Documente Academic

Documente Profesional

Documente Cultură

TLV - Manifolds Vapor y Condensado PDF

Încărcat de

sirballesterosDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TLV - Manifolds Vapor y Condensado PDF

Încărcat de

sirballesterosDrepturi de autor:

Formate disponibile

STEAM & CONDENSATE

MANIFOLDS

SM Series

CM Series

Pamphlet U4808

Features

Typical Application

Steam Main

Condensate Return Line

Product Line

Product Line

Tracing Line

Blowdown

to a pit

Steam Distribution

Manifold Package

SM8

Condensate Collection

Manifold Package

CM8

CM Series

Condensate Manifold

SM Series

Steam Manifold

Steam Distribution

Manifold Package

SM8

Condensate Collection

Manifold Package

CM8

Bellows-sealed

Valve

(Steam Inlet)

Bellows-sealed

Valve

(Condensate

Outlet)

Bellows-sealed

Valve

(Drain Connection)

Bellows-sealed

Valve

(Blowdown Connection)

M4*

Manifold

FS3

Steam Trap

V1-RB

Trap Station

V1-LB

Trap Station

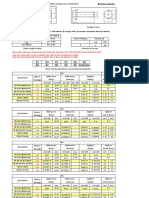

Product lineup

Manifold

Package

PMO

(barg)

TMO

(

C)

S

t

e

a

m

M

a

n

i

f

o

l

d

s

C

o

n

d

e

n

s

a

t

e

M

a

n

i

f

o

l

d

s

Branches

SM4

SM8

SM12

CM4

CM8

CM12

4-way

8-way

12-way

4-way

8-way

12-way

50

* M4 is the basic manifold; SM and CM are the manifold packages combining one or more M4 units with

steam traps and valves. For further information please see Specification Data Sheet (SDS) M4/SM/CM.

Note: Connection types/sizes and pressure/temperature ratings for the SM and CM manifold packages

will vary depending on the valves and steam traps installed.

400

Durable - Forged Steel Body

No Gland Leak - Bellows Sealed Valve

Easy Trap Replacement - Trap Station

Choice of Steam Trap - QuickTrapR

TLV Manifolds are constructed with a forged steel body for high endurance and an

extremely long service life, minimizing maintenance and replacement costs.

Conserves energy by eliminating gland leaks.

Improves working environment by removing steam clouds.

Enjoys a long service life through the utilization of stellite-hardened surfaces on

valve plug and valve seat.

Allows easy removal and replacement of steam traps with only 2 bolts, greatly

reducing maintenance time and labour costs.

Traps can be removed and replaced without disturbing piping.

Built-in blow valve and strainer reduces scale build up.

Freely choose from 3 different types of steam trap - free float, disc or thermostatic

type - depending on the application requirements. (See back page for further

information.)

Streamline Your Steam Line

A typical plant employs countless steam supply and condensate recovery

lines with huge numbers of valves and steam traps.

Utilize the rugged, compact and versatile design of TLV's all-in-one

packages for steam distribution and condensate collection to simplify and

rationalize the control of your steam system.

TLV manifold packages are ideal for use

in areas where steam distribution points

or condensate collection points are

gathered, e.g. tube tracing (right) or small

equipment piping. The compact size

reduces installation space and organises

different steam and condensate lines,

steam traps and isolation valves into one

manageable package.

Features

Typical Application

Steam Main

Condensate Return Line

Product Line

Product Line

Tracing Line

Blowdown

to a pit

Steam Distribution

Manifold Package

SM8

Condensate Collection

Manifold Package

CM8

CM Series

Condensate Manifold

SM Series

Steam Manifold

Steam Distribution

Manifold Package

SM8

Condensate Collection

Manifold Package

CM8

Bellows-sealed

Valve

(Steam Inlet)

Bellows-sealed

Valve

(Condensate

Outlet)

Bellows-sealed

Valve

(Drain Connection)

Bellows-sealed

Valve

(Blowdown Connection)

M4*

Manifold

FS3

Steam Trap

V1-RB

Trap Station

V1-LB

Trap Station

Product lineup

Manifold

Package

PMO

(barg)

TMO

(

C)

S

t

e

a

m

M

a

n

i

f

o

l

d

s

C

o

n

d

e

n

s

a

t

e

M

a

n

i

f

o

l

d

s

Branches

SM4

SM8

SM12

CM4

CM8

CM12

4-way

8-way

12-way

4-way

8-way

12-way

50

* M4 is the basic manifold; SM and CM are the manifold packages combining one or more M4 units with

steam traps and valves. For further information please see Specification Data Sheet (SDS) M4/SM/CM.

Note: Connection types/sizes and pressure/temperature ratings for the SM and CM manifold packages

will vary depending on the valves and steam traps installed.

400

Durable - Forged Steel Body

No Gland Leak - Bellows Sealed Valve

Easy Trap Replacement - Trap Station

Choice of Steam Trap - QuickTrapR

TLV Manifolds are constructed with a forged steel body for high endurance and an

extremely long service life, minimizing maintenance and replacement costs.

Conserves energy by eliminating gland leaks.

Improves working environment by removing steam clouds.

Enjoys a long service life through the utilization of stellite-hardened surfaces on

valve plug and valve seat.

Allows easy removal and replacement of steam traps with only 2 bolts, greatly

reducing maintenance time and labour costs.

Traps can be removed and replaced without disturbing piping.

Built-in blow valve and strainer reduces scale build up.

Freely choose from 3 different types of steam trap - free float, disc or thermostatic

type - depending on the application requirements. (See back page for further

information.)

Streamline Your Steam Line

A typical plant employs countless steam supply and condensate recovery

lines with huge numbers of valves and steam traps.

Utilize the rugged, compact and versatile design of TLV's all-in-one

packages for steam distribution and condensate collection to simplify and

rationalize the control of your steam system.

TLV manifold packages are ideal for use

in areas where steam distribution points

or condensate collection points are

gathered, e.g. tube tracing (right) or small

equipment piping. The compact size

reduces installation space and organises

different steam and condensate lines,

steam traps and isolation valves into one

manageable package.

Trap Stations - V1/V2

Station Picture

QuickTrap - Steam Trap Units

For more information, see the QuickTrap Specifications Data Sheet (SDS) for the steam trap employing the desired trap unit (trap unit - QuickTrap

data sheet): S3 - FS3; S5 - FS5; S5H - FS5; P32 - FP32; L21 - FL21/FL32; L32 - FL21/FL32.

Actual discharge capacity will vary depending on operating conditions; see relevant SDS for details.

*

**

V1 Series is for use with condensate manifolds.

V2 Series is for independent use on applications with

limited installation space.

To avoid abnormal operation, accidents or serious injury, DO NOT use this product outside of the specification range.

Local regulations may restrict the use of this product to below the conditions quoted.

CAUTION

MODEL

Flow Diagram

Flow Direction

Inlet Valve

Outlet Valve

Trap Inlet Blowdown Valve

Trap Outlet Blowdown Valve

Maximum Operating Pressure (barg) PMO

Maximum Operating Temperature (C) TMO

V1-RB

Right

V1-LB

Left

V2-RB

Right

V2-LB

Left

46*

400*

Please see Specification Data Sheet (SDS) V1/V2 for further details.

* Pressure/temperature ratings will vary depending on the steam traps installed.

R

Internet World Wide Web URL http://www.tlv.com

Pamphlet U4808 Rev. 6/2008

Specifications subject to change without notice.

Manufacturer

Kakogawa, Japan

is approved by LRQA Ltd. to ISO 9001/14001

ISO 9001/ ISO 14001

(M)

V1-RB

V2-RB

Free float ensures rapid removal of

condensate

Unique 3-point seating provides

tight shutoff

Bimetal vent for rapid removal of air

at startup

Free Float Steam Trap

Model

*

PMO (barg)

TMO (C)

S3

21

400

215

S5

32

400

670

S5H

46

425

245

Max. Discharge

Capacity** (kg/h)

Float Valve Seat Bimetal

(Air Vent Strip)

Thermodynamic Steam Trap

Model

*

PMO (barg)

TMO (C)

P32

32

350

540

Max. Discharge

Capacity** (kg/h)

Rugged thermodynamic principle

for arduous conditions

Air-jacketed cap as standard

prevents rapid cycling

Bimetal vent as standard for

discharge of air at startup

Air jacket

Disc

Valve Seat

Bimetal

(Air Vent Ring)

Thermostatic Steam Trap

L32

32

240

530

Model

*

PMO (barg)

TMO (C)

L21

21

235

760

Max. Discharge

Capacity** (kg/h)

Patented "Fail Open" feature of

balanced pressure X-element

Outstanding air venting capability

X-element will continue to operate

against high back pressure

Valve Seat

X-element

Star Lodge, Montpellier Drive, Cheltenham, Gloucestershire, GL50 1TY, U.K.

Tel: [44]-(0)1242-227223 Fax: [44]-(0)1242-223077

S-ar putea să vă placă și

- EP - EngineDocument4 paginiEP - EngineAkhmad HasimÎncă nu există evaluări

- Validation Master PlanDocument27 paginiValidation Master PlanPrashansa Shrestha85% (13)

- Dimensions of Bolts and Nuts BS3692Document6 paginiDimensions of Bolts and Nuts BS3692azam RazzaqÎncă nu există evaluări

- Apollo TyresDocument78 paginiApollo TyresADITYA33% (3)

- The Weir Direct-Acting Feed Pump - Working InstructionsDe la EverandThe Weir Direct-Acting Feed Pump - Working InstructionsÎncă nu există evaluări

- 91Document12 pagini91Zoran DanilovÎncă nu există evaluări

- Piping MaterialsDocument1 paginăPiping Materialslibid_rajÎncă nu există evaluări

- Steam Tracing StudyDocument4 paginiSteam Tracing StudypalluraviÎncă nu există evaluări

- Drainage Calc Tank Cylindrical Cross SectionDocument7 paginiDrainage Calc Tank Cylindrical Cross SectionparykoochakÎncă nu există evaluări

- NDE Procedure - Radiographic TestingDocument43 paginiNDE Procedure - Radiographic TestingJeganeswaranÎncă nu există evaluări

- Project On Stones & TilesDocument41 paginiProject On Stones & TilesMegha GolaÎncă nu există evaluări

- Lyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticDocument13 paginiLyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticJayr Mercado0% (1)

- 11d Pms Rev00a Ongc 27jul15Document3 pagini11d Pms Rev00a Ongc 27jul15abhiÎncă nu există evaluări

- 01 PDFDocument6 pagini01 PDFSherif AdelÎncă nu există evaluări

- Combined Status of BoqmDocument22 paginiCombined Status of Boqmhemant1284Încă nu există evaluări

- Technical Data: 150x100 FS2KA 5 90Document5 paginiTechnical Data: 150x100 FS2KA 5 90infonetsmgÎncă nu există evaluări

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocument4 paginiUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiÎncă nu există evaluări

- Pressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)Document6 paginiPressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)KOMATSU SHOVELÎncă nu există evaluări

- Bom Storage Tank (M.S.)Document8 paginiBom Storage Tank (M.S.)Varun MalhotraÎncă nu există evaluări

- Technical Data: 150x125 CNHA 5 18.5Document5 paginiTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىÎncă nu există evaluări

- CouplingsDocument6 paginiCouplingsSherif AdelÎncă nu există evaluări

- 7-12-0008 Rev 5Document1 pagină7-12-0008 Rev 5cynideÎncă nu există evaluări

- 7-13-0001 Rev 6Document1 pagină7-13-0001 Rev 6cynideÎncă nu există evaluări

- Tender Evaluation Method For Works Contract PDFDocument47 paginiTender Evaluation Method For Works Contract PDFhorry02Încă nu există evaluări

- 7-12-0014 Rev 5Document1 pagină7-12-0014 Rev 5cynideÎncă nu există evaluări

- 7-12-0021 Rev 5Document1 pagină7-12-0021 Rev 5cynideÎncă nu există evaluări

- HAC Drawings (Draft)Document4 paginiHAC Drawings (Draft)adrianstydÎncă nu există evaluări

- 7-12-0028 Rev 5Document1 pagină7-12-0028 Rev 5cynideÎncă nu există evaluări

- Common Alloys SpecificationsDocument1 paginăCommon Alloys SpecificationsSARATH KRISHNAKUMARÎncă nu există evaluări

- Equivalent Pipe Length Elbow Tee Stop Valve Bore of Pipe MMDocument152 paginiEquivalent Pipe Length Elbow Tee Stop Valve Bore of Pipe MMAwokeÎncă nu există evaluări

- 7-12-0037 Rev 3Document1 pagină7-12-0037 Rev 3cynideÎncă nu există evaluări

- Fixed Nozzle Desuperheater ManualDocument12 paginiFixed Nozzle Desuperheater ManualjabalpuramitÎncă nu există evaluări

- Dgar Famegvir: Laftetitersigineas India Umit1EdDocument2 paginiDgar Famegvir: Laftetitersigineas India Umit1EdcynideÎncă nu există evaluări

- BP Variable Catalog 09VDocument52 paginiBP Variable Catalog 09VPetros IosifidisÎncă nu există evaluări

- 7-12-0033 Rev 4Document1 pagină7-12-0033 Rev 4cynideÎncă nu există evaluări

- Induced Vibration HXDocument7 paginiInduced Vibration HXPatricia.PÎncă nu există evaluări

- Specs Chart PDFDocument1 paginăSpecs Chart PDFsojeckÎncă nu există evaluări

- Project: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetDocument36 paginiProject: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetGeorge Georgian100% (1)

- J3X & JF3X PDFDocument2 paginiJ3X & JF3X PDFMukiara LuffyÎncă nu există evaluări

- 7 68 0417Document7 pagini7 68 0417Parveen DhimanÎncă nu există evaluări

- Option-2-Piping Support Structural BOQDocument12 paginiOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenÎncă nu există evaluări

- 7-12-0018 Rev 5Document1 pagină7-12-0018 Rev 5cynideÎncă nu există evaluări

- PVC Drain Discharge Rates ChartDocument4 paginiPVC Drain Discharge Rates ChartThiru MuruganÎncă nu există evaluări

- Contractor ITP Shell & Tube Heat ExchangerDocument16 paginiContractor ITP Shell & Tube Heat ExchangerAlexandru AsmarandeiÎncă nu există evaluări

- IS, I I I: Name of ManufacturerDocument1 paginăIS, I I I: Name of ManufacturercynideÎncă nu există evaluări

- 6-12-0011 STD Spec For Boiler Quality Cs PlatesDocument7 pagini6-12-0011 STD Spec For Boiler Quality Cs PlatesMurli ramchandranÎncă nu există evaluări

- Common Materilas For CS PipingDocument2 paginiCommon Materilas For CS PipingValiullah SarpanchÎncă nu există evaluări

- Final ReportDocument30 paginiFinal ReportAjith JoeÎncă nu există evaluări

- TABLE-3 LIST OF ATTACHMENTS - Rev 0Document5 paginiTABLE-3 LIST OF ATTACHMENTS - Rev 0Anonymous AyDvqgÎncă nu există evaluări

- Spring Supports CP Catalog 09VDocument52 paginiSpring Supports CP Catalog 09VNizarHamrouniÎncă nu există evaluări

- 175-Ir022501, (850146), 07.12.2017Document2 pagini175-Ir022501, (850146), 07.12.2017Rami ELLOUMIÎncă nu există evaluări

- PVRVDocument4 paginiPVRVbkkbrazil100% (1)

- API 2000 5th Vs 6th FinalDocument21 paginiAPI 2000 5th Vs 6th FinalCepopaky CangkrukanÎncă nu există evaluări

- MM T-CODE ROLESDocument9 paginiMM T-CODE ROLESsiva prasadÎncă nu există evaluări

- SP-P-002 - Rev 1 - Spring Hanger and SupportDocument7 paginiSP-P-002 - Rev 1 - Spring Hanger and Supportvishal bhamreÎncă nu există evaluări

- Gascat Slam Shut-Off Valve Installation ManualDocument29 paginiGascat Slam Shut-Off Valve Installation ManualluieduÎncă nu există evaluări

- Tanky 53 KL Rev.1Document187 paginiTanky 53 KL Rev.1Priyo Jati WahyonoÎncă nu există evaluări

- Mechanical Engineering Training Calendar 2015Document4 paginiMechanical Engineering Training Calendar 2015dharwinÎncă nu există evaluări

- 7-12-0026 Rev 5Document1 pagină7-12-0026 Rev 5cynideÎncă nu există evaluări

- Piping Material Specification Rev0 PDF FreeDocument25 paginiPiping Material Specification Rev0 PDF FreeBenyamin heidariÎncă nu există evaluări

- ASTM GradesDocument1 paginăASTM GradesBill GuÎncă nu există evaluări

- DAM DesuperheaterDocument4 paginiDAM DesuperheaterangeloÎncă nu există evaluări

- Spirax Sarco PDFDocument4 paginiSpirax Sarco PDFandresaroÎncă nu există evaluări

- Estacion de Trampeo STS17.2Document2 paginiEstacion de Trampeo STS17.2Fernando CeballosÎncă nu există evaluări

- Compact Steam Trap AssemblyDocument8 paginiCompact Steam Trap AssemblyJozsef MagyariÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Catalogo Termocupla Daily Modelo 210Document1 paginăCatalogo Termocupla Daily Modelo 210sirballesterosÎncă nu există evaluări

- Cargoboss - The Marine Monitoring SoftwareDocument2 paginiCargoboss - The Marine Monitoring SoftwaresirballesterosÎncă nu există evaluări

- Safety ManualDocument24 paginiSafety ManualsirballesterosÎncă nu există evaluări

- CA 08-GB 05 I Storage-Radar GaugeDocument5 paginiCA 08-GB 05 I Storage-Radar GaugesirballesterosÎncă nu există evaluări

- Solutions For Improved Thermal Process Performance: Field ProductsDocument8 paginiSolutions For Improved Thermal Process Performance: Field ProductssirballesterosÎncă nu există evaluări

- TLV - Trapman PDFDocument8 paginiTLV - Trapman PDFsirballesterosÎncă nu există evaluări

- Hydrocarbon Engineering Spring2016 HPCLDocument3 paginiHydrocarbon Engineering Spring2016 HPCLsirballesterosÎncă nu există evaluări

- TLV - Reducing Valve For Steam and Air PDFDocument2 paginiTLV - Reducing Valve For Steam and Air PDFsirballesterosÎncă nu există evaluări

- TLV - Air and Drain Traps PDFDocument8 paginiTLV - Air and Drain Traps PDFsirballesterosÎncă nu există evaluări

- TLV - Electro-Pneumatic Control Valve For Steam PDFDocument2 paginiTLV - Electro-Pneumatic Control Valve For Steam PDFsirballesterosÎncă nu există evaluări

- TLV - Sight Glass PDFDocument4 paginiTLV - Sight Glass PDFsirballesterosÎncă nu există evaluări

- IR5500 Data SheetDocument2 paginiIR5500 Data SheetsirballesterosÎncă nu există evaluări

- Religion in Space Science FictionDocument23 paginiReligion in Space Science FictionjasonbattÎncă nu există evaluări

- Emerson EPC48150 1800 FA1EPC48300 3200 FA1 V PDFDocument26 paginiEmerson EPC48150 1800 FA1EPC48300 3200 FA1 V PDFRicardo Andrés Soto Salinas RassÎncă nu există evaluări

- O2 Orthodontic Lab Catalog PDFDocument20 paginiO2 Orthodontic Lab Catalog PDFplayer osamaÎncă nu există evaluări

- Lesson Plan: Lesson: Projectiles Without Air ResistanceDocument4 paginiLesson Plan: Lesson: Projectiles Without Air ResistanceeltytanÎncă nu există evaluări

- Stability Calculation of Embedded Bolts For Drop Arm Arrangement For ACC Location Inside TunnelDocument7 paginiStability Calculation of Embedded Bolts For Drop Arm Arrangement For ACC Location Inside TunnelSamwailÎncă nu există evaluări

- GLOBAL Hydro Turbine Folder enDocument4 paginiGLOBAL Hydro Turbine Folder enGogyÎncă nu există evaluări

- Gotham City: A Study into the Darkness Reveals Dangers WithinDocument13 paginiGotham City: A Study into the Darkness Reveals Dangers WithinajÎncă nu există evaluări

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualDocument18 paginiKAC-8102D/8152D KAC-9102D/9152D: Service ManualGamerAnddsÎncă nu există evaluări

- Revolutionizing Energy Harvesting Harnessing Ambient Solar Energy For Enhanced Electric Power GenerationDocument14 paginiRevolutionizing Energy Harvesting Harnessing Ambient Solar Energy For Enhanced Electric Power GenerationKIU PUBLICATION AND EXTENSIONÎncă nu există evaluări

- Chemistry of FormazanDocument36 paginiChemistry of FormazanEsteban ArayaÎncă nu există evaluări

- Project Binder 2Document23 paginiProject Binder 2Singh DhirendraÎncă nu există evaluări

- Lightwave Maya 3D TutorialsDocument8 paginiLightwave Maya 3D TutorialsrandfranÎncă nu există evaluări

- Motor GraderDocument24 paginiMotor GraderRafael OtuboguatiaÎncă nu există evaluări

- Sattvik Brochure - Web VersionDocument4 paginiSattvik Brochure - Web Versionudiptya_papai2007Încă nu există evaluări

- Philippines' Legal Basis for Claims in South China SeaDocument38 paginiPhilippines' Legal Basis for Claims in South China SeaGeeÎncă nu există evaluări

- De Thi HSG Tinh Binh PhuocDocument9 paginiDe Thi HSG Tinh Binh PhuocDat Do TienÎncă nu există evaluări

- Monodisperse Droplet Generators As Potential Atomizers For Spray Drying Technology PDFDocument11 paginiMonodisperse Droplet Generators As Potential Atomizers For Spray Drying Technology PDFfishvalÎncă nu există evaluări

- Accomplishment Report Yes-O NDCMC 2013Document9 paginiAccomplishment Report Yes-O NDCMC 2013Jerro Dumaya CatipayÎncă nu există evaluări

- Concept Page - Using Vagrant On Your Personal Computer - Holberton Intranet PDFDocument7 paginiConcept Page - Using Vagrant On Your Personal Computer - Holberton Intranet PDFJeffery James DoeÎncă nu există evaluări

- Maureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichDocument20 paginiMaureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichAni LupascuÎncă nu există evaluări

- DR-M260 User Manual ENDocument87 paginiDR-M260 User Manual ENMasa NourÎncă nu există evaluări

- Nickel-Metal Hydride Battery Safety Data SheetDocument8 paginiNickel-Metal Hydride Battery Safety Data SheetYeong WheeÎncă nu există evaluări

- FST Handbook 2014-Final Copy 1 PDFDocument382 paginiFST Handbook 2014-Final Copy 1 PDFDelvon DownerÎncă nu există evaluări

- The Art of Now: Six Steps To Living in The MomentDocument5 paginiThe Art of Now: Six Steps To Living in The MomentGiovanni AlloccaÎncă nu există evaluări