Documente Academic

Documente Profesional

Documente Cultură

Provisional Water Bore Completion

Încărcat de

Kim MissonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Provisional Water Bore Completion

Încărcat de

Kim MissonDrepturi de autor:

Formate disponibile

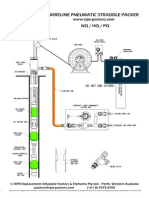

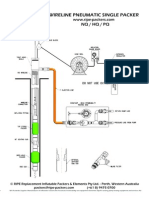

REPLACEMENT INFLATABLE PACKERS & ELEMENTS PTY LTD

29 WHEELER STREET, BELMONT, WESTERN AUSTRALIA 6104 PH: .61 (08) 9475 0700, Fax: .61 (08) 9475 0770 packersripe-packers.com www.ripe-packers.com

PROVISIONAL WATER BORE COMPLETION

270613NBKO

BEFORE HEADWORKS INSTALLATION 125mm NB FRP CASING WITH 80mm NB SCREENS TELESCOPED

Anticipated Casing String Run Casing float shoe 396.00 - 395.55 Drill-out Pipe 395.55 - 390.05 Centron x/over 390.05 - 389.60 45 lengths FRP 389.60 - +0.68 Stick-Up is 0.68metres

273.10mm OD STEEL SURFACE CASING PRESSURE GROUTED IN AT - 66 METERS

FRP Casing Grades DHC200 30 joints 0-266 Approx DHC250 9 joints 266 - 389 Approx

ENTRALISERS 1 PER CASING LENGTH

125mm NB FRP MAIN CASING WITH RELEVANT GRADE TO SUIT DEPTH - PRESSURE GROUTED IN

Screen Assembly SS end plate 80mm 55 Sump 80mm Screen 80mm Riser Pipe 80 x 125 Packer 416.000 410.00 - 408.00 408.00 - 396.00 396.00 - 392.00 392.00 - 391.50

.50 METRE125mm NB SS DRILL-OUT PIPE PLUS X/OVER

6.50 - METRE 80mm RISER PIPE WITH VULCANISED BORE K-PACKER

OTTOM OF 125mm NB CASING FLOAT SHOE AT -396 METRES

12 METRES 80mm NB SS SCREEN FROM 396m TO 408m

CASING FLOAT SHOE

2 METRES SUMP 80mm NB SS WITH END PLATE

TOTAL SCREEN ASY EXTENDS FROM TOP OF PACKER AT 389m TO BASE OF SUMP (BOTTOM OF HOLE) AT - 410m

Replacement Inflatable Packers and Elements Pty Ltd 29 Wheeler St Belmont 6104, Perth Western Australia Tel: (+61 (08) 9475 0700 Fax: +61 (08) 9475 0770 13ackers@ripe - packers.com

www.ripe-packers.com

Australian supplier and manufacturer of well screen PVC rubber k-packers, well packer tri-seals, equipment and services

REPLACEMENT INFLATABLE PACKERS & ELEMENTS PTY LTD

29 WHEELER STREET, BELMONT, WESTERN AUSTRALIA 6104 PH: +61 (08) 9475 0700, Fax: +61 (08) 9475 0770 packers@ripe-packers.com www.ripe-packers.com

Drilling and Construction of New Bores

X X

Suggested General Work Procedure

Drilling Technique: Surface Casing: Main Casing: Screen Assembly: Mud Rotary 273.0m OD steel 125mm NB FRP - 167mm maximum OD at tools joints Stainless Steel drill-out pipe, casing float shoe and cross-over Stainless Steel end plate 2metres 80mm NB stainless steel sump extension 12 metres of 80mm NB, grade 316 stainless steel bore screen 6.50 metres 80mm NB stainless steel riser pipe extension vulcanised bore packer

Bore Construction: Drill for and install 273.10mm OD steel surface casing at ~66metres with a casing float shoe and centralisers and pressure grout it into place. take 2 samples of the grout slurry. Allow 12 hours for grout cure; Top up the annulus with grout to ground level as required; Drill out the shoe and drill a hole of suitable diameter to the target depth which is expected to be approximately 410metres; Stand-by while the contracted operator conducts a geophysical log of the bore; Install 125mm NB FRP casing with casing float shoe, bottom drill-out pipe, crossover and centralisers and pressure grout it into place at the depth directed expected to be at ~ 396metres. Take 2 samples of the grout slurry. (125mm NB FRP casing has a maximum diameter over the tool joints of 167mm); **The decision to grout without the bottom of the hole or to gravel pack the bottom of the hole prior to grouting is entirely at the contractor's discretion.** Allow 24 hours for grout cure; Run in and drill out the cement at the shoe; Continue to clean out the borehole to the depth required for the screen assembly, anticipated to be ~410metres; Run the 80mm NB stainless steel screen assembly and vulcanised bore packer and set it at the depth directed; develop the bore in line with the requirements of the contract; fit the head works assembly standpipe; Cast a concrete block around the standpipe at surface. the block shall be a minimum of 750mm square x 350mm deep. The top of the block shall be at ground level. The top of the standpipe shall be not less than 600mm and not more than 750mm above the top of the block. ** Surface casing depth should be decided on-site as drilling is undertaken.**

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Wireline Pneumatic Straddle PackerDocument1 paginăWireline Pneumatic Straddle PackerKim MissonÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Permeability TestingDocument1 paginăPermeability TestingKim MissonÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Wireline Pneumatic Single PackerDocument1 paginăWireline Pneumatic Single PackerKim MissonÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Wireline Hydraulic Straddle PackerDocument1 paginăWireline Hydraulic Straddle PackerKim MissonÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Replacements and RebuildsDocument1 paginăReplacements and RebuildsKim MissonÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Mini Hydrualic Frac PackersDocument1 paginăMini Hydrualic Frac PackersKim MissonÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Wireline Hydraulic Single PackerDocument1 paginăWireline Hydraulic Single PackerKim MissonÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Ripe K Packers and Telescopic SealsDocument1 paginăRipe K Packers and Telescopic SealsKim MissonÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Hydraulic Fracturing Inflatable PackersDocument1 paginăHydraulic Fracturing Inflatable PackersKim MissonÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- RIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsDocument1 paginăRIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsKim MissonÎncă nu există evaluări

- Kpackers MetricDocument1 paginăKpackers MetricKim MissonÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- K PackersDocument1 paginăK PackersKim MissonÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Grab Packer ImperialDocument1 paginăGrab Packer ImperialKim MissonÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Grab Packer MetricDocument1 paginăGrab Packer MetricKim MissonÎncă nu există evaluări

- 60 Standard Wireline Packer System ReplacementsDocument1 pagină60 Standard Wireline Packer System ReplacementsKim MissonÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- 56 DST Packer Test ToolDocument2 pagini56 DST Packer Test ToolKim MissonÎncă nu există evaluări

- 73 DST Packer Test ToolDocument2 pagini73 DST Packer Test ToolKim MissonÎncă nu există evaluări

- Drill Able Bridge PlugsDocument1 paginăDrill Able Bridge PlugsKim MissonÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- 83 Standard Wireline Packer System ReplacementsDocument1 pagină83 Standard Wireline Packer System ReplacementsKim MissonÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- 72 DST Packer Test ToolDocument2 pagini72 DST Packer Test ToolKim MissonÎncă nu există evaluări

- 42 DST Packer Test ToolDocument2 pagini42 DST Packer Test ToolKim MissonÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- 54 DST Packer Test ToolDocument2 pagini54 DST Packer Test ToolKim MissonÎncă nu există evaluări

- 43 DST Packer Test ToolDocument2 pagini43 DST Packer Test ToolKim MissonÎncă nu există evaluări

- 30 Bridge Plug Metric Sliding EndDocument1 pagină30 Bridge Plug Metric Sliding EndKim MissonÎncă nu există evaluări

- 30 Bridge Plug Imperial Fixed EndDocument1 pagină30 Bridge Plug Imperial Fixed EndKim MissonÎncă nu există evaluări

- 42 Standard Wireline Packer System ReplacementsDocument1 pagină42 Standard Wireline Packer System ReplacementsKim MissonÎncă nu există evaluări

- 30 Bridge Plug Imperial Sliding EndDocument1 pagină30 Bridge Plug Imperial Sliding EndKim MissonÎncă nu există evaluări

- 30 Bridge Plug Metric Fixed EndDocument1 pagină30 Bridge Plug Metric Fixed EndKim MissonÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- 26 Bridge Plug Metric Sliding EndDocument1 pagină26 Bridge Plug Metric Sliding EndKim MissonÎncă nu există evaluări

- 26 Bridge Plug Imperial Sliding EndDocument1 pagină26 Bridge Plug Imperial Sliding EndKim MissonÎncă nu există evaluări

- HC SB 61 227Document22 paginiHC SB 61 227Hamed BarjestehÎncă nu există evaluări

- Carti Libraria Victor Papilian Ian 2015Document8 paginiCarti Libraria Victor Papilian Ian 2015Petru AcozmeiÎncă nu există evaluări

- Resume - Niloofar MojaradDocument2 paginiResume - Niloofar Mojaradmohammadrezahajian12191Încă nu există evaluări

- Tle - H.E.-Cookery: Quarter 2 - Module 2: Prepare Salad DressingDocument26 paginiTle - H.E.-Cookery: Quarter 2 - Module 2: Prepare Salad DressingRodel Camposo88% (25)

- Antithesis Essay Joseph JaroszDocument3 paginiAntithesis Essay Joseph JaroszJoseph JaroszÎncă nu există evaluări

- Manoshe Street Takeaway MenuDocument9 paginiManoshe Street Takeaway MenuimaddakrÎncă nu există evaluări

- An Assestment of The Trinidad and Tobago Health Care SystemDocument4 paginiAn Assestment of The Trinidad and Tobago Health Care SystemMarli MoiseÎncă nu există evaluări

- Chapter 8 Sensation and PerceptionDocument66 paginiChapter 8 Sensation and Perceptionapi-726122866Încă nu există evaluări

- CH - 3 DrainageDocument3 paginiCH - 3 DrainageVeena VermaÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Minibeasts Differentiated Reading Comprehension ActivityDocument15 paginiMinibeasts Differentiated Reading Comprehension Activitymariam helmyÎncă nu există evaluări

- Roadshow Advanced 7.2 V3.2 221004 FinalDocument347 paginiRoadshow Advanced 7.2 V3.2 221004 FinalEddy StoicaÎncă nu există evaluări

- PM PillarDocument56 paginiPM PillarNavneet Sharma75% (4)

- 1716 ch05Document103 pagini1716 ch05parisliuhotmail.comÎncă nu există evaluări

- Ra Radtech Cdo July2018Document4 paginiRa Radtech Cdo July2018Angelo MercedeÎncă nu există evaluări

- Industrial Diesel Generator Set - 50 HZ: General Specifications KOHLER Premium QualityDocument7 paginiIndustrial Diesel Generator Set - 50 HZ: General Specifications KOHLER Premium QualityABCD123655Încă nu există evaluări

- Passive In-Line Chlorination For Drinking Water DiDocument18 paginiPassive In-Line Chlorination For Drinking Water DitefovÎncă nu există evaluări

- Boiler Installation - AfbcDocument2 paginiBoiler Installation - AfbcSarah FrazierÎncă nu există evaluări

- Dr. Shekhar Challa Joins Bioscience Americas Board of AdvisorsDocument2 paginiDr. Shekhar Challa Joins Bioscience Americas Board of AdvisorsPR.comÎncă nu există evaluări

- Lecture 16 - Bleeding Tendency DiseasesDocument64 paginiLecture 16 - Bleeding Tendency Diseasesapi-3703352100% (1)

- Material Science & Metallurgy: Third Semester B.E. Degree (CBCS) Examination, Dec.2016/Jan.2017Document2 paginiMaterial Science & Metallurgy: Third Semester B.E. Degree (CBCS) Examination, Dec.2016/Jan.2017Shaikh MuzaffarÎncă nu există evaluări

- The Safe Motherhood InitiativeDocument3 paginiThe Safe Motherhood InitiativeAnonymous g6L7jJWÎncă nu există evaluări

- Chapter 2 Body CoordinationDocument25 paginiChapter 2 Body CoordinationnanarahmannaimÎncă nu există evaluări

- Football Speed TrainingDocument6 paginiFootball Speed TrainingTBM607Încă nu există evaluări

- Why Is ICS Important For Schools?Document8 paginiWhy Is ICS Important For Schools?Spit FireÎncă nu există evaluări

- Intermediate Home/Office Electrical/Electronic Equipment ServicingDocument53 paginiIntermediate Home/Office Electrical/Electronic Equipment ServicingSha Tu BolaÎncă nu există evaluări

- DSE8620 MKII Operator ManualDocument224 paginiDSE8620 MKII Operator Manualhenrygrados44Încă nu există evaluări

- Instructions For Assembling Your Owners ManualDocument8 paginiInstructions For Assembling Your Owners ManualJim PowersÎncă nu există evaluări

- Electrosurgery: The Compact Electrosurgical Unit With High CapacityDocument6 paginiElectrosurgery: The Compact Electrosurgical Unit With High CapacityPepoÎncă nu există evaluări

- Personal Loan For JoiningDocument3 paginiPersonal Loan For JoiningAzim SengalÎncă nu există evaluări

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDe la EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsÎncă nu există evaluări

- Analog Design and Simulation Using OrCAD Capture and PSpiceDe la EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceÎncă nu există evaluări

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe la EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tEvaluare: 4.5 din 5 stele4.5/5 (27)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDe la EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceEvaluare: 4 din 5 stele4/5 (19)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsDe la EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsEvaluare: 5 din 5 stele5/5 (1)