Documente Academic

Documente Profesional

Documente Cultură

Fermi Lab Orbital Welding Procedure

Încărcat de

Pramod AthiyarathuTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fermi Lab Orbital Welding Procedure

Încărcat de

Pramod AthiyarathuDrepturi de autor:

Formate disponibile

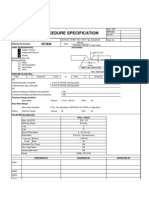

Fermi National Accelerator Laboratory

Technical Division-Machine Shop

Welding Procedure Specification

Welding Procedure Specification No.:

Revision No.: Revision Date:

WPS AMI/Orbital 001

Remarks:

Date: 12/29/2009**

Supporting PQR No.(s): PQR AMI/Orbital 001

Welding Processes:

GTAW/Automatic

(2)

(Manual, Automatic, Machine, Semi-automatic)

Joints (QW-402): Joint Design: Square Edge Groove Retainer: No Joint Details:

Backing: Gas Backing Material (Type): Argon Gas Type: Non-Metallic *** Metallic (Non-fusing)

Remainder:

.035

.250 0.0to 0.002 opening Square Edge Butt

ASTM A269 316/316L .035 x 0.250

AMI Orbital Welding Machine (Autogenous only) S-No.: 8 Group1 TO Base Metals (QW403): Specification Type and Grade: ASTM A 269 Type 316/316L TO Specification Type and Grade: ASTM A 269 Type 316/316L OR Chemical Analysis and Mechanical Properties: TO Chemical Analysis and Mechanical properties: Thickness Range: Process 1 Groove: . 035 Fillet: Unlimited Base Metal: Groove: .035 Fillet: Unlimited Deposited Weld Metal: Groove: .250 Minimum Fillet: Unlimited Pipe Diameter Range: Other: Filler Metals (QW-404) Specification No. (SFA): AWS No, (Class): F-No.: A No.: Size of Filler Metals: Deposited Weld Metal Thickness Range: Electrode-Flux (Class): Flux Trade Name: Consumable Insert:

Other:

Each Base Metal-Filler Metal Combination should be recorded individually

S-No.:

8 Group 1

Process 2

Groove: Groove: Groove: Fillet: Fillet: Fillet:

Process 1 Autogenous No Filler

Process 2

Groove:

Fillet: Unlimited

Groove:

Fillet:

Page 1 of 2

12/29/09

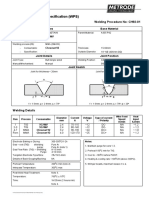

Fermi National Accelerator Laboratory

Technical Division-Machine Shop

Welding Procedure Specification

Positions (QW-405 Positions of Groove: Welding Progression Positions of Fillet Preheat (QW-408) Preheat Temperature: Interpass Temperature: Preheat Maintenance: Minimum Welding Temperature All Upward & downward All Post Heat Treatment (QW-407) Temperature Range: None Time Range N/A

Gas (QW-408) Minimum 50 F Maximum-Not Recorded None 32 F

% Composition

Shielding Trailing Backing

Gases Argon None Argon

Mixture 99.9% *** 99.9%

Flow Rate 10-15 CFH *** 8-12 CFH

Electrical Characteristics (QW-409) Current AC or DC: Direct Current Tungsten Electrode: Size: .040 Mode of Metal Transfer for GMAW: N/A Electrode Wire Feed Speed Range: N/A

Polarity:

Straight EWCe-2

Characteristics .030 arc gap

Pulsing

Technique (QW-410) String or Weave Bead: String Orifice or Gas Cup Size: AMI Orbital Head 9-500 Initial Interpass Cleaning (Brushing, Grinding, etc.): Initial Solvent Clean***Do not Brush after Welding Method of Back Gouging: None Oscillation: None Contact Tube to Work Distance: N/A Multiple or Single Pass (per side): Single Multiple or Single Electrode(s): Single Travel Speed (Range): See Sequence Chart Peening: None Other: Use manufacturer shaped and sized electrode. .040 tungsten with a .020 tip and a .30 arc gap

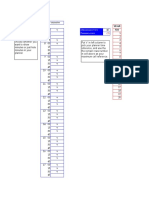

Sequence Chart : AMI Orbital Model 227 STD2.1 with Model 9-500 Weld Head and .40 Tungsten

.035wall x .500x ASTM A 269

Weld Levels 1 2 3 4 5 6

RPM Pulse ON Rotation

Continuous Primary Back

AMPS -Time 109

Primary Back

PULSE

Primary Back

1.00

24

.20

.20

Manual GTAW Tacking of assembly optional by qualified welder. Use pre-shaped and pre-sized factory supplied tungsten

Page 2 of 2

12/29/09

S-ar putea să vă placă și

- Wps Gtaw Monel b127 b164Document2 paginiWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- DiesDocument80 paginiDiesRajyalakshmi.G50% (2)

- Complying With ISO 17025 A Practical GuidebookDocument122 paginiComplying With ISO 17025 A Practical Guidebookyes17025100% (8)

- 1define The Problem 2 Identify The Team 4determine The Root Causes 5look Across 7verify The SolutionDocument8 pagini1define The Problem 2 Identify The Team 4determine The Root Causes 5look Across 7verify The SolutionALFA ENGINEERINGÎncă nu există evaluări

- Drawings & Replacemnt PartsDocument11 paginiDrawings & Replacemnt PartsJohn Jairo Simanca CastilloÎncă nu există evaluări

- WELDER QUALIFICATION REPORTDocument2 paginiWELDER QUALIFICATION REPORTAkash Singh TomarÎncă nu există evaluări

- WPS GTAW Stainless SteelDocument2 paginiWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 paginiWps & PQR For Valve Installation - XLSX Fix TerbarufebriÎncă nu există evaluări

- API 6A RadiographyDocument4 paginiAPI 6A RadiographyminakshissawantÎncă nu există evaluări

- Wps Sp14 Reva PDFDocument9 paginiWps Sp14 Reva PDFravi00098Încă nu există evaluări

- Cast IronDocument34 paginiCast IronMiguel Angel EscalanteÎncă nu există evaluări

- Kaizen Report ExampleDocument1 paginăKaizen Report ExamplePramod AthiyarathuÎncă nu există evaluări

- WPS (AsmeDocument8 paginiWPS (AsmeMohammad Elhedaby100% (6)

- Ami-003 WPSDocument2 paginiAmi-003 WPSBenjamin BrownÎncă nu există evaluări

- EN 15085 Part 5 - GaneshDocument36 paginiEN 15085 Part 5 - GaneshNiranjan Rajavel TigerÎncă nu există evaluări

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 paginiPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 paginiWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabÎncă nu există evaluări

- PQR WPQ Witness Report LatestDocument1 paginăPQR WPQ Witness Report LatestSatish KeskarÎncă nu există evaluări

- S 705v2020 06 Supplementary Specification To API Recommended Practice 582 For Welding of Pressure Containing Equipment and PipingDocument58 paginiS 705v2020 06 Supplementary Specification To API Recommended Practice 582 For Welding of Pressure Containing Equipment and PipingandyÎncă nu există evaluări

- Metal CuttingDocument39 paginiMetal Cuttingavinashn12Încă nu există evaluări

- A Comparison of ISO 15614 Part 1 and ASME IXDocument3 paginiA Comparison of ISO 15614 Part 1 and ASME IXsusanwebÎncă nu există evaluări

- WPS 316 LDocument4 paginiWPS 316 Llaz_k100% (2)

- Cajon-001 WPSDocument2 paginiCajon-001 WPSDanem HalasÎncă nu există evaluări

- Welding Procedure Specification for Vertical Storage TanksDocument6 paginiWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghÎncă nu există evaluări

- Cable Tray SpecDocument2 paginiCable Tray Specchegudi_vijaykumar100% (1)

- Heat Treatment of Nodular Cast IronDocument4 paginiHeat Treatment of Nodular Cast IronRoman_RomeoÎncă nu există evaluări

- P91 Repair With NiCrDocument76 paginiP91 Repair With NiCrElias KapaÎncă nu există evaluări

- Brazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Document3 paginiBrazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Joyce GordonioÎncă nu există evaluări

- Gta+sma PQRDocument3 paginiGta+sma PQRRahul MoottolikandyÎncă nu există evaluări

- O'Mealy ReamersDocument13 paginiO'Mealy ReamersRusty_Iron_WorksÎncă nu există evaluări

- WPS 2014-002 006 - 6G PipeDocument3 paginiWPS 2014-002 006 - 6G PipejeswinÎncă nu există evaluări

- Metrode - P92 WPS PDFDocument3 paginiMetrode - P92 WPS PDFXing ChenÎncă nu există evaluări

- Enclosure Standards PDFDocument8 paginiEnclosure Standards PDFnecmettinsengunÎncă nu există evaluări

- Blacksmith Knife TutorialDocument18 paginiBlacksmith Knife TutorialAndre Balen100% (2)

- WPQ Process As Per ISO-9606-1 2013Document4 paginiWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- D17.1 D17.1M 2017 Sample PQTR FormDocument1 paginăD17.1 D17.1M 2017 Sample PQTR FormPabloLamelaÎncă nu există evaluări

- InteractiveFormQB 482Document1 paginăInteractiveFormQB 482Afriadi Budi PrasetyoÎncă nu există evaluări

- Procedure for Welder QualificationDocument1 paginăProcedure for Welder QualificationSatish KeskarÎncă nu există evaluări

- Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchDocument4 paginiWelding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchaÎncă nu există evaluări

- SAFed TC 4 Welding Procedure and Welder Approval Testing 21 Mar 2019 PDFDocument24 paginiSAFed TC 4 Welding Procedure and Welder Approval Testing 21 Mar 2019 PDFFirdaus NasirÎncă nu există evaluări

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 paginiWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEÎncă nu există evaluări

- Filler Metal Selection ChartDocument1 paginăFiller Metal Selection ChartMuhammed NoorulÎncă nu există evaluări

- VP16 PDFDocument13 paginiVP16 PDFKara WhiteÎncă nu există evaluări

- ASME P Material NumbersDocument1 paginăASME P Material Numbersmahi1437100% (1)

- TIG-welding Gases PDFDocument2 paginiTIG-welding Gases PDFwenigmaÎncă nu există evaluări

- Gmaw Complete Aws d1.6Document1 paginăGmaw Complete Aws d1.6Hamza Nouman100% (1)

- En ASME ComparisonDocument18 paginiEn ASME ComparisonPeterWay100% (1)

- Efqm Self AssessmentDocument60 paginiEfqm Self AssessmentPramod AthiyarathuÎncă nu există evaluări

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 paginiWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielÎncă nu există evaluări

- P91 Profile WpsDocument6 paginiP91 Profile WpsManzar KhanÎncă nu există evaluări

- Filler Materials TestingDocument34 paginiFiller Materials TestingSunilÎncă nu există evaluări

- SP010 2 Corrective Action ProcedureDocument3 paginiSP010 2 Corrective Action ProcedurePramod AthiyarathuÎncă nu există evaluări

- Fcaw 16 THKDocument5 paginiFcaw 16 THKparesh2387Încă nu există evaluări

- Sample Procedure Qualification Record (PQR) : (Smaw, Gmaw, Gtaw, Fcaw, Ofw, Paw)Document2 paginiSample Procedure Qualification Record (PQR) : (Smaw, Gmaw, Gtaw, Fcaw, Ofw, Paw)Thanakit Srisaeng0% (1)

- 1035 03Document2 pagini1035 03Anuj ShahiÎncă nu există evaluări

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 paginiTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanÎncă nu există evaluări

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 paginiPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyÎncă nu există evaluări

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDocument1 paginăWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0Încă nu există evaluări

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 paginiWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniÎncă nu există evaluări

- BPV IX-16-3 QW-283 - ButteringDocument1 paginăBPV IX-16-3 QW-283 - ButteringyutweldingÎncă nu există evaluări

- WPS API1104 A516 GR 70Document1 paginăWPS API1104 A516 GR 70Erick HoganÎncă nu există evaluări

- SB410 (JIS) - Worldwide Equivalent Grades 11Document1 paginăSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)

- Data Sheet Material 2.4819Document3 paginiData Sheet Material 2.4819BoberÎncă nu există evaluări

- WPQR Welding Procedure QualificationDocument3 paginiWPQR Welding Procedure QualificationThanasis KyrgiazoglouÎncă nu există evaluări

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 paginiBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarÎncă nu există evaluări

- PT Kuwera Karya Me: PanduDocument2 paginiPT Kuwera Karya Me: PanduGalang Pratama PutraÎncă nu există evaluări

- Equivalent ASME en MaterialsDocument3 paginiEquivalent ASME en MaterialsChee WeiÎncă nu există evaluări

- Model WopqDocument2 paginiModel WopqAnilkumarGopinathanNairÎncă nu există evaluări

- 004 Gtaw P5aDocument16 pagini004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 paginiISO - TR - 15608 - Welding Guide Line PDFDacher DanielÎncă nu există evaluări

- Wps For Aluminium WeldingDocument8 paginiWps For Aluminium WeldingMohammed MusaÎncă nu există evaluări

- Welding of Dissimilar Ferritic Joints For New Power Plant SteelsDocument21 paginiWelding of Dissimilar Ferritic Joints For New Power Plant SteelsspinpinÎncă nu există evaluări

- p91 Pwht. AwsDocument4 paginip91 Pwht. AwssantyagoÎncă nu există evaluări

- Supercito (E 42 5 B 32 h5)Document1 paginăSupercito (E 42 5 B 32 h5)brunizzaÎncă nu există evaluări

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Document2 paginiSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzÎncă nu există evaluări

- KGP-Flamme Cutting Proce For BEI PDFDocument4 paginiKGP-Flamme Cutting Proce For BEI PDFoomoomÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- Implementing ISO 10002 To Handle Customer ComplaintsDocument14 paginiImplementing ISO 10002 To Handle Customer ComplaintsPramod AthiyarathuÎncă nu există evaluări

- As ISO 10002 Guiding Principles-Bill DeeDocument12 paginiAs ISO 10002 Guiding Principles-Bill DeeDarren TanÎncă nu există evaluări

- This Document Has Been Supplied Under License by Shell To:: Replaced Not ReplacDocument2 paginiThis Document Has Been Supplied Under License by Shell To:: Replaced Not ReplacPramod Athiyarathu100% (1)

- Improvement Projects - Selection: YearDocument3 paginiImprovement Projects - Selection: YearPramod AthiyarathuÎncă nu există evaluări

- ISO 9001:2000 - Control of RecordsDocument2 paginiISO 9001:2000 - Control of RecordsPramod AthiyarathuÎncă nu există evaluări

- Pure Savings On Your New Mashreq Credit Card!: Offer DetailsDocument2 paginiPure Savings On Your New Mashreq Credit Card!: Offer DetailsPramod AthiyarathuÎncă nu există evaluări

- PREN Calculator Rev Feb 2011Document2 paginiPREN Calculator Rev Feb 2011Sales HBS SolutionsÎncă nu există evaluări

- Guide to ASME's CA Connect Customer User SystemDocument258 paginiGuide to ASME's CA Connect Customer User SystemPramod AthiyarathuÎncă nu există evaluări

- Accreditation or CertificationDocument8 paginiAccreditation or CertificationOsman AitaÎncă nu există evaluări

- Monthly Planner V1.2Document10 paginiMonthly Planner V1.2Pramod AthiyarathuÎncă nu există evaluări

- To Do List V1.0Document1 paginăTo Do List V1.0Pramod AthiyarathuÎncă nu există evaluări

- Schedule minutes showDocument9 paginiSchedule minutes show_Hennet_Încă nu există evaluări

- Six Sigma Applied To Reduce Patients' Waiting Time in A Cancer PharmacyDocument21 paginiSix Sigma Applied To Reduce Patients' Waiting Time in A Cancer PharmacyPramod AthiyarathuÎncă nu există evaluări

- Information Requirements For Welding of Pressure Containing Equipment and PipingDocument20 paginiInformation Requirements For Welding of Pressure Containing Equipment and PipingPramod Athiyarathu100% (1)

- Credit Card Pay Off Calculator V1.11Document2 paginiCredit Card Pay Off Calculator V1.11Pramod AthiyarathuÎncă nu există evaluări

- 2019s PDFDocument156 pagini2019s PDFvladkulÎncă nu există evaluări

- Quality in Outsourcing ISO9001 2015 PerspectiveDocument14 paginiQuality in Outsourcing ISO9001 2015 PerspectivePramod AthiyarathuÎncă nu există evaluări

- Data Sheet For Welding of Pressure Containing Equipment and PipingDocument9 paginiData Sheet For Welding of Pressure Containing Equipment and PipingPramod AthiyarathuÎncă nu există evaluări

- NCPWBBulletin 2010-07 Flange AssemblyDocument4 paginiNCPWBBulletin 2010-07 Flange AssemblyPramod AthiyarathuÎncă nu există evaluări

- HR Policies Required by Law - First Ref - 2018 PDFDocument33 paginiHR Policies Required by Law - First Ref - 2018 PDFImran AkbarÎncă nu există evaluări

- What Is LeanDocument16 paginiWhat Is LeanPramod AthiyarathuÎncă nu există evaluări

- Basics of LeanDocument21 paginiBasics of LeanPiter KiiroÎncă nu există evaluări

- Lecture 2 Overview Lean Waste EliminationDocument29 paginiLecture 2 Overview Lean Waste EliminationLucianÎncă nu există evaluări

- CNC machining problems and solutions optimized for SEODocument1 paginăCNC machining problems and solutions optimized for SEOMinh NhậtÎncă nu există evaluări

- SNAP+Documentation V1-2 ENDocument48 paginiSNAP+Documentation V1-2 ENVíctorAltamirano100% (1)

- Subject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IDocument2 paginiSubject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IMech DeptÎncă nu există evaluări

- Welding electrode filler wire consumption calculationDocument2 paginiWelding electrode filler wire consumption calculationRanjan Kumar100% (1)

- Mechanical Properties: Steel NutsDocument1 paginăMechanical Properties: Steel NutsJoseph BookerÎncă nu există evaluări

- Aws A5.5 - 96 PDFDocument55 paginiAws A5.5 - 96 PDFRichard Nelson Antonio EspinozaÎncă nu există evaluări

- Extrusion Process Seminar ReportDocument11 paginiExtrusion Process Seminar ReportHimanshu PatelÎncă nu există evaluări

- World Leading 2, 3 and 5-Axis CAM SoftwareDocument13 paginiWorld Leading 2, 3 and 5-Axis CAM SoftwarepatgigÎncă nu există evaluări

- GH4 Hammer Assembly Seals KitDocument6 paginiGH4 Hammer Assembly Seals Kitjose sierraÎncă nu există evaluări

- Weld AbilityDocument34 paginiWeld Abilityae1329Încă nu există evaluări

- Hybrid Electrochemical ProcessesDocument19 paginiHybrid Electrochemical ProcessesYahya Abdelhameed AamerÎncă nu există evaluări

- Hammers and Hatchets Catalog Showcases New Rocket HammerDocument12 paginiHammers and Hatchets Catalog Showcases New Rocket HammerJay SÎncă nu există evaluări

- ASTM A123 and G90 Specifications - American Galvanizers AssociationDocument3 paginiASTM A123 and G90 Specifications - American Galvanizers AssociationwinarnobÎncă nu există evaluări

- A385 11 PDFDocument8 paginiA385 11 PDFMajid Dawood KhanÎncă nu există evaluări

- Os Três Tipos de Operações de Dobra de ChapasDocument2 paginiOs Três Tipos de Operações de Dobra de ChapasFuinha120194Încă nu există evaluări

- ReCoil KeysertsDocument11 paginiReCoil KeysertsThor InternationalÎncă nu există evaluări

- AMPT (3140204) LAB MANUAL 2022 LNJDocument100 paginiAMPT (3140204) LAB MANUAL 2022 LNJShubham JadavÎncă nu există evaluări

- 07 Structural Steel inDocument10 pagini07 Structural Steel inpranesh09Încă nu există evaluări

- 01 Student M300 Ex S PDFDocument3 pagini01 Student M300 Ex S PDFMarlon GilerÎncă nu există evaluări