Documente Academic

Documente Profesional

Documente Cultură

Horner

Încărcat de

andrei_nokDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Horner

Încărcat de

andrei_nokDrepturi de autor:

Formate disponibile

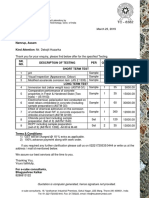

MAN0907-01-EN

Specifications / Installation

XLE OCS Model: HE-XE102-62

12 Digital DC Inputs ES2T-250/300 Temperature Sensor, ESP-100 Pressure Sensor, 2 Analog Inputs (Medium Resolution) 6 Digital Relay Outputs

1 Specifications HE-XE102 Specifications Digital DC Inputs Inputs per Module 12 including 4 configurable HSC inputs Commons per Module 1 Input Voltage Range 12 VDC / 24 VDC Absolute Max. Voltage 35 VDC Max. Input Impedance 10 k Input Current Positive Logic Negative Logic Upper Threshold 0.8 mA -1.6 mA Lower Threshold 0.3 mA -2.1 mA Max Upper Threshold 8 VDC Min Lower Threshold 3 VDC OFF to ON Response 1 ms ON to OFF Response 1 ms 10 kHz Totalizer/Pulse, Edges HSC Max. Switching Rate 5 kHz Frequency/Pulse, Width 2.5 kHz Quadrature Digital Relay Outputs Outputs per Module 6 relay Commons per Module 6 Max. Output Current per Relay 3 A at 250 VAC, resistive Max. Total Output Current 5 A continuous Max. Output Voltage 275 VAC , 30 VDC Max. Switched Power 1250 VA, 150 W Contact Isolation to XLE ground 1000 VAC Max. Voltage Drop at Rated 0.5 V Current Expected Life No load: 5,000,000 (See Derating section for chart.) Rated load: 100,000 300 CPM at no load Max. Switching Rate 20 CPM at rated load Type Mechanical Contact One update per ladder scan plus 10 Response Time ms Analog Inputs, Medium Resolution Number of Channels 2 0 - 10 VDC, Input Ranges 0 20 mA, 4 20 mA Safe input voltage range -0.5 V to +12V Current Mode Voltage Mode Input Impedance (Clamped @ -0.5 VDC to 12VDC) 100 500 k Nominal Resolution 10 Bits %AI full scale 32,000 counts Max. Over-Current 35 mA All channels converted once per Conversion Speed ladder scan Max. Error at 25C 4-20 mA 1.00% (excluding zero) 0-20 mA 1.00% *can be made tighter (~0.25%) by 0-10 VDC 1.50%* adjusting the digital filter setting to 3. Additional error for temperatures TBD o other than 25 C 160 Hz hash (noise) filter Filtering 1-128 scan digital running average filter Temperature/Pressure Sensor ES2T 250/300 ESP-100 Channel 1 2 Range 0-100 PSIG 5F - 300F Input Im 2.49 K ohms 249 ohms Nominal Res 10 bits Nominal %AI = 15000 2.49K ohms 249 ohms Conversion Speed All channels converted once per scan Typical Error Including Linearization 1 PSIG 2F Additional error for reading / ambient temperatures other than TBD 25 o C 160 Hz has (noise filter) Filtering 1-128 scan digital running average filter General Specifications Required Power(Steady State) 130 mA @ 24 VDC Required Power (Inrush) 30 A for 1 ms @ 24 VDC Primary Power Range 10 30 VDC Relative Humidity 5 to 95% Non-condensing Operating Temperature 0C to +50C 7/22/2009 Terminal Type Weight CE UL General Specifications Screw Type, 5 mm Removable 12 oz. (340.19 g)

See Compliance Table at

http://www.heapg.com/Pages/TechSupport/ProductCert.html o Clock Accuracy +/- 7 Minute/Month at 20 C Highest usable frequency for PWM output is 65 KHz

Panel Cut-Out and Dimensions

Note: Max. panel thickness: 5 mm. Refer to XLE User Manual (MAN0805) for panel box information and a handy checklist of requirements. Note: The tolerance to meet NEMA standards is 0.005 (0.1 mm).

3.622 [92mm]

3.622 [92mm]

001XLE002

Ports / Connectors / Cables

Note: The case of the XLE is black, but for clarity, it is shown in a lighter gray color. To Remove Back Cover: Unscrew 4 screws located on the back of the unit. Lift lid. I/O Jumpers: (Not Shown): I/O Jumpers (JP) are located internally. To access, remove back cover of unit. Wiring Connectors (J1 / J2): I/O Jumpers (JP1 / JP2), and External Jumpers (RS485) are described in the Wiring and Jumpers section of this document. CAUTION: Do not over tighten screws when screwing the lid back on.

DIP Switch

Memory Slot

J2 MJ2

(RS-232 / RS-485) I/O Jumper

MJ1

(RS-232 / RS-485)

J1

I/O Jumper

NET 1

(CsCAN)

Power

001XLE029-R2

Memory Slot: Uses Removable Memory for data logging, screen captures, program loading and recipes. Horner Part No.: HE-MC1 Serial Communications: MJ1: (RS-232 / RS-485) Use for Cscape programming and Application-Defined Communications. MJ2: (RS-232 / RS-485) Use for Application-Defined Communications.

Power Connector Power Up: Connect to Earth Ground. Apply 10 - 30 VDC. Screen lights up.

CAN Connector Use the CAN Connector when using CsCAN network.

__________________________________________________________________________________________________________________________________________________________________________

Page 1 of 4

ECN # 958

MAN0907-01-EN

Specifications / Installation XE102 J2 Black Positive Logic Digital In / Relay Out

230VAC OR 25VDC 230VAC OR 25VDC 230VAC OR 25VDC 230VAC OR 25VDC 230VAC OR 25VDC 230VAC OR 25VDC

N L

LOAD

Serial Communications J2 Black Terminal Connector C6 R6 C5 R5 C4 R4 C3 R3 C2 R2 C1 R1 H4 H3 H2 XE102 Name Relay 6 COM Relay 6 NO Relay 5 COM Relay 5 NO Relay 4 COM Relay 4 NO Relay 3 COM Relay 3 NO Relay 2 COM Relay 2 NO Relay 1 COM Relay 1 NO HSC4 / IN12 HSC3 / IN11 HSC2 / IN10

Serial Communications: MJ1: (RS-232 / RS-485) Use for Cscape programming and ApplicationDefined Communications. MJ2: (RS-232 / RS-485) Use for Application-Defined Communications.

C6 R6 C5

LOAD

N L

R5 C4

Pin

MJ1 Pins

Signal Direction

MJ2 Pins

Signal Direction

N L

LOAD

8

8 7 6 5 4 3 2 1

R4 C3

TXD RXD 0V NC RTS CTS RX- / TXRX+ / TX+

OUT IN Ground No Connect OUT IN IN / OUT IN / OUT

TXD RXD 0V NC TXTX+ RXRX+

OUT IN Ground No Connect OUT OUT IN IN

N L

LOAD

R3 C2

N L

LOAD

R2 C1

N L

LOAD

R1 H4

12-24VDC

0V ON J1

H3 H2

001XLE015

Wiring and Jumpers

5.2.

I/O Jumpers Settings (JP1 - JP2)

Wire according to the type of inputs / outputs used, and select the appropriate jumper option. Wiring Specifications For I/O wiring (discrete), use the following wire type or equivalent: Belden 9918, 18 AWG or larger. For shielded Analog I/O wiring, use the following wire type or equivalent: Belden 8441, 18 AWG or larger. For CAN wiring, use the following wire type or equivalent: Belden 3084, 24 AWG or larger. Location of I/O jumpers (JP) and wiring connectors (J1 and J2).

JP1 Digital DC In / HSC Positive Negative Logic Logic

JP2 Analog In (A3 A4) Current Voltage (20 mA) (10 V)

Note: When using JP2 (A3-A4), each channel can be independently configured.

001XLE066

Default

001XLE026

Note: The Cscape Module Setup configuration must match the selected I/O (JP) jumper settings.

J1 JP2 JP1 J2

5.3.

001XLE062

External DIP Switch Settings (or Jumpers Settings)

Positive Logic vs. Negative Logic Wiring The XLE can be wired for Positive Logic inputs or Negative Logic inputs.

I1

12-24VDC

Some XLes have jumpers to set RS-485 port termination, though most use DIP Switches. The External Jumpers or DIP Switches are used for termination of the RS-485 ports. The XLE is shipped un-terminated. To terminate, select one of the jumpers shipped with the product and insert it based upon the option that is desired or, select the switch and configure based upon the option that is desired.

As seen when looking at the top of the XLE unit: Refer to Section 3 for the location of the External Jumpers.

Factory Use (default none) MJ2 Termination (default none) MJ1 Termination (default none)

I1

0V

0V

001XLE036

Positive Logic In

Negative Logic In

001XLE037

5.1. J1 Orange Terminal Connector I1 I2 I3 I4 I5 I6 I7 I8 H1 0V A1 A2 A3 A4 0V

Wiring Examples

I1

Factory Use (default none) MJ2 Termination (default none) MJ1 Termination (default none)

001XLE037-R1

XE102 Name IN1 IN2 IN3 IN4 IN5 IN6 IN7 IN8 HSC1 /IN9 Ground ES2T-250/300 ESP-100 Analog IN3 Analog IN4 Ground

12-24VDC

I2 I3 I4 I5 I6 I7 I8 H1 0V

T P

Derating

A1 A2 A3 A4

XLE102 Relay Life Expectancy 40 30 20 10 0 1 2 3 4 Contact Current (A) Operation (x104)

Page 2 of 4

0-10VDC

20mA LOOP

0V

001XLE067

Note: Loop Power requirements are determined by the transmitter specification.

XE102 J1 Orange Positive Logic in Digital In / Analog In

__________________________________________________________________________________________________________________________________________________________________________

7/22/2009

ECN # 958

MAN0907-01-EN Registers (Real) R0031 R0033 R0035 R0037 R0039 R0041 R0043 R0045 PSIG +3.78384517359524e-28 -1.95900825431083e-23 +4.60841168052757e-19 -5.69061024051414e-15 +4.02188808100642e-11 -2.87389870540659e-07 -6.13292635022654e-03 +1.28157611098246e+02

Specifications / Installation

Analog Conditioning 7.1 Filter

Filter Constant sets the level of digital filtering according to the following chart.

0 100 90 80 70 60 50 40 30 20 10 0 0 20 40 60 80 100 Scans 1 2 3 4 5 6 7 Filter Constant

2) Load %AI0002 into %R00051 as a Real. 3) Perform the Real Math Expression 4) %R53 = (((%R31*%R51+%R33)*%R51+%R35)*%R51+%R37) 5) Perform the Real Math Expression %R55 = (((%R53*%R51+%R39)*%R51+%R41)*%R51+%R43)*%R51+%R45 6) Load %R00055 result into another register such as %R00057 to save the temperature value. 7) Steps 2 though 5 can be on a single rung. Contact Horner APG Technical Support for an example file containing the above program.

Digital Filtering. The illustration above demonstrates the effect of digital filtering (set with Filter Constant) on module response to a temperature change. It is recommended that the filter constant for the HE-XE103-10 be set to a value of 7. This will minimize noise and jitter, improve effective resolution, and provide adequate speed for most temperature monitor and control applications.

%Complete [

8 7.2 7.2.1 Sensor Linearization ES2T-250/300 Channel 1

I/O Register Map

Registers %I1 to %I24 %I32 %I25 to %I31 %Q1 to %Q16 %Q17 %Q18 %Q19 %Q20 %Q21 to %Q32 %AI1 to %AI4 %AI5, %AI6 %AI7, %AI8 %AI9, %AI10 %AI11, %AI12

Description Digital Inputs Output Fault Reserved Digital outputs Clear HSC1 accumulator to 0 Totalizer: Clear HSC2 Quadrature 1-2: Accumulator 1 Reset to max 1 Clear HSC3 Accumulator to 0 Totalizer: Clear HSC4 Quadrature 3-4: Accumulator 3 Reset to max 1 Reserved Analog inputs HSC1 Accumulator HSC2 Accumulator HSC3 Accumulator HSC4 Accumulator

Linearization must be performed by the user in the ladder application code, using 26 internal %R registers per channel. The example below uses %R1-26 to linearize one channel - %AI1. Linearization consists of the following example steps. 1) 1) Load the desired linearization coefficients into a table on first scan using a Move Constant Data block. Registers (Real) R0011 R0013 R0015 R0017 R0019 R0021 R0023 R0025 2) 3) 4) 5) Degrees F -1.56518643899245e-27 +1.85504500007145e-22 -8.93939520118636e-18 +2.24997847156420e-13 -3.16779760556092e-09 +2.49133478160033e-05 -1.08497438404356e-01 +3.42114564669736e+02

Load %AI0001 into %R0001 as a Real. Perform the Real Math Expression %R3 = (((%R11*%R1+%R13)*%R1+%R15)*%R1+%R17) Perform the Real Math Expression %R5 = (((%R3*%R1+%R19)*%R1+%R21)*%R1+%R23)*%R1+%R25 9

%AQ1, %AQ2 PWM1 Duty Cycle %AQ3, %AQ4 PWM2 Duty Cycle %AQ5, %AQ6 PWM Prescale %AQ7, %AQ8 PWM Period %AQ9 to %AQ14 Analog outputs Note: Not all XLe units contain the I/O listed in this table.

Safety When found on the product, the following symbols specify: Warning: Electrical Shock Hazard.

6)

Load %R0005 result into another register such as %R0007 to save the temperature value. Steps 2 though 5 can be on a single rung.

7)

Warning: Consult user documentation.

7.2.2

ESP-100 Channel 2

Linearization must be performed by the user in the ladder application code, using 26 internal %R registers per channel. The example below uses %R31-57 to linearize one channel - %AI2. Linearization consists of the following example steps. 1) Load the desired linearization coefficients into a table on first scan using a Move Constant Data block.

WARNING: To avoid the risk of electric shock or burns, always connect the safety (or earth) ground before making any other connections. WARNING: To reduce the risk of fire, electrical shock, or physical injury it is strongly recommended to fuse the voltage measurement inputs. Be sure to locate fuses as close to the source as possible. WARNING: Replace fuse with the same type and rating to provide protection against risk of fire and shock hazards. WARNING: In the event of repeated failure, do not replace the fuse again as a repeated failure indicates a defective condition that will not clear by replacing the fuse. WARNING: Only qualified electrical personnel familiar with the construction and operation of this equipment and the hazards involved should install, adjust, operate, or service this equipment. Read and understand this manual and other applicable manuals in their entirety before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

__________________________________________________________________________________________________________________________________________________________________________

7/22/2009

Page 3 of 4

ECN # 958

MAN0907-01-EN

Specifications / Installation

For detailed installation and a handy checklist that covers panel box layout requirements and minimum clearances, refer to the hardware manual of the controller you are using. (See the Additional References section in this document.) All applicable codes and standards need to be followed in the installation of this product. Adhere to the following safety precautions whenever any type of connection is made to the module: Adhere to the following safety precautions whenever any type of connection is made to the module. Connect the safety (earth) ground on the power connector first before making any other connections. When connecting to electric circuits or pulse-initiating equipment, open their related breakers. Do not make connections to live power lines. Make connections to the module first; then connect to the circuit to be monitored. Route power wires in a safe manner in accordance with good practice and local codes. Wear proper personal protective equipment including safety glasses and insulated gloves when making connections to power circuits. Ensure hands, shoes, and floor are dry before making any connection to a power line. Make sure the unit is turned OFF before making connection to terminals. Make sure all circuits are de-energized before making connections. Before each use, inspect all cables for breaks or cracks in the insulation. Replace immediately if defective.

10

Technical Support

For assistance and manual updates, contact Technical Support at the following locations: North America: Tel: 317 916-4274 Fax: 317 639-4279 Web: http://www.heapg.com Email: techsppt@heapg.com Europe: Tel: +353-21-4321266 Fax: +353-21-4321826 Web: http://www.horner-apg.com Email: tech.support@horner-apg.com

No part of this publication may be reproduced without the prior agreement and written permission of Horner APG, Inc. Information in this document is subject to change without notice.

__________________________________________________________________________________________________________________________________________________________________________

7/22/2009

Page 4 of 4

ECN # 958

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Pcvue Vba TutorialDocument49 paginiPcvue Vba Tutorialandrei_nok100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- AW Continuous v9 Opt PDFDocument94 paginiAW Continuous v9 Opt PDFandrei_nokÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Survey On Modern Fault Detection and Dignosis MethodsDocument3 paginiSurvey On Modern Fault Detection and Dignosis Methodsandrei_nokÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Easypic v7 Schematic v104Document2 paginiEasypic v7 Schematic v104andrei_nokÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Easypic v7 Manual v104Document38 paginiEasypic v7 Manual v104Rodolfo Víctor Hilario Poma100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Lesson 1 - Intro To Highway EngineeringDocument15 paginiLesson 1 - Intro To Highway EngineeringSaoirseÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- PEOPLE V JAURIGUE - Art 14 Aggravating CircumstancesDocument2 paginiPEOPLE V JAURIGUE - Art 14 Aggravating CircumstancesLady Diana TiangcoÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- CXC - Past - Paper - 2022 Solutions PDFDocument17 paginiCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- J130KDocument6 paginiJ130KBelkisa ŠaćiriÎncă nu există evaluări

- Republic Act No. 10389Document5 paginiRepublic Act No. 10389Marge RoseteÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Critical Appreciation of Ode To NightingaleDocument3 paginiA Critical Appreciation of Ode To NightingaleBaloch Karawan100% (2)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- EP500 Standard Electropneumatic Positioner: Installation and Maintenance InstructionsDocument28 paginiEP500 Standard Electropneumatic Positioner: Installation and Maintenance InstructionsAlan ValdezÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Procedure FireDocument28 paginiProcedure FireRichard D DuÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Solo ParentsDocument1 paginăSolo ParentsOZ CincoÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- GEC - ReviewerDocument23 paginiGEC - ReviewerGlycel BagabagonÎncă nu există evaluări

- M.Info M.Info: Minfo@intra - Co.mzDocument8 paginiM.Info M.Info: Minfo@intra - Co.mzAntonio ValeÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Yogananda Scientific HealingDocument47 paginiYogananda Scientific HealingSagar Pandya100% (4)

- Sop For Enlistment of Engineering ConsultantsDocument1 paginăSop For Enlistment of Engineering Consultantssatheb319429Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Service Bulletins For Engine Model I0360kb.3Document6 paginiService Bulletins For Engine Model I0360kb.3Randy Johel Cova FlórezÎncă nu există evaluări

- Health Promotion Officers - CPD Booklet Schedule PDFDocument5 paginiHealth Promotion Officers - CPD Booklet Schedule PDFcharles KadzongaukamaÎncă nu există evaluări

- Report in Per Dev CorrectedDocument34 paginiReport in Per Dev CorrectedJosh lyan RiveraÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Education in America: The Dumbing Down of The U.S. Education SystemDocument4 paginiEducation in America: The Dumbing Down of The U.S. Education SystemmiichaanÎncă nu există evaluări

- User ManualDocument21 paginiUser ManualKali PrasadÎncă nu există evaluări

- ZX110to330 ELEC E PDFDocument1 paginăZX110to330 ELEC E PDFYadi100% (1)

- Benzil PDFDocument5 paginiBenzil PDFAijaz NawazÎncă nu există evaluări

- Task 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Document5 paginiTask 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoÎncă nu există evaluări

- FEM 3004 - Lab 10 Part 2editedDocument26 paginiFEM 3004 - Lab 10 Part 2editedAINA NADHIRAH BINTI A ROZEY / UPMÎncă nu există evaluări

- Starkville Dispatch Eedition 9-10-20Document12 paginiStarkville Dispatch Eedition 9-10-20The DispatchÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Service Manual: Multifunction Electrical Tester CalibratorDocument106 paginiService Manual: Multifunction Electrical Tester CalibratorJuan Carlos Ferrer OrtizÎncă nu există evaluări

- MajorProjects 202112 e 1Document64 paginiMajorProjects 202112 e 1xtrooz abiÎncă nu există evaluări

- Carboset CA-600 - CST600 - CO - enDocument3 paginiCarboset CA-600 - CST600 - CO - enNilsÎncă nu există evaluări

- Biopolymers: Overview of Several Properties and Consequences On Their ApplicationsDocument10 paginiBiopolymers: Overview of Several Properties and Consequences On Their ApplicationsrafacpereiraÎncă nu există evaluări

- Heart Sounds: Presented by Group 2A & 3ADocument13 paginiHeart Sounds: Presented by Group 2A & 3AMeow Catto100% (1)

- Kyocera Fleet Services White Paper: SecurityDocument20 paginiKyocera Fleet Services White Paper: SecurityHoratiu OanaÎncă nu există evaluări

- QA-QC TPL of Ecube LabDocument1 paginăQA-QC TPL of Ecube LabManash Protim GogoiÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)