Documente Academic

Documente Profesional

Documente Cultură

FlowCon EVC Instr US

Încărcat de

b82monica0 evaluări0% au considerat acest document util (0 voturi)

94 vizualizări4 paginiFlowCon EVC Instr US

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentFlowCon EVC Instr US

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

94 vizualizări4 paginiFlowCon EVC Instr US

Încărcat de

b82monicaFlowCon EVC Instr US

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

INSTALLATION AND OPERATION INSTRUCTION

Denmark Dubai Singapore USA www.owcon.com

1D95000NPT 05/2010

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

FlowCon EVC

- 1 -

FlowCon EVC 1/2 -1 , 15-25mm

Figure 2

Figure 1

The temperature control and automatic

balancing valve FlowCon EVC is for

use as terminal valve in an air condition

or heating system to control the room

temperature and automatic maintain the

balance of the system.

Install the FlowCon EVC as called for

in the design drawings. Although the per-

formance of the valve is not affected either

way, industry standards call for balancing

devices to be installed on the downstream

side of the terminal unit INSTALL THE

VALVE HOUSING WITH THE FLOW

DIRECTIONAL ARROW POINTING IN

THE CORRECT DIRECTION.

The FlowCon EVC is available with

union end connection on the inlet and fixed

female threaded outlet (see figures 1

and 2).

Two types of union end connections are

available for use with the union nut:

Threaded inlet (male or female):

The thread standard is ISO 228, which is

a straight metric thread (compatible with

BS-2779) or NPT threading standard,

depending on the end connection ordered.

The threads on both the connection

and piping should be cleaned carefully.

The union nut and the end connection

should be re-moved for installation.

An o-ring is supplied with the valve body

and is used to seal the connection. It is

recommended to grease the o-ring with

a silicone grease before installation. IM-

PORTANT: Never use mineral oil or pet-

rol based grease or oil on the o-ring.

Please make sure it is in place in the

o-ring groove in the inlet of the valve body,

when installing the housing and REMEM-

BER TO TIGHTEN THE UNION NUT

TO ENSURE SEALING.

Soldered end inlet (sweat):

REMOVE THE END CONNECTION

FROM THE HOUSING BEFORE SOL-

DERING. THIS ENSURES THAT O-RING

AND INTERNAL PARTS ARE NOT

DAMAGED BY HEAT.

Threaded outlet:

The thread standard on the outlet is either

ISO 228, which is a straight metric thread

(compatible with BS-2779) or NPT thread-

ing standard, depending on the product

number ordered.

Denmark Dubai Singapore USA www.owcon.com

1D95000NPT 05/2010

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

FlowCon EVC

- 2 -

FlowCon EV.0.3, EV.0.4 and EV.0.5

FlowCon EV.0.2

Figure 3

For all thread connections please clear

threads on both valve and piping of debris.

Sealant such as pipe dope or teflon tape is

recommended. WHEN USING HEMP AS

PIPE SEALANT, ENSURE NO STRANDS

ARE LEFT IN THE VALVE OR PIPING.

Pressure/temperature fittings (p/t plugs)

are available upon request for the EVC

valve. Before finger mounting the p/t

plugs in the body tappings please seal the

threads of the p/t plugs (DO NOT OVER

TIGHTEN).

Alternatively to the p/t plugs, the valve

body can be ordered with plugs for

the body tappings. Each plug is sealed

by a gasket.

Actuators:

The actuator types FlowCon EV.0.2,

EV.0.3, EV.0.4 and EV.0.5 (i.e. figure 3)

are supplied with a seperate green color-

ed adaptor nut. Use this adaptor nut and

screw it finger tight to the connection

thread at top of the valve. Do not use

additional tools. The actuator can now be

fitted to the adaptor nut. A click noise will

indicate that the actuator is fitted into a

correct position.

The visor on the FlowCon EV.0.2 actuator is

used to activate a release mechanism and

when pushing, the actuator is released

and can be removed from the adaptor

nut. By removing the visor after fitting the

actuator, the actuator becomes tamper-

proof. For the FlowCon EV.0.3, EV.0.4 and

EV.0.5 actuators, these are released by

pushing the button in the front side of the

actuator and then removing the actuator

from the adaptor nut.

To insure that the valve is in an open posi-

tion during commissioning of the system,

all mentioned actuators will be delivered

in a Normally Open position and remain in

this position until it is electrically operated

first time. During FIRST TIME POWERING

operating voltage must be applied for

approximately 6 minutes.

Upside down installation is allowed for all

mentioned actuators along with the

standard horizontal and vertical installation.

Denmark Dubai Singapore USA www.owcon.com

1D95000NPT 05/2010

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

FlowCon EVC

- 3 -

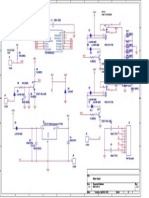

Wiring diagram:

FlowCon EV.0.2

FlowCon EV.0.4

Wiring diagram:

FlowCon EV.0.3 and EV.0.5

Calculation of maximum cable length (copper

cable) for 24 V rated voltage

L = K

x

A / n

A Conductor cross-section in mm

n Number of actuators

K Constant (269m/mm)

L Cable length in m

It is recommended the following lines for

installing a 24 V system:

Bell wire: Y(R) 0,6/0,8 mm

Light plastic-sheathed cable: NYM 1,5 mm

Flat webbed building wire: NYIF 1,5 mm

A safey isolation transformer according to EN

61558-2-6 must always be used. Transformer

dimensioning results from the making capacity

of the actuators and based on the rule-of-thumb

formula:

P

Transformer

= 6W

r

x

n

n =number of actuators.

It is recommended the following lines for install-

ing a 120 V / 230 V system:

Light plastic-sheathed cable: NYM 1,5 mm

Flat webbed building wire: NYIF 1,5 mm

Denmark Dubai Singapore USA www.owcon.com

1D95000NPT 05/2010

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

FlowCon EVC

- 4 -

Figure 4

E

A

B2

B1

C

G

F2

Choice of cartridge:

FlowCon EVC valves can be installed with

either a standard composite cartridge,

internally adjustable to one of eight flow

rates or the FlowCon E-J UST cartridge,

externally adjustable to one of 41 different

flow rates in the same cartridge.

It is recommended that the o-rings located

around the cartridge are lubricated with

silicone grease, before the cartridge is

installed into the valve body. IMPORTANT:

Never use mineral oil or petrol based

grease or oil on the o-rings.

Assembly drawing

FlowCon EVC:

A: Valve housing

B1: E-J UST cartridge

B2: Standard composite cartridge

C: Adjustment key

D1: P/t plug (2 pcs.)

D2: Plug and gasket (2 of each)

E: Union end connection

F1: Actuator (here EV.0.3 to 5-type)

F2: Adaptor nut

G: Push button.

General.

It is recommended flushing the system

before installing the cartridge in the valve

body. Suitable flushing caps are available.

Water must always be suitable treated,

clean and free of debris. It is recommended

that a strainer be installed prior to the valve

body to prevent damage or blockage due

to debris. Ensure that the valve is not in the

fully closed position when filling the system

with water. Further it is recommended not

to exceed maximum differential pressure

control range for the cartridge.

Warranty obligation.

Failure to abide by all recommendations

as per this installation and operation

instruction will void warranty.

For latest updates please see www.flowcon.com

S-ar putea să vă placă și

- FlowCon EVC Instruction 05.2010Document4 paginiFlowCon EVC Instruction 05.2010Jeff Anderson CollinsÎncă nu există evaluări

- FlowCon EVS Instruction 04 2012Document8 paginiFlowCon EVS Instruction 04 2012Jeff Anderson CollinsÎncă nu există evaluări

- Flowcon ABM InstructionDocument4 paginiFlowcon ABM InstructionJeff Anderson CollinsÎncă nu există evaluări

- WP10EX: Installation ManualDocument8 paginiWP10EX: Installation ManualSpartÎncă nu există evaluări

- Abs Wabco Manutec3Document12 paginiAbs Wabco Manutec3Bom_Jovi_681Încă nu există evaluări

- Orbinox VG08 Knife Gate ValveDocument8 paginiOrbinox VG08 Knife Gate ValveYorkistÎncă nu există evaluări

- VC Series: Installation Instruction - EinbauanleitungDocument12 paginiVC Series: Installation Instruction - EinbauanleitungIon VasileÎncă nu există evaluări

- RTHC Svn02c enDocument16 paginiRTHC Svn02c enRicardo100% (1)

- HKS EVC V Boost Controller Setup InstructionsDocument7 paginiHKS EVC V Boost Controller Setup InstructionsDave_B100% (2)

- Standard Gate Valves ManualDocument8 paginiStandard Gate Valves ManualmechanikyÎncă nu există evaluări

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocument47 paginiInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasÎncă nu există evaluări

- DME Valve Gate ControllerDocument15 paginiDME Valve Gate ControllerEsteban Vanegas AlvarezÎncă nu există evaluări

- Novec 1230 Extinguishing Agent DescriptionDocument12 paginiNovec 1230 Extinguishing Agent Descriptionmoh_essamoÎncă nu există evaluări

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocument7 pagini52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeÎncă nu există evaluări

- Installation Operation Maintenance: HFO Fan CoilsDocument12 paginiInstallation Operation Maintenance: HFO Fan CoilsRd GzÎncă nu există evaluări

- 189 010 - en 15.710057 V3.0Document12 pagini189 010 - en 15.710057 V3.0balzac191Încă nu există evaluări

- Valve Adjustment PDFDocument34 paginiValve Adjustment PDFlilo6romeroÎncă nu există evaluări

- Electric Actuator InstructionDocument40 paginiElectric Actuator Instructiongasm220% (1)

- Altronic EPC 110-120 Operating Manual (FORM EPC-110/120 OM)Document55 paginiAltronic EPC 110-120 Operating Manual (FORM EPC-110/120 OM)francis_mouille_iiÎncă nu există evaluări

- Differential Air-Pressure Transmitter: Installation InstructionsDocument12 paginiDifferential Air-Pressure Transmitter: Installation InstructionssabÎncă nu există evaluări

- Document PotterDocument28 paginiDocument PotterSuciu MariusÎncă nu există evaluări

- VC Series: Installation Instruction - EinbauanleitungDocument12 paginiVC Series: Installation Instruction - EinbauanleitungGabriel RodriguezÎncă nu există evaluări

- Steam Generator Steam Generator: Quality of LifeDocument29 paginiSteam Generator Steam Generator: Quality of LifeMiguel DexsÎncă nu există evaluări

- Ebeam ManualDocument11 paginiEbeam ManualMarco SalvatoriÎncă nu există evaluări

- Altronic GSVDocument8 paginiAltronic GSVhamadaÎncă nu există evaluări

- V4043H Installation Guide PDFDocument2 paginiV4043H Installation Guide PDFkevthegerbilÎncă nu există evaluări

- Syncrotrak Manual v20mDocument50 paginiSyncrotrak Manual v20mPrzemyslaw SzumnyÎncă nu există evaluări

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDocument14 paginiWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثÎncă nu există evaluări

- ZEC310 Zone Damper and BYP200 Bypass Damper Controllers: Installation InstructionsDocument15 paginiZEC310 Zone Damper and BYP200 Bypass Damper Controllers: Installation InstructionsRyn YahuFÎncă nu există evaluări

- VAV WiringDocument12 paginiVAV WiringKevin WakarykÎncă nu există evaluări

- Manual Elevated Monitor Style 3530 Installation, Operating and Maintenance InstructionsDocument6 paginiManual Elevated Monitor Style 3530 Installation, Operating and Maintenance Instructionshendra saputraÎncă nu există evaluări

- Worcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeDocument16 paginiWorcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeMijin28Încă nu există evaluări

- Operating Manual: Altronic Gas Control Valve, 690210Document12 paginiOperating Manual: Altronic Gas Control Valve, 690210Esau Jose PabloÎncă nu există evaluări

- CVS 1000L Electro Pneumatic PositionerDocument12 paginiCVS 1000L Electro Pneumatic Positioneradyro12Încă nu există evaluări

- Seko TEKNA DPG Pump Instruction ManualDocument23 paginiSeko TEKNA DPG Pump Instruction ManualManuel Marín MartínezÎncă nu există evaluări

- Sony KDL 55ex505 Chassis Az1 LDocument64 paginiSony KDL 55ex505 Chassis Az1 LJavier OrtizÎncă nu există evaluări

- Wayne-Dresser 1V, 2V & 3V Retrofit For Healy Systems, Inc. MODEL VP1000 Vapor Recovery Assist SystemDocument17 paginiWayne-Dresser 1V, 2V & 3V Retrofit For Healy Systems, Inc. MODEL VP1000 Vapor Recovery Assist SystemRafatHatmÎncă nu există evaluări

- Stop and Check ValvesDocument24 paginiStop and Check ValvesRahul PatilÎncă nu există evaluări

- 623V Vent Installation and Maintenance Instructions - H14898PADocument3 pagini623V Vent Installation and Maintenance Instructions - H14898PAJonathanÎncă nu există evaluări

- PFS Mcquay Manual 01 PDFDocument30 paginiPFS Mcquay Manual 01 PDFevrimk75% (4)

- Chemetron Novec Gamma Specs PDFDocument6 paginiChemetron Novec Gamma Specs PDFambition1340cnÎncă nu există evaluări

- With Bonnet: ModelDocument11 paginiWith Bonnet: ModelSamet BabaÎncă nu există evaluări

- 7.1FA Zero Loss Auto Drain User GuideDocument16 pagini7.1FA Zero Loss Auto Drain User Guidepachara sarntiyakulÎncă nu există evaluări

- CB30 Installation ManualDocument24 paginiCB30 Installation ManualMick HalesÎncă nu există evaluări

- How To Use Solenoid ValvesDocument47 paginiHow To Use Solenoid ValvesvickersÎncă nu există evaluări

- Ambit PF Series Hydrant Tester InstructionsDocument5 paginiAmbit PF Series Hydrant Tester InstructionsPremfeb27Încă nu există evaluări

- Series EMVII-6400SS Installation InstructionsDocument4 paginiSeries EMVII-6400SS Installation InstructionsWattsÎncă nu există evaluări

- BOSS 84VOX104InstallationandOperationInstructions 1 1Document12 paginiBOSS 84VOX104InstallationandOperationInstructions 1 1Jai YansenÎncă nu există evaluări

- Model: Installation, Operation & Maintenance ManualDocument9 paginiModel: Installation, Operation & Maintenance ManualNaveenRajÎncă nu există evaluări

- 2 Installation Maintenance - FantechDocument12 pagini2 Installation Maintenance - FantechLoi Chan TuÎncă nu există evaluări

- CEDASPE® VP VP150 InstructionsDocument2 paginiCEDASPE® VP VP150 InstructionssvismaelÎncă nu există evaluări

- Apv Delta Sv1Document20 paginiApv Delta Sv1VLASTARÎncă nu există evaluări

- Red Jacket Leak DetctorDocument16 paginiRed Jacket Leak DetctorMisbah SayedÎncă nu există evaluări

- Proinert® Cylinder Completer Kit - Ig-541Document2 paginiProinert® Cylinder Completer Kit - Ig-541Марко НакићÎncă nu există evaluări

- 3 WayDocument18 pagini3 WayLeonardÎncă nu există evaluări

- LG Bh9520twDocument147 paginiLG Bh9520twdanielradu27100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDe la EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationÎncă nu există evaluări

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe la EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGÎncă nu există evaluări

- Desire HTC Um WweDocument211 paginiDesire HTC Um Wweb82monicaÎncă nu există evaluări

- Electric EGR Valves (Renault, Opel)Document3 paginiElectric EGR Valves (Renault, Opel)audiovox_ro8872Încă nu există evaluări

- PG Si 0039 en WebDocument2 paginiPG Si 0039 en Webb82monicaÎncă nu există evaluări

- Buton Impuls SchemaDocument1 paginăButon Impuls SchemaVasile SimionÎncă nu există evaluări

- Connect AUX Input On Renault Update List HUDocument2 paginiConnect AUX Input On Renault Update List HUnafetsmalsaÎncă nu există evaluări

- Ad2000 - Kullanım KılauzuDocument8 paginiAd2000 - Kullanım Kılauzuyunuska3233% (3)

- Ad2000 - Kullanım KılauzuDocument8 paginiAd2000 - Kullanım Kılauzuyunuska3233% (3)

- Solahart Domestic Heat Pump - Sample CatalogueDocument2 paginiSolahart Domestic Heat Pump - Sample CatalogueManju NaikÎncă nu există evaluări

- Lesson 6 - CGIDocument66 paginiLesson 6 - CGIJaime castroÎncă nu există evaluări

- Triple Gear Pump (S - N 512915200 & Above, 517711001 & Above, 516711001 & Above) - 331Document4 paginiTriple Gear Pump (S - N 512915200 & Above, 517711001 & Above, 516711001 & Above) - 331Juan Esteban TabordaÎncă nu există evaluări

- Dynamics Lab Sheet 3 - Forced Vibration Experiment - PKPDocument3 paginiDynamics Lab Sheet 3 - Forced Vibration Experiment - PKPfaqhrulÎncă nu există evaluări

- Massey Ferguson Mf2400 2006 Operation and Maintenance ManualDocument10 paginiMassey Ferguson Mf2400 2006 Operation and Maintenance Manualmarcia100% (43)

- Me PDFDocument553 paginiMe PDFSoma GhoshÎncă nu există evaluări

- Section - 1: Page 1 of 3Document3 paginiSection - 1: Page 1 of 3majjisatÎncă nu există evaluări

- MHI Multi - 20R01EDocument88 paginiMHI Multi - 20R01EMinh PhatÎncă nu există evaluări

- RETAININGWALLDocument11 paginiRETAININGWALLiwanÎncă nu există evaluări

- Chapter 14 Governing SystemDocument7 paginiChapter 14 Governing Systemsambhu100% (1)

- Motor Operated ValveDocument2 paginiMotor Operated Valveprihartono_diasÎncă nu există evaluări

- E 993 KatalogDocument488 paginiE 993 KatalogGigi DuruÎncă nu există evaluări

- Retrofitting of Reinforced Concrete BuildingsDocument44 paginiRetrofitting of Reinforced Concrete BuildingsKrupakl Gowda100% (8)

- Commercial N40 250 E 169 KWDocument2 paginiCommercial N40 250 E 169 KWEnzo SovittiÎncă nu există evaluări

- TDS Motor ReprotDocument14 paginiTDS Motor ReprotSanju laaÎncă nu există evaluări

- Example Calculations: Example Problems For Concentrated LoadsDocument4 paginiExample Calculations: Example Problems For Concentrated LoadsKho C AhlÎncă nu există evaluări

- Project of Pressure VesselDocument25 paginiProject of Pressure VesselKalkidan DanielÎncă nu există evaluări

- HP ChokesDocument24 paginiHP Chokesghoulin01Încă nu există evaluări

- Datasheet - AWC 25-350 A - EnglishDocument4 paginiDatasheet - AWC 25-350 A - EnglishLeonardo Augusto Ramirez SaenzÎncă nu există evaluări

- XCD 125-SPC 30-03-2011 ExportDocument51 paginiXCD 125-SPC 30-03-2011 ExportWilly Mansilla AÎncă nu există evaluări

- BS 1139-2-2Document14 paginiBS 1139-2-2murali krishÎncă nu există evaluări

- Max1300 OM PDFDocument23 paginiMax1300 OM PDFSashaAlexeevÎncă nu există evaluări

- Data Sheets Lu2-26-C009980Document22 paginiData Sheets Lu2-26-C009980Indir MujanićÎncă nu există evaluări

- Critical Wear Areas & Vacuum Test Locations: FORD 4R44E, 4R55E, 5R44E, 5R55EDocument2 paginiCritical Wear Areas & Vacuum Test Locations: FORD 4R44E, 4R55E, 5R44E, 5R55ECesar Isac PalominoÎncă nu există evaluări

- NT 2180 GKDocument3 paginiNT 2180 GKJean Christiam Zegarra SoloÎncă nu există evaluări

- Which Are The Best Companies For A Mechanical Engineer 1Document7 paginiWhich Are The Best Companies For A Mechanical Engineer 1Himanshu GuptaÎncă nu există evaluări

- CFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesDocument7 paginiCFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesMahmood ElnagarÎncă nu există evaluări

- Technical Guide Wavin PVC Pressure Pipe SystemsDocument50 paginiTechnical Guide Wavin PVC Pressure Pipe SystemsShailendra RamchurnÎncă nu există evaluări

- GMH 14 NoRestrictionDocument9 paginiGMH 14 NoRestrictionKarma Pema DorjeÎncă nu există evaluări

- Slu Ce Structural June 2020 Problem SetDocument9 paginiSlu Ce Structural June 2020 Problem SetJonathan Basilio100% (1)