Documente Academic

Documente Profesional

Documente Cultură

Shrimp Acquaculture: The Philippine Experience: Rolando R. Platon

Încărcat de

ChaiiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Shrimp Acquaculture: The Philippine Experience: Rolando R. Platon

Încărcat de

ChaiiDrepturi de autor:

Formate disponibile

63

SHRIMP aquaculture has a long history in the Philip-

pines. It can be said to have its beginning at the same

time as brackish-water aquaculture which, according

to some accounts, predates even the arrival of Magel-

lan in 1521 (Yap et al. 1995). However, it was in the

early 1950s that culture in earthen ponds of the jumbo

tiger shrimp, Penaeus monodon, was first docu-

mented by Villadolid and Villaluz (1951). This was

followed by the first account on its phenomenal

growth rate by Delmendo and Rabanal (1953). After

only 16 years, the first successful attempt in breeding

the species was reported (Villaluz et al. 1969). The

industry took off in the 1970s, bloomed in the eight-

ies, only to stagnate and even decline in the nineties.

Brief Status of the Shrimp Aquaculture

Industry

Farm production and exports

In 1995, the shrimp farming industry in the Philip-

pines had 54,912 ha of shrimp ponds, a production of

88,815 t and contributed about peso (Ps) 19.0 billion to

the economy (Ps 26.20 to US$1.00). This production

figure is based on estimates by the Philippine Govern-

ment (BAS 1996). Rosenberry (1995) reported a much

lower production figure of less than 20,000 t for 1995,

but it appears that those figures were based on export

volumes rather than on total production. While Rosen-

berry`s figures appear to be too low, those of the gov-

ernment appear to be too high.

In the Western Visayas Region, where most of the

intensive shrimp farms are found, shrimp farming

activity is down because of massive disease prob-

lems. In the province of Negros Occidental alone, it

was estimated that only 10% of the shrimp farms

were still operating in 1996. However, even as the

industry suffers, Region VI (Western Visayas),

Region IX (Western Mindanao) and Region XII

(Southern Mindanao) appear to be enjoying an

upsurge. Region III (Central Luzon) doubled its pro-

duction from a maximum of only 13,510 t between

1986 and 1993 to 27,749 t in 1994, although it dipped

slightly to 25,591 t in 1995. It should be noted that in

all the regions where the industry remains strong, the

growers practice either extensive culture, semi-inten-

sive culture, or even polyculture with milkfish.

Hatcheries, processors and feed mills

In 1992 there were 461 hatcheries of which 342

were operating. However, in 1995 only 298 hatcher-

ies remained, of which 164 were in operation. The

number of processors also declined-in 1990 there

were 53 companies listed and in 1995 this dropped to

only 18 companies.

Due to a greater degree of awareness of shrimp fry

quality standards, it was the very small, backyard

hatcheries that were not able to survive. The Philip-

pines probably has the strictest industry standard for

shrimp fry quality in the region. The quality criteria

include: presence and degree of infection in the

hepatopancreas, gut, gills and appendages; and body

length as related to number of rostral spines and mus-

cle development. These criteria are used in addition

to the traditional practice of visual examination of

size, distribution, activity, colour and environmental

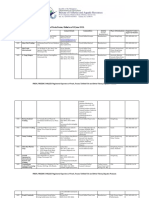

stress resistance. Figure 1 shows a scoring system

Shrimp Acquaculture: the Philippine Experience

Rolando R. Platon*

* Chief, Aquaculture Department, Southeast Asian Fisher-

ies Development Center (SEAFDEC), Tigauan, Iloilo,

the Philippines.

64

C

l

i

e

n

t

:

S

o

u

r

c

e

:

T

a

n

k

n

o

:

P

o

p

:

P

L

a

g

e

:

D

a

t

e

r

e

c

e

i

v

e

d

:

SAMPLES

M

B

V

G

U

T

M

U

S

C

L

E

S

R

O

S

T

R

U

M

A

P

P

E

N

D

A

G

E

S

B

O

D

Y

L

E

N

G

T

H

(

r

o

s

t

r

u

m

t

o

t

e

l

s

o

n

)

H

e

p

a

t

o

p

a

n

c

r

e

a

s

D

-

I

N

F

R

a

t

i

n

g

S

H

G

G

N

R

a

t

i

n

g

M

N

G

M

R

R

a

t

i

n

g

F

B

I

/

P

I

N

R

a

t

i

n

g

G

I

L

L

N

R

N

+

N

R

S

R

N

F

B

I

P

I

R

a

t

i

n

g

R

a

t

i

n

g

R

a

t

i

n

g

D

e

g

r

e

e

D

e

g

r

e

e

TOTAL

%

X

3

0

%

=

X

2

0

%

=

X

1

5

%

=

X

1

0

%

=

=

=

=

=

=

=

=

A

v

e

.

:

L

e

g

e

n

d

:

D

-

I

N

F

,

d

e

g

r

e

e

o

f

M

B

V

i

n

f

e

c

t

i

o

n

;

S

H

G

,

s

w

o

l

l

e

n

h

i

n

d

g

u

t

;

G

N

,

g

u

t

n

e

c

r

o

s

i

s

;

M

N

,

m

u

s

c

l

e

n

e

c

r

o

s

i

s

;

G

M

R

,

g

u

t

-

t

o

-

m

u

s

c

l

e

r

a

t

i

o

;

F

B

I

,

f

i

l

a

m

e

n

t

o

u

s

b

a

c

t

e

r

i

a

l

i

n

f

e

s

t

a

t

i

o

n

;

P

I

,

p

r

o

t

o

z

o

a

n

i

n

f

e

s

t

a

t

i

o

n

;

N

,

n

e

c

r

o

s

i

s

;

R

S

,

r

o

s

t

a

l

s

p

i

n

e

;

R

N

,

r

o

s

t

r

a

l

n

e

c

r

o

s

i

s

;

N

/

A

,

n

e

c

r

o

s

i

s

p

e

r

a

n

i

m

a

l

.

T

o

t

a

l

b

o

d

y

l

e

n

g

t

h

(

t

i

p

o

f

r

o

s

t

r

u

m

t

o

t

i

p

o

f

t

e

l

s

o

n

)

=

(

a

c

t

u

a

l

b

o

d

y

l

e

n

g

t

h

-

6

)

/

(

t

h

e

o

r

e

t

i

c

a

l

b

o

d

y

l

e

n

g

t

h

-

6

)

x

1

0

0

T

O

T

A

L

S

C

O

R

E

:

R

e

m

a

r

k

s

:

A

n

a

l

y

z

e

d

:

N

o

t

e

d

:

F

r

y

A

n

a

l

y

s

i

s

S

u

m

m

a

r

y

R

e

p

o

r

t

R

N

+

-A N

X

1

5

%

=

A

v

e

.

:

=

A

/

N

F

i

g

u

r

e

1

.

A

n

e

x

a

m

p

l

e

o

f

a

s

c

o

r

i

n

g

s

h

e

e

t

u

s

e

d

t

o

j

u

d

g

e

t

h

e

q

u

a

l

i

t

y

o

f

f

r

y

f

r

o

m

h

a

t

c

h

e

r

i

e

s

.

65

used to quantify fry quality. It is not uncommon for a

grower to have fry from a hatchery examined by

more than one laboratory to ascertain their quality

before making a commitment to purchase. Thus, the

actual drop in the fry production may not be as severe

as the drop in the number of operational hatcheries.

Current Key Constraints

Technical constraints to fry production

Shrimp hatchery technology in the Philippines

appears to have matured. Consistent and predictable

results are now the norm. Erratic production due to

perceived water quality problems, disease outbreaks

and a host of other unexplainable reasons appear to

be a thing of the past. The main concern of Philippine

hatcheries has shifted from merely attaining a target

number to producing high health fry and marketing.

The present concern of hatcheries to produce high

health shrimp fry has pointed to the need to have a

captive broodstock and with it the capability of selec-

tive breeding. Thus the lack of a truly domesticated

breeding stock can be considered the major constraint

to shrimp fry production. The present production cri-

sis in intensive grow-out operations has generated an

increased demand for specific pathogen-resistant

strains of shrimp.

Technical constraints to the grow-out operation

The production problems which used to plague the

hatcheries have shifted to the grow-out operation.

This includes the luminescent bacterial disease which

is caused mainly by Vibrio harveyii. This is espe-

cially acute in the province of Negros Occidental

which has the highest concentration of intensive

farms. Since this problem is mainly due to poor sani-

tation, the approaches that are now being tried follow

what has been found successful in hatcheries. These

include the use of chemotherapeutics such as chlo-

rine, benzylkonium chloride, formaline and even

antibiotics. However, such approaches have been

found to be impractical and costly for grow-out ponds

due to the wider areas and much larger volume of

water involved.

Shrimp growers in the Philippines are now also try-

ing bio-remediation or bio-augmentation. This

approach includes use of the so-called green water`

system wherein finfish are also stocked in the grow-

ing pond to induce chlorella to bloom. Commercial

probiotics, which were actually developed for sewage

treatment, are now also finding their way to shrimp

farms as growers become desperate. The results have

not always been consistent.

Use is also being made of immunoenhancers.

These are typically applied to the feed as dressing

immediately before feeding. The theory is that such

substances will intensify the capacity of the shrimp to

resist diseases.

Another approach, which has been talked about but

has had only limited trials so far, is the use of a reser-

voir pond to store incoming water for a certain time

before using it in the rearing ponds. In addition, with

the growing understanding of the role of intensive

shrimp farms in polluting nearshore waters, the con-

cepts of aquaculture wastewater treatment and recir-

culating or low-discharge systems have been

introduced.

While the tools to rehabilitate the industry seem

within reach, these are not immediately useable until

the production protocols for their use have been

established. The present constraints therefore now lie

in coming up with answers to the following ques-

tions.

Which of the commercially available probiotics are

effective for shrimp pond use and how should they

be applied?

If the use of finfish improves the condition of pond

water for shrimp culture, what is the optimum bio-

mass per unit area and when should the fish be

stocked?

What is the ideal ratio of rearing pond to reservoir

pond for incoming and outgoing water?

Can the reservoirs be used to grow other crops

instead of merely holding water? If so, what spe-

cies can be stocked in such ponds?

How does one deal with pond discharge during

harvests?

Environmental constraints

The problems now facing the intensive shrimp

farming areas in the Philippines are partly due to

shrimp farm discharges which exceed the natural car-

rying capacity of the surrounding waters. Part of the

problem, however, lies also with exogenous factors

not related to shrimp aquaculture.

There is a need to determine the hydrography of

water bodies which serve both as supply and dis-

charge points for shrimp farms. This will assist in

determining residence times of specific indicators of

organic and nutrient load (i.e. total nitrogen and total

phosphorus). By knowing these, it might be possible

to regulate shrimp farm density to a level which the

66

environment can support and sustain. This will

require the setting up of water quality standards, not

only for discharge from shrimp farms but for other

industries as well.

Social constraints

The general perception of shrimp aquaculture is

that it is the domain of the rich and has not benefited

the poor, even in terms of employment. The percep-

tion is that shrimp aquaculture has, at best, no effect

and, at worst, negative effects on employment, living

standards and health (Amante et al. 1989).

When the Comprehensive Agrarian Reform Pro-

gram was passed as a law, fishponds were also

included. The implementation of such a law should

have led towards a more equitable distribution of

aquaculture resources. This was welcomed by most

of the farmers and fisherfolk groups. However, with a

very strong lobby from the fishpond sector, and to the

consternation of the grassroots sector, fishponds were

recently granted exemption from land reform.

It appears that the Department of Agrarian Reform

was never able to come up with a model for sub-

dividing a large fishpond into several independent

units for distribution to farmers and fisherfolk. There

are problems of supply and discharge canals as well

as access to the waterways. Also, there is the problem

of defining what is an economically viable unit,

which of course will depend on the species to be cul-

tured and the intensity of culture.

The concept of a fishpond estate consisting of inde-

pendent small growers with a company, or even a

cooperative of farmers, operating the common cen-

tralised facilities (i.e. hatchery and or nursery,

processing shed, pumping station) has been floated

for a long time, but a working model has never been

established. If such a system could be demonstrated

to be feasible and profitable, much of the objection

over the inequitable features of the shrimp culture

industry could be greatly minimised if not totally

eliminated. This remains the dream for fisheries

development planners in the Philippines.

Economic constraints

In the Philippine Prawn Industry Policy Study

made by Auburn University (1992), the economic

constraints were as follows.

The cost of feed was identified as the most serious

constraint, being significantly higher than in Thai-

land and Indonesia.

Receipt of tax credit is often delayed for 612

months.

The cost of electric power varies greatly within the

country, but is substantially higher than in many

other shrimp producing countries.

All loans have to be secured with real estate and

carry very high interest rates.

Further, the effect on shrimp aquaculture of two

new developments will need to be studied. These are

(i) the present import liberalisation and change in tar-

iff structure on all commodities under the General

Agreement on Tariffs and Trade (GATT), and (ii) the

partial deregulation and eventual total deregulation of

petroleum products.

Political and administrative constraints

Many in the shrimp industry complain about gov-

ernment laws, requirements and regulations. Bureau-

cratic obstacles to getting permits and tax credits are

common complaints. Lack of communication and

coordination has been reported for various agencies,

particularly the Department of Agriculture and the

Department of Environment and Natural Resources.

There is also a perceived lack of political will to

enforce environmental laws whenever the rich and

politically connected are involved.

Research Activities and Priorities for

Future Research

The task force for shrimp farm research

The present problems in the shrimp culture indus-

try are caused by over-intensification of culture oper-

ations wherein the effluents produced by the shrimp

farms themselves exceed the capacity of the natural

environment to degrade and render them harmless.

This causes deterioration of soil and water quality

within the shrimp farms as well their surrounds.

It is for this reason that the Director of the Bureau

of Fisheries and Aquatic Resources (BFAR) con-

ceived of a task force` which consists of technical

people from various agencies working on the shrimp

disease and production problem, in order to have a

unified and concerted effort to rehabilitate the coun-

try`s shrimp farms. The task force is named OPLAN

SAGIP SUGPO.

In the process of devising the strategies and

detailed action plans, the task force has considered

the recommendations for shrimp research which were

raised at various meetings and conferences under-

67

taken by the Southeast Asian Fisheries Development

Center (SEAFDEC) Aquaculture Division.

The general objective of the task force is to rehabil-

itate the shrimp culture industry and make it sustaina-

ble through a focused effort to develop sound shrimp

health management techniques.

The specific objectives are:

to tailor-make culture techniques for each spe-

cific culture system;

to determine the carrying capacity of each given

area for shrimp production and develop practical

guidelines on regulating the development and oper-

ation of shrimp farms;

to set in place a monitoring system to ensure com-

pliance of whatever regulation the task force may

recommend for implementation; and

to train shrimp farm operators and technicians on

sustainable shrimp culture techniques.

Research activities

The detailed activities to be undertaken under each

strategy are as follows:

Identification of expertise

To make an inventory of technical persons with

BFAR, SEAFDEC, University of the Philippines in

the Visayas (UPV) and other agencies who are

directly involved in the study of shrimp diseases, cul-

ture, genetics etc.

Short-term studies (12 years)

A. Field evaluation of biological interventions (probi-

otics, integration of finfish, molluscs, and/or sea-

weeds with shrimp).

Validation of commercially available probiotics on

growth and survival of shrimp (to be undertaken by

SEAFDEC/Negros Prawn Producers Marketing

Cooperative, Inc.NPPMCI).

Documentation of lumbac-free (i.e. no luminous

bacteria) shrimp pond areas (SEAFDEC/BFAR).

Evaluation of the use of green water on growth

and survival of shrimp (BFAR/NPPMCI).

Effectiveness of integrating finfish and other

aquatic organisms with shrimp to prevent or mini-

mise incidence of luminous vibriosis (BFAR/NPP-

MCI).

Pond dynamics and nutrient budgets (UPV).

Use of molluscs and Gracilaria as biofiltering

agents (BFAR).

Screening and identification of beneficial bacteria

with potentials as probiotics (BFAR).

Establishment of the bacterial profile of healthy,

normal shrimp (SEAFDEC).

B. Field evaluation of physical interventions (recircu-

lating systems, reservoirs, semi-closed systems).

Development of a prototype recirculating system

using existing shrimp ponds (Society of Aquacul-

ture Engineers of the PhilippinesSAEP/BFAR).

Evaluation of the use of reservoirs in shrimp farms

(NPPMCI).

Documentation on the effectiveness of backfilled

shrimp ponds. (UPV/Department of Agriculture

Regional Fisheries UnitDARFU).

C. Field evaluation of chemical interventions (resi-

due studies, alternatives to antibiotics).

Study of the fate of antibiotics (SEAFDEC).

Study of the residual effects of chlorine, formalin,

and other chemicals in brackish-water ponds

(SEAFDEC).

Screening of environmentally friendly chemicals

for pond conditioning and disinfection (SEAF-

DEC).

Promotion of the use of tobacco dust as a pond pes-

ticide (BFAR).

D. Development of an aquaculture effluent treatment

system (BFAR/Department of Environment and Nat-

ural ResourcesDENR).

E. Field evaluation of crop rotation/fallowing (data

already available at Philippine Council for Aquatic

and Marine ResearchPCAMRD).

Medium-term studies (35 years)

A. Immune enhancement in shrimp (basic and

applied) (BFAR/SEAFDEC/UPV).

B. Determination of water quality standards for dis-

charges from shrimp farms (NPPMCI/Bureau of

Agricultural Research/Environmental Management

BureauEMB-DENR).

C. Development of an aqua-silviculture prototype

(SEAFDEC/DENR/DA-RFU).

D. Development of systems for monitoring impacts

of shrimp farming on coastal ecosystems

(DENR/BFAR/Local Government Unit LGU/

RFU).

E. Mass production of beneficial bacteria which have

potential as probiotics (BFAR).

F. Development of rapid sero-diagnostic kits for

detection of Vibrio (SEAFDEC/BFAR).

68

Long-term studies (610 years)

A. Development of captive shrimp broodstock

(SEAFDEC/BFAR).

B. Development of disease-resistant shrimp stock

(SEAFDEC/BFAR).

C. Determination of the effluent absorbing capacity

of mangroves (SEAFDEC/DENR/Ecosystems

Research and Development BureauERDB).

D. Upgrading of field diagnostic facilities

(BFAR/SEAFDEC).

E. Development of human resources in shrimp health

diagnostics and management through both short-term

and formal training (BFAR/SEAFDEC/UPV/

PCAMRD).

F. Development of formal academic programs in

aquatic veterinary science (UPV).

Constraints and dissemination of results

The research action plans call for some studies that

require innovative, biotechnological expertise and

facilities. Although we may have the biotechnical

expertise, lack of laboratory equipment and facilities

will be a major constraint in the conduct of important

studies.

The effective translation of research findings into

workable techniques for individual farmers is some-

times under question. The language gap may be a

constraint in the process of writing for publication of

research findings and also in attendance at training

courses and seminars. The problem of site specificity

may also be a constraint in the repeatability of results.

The conduct of verification tests in different areas

may iron out problems related to site specificity.

These trials may eventually serve as demonstrations

or pilot projects where farmers and technicians can

obtain first hand experience on technical, economic

and environmental aspects.

References

Amante, M., Castillo, F. and Segovia, L. 1989. The aquacul-

ture industry in Panay; a question of genuine peoples

development. Manila, Philippines, Panay Self Reliance

Institute Research Center, Philippine Normal College,

61p.

Auburn University 1992. Philippines prawn industry policy

study. Alabama, USA, Auburn University.

BAS (Bureau of Agricultural Statistics) 1996. Fishery year-

book, 1986 to 1995. Quezon City, Department of Agri-

culture, Bureau of Agricultural Statistics, 77p.

Delmendo, M. and Rabanal, H.R. 1953. Studies on the rate

of growth of the jumbo tiger shrimp or sugpo, Penaeus

monodon Fabricius with accounts of methods and prob-

lems of its cultivation in estuarine ponds in the Philip-

pines. Intramuros, Manila, Bureau of Fisheries, 19p.

Rosenberry, B. (ed.) 1995. World shrimp farming 1995:

annual report. San Diego, Shrimp News International,

68p.

Villadolid, D.V. and Villaluz, D.K. 1951. Cultivation of

sugpo (Penaeus monodon Fabricius) in the Philippines.

Philippine Journal of Fisheries, 1, 6878.

Villaluz, D.K., Villaluz, A., Ladrera, B., Sheik, M. and

Gonzaga, A. 1969. Production, larval development, and

cultivation of sugpo (Penaeus monodon Fabricius). Phil-

ippine Journal of Science, 98, 205233.

Yap, W.G., Rabanal, H.R. and Llobrera, J.A. 1995. Winning

the future in fisheries. Manila, Mary Jo Educational Sup-

ply, 132p.

S-ar putea să vă placă și

- A Training Manual on Aquaculture for Caribbean Sids: Improving Water-Related Food Production Systems in Caribbean Smal L Island Developing States (Sids)De la EverandA Training Manual on Aquaculture for Caribbean Sids: Improving Water-Related Food Production Systems in Caribbean Smal L Island Developing States (Sids)Încă nu există evaluări

- Aquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaDe la EverandAquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaÎncă nu există evaluări

- Aem 25Document28 paginiAem 25Edilyn San PedroÎncă nu există evaluări

- SEAFDEC/AQD Institutional Repository (SAIR) : This Document Is Downloaded At: 2013-07-02 06:52:50 CSTDocument29 paginiSEAFDEC/AQD Institutional Repository (SAIR) : This Document Is Downloaded At: 2013-07-02 06:52:50 CSTfaithphaulinne regalaÎncă nu există evaluări

- Milk Fish ResearchDocument11 paginiMilk Fish ResearchjpegÎncă nu există evaluări

- Factors Affecting The Milkfish Production in Korondal CityDocument9 paginiFactors Affecting The Milkfish Production in Korondal CityRalph GonzalesÎncă nu există evaluări

- Rotifers - They Often Evoke A Love-Hate Relationship, But You Just Can't Get Away From ThemDocument4 paginiRotifers - They Often Evoke A Love-Hate Relationship, But You Just Can't Get Away From ThemInternational Aquafeed magazineÎncă nu există evaluări

- Limitations Facing Giant Clam Aquaculture: Paci C Oceans Species Production Has Breeding, Disease, Restocking IssuesDocument5 paginiLimitations Facing Giant Clam Aquaculture: Paci C Oceans Species Production Has Breeding, Disease, Restocking IssuesHoward WoodÎncă nu există evaluări

- Milkfish Farm ProductionDocument31 paginiMilkfish Farm ProductionMika Patoc50% (2)

- W4 Fish Raising Mod10Document23 paginiW4 Fish Raising Mod10alfredo pintoÎncă nu există evaluări

- Mud Crab Aquaculture: A Practical ManualDocument100 paginiMud Crab Aquaculture: A Practical ManualTrieu Tuan100% (4)

- Aquakultur Scylla (Kepiting Bakau)Document100 paginiAquakultur Scylla (Kepiting Bakau)sjahrierÎncă nu există evaluări

- Sustainable Fish Farming: 5 Strategies To Get Aquaculture Growth RightDocument11 paginiSustainable Fish Farming: 5 Strategies To Get Aquaculture Growth RightVladimir FontillasÎncă nu există evaluări

- January - February 2013 - International Aquafeed Magazine - Full EditionDocument68 paginiJanuary - February 2013 - International Aquafeed Magazine - Full EditionInternational Aquafeed magazineÎncă nu există evaluări

- LacQua15 AbstractBookDocument614 paginiLacQua15 AbstractBookJONATHAN PEÑA ABARCAÎncă nu există evaluări

- Proceedings National Seaweed Planning WorkshopDocument112 paginiProceedings National Seaweed Planning WorkshopRomeo Jr VelosoÎncă nu există evaluări

- FW Vannamei Culture in Heterotrophic SystemsDocument140 paginiFW Vannamei Culture in Heterotrophic SystemsmhanifazharÎncă nu există evaluări

- T - 1437039951caipang 9Document15 paginiT - 1437039951caipang 9Doge WoweÎncă nu există evaluări

- On-Farm Feed Management Practices For Nile Tilapia in ThailandDocument31 paginiOn-Farm Feed Management Practices For Nile Tilapia in ThailandDel rosario SunshineÎncă nu există evaluări

- Milkfish Production and Processing Technologies in The PhilippinesDocument97 paginiMilkfish Production and Processing Technologies in The PhilippinesMayeth Maceda67% (3)

- Milkfish Culture Techniques Generated and Developed by The Brackishwater Aquaculture CenterDocument13 paginiMilkfish Culture Techniques Generated and Developed by The Brackishwater Aquaculture CenterEva MarquezÎncă nu există evaluări

- BIOFLOC TECHNOLOGY For The Cultivation of Litopenaeus Vannamey Era Edicion 2024Document31 paginiBIOFLOC TECHNOLOGY For The Cultivation of Litopenaeus Vannamey Era Edicion 2024Rodrigo CoelloÎncă nu există evaluări

- The Growth of Microalgae in Shrimp Hatchery: Impact of Environment On Nutritional ValuesDocument8 paginiThe Growth of Microalgae in Shrimp Hatchery: Impact of Environment On Nutritional ValuesIOSRjournalÎncă nu există evaluări

- African Organic Agriculture Training ManualDocument25 paginiAfrican Organic Agriculture Training Manualfshirani7619Încă nu există evaluări

- Sustainable Crab Industry Development in Surigao Del SurDocument12 paginiSustainable Crab Industry Development in Surigao Del SurHannah Joy F. FabelloreÎncă nu există evaluări

- Colombian Tilapia - Increased Fry Survivability With Orego-Stim®Document4 paginiColombian Tilapia - Increased Fry Survivability With Orego-Stim®International Aquafeed magazineÎncă nu există evaluări

- Global Review TilapiaDocument7 paginiGlobal Review Tilapialuis ruperto floresÎncă nu există evaluări

- Milkfish Culture Techniques Developed in Brackishwater Aquaculture CenterDocument14 paginiMilkfish Culture Techniques Developed in Brackishwater Aquaculture CenterMiguel MansillaÎncă nu există evaluări

- Review-Aquaculture of Two Commercially Important Molluscs Abalone and Limpet Existing Knowledge and Future ProspectsDocument15 paginiReview-Aquaculture of Two Commercially Important Molluscs Abalone and Limpet Existing Knowledge and Future Prospects陈浩Încă nu există evaluări

- The Proper Management of Commercial Shrimp Feeds, Part 1Document7 paginiThe Proper Management of Commercial Shrimp Feeds, Part 1Mohammad AhmadiÎncă nu există evaluări

- Case Study Presentation - Sea UrchinDocument13 paginiCase Study Presentation - Sea UrchinRalen Faye VillaseñorÎncă nu există evaluări

- Thesis AquapolycultureDocument43 paginiThesis AquapolycultureNehru Valdenarro ValeraÎncă nu există evaluări

- 5842 Romana EguiaMRR2020 AEM66Document64 pagini5842 Romana EguiaMRR2020 AEM66Rosalie Gomez - PrietoÎncă nu există evaluări

- Term Paper On Fish FarmingDocument4 paginiTerm Paper On Fish Farmingafdtakoea100% (1)

- Magdalene Project WorkDocument25 paginiMagdalene Project WorkYARO TERKIMBIÎncă nu există evaluări

- Environmental Impacts of Seaweed Farming in TheDocument89 paginiEnvironmental Impacts of Seaweed Farming in TheJapsja JaÎncă nu există evaluări

- Subsistence Fish Farming in Africa A Technical Manual 10.2013 3Document294 paginiSubsistence Fish Farming in Africa A Technical Manual 10.2013 3Delfina MuiochaÎncă nu există evaluări

- Hamidoghlietal 2020-Flounder PDFDocument19 paginiHamidoghlietal 2020-Flounder PDFJo CynthiaÎncă nu există evaluări

- Spirulina:: Mass Production of The Blue-Green Alga An OverviewDocument15 paginiSpirulina:: Mass Production of The Blue-Green Alga An Overviewdya97Încă nu există evaluări

- Integrated Livestock-Fish Production System in The PhilippinesDocument5 paginiIntegrated Livestock-Fish Production System in The PhilippinesKylie MayʚɞÎncă nu există evaluări

- Research Paper On Fish FarmingDocument6 paginiResearch Paper On Fish Farminggzvp7c8x100% (1)

- HTTPS:WWW Fao Org:3:bm332e:bm332eDocument11 paginiHTTPS:WWW Fao Org:3:bm332e:bm332eOliWan2Încă nu există evaluări

- Thesis Chapters 1-3 Group 5Document9 paginiThesis Chapters 1-3 Group 5KB. ACEBRO100% (1)

- Introduction To PeryphetonDocument33 paginiIntroduction To PeryphetonrejdasukiÎncă nu există evaluări

- Basic Course On AquacultureDocument46 paginiBasic Course On AquacultureMike Nichlos100% (3)

- Banana Industry Faces Land Problems in Davao RegionDocument5 paginiBanana Industry Faces Land Problems in Davao RegionAntonette NoyaÎncă nu există evaluări

- Browdy - Recent Developments in Penaeid Broodstock and Seed Production Technologies - Improving The Outlook For Superior Captive StocksDocument19 paginiBrowdy - Recent Developments in Penaeid Broodstock and Seed Production Technologies - Improving The Outlook For Superior Captive StocksDet GuillermoÎncă nu există evaluări

- Paul OlinDocument33 paginiPaul OlinNational Press FoundationÎncă nu există evaluări

- TilapiaDocument47 paginiTilapiaJohn Mae RachoÎncă nu există evaluări

- Aquate Shrimp Helps Provide Economic Benefit To Shrimp Farmers in HondurasDocument4 paginiAquate Shrimp Helps Provide Economic Benefit To Shrimp Farmers in HondurasInternational Aquafeed magazineÎncă nu există evaluări

- 8.4 Van Der Riet 1Document36 pagini8.4 Van Der Riet 1kiura_escalanteÎncă nu există evaluări

- Fish Farming Literature ReviewDocument6 paginiFish Farming Literature Reviewc5pjg3xh100% (1)

- Tilapia VC Report 2012 - Final PDFDocument26 paginiTilapia VC Report 2012 - Final PDFCharlene ManalastasÎncă nu există evaluări

- KappaphycusDocument32 paginiKappaphycuskyla santosÎncă nu există evaluări

- Clarissa L. Marte and Joebert D. Toledo: Marine Fish Hatchery: Developments and Future TrendsDocument12 paginiClarissa L. Marte and Joebert D. Toledo: Marine Fish Hatchery: Developments and Future TrendsAgnes reski renataÎncă nu există evaluări

- Aquaculture Report TechnicalDocument59 paginiAquaculture Report TechnicalBhavin VoraÎncă nu există evaluări

- ThesisDocument6 paginiThesisdanteÎncă nu există evaluări

- FAO Fisheries & Aquaculture National Aquaculture Sector Overview (NASO)Document12 paginiFAO Fisheries & Aquaculture National Aquaculture Sector Overview (NASO)Elisha TajanÎncă nu există evaluări

- Hatchery MNGT PresentationDocument16 paginiHatchery MNGT PresentationKarl KiwisÎncă nu există evaluări

- How To Make A Million Dollars With Mealworms: The Ultimate Guide To Profitable Mealworm BreedingDe la EverandHow To Make A Million Dollars With Mealworms: The Ultimate Guide To Profitable Mealworm BreedingÎncă nu există evaluări

- Expert EvidenceDocument15 paginiExpert EvidenceChaii100% (1)

- Jessie, Gurp, Jeana, Ashley, Jackie D. & Jackie JDocument30 paginiJessie, Gurp, Jeana, Ashley, Jackie D. & Jackie JChaiiÎncă nu există evaluări

- People Vs Angus, August 3, 2010Document11 paginiPeople Vs Angus, August 3, 2010ChaiiÎncă nu există evaluări

- Torture ..Document112 paginiTorture ..Chaii0% (1)

- CenPEG SOP FOI Issues Luis Teodoro Jly 24 2012Document12 paginiCenPEG SOP FOI Issues Luis Teodoro Jly 24 2012ChaiiÎncă nu există evaluări

- Criminal Law Case DigestsDocument251 paginiCriminal Law Case DigestsChaii83% (6)

- Perceptions of Political Party Corruption and Voting Behavior in PolandDocument31 paginiPerceptions of Political Party Corruption and Voting Behavior in PolandChaiiÎncă nu există evaluări

- Measurement of Inflation and The Philippine Monetary Policy FrameworkDocument11 paginiMeasurement of Inflation and The Philippine Monetary Policy FrameworkChaiiÎncă nu există evaluări

- Political LawDocument364 paginiPolitical LawJingJing Romero100% (99)

- FM 100 Cash Flow AnalysisDocument31 paginiFM 100 Cash Flow AnalysisChaiiÎncă nu există evaluări

- CorruptionDocument158 paginiCorruptionTaher TobaliaÎncă nu există evaluări

- Legal EnglishDocument0 paginiLegal EnglishChaiiÎncă nu există evaluări

- Barangay Structure and Barangay Officials Duties Powers and ResponsibilitiesDocument4 paginiBarangay Structure and Barangay Officials Duties Powers and ResponsibilitiesChaii86% (65)

- The Following Is The List of Registered Exporters of Fresh Frozen ChilledDocument21 paginiThe Following Is The List of Registered Exporters of Fresh Frozen Chilledtapioca leÎncă nu există evaluări

- The Islamic Republic of PakistanDocument18 paginiThe Islamic Republic of PakistanYee AhmedÎncă nu există evaluări

- Philippine Shrimp Industry Roadmap 2021 2040Document454 paginiPhilippine Shrimp Industry Roadmap 2021 2040Hector John SilvaÎncă nu există evaluări

- Unit 5: Key PointsDocument6 paginiUnit 5: Key PointsWaleed AftabÎncă nu există evaluări

- CXS - 092e - Codex ShrimpDocument6 paginiCXS - 092e - Codex ShrimpldfdÎncă nu există evaluări

- GSP TariffsDocument612 paginiGSP TariffssbfusfsjfubsjfnsÎncă nu există evaluări

- Report 3 InvertabrateDocument10 paginiReport 3 InvertabrateZulÎncă nu există evaluări

- CME Seafood E-Catalogue 2017Document57 paginiCME Seafood E-Catalogue 2017Awqaf PC 2Încă nu există evaluări

- The Ginger Shrimp - Metapenaeus Kutchensis: A Promising Species For Shrimp Aquaculture in Coastal Gujarat State, IndiaDocument2 paginiThe Ginger Shrimp - Metapenaeus Kutchensis: A Promising Species For Shrimp Aquaculture in Coastal Gujarat State, IndiaInternational Aquafeed magazineÎncă nu există evaluări

- Roubachetal 2003 AquacultureinBrazil WasDocument9 paginiRoubachetal 2003 AquacultureinBrazil WasPalomaRodriguesÎncă nu există evaluări

- 1.fish and Fisheries of IndiaDocument36 pagini1.fish and Fisheries of IndiaRahul SainiÎncă nu există evaluări

- Fisheries and AquacultureDocument9 paginiFisheries and AquaculturechaibalinÎncă nu există evaluări

- 2017-03-02 St. Mary's County TimesDocument32 pagini2017-03-02 St. Mary's County TimesSouthern Maryland OnlineÎncă nu există evaluări

- Principle of Aquaculture ICAR EcourseDocument83 paginiPrinciple of Aquaculture ICAR Ecoursecontact.arindamdas7Încă nu există evaluări

- Marine Shrimp FarmingDocument19 paginiMarine Shrimp FarmingVikas SainiÎncă nu există evaluări

- Marine BiodiversityDocument178 paginiMarine Biodiversityshanujss100% (1)

- GIS - Brazil - ThesisDocument264 paginiGIS - Brazil - Thesispcscott01Încă nu există evaluări

- FAO - Fish SauceDocument104 paginiFAO - Fish SauceNhan VoÎncă nu există evaluări

- Impact of Shrimp Farming On Bangladesh-Challenges and AlternativesDocument11 paginiImpact of Shrimp Farming On Bangladesh-Challenges and AlternativesJavier SolanoÎncă nu există evaluări

- Updated List of Active Exporters FF CDocument24 paginiUpdated List of Active Exporters FF CBryan MendozaÎncă nu există evaluări

- H230Document15 paginiH230anon-776373100% (2)

- The Impacts of Shrimp Farming On Mangrove ForestsDocument55 paginiThe Impacts of Shrimp Farming On Mangrove ForestsjohnnyorithroÎncă nu există evaluări

- Aquaculture in India WEBDocument20 paginiAquaculture in India WEBManish yadavÎncă nu există evaluări

- 24.9.19 Eppa-1Document54 pagini24.9.19 Eppa-1ei phyuphyu aungÎncă nu există evaluări

- Nutritional Values in Shell and Flesh of The Giant Tiger Prawn Penaeus Monodon (Fabricius, 1798)Document4 paginiNutritional Values in Shell and Flesh of The Giant Tiger Prawn Penaeus Monodon (Fabricius, 1798)International Journal of Current Innovations in Advanced ResearchÎncă nu există evaluări

- Marine Engineering Multiple Choice Question With AnswersDocument6 paginiMarine Engineering Multiple Choice Question With AnswersFarman Ali100% (1)

- Prawn ProcessingDocument21 paginiPrawn ProcessingKrishnaÎncă nu există evaluări

- V4.0 Guide On Sales Tax Rates For Various Goods - 07.09 PDFDocument130 paginiV4.0 Guide On Sales Tax Rates For Various Goods - 07.09 PDFKiekie Eyebrow EmbroideryÎncă nu există evaluări

- Stocking Density, Survival Rate and Growth Performance of Shrimp FarmsDocument7 paginiStocking Density, Survival Rate and Growth Performance of Shrimp FarmsVijay Varma RÎncă nu există evaluări

- Feasibility Study TBBDocument12 paginiFeasibility Study TBBtryasihÎncă nu există evaluări