Documente Academic

Documente Profesional

Documente Cultură

Safety and Kelly Valves

Încărcat de

flasher_for_nokiaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Safety and Kelly Valves

Încărcat de

flasher_for_nokiaDrepturi de autor:

Formate disponibile

PRESSURE CONTROL SYSTEMS

TIW CORPORATION A PEARCE INDUSTRIES COMPANY

SAFETY & KELLY VALVE SYSTEMS

TIW SAFETY & KELLY VALVES

TIW Stab-In Safety Valve is designed to quickly stab into the drill pipe or tubing and close in case a well kicks. The ball-type design permits it to be compact, easy to handle and yet very strong. This valve is designed to only hold pressure from below the ball. While API does not address the requirements of this valve design, TIW manufactures and tests these valves with the same specifications as the Class I Kelly Valve with exception of the upper ball test. TIW Class I & Class II Kelly Valves may be utilized as a Drill Stem Safety Valve or as an Upper or Lower Kelly Cock and is designed to hold pressure from both directions. The ball is stainless steel and closes easily. The full bore Kelly Valve provides bores equivalent to the drill pipe or tubing connections and wont interfere with running tools like core barrels or survey tools. Valves can be configured to match field end connections up to a 4 bore. TIW Kelly Valve Design and Quality System are certified by API. TIW Safety and Kelly Valves are also offered for H2S service, meeting all NACE standards Standard Pressure rating is 10,000 PSI Test with higher pressure ratings available.

VALVE MATRIX

TYPE SAFETY VALVES

CLASS I KELLY VALVES

CLASS II KELLY VALVES

5,000 WP/10,000 Test 10,000 WP/15,000 Test 15,000 WP/22,000 Test Available in H2S design.

X X X X

X X X X

X X X X

Headquarters: 12300 S. Main (77035) - P.O. Box 35729 (77235-5729) - Houston, Texas - Tel 713-729-2110

www.tiwtools.com

Safety & Kelly Valves

CLASS I & CLASS II KELLY VALVES

CLASS I BALL TYPE KELLY VALVE

APIs current Spec 7-1, Section 5, has created two classifications for Kelly and Drill Stem Safety Valves, Class I and Class II. Material specifications for both classes of valves remain the same. Class I valves are any valves produced prior to the First Edition of Spec 7-1, plus any new valve ordered under the specification as a Class I Valve. The Class I Valve design and testing criteria has remained the same as previous Specs. Each new valve shall be tested to the hydrostatic test pressure by the following method. A Shell pressure test will be performed in two steps. One, the valve will have a low pressure test of 250 PSI both above and below the ball. Two, the valve will be pressure tested to the full working rating of the valve from below the ball. This class of valve remains the same as the Mud Saver/Kick Protection Valve manufactured by TIW for over 40 years.

Headquarters: 12300 S. Main (77035) - P.O. Box 35729 (77235-5729) - Houston, Texas - Tel 713-729-2110

www.tiwtools.com

Safety & Kelly Valves

CLASS I & CLASS II KELLY VALVES

CLASS II BALL TYPE KELLY VALVE

Under the new specification the Class 2 valve has the major design changes and hydrostatic testing. The valve is now required to be tested above and below the ball at full working pressure along with a low pressure test of 250 psi. The valve will be shell pressure tested to the test rating of the valve. In addition, the valve will have an external test of 2500 psi above the operating stem. It should be noted that the external test is onlyrequired one time for verification of the valve design. TIWs major design improvementsto the Class 2 Kelly and Drill Stem Safety Valves are as follow: 1. High torque middle connection 2. Tighter tolerances for external testing 3. Bottom located operating stem for longer and more accurate operation on ball 4. Radius seat providing a larger seat/seal to ball contact, resulting in better sealing under high/low pressure 5. Double lead thread on middle connection for easy make-up and resistance to high torque 6. New design spring for maximum deflection providing constant force on ball 7. Testing above and below the ball at full working pressure API does not address Valves manufactured to H2S requirements. TIW meets the requirements of NACE MRO175-2003 specification for materials when designing and manufacturing Kelly valves. The test requirements are the same as Class 1 or Class 2 as specified by the customers Purchase Order.

Headquarters: 12300 S. Main (77035) - P.O. Box 35729 (77235-5729) - Houston, Texas - Tel 713-729-2110

www.tiwtools.com

Safety & Kelly Valves

Kelly Valve Class I & II API Spec. 7-1 First Edition Section 5

1. Design minimum 1.25 of test pressure (Class I & II) A. B. C. D. E. High torque middle connection Double lead threadflat shoulder (no angle) (Class II only) Radius seat w/seal ring (Class II only) Bottom Locate control (Class II only) Control ORing positioned for external pressure (Class II only) Modified lower seat for corrugated spring optimum deflection and double step (Class II)

2. Valve will hold pressure from top and bottom-(Class II only) A. B. C. D. Stem 2,000 psi externallow pressure 250 psi (Stem test performed once, for each valve design, not for each valve manufactured) (Class II) Top seat 250 psi low pressuremax. working pressure (Class II) Bottom seat 250 psi max. working pressure (Class I & II) Valve shell test Test pressure (Class I & II)

3. Seals will be tested @ 14 deg F and 194 deg F with test fluid as per test procedure as per 4.5.2 and 4.5.3 (once for each valve design, not for each valve manufactured) (Class II only) 4. Testing: Shell testing: Both ends caped with Ball half closed. Both the low pressure and high pressure test shall be conducted in three parts. (low pressure 250 psi)(high pressuretest rating of valve) (Applies to both Class I & II) a. Initial pressure holding period for 3 minutes b. Reduction of pressure to zero c. Final pressure 10 minutes minimum B. Working pressure test: Test period shall be for a minimum of 5 minutes a. Pressure from belowLow pressure 250 psihigh pressure shall be working pressure of valve (Applies to both Class I & II) b. Pressure from aboveLow pressure 250 psihigh pressure shall be working pressure of valve (Class II only) 5. Marking: (Class I & II) A. Low Stress Stamp All of B will be placed in mill recess B. Manufacture name or Mark (logo) Class of service (type I or II) Serial Number Date of manufacture (year/month) Maximum working pressure C. Connection Size and style on O.D. surface adjacent to connection D. Indication of Rotation direction required to position valve in closed position. E. Indication of mud flow shall be marked on Class I valves with and arrow ( ) and word flow 6. NDT Testing: (Class I & II) A. End connections and any service connections shall be non-destructively inspected by the wet magnetic particle method for both transverse and longitudinal defects in accordance with ASTM E709. 7. Materials: A. Materials will not change as per TIW specifications for both Class I & II. A.

Headquarters: 12300 S. Main (77035) - P.O. Box 35729 (77235-5729) - Houston, Texas - Tel 713-729-2110

www.tiwtools.com

Safety & Kelly Valves

CLASS II BALL TYPE KELLY VALVE

Designed to API Spec 7-1 , First Edition, Section 5

Tested to full pressure from above and below the ball

TIW Valve Design and Quality System certified by API

Full open bore to match field end connection in most sizes

Bottom located Operating Stem

Available in 5K, 10K or 15K working pressure design

High Torque Middle Connection

Design tested to 2500 PSI external pressure Can be orderd with field connections to match drill pipe or tubing

Headquarters: 12300 S. Main (77035) - P.O. Box 35729 (77235-5729) - Houston, Texas - Tel 713-729-2110

www.tiwtools.com

Safety & Kelly Valves

S-ar putea să vă placă și

- Tiw Valves BrochureDocument4 paginiTiw Valves BrochureBahman MatouriÎncă nu există evaluări

- Valvula Chek Cameron PDFDocument4 paginiValvula Chek Cameron PDFelisanaÎncă nu există evaluări

- Technical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Document16 paginiTechnical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Riski KurniawanÎncă nu există evaluări

- Packard CatalogDocument22 paginiPackard Catalogcrni roko100% (1)

- 5-0001 Wire Line Guide BJDocument1 pagină5-0001 Wire Line Guide BJJacekÎncă nu există evaluări

- BOP Replacement Parts CatalogDocument60 paginiBOP Replacement Parts Catalogdesavinicius100% (1)

- Catalogo Completo GuibersonDocument63 paginiCatalogo Completo Guibersonjohangomezruiz100% (3)

- Model FC PDFDocument22 paginiModel FC PDFAbde Esselam100% (1)

- Anson E Typs Gate Valve With Fail Safe Closed ActuatorDocument12 paginiAnson E Typs Gate Valve With Fail Safe Closed ActuatorWeniton Oliveira0% (1)

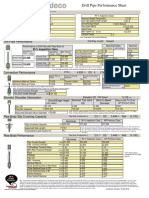

- Drill Pipe Performance Data SheetDocument3 paginiDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Oil Field Elastomer LeadersDocument21 paginiOil Field Elastomer Leadersjesus100% (1)

- 16 25 Hydraulic Casing TongDocument2 pagini16 25 Hydraulic Casing TongAdel Ahmed100% (1)

- INTEGRATED OEM GENERAL ELASTOMER CATALOG - 1 2020bDocument45 paginiINTEGRATED OEM GENERAL ELASTOMER CATALOG - 1 2020bMehdi Soltani0% (1)

- PTC VR Lubricator Tool: Safest & Most Versatile for Wellhead InterventionDocument2 paginiPTC VR Lubricator Tool: Safest & Most Versatile for Wellhead InterventionChrisÎncă nu există evaluări

- MUD PUMP EXPENDABLES Emsco PDFDocument9 paginiMUD PUMP EXPENDABLES Emsco PDFleoÎncă nu există evaluări

- Side Pocket Mandrel CatalogDocument32 paginiSide Pocket Mandrel CatalogAliyah Khan100% (1)

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts ListDocument10 paginiSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts ListBaris Unal100% (3)

- Access Manual ToolsDocument72 paginiAccess Manual ToolsJinhichi Molero Rodriguez0% (1)

- Hi Kal Catalogue New OptDocument16 paginiHi Kal Catalogue New Optask101Încă nu există evaluări

- Manual: CDQ (S) Sucker Rod ElevatorsDocument5 paginiManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaÎncă nu există evaluări

- Power Slip Lifter Systems CatalogDocument36 paginiPower Slip Lifter Systems CatalogAdrian Cantaragiu100% (1)

- Blowout Preventer (BOP) Stack API Spec 16A: Shanghai Sunry Petroleum Equipment Co., LTDDocument4 paginiBlowout Preventer (BOP) Stack API Spec 16A: Shanghai Sunry Petroleum Equipment Co., LTDMattar NizwaÎncă nu există evaluări

- Cameron Type U BOPDocument4 paginiCameron Type U BOPana1312Încă nu există evaluări

- Kline Technical Units Service Tools and Accessories WEB PDFDocument320 paginiKline Technical Units Service Tools and Accessories WEB PDFAdhie Waelacxh50% (2)

- Hydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedDocument4 paginiHydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedJose BarreroÎncă nu există evaluări

- Axon-Type50u Ram BopDocument4 paginiAxon-Type50u Ram BopMohie Khosravani0% (1)

- BVM Catelogue New-2016 PDFDocument116 paginiBVM Catelogue New-2016 PDFOperationÎncă nu există evaluări

- Cameron CatalogDocument53 paginiCameron CatalogJAY SINGHAM0% (1)

- Providing Comprehensive Drilling Solutions WorldwideDocument40 paginiProviding Comprehensive Drilling Solutions WorldwideLuis Rolando SirpaÎncă nu există evaluări

- Swivel Joints, Interchangeable FMC and SPMDocument3 paginiSwivel Joints, Interchangeable FMC and SPMAlice MiÎncă nu există evaluări

- TC104 00天车图册-EDocument16 paginiTC104 00天车图册-EKaleem UllahÎncă nu există evaluări

- Section 4: Pressure Control EquipmentDocument47 paginiSection 4: Pressure Control Equipmentgonzalito777Încă nu există evaluări

- Atlas Bradford (Ver03-Apr05)Document8 paginiAtlas Bradford (Ver03-Apr05)Gabriel IbarraÎncă nu există evaluări

- Master Bushing-Bowls - DENCON ToolDocument5 paginiMaster Bushing-Bowls - DENCON ToolcristinelbÎncă nu există evaluări

- Cameron DL Packer Assembly 11in - TC9609 - E-22Document1 paginăCameron DL Packer Assembly 11in - TC9609 - E-22Marcos ChavarriaÎncă nu există evaluări

- Hydril GK Annular Blowout PreventersDocument13 paginiHydril GK Annular Blowout PreventersJIN WANGÎncă nu există evaluări

- Engineering Bulletin on High Temperature BOP ElastomersDocument1 paginăEngineering Bulletin on High Temperature BOP ElastomersWaleed Barakat MariaÎncă nu există evaluări

- Running Procedure WeatherfordDocument46 paginiRunning Procedure WeatherfordiswantmachooÎncă nu există evaluări

- Heshka Oil Catalog 2019Document16 paginiHeshka Oil Catalog 2019Michael PerschkeÎncă nu există evaluări

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 paginiDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaÎncă nu există evaluări

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 paginiTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedÎncă nu există evaluări

- Catalog 2Document44 paginiCatalog 2Enrique HortaÎncă nu există evaluări

- Wellhead Equipment CatalogDocument29 paginiWellhead Equipment CatalogDewy PambayunÎncă nu există evaluări

- Low Force Shear Ram Test Results SummaryDocument2 paginiLow Force Shear Ram Test Results SummaryBala KrishnanÎncă nu există evaluări

- Nov Bushings Slips ClampsDocument8 paginiNov Bushings Slips ClampsRICHARDÎncă nu există evaluări

- Bop Test Info PDFDocument18 paginiBop Test Info PDFjairaso2950Încă nu există evaluări

- Maintain Annular BOP EfficiencyDocument21 paginiMaintain Annular BOP EfficiencyDavid GonzalezÎncă nu există evaluări

- Ball-Type Kelly and Safety Valves GuideDocument3 paginiBall-Type Kelly and Safety Valves GuideAlfred Hernandez Mendoza50% (2)

- Handling ToolsDocument33 paginiHandling ToolsDaladier LozanoÎncă nu există evaluări

- Varcoshafer BOP PartsDocument94 paginiVarcoshafer BOP PartsChris Chapman60% (5)

- DL Bop BrochureDocument4 paginiDL Bop BrochurekrishnsgkÎncă nu există evaluări

- Inside BOP Specs and SizesDocument1 paginăInside BOP Specs and SizesWanto SupriyoÎncă nu există evaluări

- TPWSD Catalog 2010Document36 paginiTPWSD Catalog 2010miguel mendozaÎncă nu există evaluări

- Bop Type U & Um Replacement Parts CatalogDocument36 paginiBop Type U & Um Replacement Parts CatalogTaras100% (2)

- API 6A ValvesDocument12 paginiAPI 6A ValvesAnonymous AKxxg80hfÎncă nu există evaluări

- API 6A Valves Design, Construction and FeaturesDocument12 paginiAPI 6A Valves Design, Construction and Featuresedo_tapia_ur100% (1)

- Butterfly Valve ConcentricDocument6 paginiButterfly Valve ConcentricpramodtryÎncă nu există evaluări

- FL - Hydronic Piping SpecialtiesDocument8 paginiFL - Hydronic Piping SpecialtiesAbdul RaheemÎncă nu există evaluări

- PDF - Gate Valve OS and YDocument10 paginiPDF - Gate Valve OS and YLENINROMEROH4168Încă nu există evaluări

- Hydril Annular BOP1Document2 paginiHydril Annular BOP1Abde EsselamÎncă nu există evaluări

- Astm A479Document7 paginiAstm A479Martin RomeroÎncă nu există evaluări

- Bimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55Document13 paginiBimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55flasher_for_nokiaÎncă nu există evaluări

- HDLS Series Switches: Installation Instructions For TheDocument4 paginiHDLS Series Switches: Installation Instructions For Theflasher_for_nokiaÎncă nu există evaluări

- Choke ParveenDocument3 paginiChoke ParveenYM Edwin Gil BeltranÎncă nu există evaluări

- Astm A479Document7 paginiAstm A479Martin RomeroÎncă nu există evaluări

- Choke and Kill Manifold Brochure PDFDocument12 paginiChoke and Kill Manifold Brochure PDFtaloslamomia9417100% (1)

- LC1D115P7: Product Data SheetDocument3 paginiLC1D115P7: Product Data Sheetflasher_for_nokiaÎncă nu există evaluări

- CX1020 - Basic CPU Module: CX1020-0xxx CX1020-0xxx CX1020-0xxxDocument2 paginiCX1020 - Basic CPU Module: CX1020-0xxx CX1020-0xxx CX1020-0xxxflasher_for_nokiaÎncă nu există evaluări

- Laboport: Mini Diaphragm Vacuum Pumps and CompressorsDocument2 paginiLaboport: Mini Diaphragm Vacuum Pumps and Compressorsflasher_for_nokiaÎncă nu există evaluări

- ANSI Flanges Dimensions Specs Grades ClassesDocument23 paginiANSI Flanges Dimensions Specs Grades ClassesVenkatesh GangadharÎncă nu există evaluări

- Thermowell For Thermometers ManualDocument40 paginiThermowell For Thermometers Manualflasher_for_nokiaÎncă nu există evaluări

- TD 670 676 680 8PG BW Oct2015Document8 paginiTD 670 676 680 8PG BW Oct2015flasher_for_nokiaÎncă nu există evaluări

- Bill of Materials for Gate ValveDocument6 paginiBill of Materials for Gate Valveflasher_for_nokiaÎncă nu există evaluări

- Hydril Annular BOP1Document2 paginiHydril Annular BOP1Abde EsselamÎncă nu există evaluări

- Assessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density LogsDocument7 paginiAssessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density Logsflasher_for_nokiaÎncă nu există evaluări

- API 7K Certified Mud Pump Parts ListDocument23 paginiAPI 7K Certified Mud Pump Parts Listflasher_for_nokiaÎncă nu există evaluări

- USDA Engineering Classification of Rock MaterialsDocument61 paginiUSDA Engineering Classification of Rock MaterialsTanÎncă nu există evaluări

- Doniflon 2010: Properties Appropriate Industries & ApplicationsDocument2 paginiDoniflon 2010: Properties Appropriate Industries & Applicationsflasher_for_nokiaÎncă nu există evaluări

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralDocument1 pagină5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralFranklin Jose Almera AcostaÎncă nu există evaluări

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralDocument1 pagină5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralFranklin Jose Almera AcostaÎncă nu există evaluări

- Manual Bomba de LodosDocument37 paginiManual Bomba de LodosJuan RuizÎncă nu există evaluări

- rfb7 de en PDFDocument2 paginirfb7 de en PDFflasher_for_nokiaÎncă nu există evaluări

- Data Sheet P 550: Technical InformationDocument1 paginăData Sheet P 550: Technical Informationflasher_for_nokiaÎncă nu există evaluări

- Rfb7 - de - en Triple Mas 6000Document2 paginiRfb7 - de - en Triple Mas 6000Miguel GonzalezÎncă nu există evaluări

- Rfb7 - de - en Triple Mas 6000Document2 paginiRfb7 - de - en Triple Mas 6000Miguel GonzalezÎncă nu există evaluări

- Ifi 115Document1 paginăIfi 115Vinay PawarÎncă nu există evaluări

- 12 Point Flange Screws Technical SpecificationsDocument1 pagină12 Point Flange Screws Technical Specificationsflasher_for_nokiaÎncă nu există evaluări

- Duraflo Composite Oemduea Mongoose PsDocument2 paginiDuraflo Composite Oemduea Mongoose Psflasher_for_nokiaÎncă nu există evaluări

- Mud Pump Consumables - enDocument24 paginiMud Pump Consumables - enflasher_for_nokia100% (1)

- 8 4078a PDFDocument5 pagini8 4078a PDFarasÎncă nu există evaluări

- 62-00 ICAO+doc+9137 Airport+Services+Manual Part+9+-+Airport+Maintenance+Practices FR 110228 GanDocument56 pagini62-00 ICAO+doc+9137 Airport+Services+Manual Part+9+-+Airport+Maintenance+Practices FR 110228 GanAnibal Jacek Quirós P.Încă nu există evaluări

- CMMS Best Practices Study Report - ReliabilitywebDocument49 paginiCMMS Best Practices Study Report - ReliabilitywebSaulo CabreraÎncă nu există evaluări

- DJL Robles Builders: General Contractor Construction SupplyDocument1 paginăDJL Robles Builders: General Contractor Construction SupplyFritz NatividadÎncă nu există evaluări

- 02 February 1990Document108 pagini02 February 1990Monitoring TimesÎncă nu există evaluări

- Oca Guideline For Seismic Restraint in Ottawa RegionDocument24 paginiOca Guideline For Seismic Restraint in Ottawa Regionlsaishankar100% (1)

- PCI Secure Software Standard v1 - 0Document67 paginiPCI Secure Software Standard v1 - 0Antonio ClimaÎncă nu există evaluări

- Automatic Wall Painting Robot JournalDocument2 paginiAutomatic Wall Painting Robot JournalAnonymous xhi01squÎncă nu există evaluări

- Canter: ECU Wire DiagramDocument6 paginiCanter: ECU Wire DiagramKristen Holmes100% (1)

- Process Filtration & EquipmentDocument8 paginiProcess Filtration & EquipmentleslieÎncă nu există evaluări

- Parallelization of Dijkstra's AlgorithmDocument14 paginiParallelization of Dijkstra's AlgorithmDionysios Zelios100% (2)

- Quiz Ece427Document16 paginiQuiz Ece427Saraswathi AsirvathamÎncă nu există evaluări

- Colt Frontier Scout Buntline Frontier Scout RevolversDocument5 paginiColt Frontier Scout Buntline Frontier Scout RevolversSerteco Coleccionista MilitariaÎncă nu există evaluări

- Chem 1221 Module 6 PDFDocument49 paginiChem 1221 Module 6 PDFMaries San PedroÎncă nu există evaluări

- Spacelab Users Guide A Short Introduction To Spacelab and Its UseDocument22 paginiSpacelab Users Guide A Short Introduction To Spacelab and Its UseBob AndrepontÎncă nu există evaluări

- Chemicals Blowing Agent in The Rubber IndustryDocument10 paginiChemicals Blowing Agent in The Rubber IndustryBenpetro ChaichuaÎncă nu există evaluări

- Chap 004 Process CostingDocument116 paginiChap 004 Process CostingdhominicÎncă nu există evaluări

- Civil and Structural BS Codes ListDocument3 paginiCivil and Structural BS Codes Listvenugopal Bedadakota100% (1)

- Bahasa Inggris BAB VIDocument4 paginiBahasa Inggris BAB VIAgus SulistionoÎncă nu există evaluări

- Brochure Course PLC Prog Basic (ST-PRO1)Document4 paginiBrochure Course PLC Prog Basic (ST-PRO1)Ciprian BeresÎncă nu există evaluări

- Alumec 89 Guide - Leading Aluminum Alloy for ToolingDocument12 paginiAlumec 89 Guide - Leading Aluminum Alloy for ToolingMedoBoudyÎncă nu există evaluări

- Zodiac Services: Transmittal SheetDocument217 paginiZodiac Services: Transmittal SheetNegin ForozeshÎncă nu există evaluări

- Goal ProgrammingDocument12 paginiGoal ProgrammingEce SunerÎncă nu există evaluări

- UNAPPROVED PARTS NOTIFICATION FOR AIRCRAFT COMPONENTSDocument18 paginiUNAPPROVED PARTS NOTIFICATION FOR AIRCRAFT COMPONENTSJose Luis Piña CanoÎncă nu există evaluări

- Types of Computer Network TopologiesDocument9 paginiTypes of Computer Network TopologiesAamna humayunÎncă nu există evaluări

- HP Quality Center Student GuideDocument106 paginiHP Quality Center Student GuideKowshik ChakrabortyÎncă nu există evaluări

- COLUMN EFFECTIVE LENGTH - Yura1971q2Document6 paginiCOLUMN EFFECTIVE LENGTH - Yura1971q2ellisbl100% (1)

- FC-M5100 SM-BB52: DEORE CranksetDocument1 paginăFC-M5100 SM-BB52: DEORE CranksetIvan IvanovÎncă nu există evaluări

- Normes ClfileDocument36 paginiNormes Clfileseb_dominiqueÎncă nu există evaluări

- Drum BrakesDocument7 paginiDrum BrakesZahir KhiraÎncă nu există evaluări