Documente Academic

Documente Profesional

Documente Cultură

Siemens PLM China Gas Turbine Establishment Cs Z5

Încărcat de

rasgeetsinghDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Siemens PLM China Gas Turbine Establishment Cs Z5

Încărcat de

rasgeetsinghDrepturi de autor:

Formate disponibile

NX

Teamcenter

China Gas Turbine Establishment

Achieving a strategic edge

Industry Aerospace and defense Business challenges Upgrade from 2D to 3D design to facilitate virtual assembly, interference checking and digital mockup Improve communications; eliminate isolated data silos Fully leverage electronic and paper-based drawings Re-use part data; eliminate design redundancy Keys to success Deploy NX and Teamcenter software in staged phases Facilitate top-down design best practices Fully automate entirely new product development environment Results Greater product innovation using 3D Concurrent, collaborative design process All design drawings and documents acutely organized and fully leveraged

China Gas Turbine Establishment integrates digital product data and processes to improve production management and business efficiency

Providing core research and product development technology Founded in 1965, China Gas Turbine Establishment (CGTE) is one of the most important institutes that perform core scientific research, product development and system qualification testing for Chinas

aero engine industry. As a member of AVIC Aviation Engine Co., Ltd., CGTE has significantly contributed to the development of gas turbine technology. During the past 20 years, CGTE has leveraged and extended its aerospace experience to develop civil machinery for the electronics, automotive, light-industrial and computer software industries. Many of CGTEs technology initiatives have facilitated the development of advanced machinery products many of which had never been manufactured in China before.

www.siemens.com/plm

Results (continued) Rework largely eliminated; data re-use significantly increased Testing functionality, review/ approval processes and automated BOM generation integrated We decided to implement our new product lifecycle management system so that we could manage our own product data. Fu Yu Overall Structure Director, PDM China Gas Turbine Establishment

Breaking the business development bottleneck As CGTEs product development tasks increased and its use of CAD technology advanced, the institute was faced with an increasing demand for new product development tools and product data management (PDM) capabilities. Traditional 2D design technology had become insufficient to fully meet CGTEs product information needs, especially with respect to providing the solid models needed for CAE and CAM or the more sophisticated functionality required for virtual assembly, interference checking and digital mockup analysis. In addition, manual data management techniques had become unsustainable as the volume of CGTEs electronic product data increased. The issues resulting from the manual approach were particularly noticeable within CGTEs engineering teams, where unwieldy data searches, excessive part design duplication and serious revision- and release-level inconsistencies between electronic documents and paperbased drawings negatively impacted both design and production efficiency. With these issues in mind during the early months of 2006, CGTE decided to launch a PDM initiative at the same time it selected and initiated a new 3D design system. CGTE had a very clear objective in mind: the institute wanted to establish an advanced digital product development solution that was capable of delivering enhanced design tools as well as meeting the design collaboration requirements of its engineering organization, particularly with respect to file query, version management, security, confidentiality and data sharing. Implementing processes according to industry needs We decided to implement our new product lifecycle management (PLM) system so that we could manage our own product data, says Fu Yu, overall structure

director, PDM, China Gas Turbine Establishment. To ensure optimal integration of 3D and PDM technologies and to facilitate seamless cooperation with companies in the same industry, CGTE selected NX software and Teamcenter software, both from Siemens PLM Software, as the foundation for its PLM approach. In 2006, CGTE implemented phase one of this initiative by migrating its design system to NX and implementing key capabilities such as product design data management, design data version control, process management, authority management and organization structure management. Users quickly became fully engaged in solid modeling, virtual assembly and digital prototyping. Phase two was initiated in 2007 with CGTE establishing an enterprise-level PDM database in two separate locations so that different sets of local users could access the same design data. This enabled the company to realize multi-site collaboration, common workflow processes and faster data transmission. Just as importantly, phase two enabled CGTE to establish both global and local versions of various parts and components so that some parts could be shared globally and others only locally. At this time, CGTE also implemented powerful revision and change management controls. Siemens PLM Software experts worked closely with CGTE during phase two to help create industry-specific templates, organization structures, applicationspecific workflows, business rules, classifications and other functionality for a testing system environment, as well as for the entire product development system. Realizing a strategic operational advantage With the successful completion of the first two phases of its PLM implementation,

Solutions/Services NX www.siemens.com/nx Teamcenter www.siemens.com/teamcenter Customers primary business China Gas Turbine Establishment (CGTE) performs aerospace technology research and product development for Chinas aviation industry, as well as develops products for the civil machinery market. www.cgte.com.cn Customer location Chengdu, Sichuan Province China By implementing NX and Teamcenter, we have achieved significant advantages in terms of our product development, product data management and even workflow control. Fu Yu Overall Structure Director, PDM China Gas Turbine Establishment

CGTE has achieved what management feels is a strategic process edge. All of the improvements resulting from the NX and Teamcenter PLM implementation are crucial to CGTEs plan for automating the whole product development cycle. By implementing NX and Teamcenter, we have achieved significant advantages in terms of our product development, product data management and even workflow control, says Yu. We are very impressed with the results. Using NX as the foundation for its topdown development approach, CGTE is realizing tangible gains across processes. 3D data is now being fully leveraged, resulting in significantly reduced work across the engineering design stage, production of innovative, high-value designs and tight control over all product development operations. With Teamcenter, CGTE teams are exchanging product data instantaneously, re-using more designs and documents, and dramatically reducing the number of duplicate parts and components produced. Management is now in sync with overall project status, including the execution of individual work tasks. This is resulting in substantially reduced development costs. Teamcenter is also facilitating online electronic design/document approval, revision control and version management, as well as automatic BOM generation.

In addition, the ability of Teamcenter to execute CGTEs technical standards and specifications is an important benefit. Strict execution of these standards is crucially important to the companys goal of delivering the highest quality products to CGTEs customers and managements goal of capturing a leading position among the industrys best.

Siemens Industry Software Americas +1 800 498 5351 Europe +44 (0) 1276 702000 Asia-Pacific +852 2230 3333 www.siemens.com/plm

2012 Siemens Product Lifecycle Management Software Inc. All rights reserved. Siemens and the Siemens logo are registered trademarks of Siemens AG. D-Cubed, Femap, Geolus, GO PLM, I-deas, Insight, JT, NX, Parasolid, Solid Edge, Teamcenter, Tecnomatix and Velocity Series are trademarks or registered trademarks of Siemens Product Lifecycle Management Software Inc. or its subsidiaries in the United States and in other countries. All other logos, trademarks, registered trademarks or service marks used herein are the property of their respective holders. Z5 21397 2/12 B

S-ar putea să vă placă și

- Setting Up Blueprints in Dassault SolidworksDocument10 paginiSetting Up Blueprints in Dassault SolidworksrasgeetsinghÎncă nu există evaluări

- Setting Up Blueprints in Dassault CATIADocument8 paginiSetting Up Blueprints in Dassault CATIArasgeetsinghÎncă nu există evaluări

- Siemens PLM Sukhoi Design Cs Z7Document4 paginiSiemens PLM Sukhoi Design Cs Z7rasgeetsinghÎncă nu există evaluări

- Siemens PLM Sipa Zoppas Group Cs Z4Document4 paginiSiemens PLM Sipa Zoppas Group Cs Z4rasgeetsinghÎncă nu există evaluări

- Siemens PLM TMC Cancela Cs Z3Document5 paginiSiemens PLM TMC Cancela Cs Z3rasgeetsinghÎncă nu există evaluări

- Siemens PLM Prima Industries Cs Z6Document3 paginiSiemens PLM Prima Industries Cs Z6rasgeetsinghÎncă nu există evaluări

- One CAM System, No Limits: Standardizing On NX CAM Saves Time, Lowers Costs and Improves QualityDocument2 paginiOne CAM System, No Limits: Standardizing On NX CAM Saves Time, Lowers Costs and Improves QualityrasgeetsinghÎncă nu există evaluări

- Siemens PLM Coastal KZN College Tooling Centre of Excellence Cs Z5Document4 paginiSiemens PLM Coastal KZN College Tooling Centre of Excellence Cs Z5rasgeetsinghÎncă nu există evaluări

- Siemens PLM Starrett Cs Z8 PDFDocument3 paginiSiemens PLM Starrett Cs Z8 PDFrasgeetsinghÎncă nu există evaluări

- Siemens PLM Atkins Nedtech Cs Z3Document2 paginiSiemens PLM Atkins Nedtech Cs Z3rasgeetsinghÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Name: Amir Bin Rossaifuddin Id: 2016307153 Group: Emd2M2ADocument2 paginiName: Amir Bin Rossaifuddin Id: 2016307153 Group: Emd2M2AamirossaifuddinÎncă nu există evaluări

- FPFH Standar InstallationDocument13 paginiFPFH Standar InstallationYulius IrawanÎncă nu există evaluări

- Ansi C37.72-1987 PDFDocument25 paginiAnsi C37.72-1987 PDFIvanÎncă nu există evaluări

- Justeq07 Product BulletinDocument1 paginăJusteq07 Product BulletinjusteqÎncă nu există evaluări

- Pressure Vessel PDFDocument8 paginiPressure Vessel PDFdanielreyeshernandezÎncă nu există evaluări

- 820-3740 Technical OverviewDocument238 pagini820-3740 Technical Overviewppjim100% (1)

- S A 20190725Document4 paginiS A 20190725krishaÎncă nu există evaluări

- GS-1930 GS-1530 Service Manual: Technical PublicationsDocument137 paginiGS-1930 GS-1530 Service Manual: Technical PublicationshabibullaÎncă nu există evaluări

- SP25Y English PDFDocument2 paginiSP25Y English PDFGarcia CruzÎncă nu există evaluări

- Quadcopter Design DocumentDocument23 paginiQuadcopter Design Documentapi-556772195Încă nu există evaluări

- Advanced Power ElectronicsDocument4 paginiAdvanced Power ElectronicsLinkan PriyadarsiniÎncă nu există evaluări

- Blue Lotus Software Development CompanyDocument3 paginiBlue Lotus Software Development CompanydP gaming0% (1)

- POLYMATH TutorialChemical Reaction Engineering PDFDocument8 paginiPOLYMATH TutorialChemical Reaction Engineering PDFAfifah SabriÎncă nu există evaluări

- MSupply BuilderDocument21 paginiMSupply BuilderRohan BagadiyaÎncă nu există evaluări

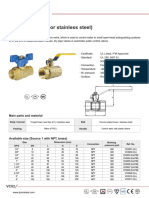

- VC02 Brass Ball Valve Full Port Full BoreDocument2 paginiVC02 Brass Ball Valve Full Port Full Boremahadeva1Încă nu există evaluări

- Issues in Timing: Digital Integrated Circuits © Prentice Hall 1995 TimingDocument14 paginiIssues in Timing: Digital Integrated Circuits © Prentice Hall 1995 TimingAbhishek BhardwajÎncă nu există evaluări

- Analysis of Challenges Facing Rice Processing in NDocument8 paginiAnalysis of Challenges Facing Rice Processing in Nanon_860431436Încă nu există evaluări

- TMB 60Document2 paginiTMB 60oac08Încă nu există evaluări

- 1 Salwico Fire Alarm SystemDocument173 pagini1 Salwico Fire Alarm SystemAung SquÎncă nu există evaluări

- Six Stroke EngineDocument19 paginiSix Stroke EngineSai deerajÎncă nu există evaluări

- M 3094 (2013-06)Document17 paginiM 3094 (2013-06)Hatada FelipeÎncă nu există evaluări

- Ansi z245 2 1997Document31 paginiAnsi z245 2 1997camohunter71Încă nu există evaluări

- EPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Document20 paginiEPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Ion IonutÎncă nu există evaluări

- B-Trees and B+-Trees: Jay Yim CS 157B Dr. LeeDocument34 paginiB-Trees and B+-Trees: Jay Yim CS 157B Dr. LeemaskplyÎncă nu există evaluări

- G700 03 603333 1Document382 paginiG700 03 603333 1Jorge CruzÎncă nu există evaluări

- Msamb Rules and Japan GuidelinesDocument3 paginiMsamb Rules and Japan GuidelineslawrgeoÎncă nu există evaluări

- 2cmc480022c0003 PDFDocument52 pagini2cmc480022c0003 PDFArul SankaranÎncă nu există evaluări

- Leadership and Management 2003Document46 paginiLeadership and Management 2003Ciella Dela Cruz100% (1)

- About Us ThinksynQ TeamDocument1 paginăAbout Us ThinksynQ TeamSai KrishanÎncă nu există evaluări

- EHB02 Technical Specifications: 1. External DimensionsDocument5 paginiEHB02 Technical Specifications: 1. External DimensionsArmandoCalderonÎncă nu există evaluări