Documente Academic

Documente Profesional

Documente Cultură

The Design of Conveyor Pulleys

Încărcat de

Jam BabDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

The Design of Conveyor Pulleys

Încărcat de

Jam BabDrepturi de autor:

Formate disponibile

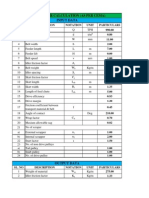

THE DESIGN OF CONVEYOR PULLEYS

B.E. Lloyd BSc (Mech.) Eng. Director Jegkurt Engineering (Pty) ltd

INTRODUCTION Up until a few years ago , when conveyors in South Africa were rather small compared with their counterpart in other countries overseas, the need for engineered systems was limited. With the advent of the oil crisis this situation changed over night for two reasons , i.e. diesel fuel vehicles became almost too expensive to use and secondly the demand for coal as a fuel became increasingly important. In order to mine the coal economically , it became necessary to increase the tonnage mined , as well as to improve the method of transporting the coal that was mined. The obvious answer to the problem was to use conveyor belts in conjunction with unit trains and sophisticated loading and unloading stations. Coal mining was not the only type of mine effected by the rise in cost of oil based fuels , but also the base minerals , such as iron are , copper and uranium. It was the base mineral mines , which at the time of the oil crisis , that were using the open cast method with electro haulpacks for transporting the ore and overburden more so than the Collieries. Unfortunately or fortunately for South Africa , the change from small or medium size conveyors to large installations happened virtually overnight and the technology to undergo the change was not readily available , hence people in the conveyor field used their limited existing knowledge to try and make the larger and more sophisticated conveyors. This knowledge was however insufficient and hence resulted in many failures. The most noticeable failures being that of terminal Pulleys and belting. The idler manufacturers seemed however , to have escaped the lime light , either because they were more prepared for the change and sufficient technology was available from their overseas parent company , or the time and the cost to replace idlers was not sufficient to warrant an investigation. With the terminal Pulleys , a different situation arose. Just about every mining house and other conveyor orientated companies saw the need to improve the standard and the design of Pulleys. However , unlike Germany and other countries , each individual concern tried to develop standard and design on their own , without consulting each other. The end result of these standards can only be classed as disastrous and unnecessary waste of money and time , as none of the standards are competable with each other , except for one thing , and that is the rigidity of the expected standard of workmanship and the amount of paper required to prove the soundness of the equipment. By the amount of paper required, I mean, this so called quality assurance procedures , whereby it has now become necessary to prove that even the smallest Pulley, which is just an oversize idler , passes full pressure vessel tests. It is not that I am opposed to quality assurance , but just that I feel that the relationship between quality control and purpose of use should be equated so as to build a unit fit for service at the right price. This bring me to the definition of an engineer , which goes as follows:- " An Engineer is someone who can build for a penny, what any old fool can build for a pound ". When our company went into the manufacture and design of Pulleys like everyone else, we went our own way to establish a standard , but with a difference. We first tried to find out how people overseas were tackling the problem. During the course of this investigation we found out that Germany , Australia and some parts of the United States had all had their problems when they changed over from small to big conveyor belts. Germany in particular , where most of the large material handling plants are designed seemed to have spent many years in developing their technology in conveying with

the emphasis on conveyor Pulleys. At Hannover University two doctorates were awarded for research and development in conveyor Pulleys. By dealing with the right people , we were able to get hold of copies of both these doctorates , as well as many other papers written about conveyor Pulleys. By tabulating this information , we arrived at the bases of our design. DISC DESIGN The most complicated part of a Pulley and the area most prone to failure is the end disc. The origin of disc design : Formula for stress and strain of disc subject to loads acting at the centre , are to be found in many technical hand books . At present we are basing our calculation on formula for disc stress , which are obtainable from book data out of " Roarks " handbook and a thesis written by " W. Schmoltz" The disc can either be regarded as subject to bending moment , while the outer periphery is imagined to be fixed rigidly (see condition A) or on the other hand , the disc can be regarded as being suspended in such a way , where it cannot transmit any bending moment (as in condition B)

Condition A

Condition B In both cases the inner diameter is taken to be rigidly connected to the shaft. Both conditions of fixing have to be considered as extreme cases for a Pulley disc. The actual loading will be somewhere in between condition "A" and "B" . Consequently it should be necessary to calculate the stress in the inner diameter of the disc for condition "A" as well as condition "B" . In Pulley design we will be simulating condition "A" to a greater degree than condition "B" and the stresses as per condition "A" result in higher stress than for condition "B" . For the abovementioned two reasons only condition "A" will be considered in this paper.

Considering now the bending moment in the shaft , disregarding the restraining action of the disc , the shaft would develop the following bending moment diagram :

In corporating the resistance of the disc and shell to restrain the deflection of the shaft , the actual bending moment looks therefore like shown below :

Bm disc =

P (B - L) L 8I ( L + 1/t3)

(Bm disc)is the portion of shaft bending moment which sets up the stress in the disc at the connection with the hub , which so often has resulted in hub to disc failure if a hub is used. " Simple solution : Don't use hubs " . The question then arises , if hubs are not used , how do you fix the disc to shaft . ( This aspect is covered in the next section headed : LOCKING ELEMENTS ). FACTORS WHICH AFFECT BENDING MOMENT AND STRESS IN DISC From the above it will be obvious that by reducing the deflection of the shaft , one immediately reduces the amount of disc deflection as well as counteracting disc restraint. Thus

1. 2.

Bm and deflection of the disc can be readily reduced by increasing the shaft diameter (expensive method) Bm disc can be readily reduced by decreasing the thickness of the disc .

A steel Pulley with a thin disc allows the shaft to deflect as it naturally would by virtue of the two loads applied to it through the disc. A Pulley made with thick discs that do not bend appreciably as a result of the bending moment applied to them causes another type of shaft deflection , namely , from the disc outwards and for all practical purposes , the shaft could just as well be cut off between the disc. Between these two extremes lies a range of thickness that causes high disc stresses , unnecessary high bending moment at the inner diameter of the disc and eventually causes Pulley breakage. Using basic data , a formula has been developed to calculate the disc stress:

SB=

P (B-L) L 4DtI(L + 1) 2I t3 k8/cm = k8 = cm = cm = cm

P = Total resultant belt pull on the pulley B = Bearing center distance D = Disc outer diameter t = Disc thickness

L = Center to center distance between disk = cm

I = Moment of inertia of shaft = Disc constant = Disc constants

= cm4

The factors and are selected after calculating the ratio : Inside diameter of disc Outside diameter of disc For derivation of formula see Appendix "A" . The actual disc stress versus thickness for a typical small diameter Pulley is illustrated below : Chosen Pulley 450 Dia x 1100 Face x 90 Shaft Pulley loading 27.25 kN resultant Load Bearing centers = 1520 Disc centers = 1020mm Disc outer diameter = 430 (10mm rim) Disc inner diameter = 185 In this example : = 6.6 = 1.65 After calculating the disc stresses for various disc thickness it will be seen that the stresses increase from 3mm to 8mm and beyond this the stresses reduced as the disc thickness increased. Please refer to the graph below :

Thus for an allowable working fatigue stress there are two disc thicknesses that can be utilised. One a thin disc and the other a thick disc. Between these two limits a high stress is inevitable. This represents one of the few cases in design , where increasing material thickness results in higher , rather then lower stress in the part. The disadvantage of employing thick disc to reduce stress is that the bending moment on the connection from the shaft to the disc is greatly increased , and if this connection is not securely made the bore of the disc wears out and the Pulley moves or what is known as "walks" on the shaft The second item effecting end disc design is the positioning of the disc relative to the bearing centers. It is quite obvious that there are again two positions to limit the stresses i.e. close together in the middle of the Pulley or alternatively as far out as possible on the face , will result in the least stress , while in between will result in high stress regions. We have chosen the outer position for an obvious reason , and that is that the conveyor belt does not always strain perfectly , and if the disc was centrally situated and the belt runs off to one side , the disc would be subjected to additional bending stresses , due to the eccentric load. When using stress formula , it has been found that the large diameter Pulleys with the low set loading are seldom problemsome as they can be designed with the thin disc , while relatively small Pulleys with big shafts become difficult , because the disc becomes impractically thin or the direct stresses are too great to use a thin disc . Thus forcing the manufacturer to use the thick disc design. Typical examples of this type of Pulley is those associated with steel cord belts , where the required diameter of the Pulley is far smaller than the equivalent required for a fabric belt.

When using the thick disc design , there are two important areas to consider namely , the fixing of the disc to the shaft (Discussed under the section of Locking Elements), and the disc to rim fixing . On extremely high loaded Pulleys , it is often an advantage not to weld in the inter-face between rim and disc, but to move the weld inboard of the disc and make a but weld on the rim. This type of disc is known as a T bottom type disc See sketch below :

The advantage of this is that it has substantial radius both inside and outside the high stress zone and to limit stress concentration it is always better to use radii rather than sharp corners. The other advantage is that the weld as positioned is firstly out of the high stress zone and secondly is in a position where it is far easier to make a perfect weld and the thickness of material to be welded is thinner. The question arises "Why are not all Pulleys made like this?" The answer is simply cost. Remember our definition of an Engineer. When looking at the sketch of the T bottom , you will notice that the disc is tapered and not parallel. There are two reasons for this :

1. 2.

Although we are using the thick disc design there is still merit in giving the Pulley certain flexibility in order to lower the stress at the shaft to disc connection. By profiling the end disc , it ensures that the stresses throughout the disc are constant and hence limit stress concentration areas.

As mentioned before not all Pulleys are T bottom , for the simple fact that they cost far more than other designs and hence we come to the second type of end disc , namely a Turbine End. In our terminology the T bottom is our heavy duty range and the Turbine and semi-Turbine our medium duty range. The Turbine Pulley is similar in characteristic to our T bottom design but has two distinct differences: a) We use a different type of Locking Element b) The welding is performed at the interface of disc to rim Although we emphasized the advantage of removing the weld from this position when we discussed the T bottom type Pulley , we must clearly state that this type of Pulley we are now discussing , is one that does not have to with- stand the same tensions as the T bottom , and hence the stress level is far lower. When performing this weld between rim and disc it is important to ensure that this weld is of a sound nature. With full penetration and no lack of side-wall fusion. To insure full penetration and to limit stress concentration an the inner face it is good practice to perform an inner fillet weld if possible. See sketch :

The last type of disc we are going to consider is a semi-turbine end or flat bottom design. This Pulley for the majority of conveyors, is the ideal type of Pulley. It is relatively in-expensive due to the easy method of machining the disc. It has most of the advantages of the turbine end but with the exception of the two zones where stress concentration occurs, but taking suitable stress concentration factors into consideration these stresses are well below acceptable levels. Again using suitable welding procedures to perform the disc to rim weld to ensure a sound weld which is fit for the duty. See sketch :

SHAFT TO DISK CONNECTION - LOCKING ELEMENTS Many people are of the opinion that the reason for using a locking element for fixing the disc to the shaft is so that the shaft can be removed if necessary. This in itself is a good reason for installing a locking element, but by no means the only reason for fitting a locking element. Below are three sketches of suitable locking elements for Pulley construction and we will discuss the advantages of these elements collectively and thereafter individually.

TYPE A

TYPE B

TYPE C the three elements share the following advantage over all other known hub to shaft connections:

a.

b.

c.

They by virtue of the torque applied to their bolts, have a controlled pressure on both, hub and shaft. By simple mathematics, this pressure can be calculated and hence eliminating the hit and miss factor which is inherent in a "shrink fit" thus making it possible to calculate, by using thick wall cylinder formula, the size of the hub required to with-stand the pressure fairly accurately and thus eliminating unnecessary hub material. Their torque, which they can transmit, is also a factor controlled by the torque applied to their bolts, thus again making it unnecessary to fit additional safe guards, such as keys and keyways, to ensure that they do not slip in the direction of the applied torque. By the elimination of these keys and keyways the stress concentration associated with the above is naturally eliminated. All three locking elements can withstand great axial thrust thus virtually eliminating the possibility of walking on the shaft, and in the unlikely event of this happening, it is relatively simple to rectify, as it is usually only necessary to place the drum back to its original position and re-torque the bolts in the locking element. If a similar situation occurs with a shrink fit, the bore has inevitably been worn away and the entire Pulley becomes redundant.

LOCKING ELEMENT TYPE A Locking element type A has been on the South African market for approximately ten years and is probably the most common locking element used in Conveyor Pulleys. In the unloaded condition it has undoubtedly the best stress pattern of the three locking elements. However, when load is applied to the drum and the shaft deflects, the stress pattern changes. See comparison sketch between locking element "A" and "B". In locking element "A" because of the angle of the tapered segments, it is neither self centering nor self locking, hence at all times the securing bolted are in tension, thus it becomes necessary to use a centralising ring as shown on the sketch, as well as having to limit the deflection of the shaft, to ensure that the bolts do not exceed their elastic limit. The acceptable level of deflection for this type of locking element is in order of 1/2500 bearing centers or if preferred, in radial units 0.05 degrees or 0.0008 radians, although this deflection restriction is not totally unfavorable, it often forces the designer to use a bigger shaft than he normally would, to satisfy acceptable stress levels of torque to be transmitted. The most unfavorable characteristic of this type of locking element is that it is virtually impossible to control the mating of the surfaces of the segments. This can result in high point loads initially and also make it necessary to re-torque the bolts after initial running in period, after the segments have settled. LOCKING ELEMENT TYPE B Locking element type B is the type we are currently using in our medium duty Pulleys, i.e. the turbine or flat bottom design. The reason for using this type of locking element and not type A, is that it has the following advantages:

a.

b.

Because of the angle of the tapers on the segments, these elements are both, self-centering and selflocking, therefore do not require a centralising step behind the disc. Because of the elimination of this step, it is always possible to withdraw the shaft from the drum, because the inevitable build-up of rust between centralising step and shaft does not occur. By having self-locking tapers, the bolts are not in tension to the same extent as type A, hence greater shaft deflections are possible. The permissible deflection being in the order of 1/1800 to 1/2000 bearing centers or expressed radially + 0.06 degrees or 0.001 radians.

c. d.

Unlike locking element type A it is not so critical that the locking element bolts are tightened in sequence as due to the tapers it is impossible to tighten this element unsymetrically. The major disadvantage of this type of locking element, is that it cannot transmit the same torque as type A. However, on conventional Pulleys this seldom causes a problem as the torque to be transmitted by the shaft is usually well within the capabilities of the chosen element.

LOCKING ELEMENT TYPE C Locking element type C was specially designed for conveyor Pulleys. It has all the advantages of type A and B , with far lower surface pressures then either , while at the same time being able to transmit between 2 and 3 times the Torque of either A or B. This element is used in all our T bottom Pulleys , with the shaft sizes up to 400mm in diameter. The Rhein Brown Coal A.G. in Germany have been using them with shaft sizes up to 600mm successfully. PRECAUTIONS WHEN USING LOCKING ELEMENTS IN CONVEYOR PULLEYS Many people think that by specifying a Pulley fitted with locking elements , they will automatically get a better Pulley than a shrink fit type Pulley. This is often not the case , as the type of hub that is used is as important as the type of locking element chosen. Often , if the hub design does not suit the locking element , the hub cracks under pressure from the locking element. or alternatively the hub diameter is increased , so as to accommodate the locking element , and this hub is too large , and when using a thin disc often limits the flexing of the disc , hence cracking the weld around the hub. TOP HAT FORGED HUBS A design has been introduced into South Africa which is quite unique. I have not seen anything quite like it anywhere in the world , and it is because of its uniqueness I feel some kind of mention should be made to try and analyze it. Firstly its origin during the change from light duty conveyors to heavy duty conveyors. The most noticeable area of failure was the two fillet welds at the hub sketch A. It then became apparent that if the hub was extended so that a double butt weld could be used , this would obviously be a far better type of hub sketch B than its predecessor A. Design B was used for a few years and was later replaced by design C , which instead of machined out of solid material could easily be forged by using a single sided dye.

This hub had one great disadvantage and that is that in order to utilise the potential of its simplicity , it has to suit various shaft diameters , drum diameters and disc thickness. This not being a sufficiently complicated exercise , this hub was further modified to be able to accept various shaft to hub fixing , such as , shrink fits , taper locks and locking element type A . The result of the exercise resulted in a large chunk of useless material which only added weight and cost to the Pulley, no wonder it is unique to South Africa.

SHAFT DESIGN

During the course of the paper many references have been made about deflection and its limits. A simple and common formula is used to calculate this deflection : PL2a 8EI 4a 3L

(1 -

Where : L = Bearing centers a = Lever arm E = Modulus of elasticity After calculating the deflection, the next step is to calculate the stress level , either for straight bending in the case of non drive Pulley, or the combination of bending and torsion for drive Pulley. The last step is to check the locking elements Torque characteristic against the applied Torque , in the case of a drive Pulley. Remembering that during starting and breaking , this Torque increases substantially and appropriate precautions must be taken into consideration to prevent the locking element slipping. RIM DESIGN Due to the complex nature of the calculations involved in rim design , we will not be discussing it in detail in this paper. For design purposes , the drum casing is regarded as a cylindrical shell with a partially loaded surface. Particular attention must be paid to the boundary conditions and the load distribution , if this approach is used for conveyor Pulleys. The rim is then regarded as a simply supported tube with no moments or axial forces. The belt forces at the edge are transmitted in the direction of the plane of the drum only on the contact surface between rim and conveyor belt. A pressure and shear stress distribution , similar to operating conditions is achieved by super-imposed sine functions. The total load of the element is obtained by summation of the individual sinusoidal loads. This calculation is far too time consuming without the use of a computer to be dealt with in this paper as they are usually unknown under eytewein boundary conditions. When the fatigue strength of a rim is calculated , it is necessary to remember that three load changes occur in each casing segment during a single drum rotation. Rim design limiting factor is usually based on fatigue strength. CENTER STIFFENERS Center stiffeners in large conveyor Pulleys are again unique to South Africa , and the only article I have seen relative to stiffeners was associated with pressure vessels titled " Collapse of Stiffened Cylinders Under External Pressure " by S.B. Kendrick. The only other association I have had with them is having seen samples of failure which have occurred in the vicinity of these center stiffeners on large Pulleys. THEORY ANALYSIS - PULLEY DETAIL (Disc)

M I

E R

But R =

{1+(dy/dx)}3/2 dy/dx

= dy/dx when dy/dx is small .'.dy/dx = M/EI (But between points S and T on the shaft the bending moment MS is constant) .'. dy/dx = MS EI dx = MS EI x+c

But when x = L/2 --> dy/dx = 0 .'. MS/EI x L/2 + c = 0 ------(1) Then C = MSL (Substitute back into (1))

2 EI Then dy/dx = .'. dy/dx = MS EI MSL 2 EI x+ = s MS L 2 EI (and x = 0)

But MD + MS = M and also S = D

ie MD + MS = MD(1 MD = But SD = = .'. = .'. SD =

P (B-L) 4 2I t L )= P (B-L) 4

MSL 2EI

MD EtL 2IMb tL

.'.MS =

P (B - L) 4(1+2I/tL) 2MD Dt 2 P (B - L) 4Dt(1+2I/tL) 2 P (B - L) 4Dt 2I/L (L/2L + 1/t) P (b - L) L 4DtI(L/2L + 1/t)

S-ar putea să vă placă și

- Scientific American Supplement, No. 794, March 21, 1891De la EverandScientific American Supplement, No. 794, March 21, 1891Încă nu există evaluări

- Belt Conveyor Pulley DesignDocument11 paginiBelt Conveyor Pulley Designthakur_raghab100% (1)

- Conveyor Pulley DrumsDocument13 paginiConveyor Pulley DrumsriysallÎncă nu există evaluări

- Belt Conveyor Pulley Design - Why The FailuresDocument16 paginiBelt Conveyor Pulley Design - Why The FailuresenrimauryÎncă nu există evaluări

- Lecture 4 - Belt Conveying - Trans CurvesDocument18 paginiLecture 4 - Belt Conveying - Trans CurvesFabio MiguelÎncă nu există evaluări

- Cintas Calculo Por SIG Engineering ManualDocument52 paginiCintas Calculo Por SIG Engineering Manualfajar abadiÎncă nu există evaluări

- Fatigue Failures of Welded Conveyor DrumsDocument11 paginiFatigue Failures of Welded Conveyor DrumsWashington MoraisÎncă nu există evaluări

- Conveyor Gallery - Structural Design ParameterDocument21 paginiConveyor Gallery - Structural Design Parametershailendra rathoreÎncă nu există evaluări

- Iso 5293 1981Document8 paginiIso 5293 1981Rajaram JayaramanÎncă nu există evaluări

- SME 2017 Design and Analysis of Conveyor Pulleys - A HustrulidDocument34 paginiSME 2017 Design and Analysis of Conveyor Pulleys - A Hustrulidtadela_553439598Încă nu există evaluări

- Design, Fabrication and Testing of A Low Headroom Conveyor Transfer ChuteDocument132 paginiDesign, Fabrication and Testing of A Low Headroom Conveyor Transfer ChuteJakesÎncă nu există evaluări

- Crane Transportation DesignDocument65 paginiCrane Transportation Designdawit100% (1)

- Belt Conveyor Take Up DesignDocument4 paginiBelt Conveyor Take Up DesignKroya HunÎncă nu există evaluări

- Pipe ConveyorDocument4 paginiPipe ConveyorDIBYENDU MONDALÎncă nu există evaluări

- Bearing Centre and Face Width in Conveyor PulleyDocument8 paginiBearing Centre and Face Width in Conveyor PulleyPrashant MishraÎncă nu există evaluări

- Designcalculation 19260009 Cal Me CNV 00Document71 paginiDesigncalculation 19260009 Cal Me CNV 00frantorÎncă nu există evaluări

- Conveyor Pulley Failure Analysis PDFDocument3 paginiConveyor Pulley Failure Analysis PDFriysallÎncă nu există evaluări

- CB Selecting The Proper Conveyor BeltDocument18 paginiCB Selecting The Proper Conveyor BeltdineshÎncă nu există evaluări

- E200704 301 PDFDocument7 paginiE200704 301 PDFvilobhsÎncă nu există evaluări

- Conveyor BeltDocument23 paginiConveyor BeltPRANOTOSUKMO100% (1)

- Bhatkar (2015) - Finite Element Analysis of Crane Hook and Optimization Using Taguchi ApproachDocument5 paginiBhatkar (2015) - Finite Element Analysis of Crane Hook and Optimization Using Taguchi ApproachGogyÎncă nu există evaluări

- Rope Towed Trolley or Machinery Trolley PDFDocument11 paginiRope Towed Trolley or Machinery Trolley PDFAdhitya ReÎncă nu există evaluări

- Belt Bucket Elevator DesignDocument14 paginiBelt Bucket Elevator Designking100% (1)

- Conveyor Screws PDFDocument9 paginiConveyor Screws PDFldavilaluceralÎncă nu există evaluări

- Conveyor Chains TsubakiDocument184 paginiConveyor Chains Tsubakitepu msosaÎncă nu există evaluări

- Axle HoldersDocument1 paginăAxle HoldersjoseocsilvaÎncă nu există evaluări

- Conveyor Belt Weigh ScaleDocument2 paginiConveyor Belt Weigh ScaleEDUARDOÎncă nu există evaluări

- Dunlop Conveyor Belt Design Manual - P2Document15 paginiDunlop Conveyor Belt Design Manual - P2perdhana2000Încă nu există evaluări

- Chain Drive CalculationsDocument42 paginiChain Drive CalculationsAchin67% (3)

- Calculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMADocument9 paginiCalculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMAretrospect1000Încă nu există evaluări

- A Review On Numerical and Experimental Study of Screw ConveyorDocument4 paginiA Review On Numerical and Experimental Study of Screw ConveyorMangatur SimamoraÎncă nu există evaluări

- Chute Design Jenike - Complex Calcs PDFDocument5 paginiChute Design Jenike - Complex Calcs PDFGeorge McMullinÎncă nu există evaluări

- Bucket Elevator SanweiDocument1 paginăBucket Elevator SanweiTriết Lãm NgôÎncă nu există evaluări

- TGN 08 Crane Rail Selection 2Document3 paginiTGN 08 Crane Rail Selection 2Prasad PatilÎncă nu există evaluări

- Mato Belt Cleaner CatalogueDocument12 paginiMato Belt Cleaner Catalogueleeyod100% (1)

- Design and Fabrication of Pneumatic Crane StartDocument6 paginiDesign and Fabrication of Pneumatic Crane StartHimani MahetaÎncă nu există evaluări

- Extract From The Book Belt FeederDocument93 paginiExtract From The Book Belt FeederPushp Dutt100% (1)

- Belt Slippage SPWP1178ENPR-01Document2 paginiBelt Slippage SPWP1178ENPR-01JrbritoÎncă nu există evaluări

- Beumer Overland Belt Conveyor enDocument16 paginiBeumer Overland Belt Conveyor enIgor San Martín PeñalozaÎncă nu există evaluări

- Belt Tension CalculationDocument5 paginiBelt Tension Calculationmanoj983@gmail.comÎncă nu există evaluări

- TGN 11 Clip Spacing 09-12Document2 paginiTGN 11 Clip Spacing 09-12kayakeras3335Încă nu există evaluări

- Jenikes' TheoryDocument209 paginiJenikes' TheoryMohammad Bataineh100% (1)

- FeederDocument13 paginiFeedernileshÎncă nu există evaluări

- Free Conveyor DesignDocument12 paginiFree Conveyor DesignRyukiÎncă nu există evaluări

- The Values Are Not Linked With Anywhere ..: Conveyor ProfileDocument33 paginiThe Values Are Not Linked With Anywhere ..: Conveyor ProfileMustafa Akbar100% (1)

- Bucket Elevator ChainDocument4 paginiBucket Elevator Chainluisreng100% (1)

- Belt Feeder Calculation CEMADocument7 paginiBelt Feeder Calculation CEMANAITIK100% (4)

- Apex Belting Conveyor HandbookDocument102 paginiApex Belting Conveyor Handbooksasha_seferovic1874Încă nu există evaluări

- Shell Strength of Conveyor Belt Pulleys - Theory and DesignDocument13 paginiShell Strength of Conveyor Belt Pulleys - Theory and DesignWilfredo BullonÎncă nu există evaluări

- Conveyor Pulley DesignDocument2 paginiConveyor Pulley DesignZoebair100% (1)

- Coal Conveyor Belt Fault DetectionDocument4 paginiCoal Conveyor Belt Fault Detectionc pawarÎncă nu există evaluări

- The Design of Conveyor PulleysDocument8 paginiThe Design of Conveyor PulleysWaris La Joi WakatobiÎncă nu există evaluări

- Design of Vertical Tank TowerDocument6 paginiDesign of Vertical Tank TowerAlan C. AbanÎncă nu există evaluări

- Foundation Design Philosophy For Bullet VesselsDocument5 paginiFoundation Design Philosophy For Bullet Vesselsdicktracy11Încă nu există evaluări

- Modern Pulley Design Techniques and Failure Analysis MethodsDocument17 paginiModern Pulley Design Techniques and Failure Analysis MethodsSiva SubramaniÎncă nu există evaluări

- Equipmrnt FoundationDocument52 paginiEquipmrnt Foundationdovi01100% (1)

- Apparatus Design IIDocument52 paginiApparatus Design IIEthio Dangote TubeÎncă nu există evaluări

- Foundation Design Philosophy For Vertical VesselDocument6 paginiFoundation Design Philosophy For Vertical VesselKeaten Claney100% (1)

- Design Concrete Ring Beam For Storage Tank - PDFDocument3 paginiDesign Concrete Ring Beam For Storage Tank - PDFbonnico0% (1)

- Selection of FenderDocument11 paginiSelection of FenderOkondu ChieduÎncă nu există evaluări

- External Gear Pump PrinciplesDocument3 paginiExternal Gear Pump PrinciplesJam BabÎncă nu există evaluări

- Split System Refrigerant Piping Guide PDFDocument8 paginiSplit System Refrigerant Piping Guide PDFJam BabÎncă nu există evaluări

- Tajweed Qur'anDocument58 paginiTajweed Qur'anJam Bab50% (2)

- How To Choose A Fishing RodDocument9 paginiHow To Choose A Fishing RodJam BabÎncă nu există evaluări

- Fluid (Gas or Liquid) Mechanics Pressure Blaise Pascal Force Hydraulic PistonDocument1 paginăFluid (Gas or Liquid) Mechanics Pressure Blaise Pascal Force Hydraulic PistonJam BabÎncă nu există evaluări

- Turbo Manifold Designs by Engine BasicsDocument17 paginiTurbo Manifold Designs by Engine BasicsJam Bab100% (1)

- Surah Fatiha With TajweedDocument10 paginiSurah Fatiha With TajweedJam Bab0% (1)

- Vibration SOPDocument4 paginiVibration SOPJam BabÎncă nu există evaluări

- Vibration Dignostic Chart CharlotteDocument1 paginăVibration Dignostic Chart CharlotteJam BabÎncă nu există evaluări

- Vibration Analysis and Signal Processing in LabVIEWDocument12 paginiVibration Analysis and Signal Processing in LabVIEWJam Bab100% (1)

- A Comprehensive Dictionary of Vibration Analysis Terms You May Run Across in Your TradeDocument54 paginiA Comprehensive Dictionary of Vibration Analysis Terms You May Run Across in Your TradeJam BabÎncă nu există evaluări

- In Considering Your Interactions With Your Classmates As You Proceed With Your Group Project, You Could and Should AddressDocument4 paginiIn Considering Your Interactions With Your Classmates As You Proceed With Your Group Project, You Could and Should AddressJam BabÎncă nu există evaluări

- Transforming LeaderDocument17 paginiTransforming LeaderJam BabÎncă nu există evaluări

- Leadership Reflection PaperDocument8 paginiLeadership Reflection PaperJam Bab100% (1)

- SOT Schedule Optimizer ToolDocument17 paginiSOT Schedule Optimizer ToolAndres GuerreroÎncă nu există evaluări

- iCON SB150 Professional Plant PDFDocument18 paginiiCON SB150 Professional Plant PDFmurci2929Încă nu există evaluări

- Proposal For Andra MassiahDocument10 paginiProposal For Andra MassiahJoel ColeÎncă nu există evaluări

- Atlas Copco ROC L8 Specifications PDFDocument4 paginiAtlas Copco ROC L8 Specifications PDFlesantiago29% (7)

- The Extractive Industries and Society: Arnab Roy Chowdhury, Kuntala Lahiri-DuttDocument13 paginiThe Extractive Industries and Society: Arnab Roy Chowdhury, Kuntala Lahiri-DuttDiego AlbertoÎncă nu există evaluări

- Maybe I Don't Know WhoDocument13 paginiMaybe I Don't Know WhoTechno EntertainerÎncă nu există evaluări

- Fire Detection and Warning SystemsDocument1 paginăFire Detection and Warning SystemsDinesh dhakarÎncă nu există evaluări

- Lepanto Consolidated Mining Corporation v. Icao - DigestDocument2 paginiLepanto Consolidated Mining Corporation v. Icao - DigestRoxanne PeñaÎncă nu există evaluări

- Executive Order No 79Document9 paginiExecutive Order No 79Ivy KatrinaÎncă nu există evaluări

- Mining Research DesignDocument142 paginiMining Research DesignRussell Hartill67% (3)

- Alimak Raise MiningDocument2 paginiAlimak Raise Miningsydneyyun100% (1)

- MDO Tender NotiDocument2 paginiMDO Tender Notiangshuman87Încă nu există evaluări

- PDFDocument7 paginiPDFLalaÎncă nu există evaluări

- UG Mid Semester ExaminationDocument7 paginiUG Mid Semester ExaminationUnknownÎncă nu există evaluări

- Phraser Connector: Fraser Lake - A Mining Town Without A Mine?Document12 paginiPhraser Connector: Fraser Lake - A Mining Town Without A Mine?Anthony StarkÎncă nu există evaluări

- Gold Mines in Ontario MapDocument3 paginiGold Mines in Ontario MapStacyÎncă nu există evaluări

- Elitech Earth Science Pvt. Ltd. - Company Profile - OldDocument23 paginiElitech Earth Science Pvt. Ltd. - Company Profile - OldsanchitagarwalismÎncă nu există evaluări

- PWC Basics of Mining Accounting UsDocument133 paginiPWC Basics of Mining Accounting Ussharanabasappa baliger100% (1)

- Garpenberg 20030407Document7 paginiGarpenberg 20030407Nils Johan BolinÎncă nu există evaluări

- Major Projects Brochure-V6-LoResDocument12 paginiMajor Projects Brochure-V6-LoResChris GonzalesÎncă nu există evaluări

- Earthrise (1990) (Interstel Corporation) (Manual)Document18 paginiEarthrise (1990) (Interstel Corporation) (Manual)jeanjean33Încă nu există evaluări

- Coal Mining WorksheetDocument4 paginiCoal Mining WorksheetmarinaperegrinaÎncă nu există evaluări

- Stuart Kirsch - Indigenous Movement and The Risk of Counter GlobalizationDocument19 paginiStuart Kirsch - Indigenous Movement and The Risk of Counter GlobalizationHasriadi Ary MasalamÎncă nu există evaluări

- Typical Project Workflow: A Guide To Mine Plan OptimisationDocument54 paginiTypical Project Workflow: A Guide To Mine Plan OptimisationMário de FreitasÎncă nu există evaluări

- Continuous MinerDocument3 paginiContinuous MinerbhsbxbmÎncă nu există evaluări

- B.Tech Course Book-12 Mining New With Co PDFDocument40 paginiB.Tech Course Book-12 Mining New With Co PDFMaloth Pramod NayakÎncă nu există evaluări

- Guidelines Safe Design Operating Standards For Tailings Storage WaDocument57 paginiGuidelines Safe Design Operating Standards For Tailings Storage Wadafo407100% (1)

- A Survey On The Risk Perception of Slips, Trips, and Falls of Coal Mine Workers in ChinaDocument6 paginiA Survey On The Risk Perception of Slips, Trips, and Falls of Coal Mine Workers in ChinaPipe GonzalezÎncă nu există evaluări

- Anglogold Limited: Exploration WorkshopDocument13 paginiAnglogold Limited: Exploration WorkshopRegina EfraimÎncă nu există evaluări

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsDe la EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsÎncă nu există evaluări

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsDe la EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsÎncă nu există evaluări

- House Rules: How to Decorate for Every Home, Style, and BudgetDe la EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetÎncă nu există evaluări

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiDe la EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiEvaluare: 4 din 5 stele4/5 (3)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiDe la Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiEvaluare: 5 din 5 stele5/5 (2)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersDe la EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersEvaluare: 3.5 din 5 stele3.5/5 (3)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastDe la EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastEvaluare: 5 din 5 stele5/5 (1)

- Edward's Menagerie: Dogs: 50 canine crochet patternsDe la EverandEdward's Menagerie: Dogs: 50 canine crochet patternsEvaluare: 3 din 5 stele3/5 (5)

- The Martha Manual: How to Do (Almost) EverythingDe la EverandThe Martha Manual: How to Do (Almost) EverythingEvaluare: 4 din 5 stele4/5 (11)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsDe la EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsEvaluare: 4.5 din 5 stele4.5/5 (10)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesDe la Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesÎncă nu există evaluări

- Crochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreDe la EverandCrochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreEvaluare: 4 din 5 stele4/5 (6)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeDe la EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeEvaluare: 5 din 5 stele5/5 (1)

- Crochet Impkins: Over a million possible combinations! Yes, really!De la EverandCrochet Impkins: Over a million possible combinations! Yes, really!Evaluare: 4.5 din 5 stele4.5/5 (10)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)De la EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Încă nu există evaluări

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsDe la EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsEvaluare: 5 din 5 stele5/5 (3)

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldDe la EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldEvaluare: 4.5 din 5 stele4.5/5 (30)

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookDe la EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookEvaluare: 4.5 din 5 stele4.5/5 (2)

- Textiles Transformed: Thread and thrift with reclaimed textilesDe la EverandTextiles Transformed: Thread and thrift with reclaimed textilesÎncă nu există evaluări

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsDe la EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsÎncă nu există evaluări

- Edward's Menagerie: Over 40 Soft and Snuggly Toy Animal Crochet PatternsDe la EverandEdward's Menagerie: Over 40 Soft and Snuggly Toy Animal Crochet PatternsEvaluare: 5 din 5 stele5/5 (10)

- Modern Crochet Sweaters: 20 Chic Designs for Everyday WearDe la EverandModern Crochet Sweaters: 20 Chic Designs for Everyday WearEvaluare: 5 din 5 stele5/5 (1)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsDe la EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsÎncă nu există evaluări

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesDe la EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesEvaluare: 5 din 5 stele5/5 (3)

- Build Your Skills Crochet Tops: 26 Simple Patterns for First-Time Sweaters, Shrugs, Ponchos & MoreDe la EverandBuild Your Skills Crochet Tops: 26 Simple Patterns for First-Time Sweaters, Shrugs, Ponchos & MoreEvaluare: 4.5 din 5 stele4.5/5 (6)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesDe la EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesÎncă nu există evaluări

- Creative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtDe la EverandCreative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtÎncă nu există evaluări