structural

drawing, is an elevation titled Typical Masonry Wall Reinforcing. In

most cases, this causes confusion for the bidders. The drawings should

clearly indicate reinforcing for structural walls, exterior walls and

interior walls. Interior walls in moderate and low seismic risk categories

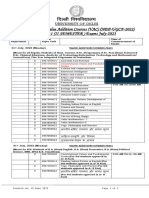

generally do not require vertical reinforcing. Figures 20 and 21 from

Macchi Engineers drawings are excellent, efcient and cost effective

examples that indicate masonry partition wall requirements.

Masonry Notes

Structural drawings usually have a page dedicated to masonry details

and notes. It is essential to coordinate these notes with the architects

specications. A common error, which causes great confusion, is

inconsistency in CMU strength requirements. The architectural

specication will call for CMU to conform to ASTM C-90 with a net

compressive strength of 1900 psi. This will yield an fm of 1500 psi

based on MSJC 2002, Section 1.4.B, 2b, Table 2. If the project requires

higher strength CMU for shear walls, rewalls or loadbearing walls,

the architect and engineer should be clear and consistent in indicating

where these units are required. The engineer is required by code to

indicate the CMU strength, as well as the intended fm. The contractor

may achieve the required design strength using lower strength block by

prism testing.

Self adhered

or spray

membrane

over exterior

shething and

steel studs

Dampproong

continued on next page

The architect and engineer also need to communicate on the

specied density of the CMU. The weight of the masonry wall will

affect the structural design. In some areas, lightweight CMU (<105

pcf ) are common while in other areas medium weight (105 to 125

pcf ) or normal weight (>125 pcf ) CMU are used. Lightweight CMU

have many advantageous characteristics and should be investigated

for use on projects. Contact IMI for more information.

The project requirements for masonry inspection and testing are

the responsibility of the engineer. The engineer must clearly identify

the type and frequency of testing, as is required by the code and the

design. It is essential that architectural specications and engineering

requirements are closely coordinated.

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

Making It Work

Construction managers, architects, engineers, masonry industry

representatives and mason contractors should be involved with plan

reviews prior to project bidding. For example: Industrial Construction,

a construction manager from Newington, CT, typically has an IMI

member mason contractor review the architectural and structural

drawings prior to nal plan release. They also involve many of the

sub-trades. The notes are then sent to the architect and engineer for

comment. A conference, or conference call, is then initiated to discuss

the items of concern. Changes are made on both architectural and

structural drawings prior to bid date. The end results yield coordinated

masonry details and thousands of dollars in cost savings.

Structural Drawings for masonry construction have evolved to meet

new and more complex code requirements, as well as new architectural

design concepts. To ensure masonry structural drawings are clear,

concise and coordinated:

5

1. Increase communications and coordination with the architect.

2. Check all column locations within the masonry wall system.

3. Check masonry coursing to the bottom of beams for bond

beam locations.

4 Involve construction managers, architects, engineers, masonry

industry representatives and mason contractors in plan reviews.

5. Provide more enlarged masonry details and sections

on the drawings.

6. Review specications and coordinate with notes on

structural drawings.

7. Designers, speciers and structural engineers should incorporate

3-D CAD images into drawings of complex building elements

and details.

8. Verify that the mason contractor and craftworkers are skilled

and experienced with the type of construction on the project,

and that they meet the project qualication requirements.

Figure 16: Grouting bond beams too close to the bottom of steel

beams can be difcult

Figure 15: Locate bond beam directly under steel beam

only if there is room to grout from the exterior side

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

6

References

1. Masonry Standards Joint Committee (MSJC) Building

Code Requirements for Masonry Structures

(ACI 530-02/ASCE 5-02/TMS 402-02),

Specications for Masonry Structures (ACI 530.1-02/ASCE

6-02/TMS 602-02) and Commentaries.

2. International Masonry Institute Detailing Masonry

Construction Educational Series

3. International Masonry Institute IMI Technical Briefs on

Masonry Construction

4. ASTM C 90-05 Standard Specications for Loadbearing

Concrete Masonry Units

see next page for gures 19, 20 and 21

Figure 18: Steel beam

Cover space

with self

adhering

membrane in

cavity

Maintain 1

space and use

slotted angles

for deection

Figure 17

Richard Filloramo is Area Director of Market

Development and Technical Services for the International

Masonry Institute New England Region Connecticut

Ofce. He has more than 28 years of experience in the

masonry industry. Mr. Filloramo is a member of the

Masonry Standards Joint Committee, the code writing

body responsible for the Masonry 530 Code. Mr. Filloramo

has been involved with the design, construction and

inspection of more than 5,000 building projects.

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

7

Figure 19: Drawings courtesy of Macchi Engineers, Moser Pilon Architects for Glastonbury Elementary School, Connecticut

Example of shear

wall indicated on the

structural drawings

with elevation.

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

8

WALL HEIGHT & TYPE

(SEE NOTE 7)

VERTICAL

REINFORCING

REMARKS

EXTERIOR WALLS ALL WALLS SEE SECTIONS

GROUT VOIDS

SOLID @

REINFORCING

SEE NOTE 5

INTERIOR WALLS ALL WALLS

NO VERTICAL

REINFORCING

REQUIRED

SEE NOTES 2, 3, 4

Figure 20: A good example to indicate masonry partition wall requirements. Drawings courtesy of Macchi Engineers, Moser Pilon Architects for Glastonbury

Elementary School, Connecticut

see next page for Figure 21a and 21b

@

@

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

9

Figure 21a: Interior partition connection details. Drawings courtesy of Macchi Engineers, Moser Pilon Architects for Glastonbury Elementary School, Connecticut

@

@

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

STRUCTURE magazine May 2006

10

Figure 21b: Interior partition connection details. Drawings courtesy of Macchi Engineers, Moser Pilon Architects for Glastonbury Elementary School, Connecticut

@

@

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

r

i

g

h

t

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Pooja Raut Resume - Java DeveloperDocument3 paginiPooja Raut Resume - Java DeveloperVaibhav PahuneÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Alessi and Trollips Model 2011Document3 paginiAlessi and Trollips Model 2011Anonymous HBT778cÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Ethics - Week 1-6 Correspondence Module PDFDocument45 paginiEthics - Week 1-6 Correspondence Module PDFChabelita MengulloÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Similarities and Differences of Word Order in English and German LanguagesDocument4 paginiSimilarities and Differences of Word Order in English and German LanguagesCentral Asian StudiesÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Course Material (Lecture Notes) : Sri Vidya College of Engineering & TechnologyDocument29 paginiCourse Material (Lecture Notes) : Sri Vidya College of Engineering & TechnologyNivas JÎncă nu există evaluări

- SCOPUS Guide For Journal Editors ELSEVIERDocument75 paginiSCOPUS Guide For Journal Editors ELSEVIERKhis HudhaÎncă nu există evaluări

- Power BI Vs Tableau - Which One Is Right For YouDocument9 paginiPower BI Vs Tableau - Which One Is Right For Youboo ajuÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Indirect Questions Exercise 21847309256Document3 paginiIndirect Questions Exercise 21847309256sirmaÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Writing Persuasive Texts PowerPoint Year 5 and Year 6 Microsoft PowerPoint 24562.potxDocument20 paginiWriting Persuasive Texts PowerPoint Year 5 and Year 6 Microsoft PowerPoint 24562.potxMr. RamÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Master Iscrizione en 12426Document2 paginiMaster Iscrizione en 12426msa65851Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Science Lesson Plan SampleDocument13 paginiScience Lesson Plan SamplePritipriyaÎncă nu există evaluări

- National Emergency Medicine Board Review CourseDocument1 paginăNational Emergency Medicine Board Review CourseJayaraj Mymbilly BalakrishnanÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Demo June 5Document10 paginiDemo June 5Mae Ann Carreon TrapalÎncă nu există evaluări

- Study and Evaluation Scheme For Diploma Programe in Sixth Semester (Civil Engineering)Document2 paginiStudy and Evaluation Scheme For Diploma Programe in Sixth Semester (Civil Engineering)AlphabetÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Updated Schedule For The Month of November 2022, UPTAC 2022Document1 paginăUpdated Schedule For The Month of November 2022, UPTAC 2022Priyanka SharmaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Week1module-1 Exemplar Math 7Document5 paginiWeek1module-1 Exemplar Math 7Myka Francisco100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Higher EducationDocument19 paginiHigher EducationAnonymous pxy22mwps5Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- PlummerDocument321 paginiPlummerEnzo100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Drohvalenko - Ea - 2021 - First Finding of Triploid in Mozh RiverDocument7 paginiDrohvalenko - Ea - 2021 - First Finding of Triploid in Mozh RiverErlkonigÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- TheraDocument4 paginiTheramaircusÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- B2016 Interpersonal and Intrapersonal Expectancies, Trusz ROUTLEDGEDocument203 paginiB2016 Interpersonal and Intrapersonal Expectancies, Trusz ROUTLEDGEricÎncă nu există evaluări

- Week 5 Data Analysis Process WorksheetsDocument6 paginiWeek 5 Data Analysis Process WorksheetsAngelica AlejandroÎncă nu există evaluări

- 2023 06 19 VacDocument2 pagini2023 06 19 VacAnanyaÎncă nu există evaluări

- Sections of A LibDocument4 paginiSections of A LibKarenah KarviÎncă nu există evaluări

- Site Directed MutagenesisDocument22 paginiSite Directed MutagenesisARUN KUMARÎncă nu există evaluări

- DBAS Assignment Spring Winter 2023 FINALDocument5 paginiDBAS Assignment Spring Winter 2023 FINALEaindra KhinÎncă nu există evaluări

- B1 Writing Intermediate 1Document2 paginiB1 Writing Intermediate 1Mohamed NasirÎncă nu există evaluări

- Solutions Manual For Power System Analysis and Design 5th Edition by Glover PDFDocument15 paginiSolutions Manual For Power System Analysis and Design 5th Edition by Glover PDFFrederick Cas50% (2)

- IPCR Portfolio MOVs TrackerDocument10 paginiIPCR Portfolio MOVs TrackerKris Tel Delapeña ParasÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Facilitator PDFDocument8 paginiFacilitator PDFAnand ChoubeyÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)