Documente Academic

Documente Profesional

Documente Cultură

Soil Improvement and Staged Embankment

Încărcat de

mbikucoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Soil Improvement and Staged Embankment

Încărcat de

mbikucoDrepturi de autor:

Formate disponibile

SOIL IMPROVEMENT AND STAGED EMBANKMENT CONSTRUCTION IN SOFT CLAYS

Sri T. Srithar1 and Max C. Ervin2

ABSTRACT Shear strength of clays will generally increase with consolidation under load. Large embankments on soft clays can be constructed by adopting a staged construction approach utilising the strength increase associated with consolidation. This paper presents a case history of a staged embankment construction carried out for the approach embankments of the My Thuan Bridge over the Mekong River, in Vietnam. The site of the My Thuan Bridge is underlain by soft clay deposits about 14 m to 18 m thick on the north and south sides of the river, respectively. Approach embankments about 7.4 m high with a 1.5 m surcharge were constructed at the site. The embankments were instrumented with inclinometers, piezometers, extensometers and survey monuments to assess the performance of the embankment during staged construction. Cone penetrometer tests and field vane shear tests were carried out after Stage 1 consolidation to assess the increase in shear strength and the stability under Stage 2 fill placement. The measured increase in shear strength was compared with predicted values. The increase in shear strength was also assessed in terms the measured settlement and applying soil mechanics theories. BACKGROUND The My Thuan Bridge site is located along the northern arm (Tien Giang branch) of the Mekong River, about 125 km south-west of Ho Chi Minh City. The bridge is a cable stayed bridge with a 350 m main span, 150 m side spans and 11 viaduct spans of 40 m on each side. The design road level at the middle of the main span is about 40 m above the high water level in the river. Approach embankments about 7.4 m high with a 1.5 m surcharge were constructed on each side. The bridge site is located on the Mekong River flood plains and comprises recent Quaternary age deposits to considerable depth. A geological cross section at the bridge site inferred from the available geotechnical information is shown in Figure 1.

Figure 1: Geological cross section of the site

1 2

Senior Geotechnical Engineer, Golder Associates Pty Ltd, 25 Burwood Road, Hawthorn, VIC 3122, Australia Principal, Golder Associates Pty Ltd, 25 Burwood Road, Hawthorn, VIC 3122, Australia

The generalised geological profile to about RL 50 m can be considered to comprise four major deposition units: Unit 1 This is the uppermost unit and consists of mainly very soft to firm silty clays and clayey silts. The sediments become more interlayered with silty sand and sandy silt layers below about RL 10 m. This unit extends to RL 14 m to RL 15 m on the northern side (typically about 14 m thick under the northern embankment) and to RL-18 m to RL 21 m on the southern side (typically about 18 m thick under the southern embankment. In the area of the southern embankment, a 1 m thick sand layer was encountered at about RL -4 m within this unit. Unit 2 This unit consists of loose to medium dense sands, clayey sands and sandy silt mixtures and underlies Unit 1. This unit does not extend to the south side of the river. Unit 3 - This units underlies Unit 2 on the northern side and Unit 1 on the southern side and comprises stiff to very stiff silty clays and sandy clays. Unit 4 - Underlies Unit 3 and comprises medium dense to dense granular sediments. This units extends to about RL 56 m. Characteristics of Unit 1 Materials The properties of the Unit 1 materials on the northern embankment side are summarised in Table 1. The undrained shear strength profile was obtained from the cone tip resistance of the cone penetrometer tests and field vane shear tests (corrected for plasticity using Bjerrum, 1972). Table 1. Average Properties of Unit 1 Materials Material Property Range Average Total unit weight, (t/m3) 1.63 to 1.76 1.7 Specific gravity 2.68 to 2.72 2.7 Natural moisture content, MC (%) 32 to 57 42 Liquid limit, LL (%) 33 to 49 38 Plasticity Index, PI (%) 12 to 29 18 Compression index, Cc 0.16 to 0.43 0.3 Coefficient of consolidation, cv (m2/year) 2 to 20 6 20 to 30 25 Drained strength parameters, (degrees) 0 0 c(kPa) Undrained shear strength, Su (kPa) 8.5 + 1 D to 8.5 + 1.6 D 8.5 + 1.3 D where D is the depth below ground surface in metre Instrumentation The embankments were instrumented with inclinometers, piezometers, magnetic extensometers and survey monuments to assess the performance of the embankment between stages. The instruments also served as indicators to control the stability of the embankment during construction. Figure 2 shows a plan of the northern embankment and details of the instrumentation.

Figure 2: Instrumentation location and wick drains details

DESIGN OF CONSTRUCTION STAGES In this paper, only the details of the northern embankment are presented. The performance of the southern embankment was similar to the northern embankment, even though the subsurface conditions are slightly different. Because of the presence of the soft clay deposits and concerns regarding stability, the embankment was designed to be constructed in three stages utilising the strength gain due to consolidation between stages. The original design profiles of the embankment stages, at the maximum height of the embankment, are shown in Figure 3. The main body of the embankment had a batter slope of 2H:1V with level benches at RL 3 m and RL 2 m. However, in order to optimise the construction time, a critical review of the stability of the embankments was carried out and the Stage 1 profile was modified to incorporate the full extent level bench at RL 3 m and additional filling to RL 5.5 m in the middle. The revised Stage 1 profile is also shown in Figure 3. As the strength of the clay materials and the stability of the embankment were expected to increase with time, a minimum factor of safety of 1.3 was adopted for the design of embankment profiles.

Figure 3: Typical cross section of embankment stages Stage 2 construction involves fill placement to the final embankment level of RL 7.4 m. Stage 3 construction involves placement of a 1.5 m surcharge fill for early removal of potential consolidation settlements and to reduce the long term creep settlements. Wick drains were installed to accelerate the consolidation and to reduce the construction period. The spacing and depth of the wick drains varied depending on the height of the embankment. Figure 2 shows the details of the wick drain depths and spacings. Adopting a Cc value of 0.3 near the surface decreasing to about 0.2 at the base of the clay layer, maximum 95% consolidation settlement for the Stage 1 embankment was estimated to be about 700 mm. The time for 50% excess pore pressure dissipation during piezocone test varied from 0.3 to 86 minutes indicating a horizontal coefficient of consolidation Ch of 5 m2/year to greater than 50 m2/year. For a Ch of 5 m2/year and for a wick drain spacing of 1.2 m, the time for 95% consolidation was estimated to be about 3 months. The above time estimate for 95% consolidation did not include any effect of smearing of the clay. An attempt has also made to quantify the effect of smearing and to check the effectiveness of wick drains based on Yeung (1997), which can be used to check the effectiveness of the wick drains. For example, a 5 mm thick smeared zone around the drains having a permeability one order of magnitude lower than the mass permeability of soil was estimated to increase the time for 95% consolidation to about 5 months. The shear strength profiles obtained from cone penetrometer testing and the strength increases obtained from multistage consolidated undrained triaxial tests indicate that the average increase in undrained shear strength due to 95% consolidation under the fill loading of P can be given by Su = 0.17 P (1)

Hence after the Stage 1 consolidation, the average strength of the clays was expected to be 23+1.3 D kPa, where D is the depth below original ground surface. Stability of the combined Stage 2 and Stage 3 filling was assessed adopting the above strength increase. The results of the stability analyses indicated the factor of safety to be marginally less than 1.3. Therefore combining Stages 2 and 3 would require a higher than predicted increase in undrained shear strength in the field tests.

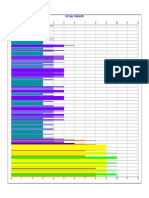

EMBANKMENT PERFORMANCE AND SOIL IMPROVEMENT Monitoring Results Stage 1 The construction of the Stage 1 embankment took about 1.5 months (from August to mid September 1998). The measured settlements at some selected survey monuments are shown in Figure 4. A maximum settlement of about 970 mm was measured at Survey Monument No. 27 in about 2 months (by mid November 1998) from the completion of Stage 1 embankment construction. This is higher than the predicted settlement and indicates an average Cc of about 0.35, which is close to the upper limit values measured in the laboratory consolidation tests.

Figure 4: Measured settlement Maximum lateral displacement was measured in Inclinometer No.2 and the results are shown in Figure 5. A maximum lateral displacement of about 70 mm was measured at about 5 m below the original ground surface. The piezometers did not respond well and therefore the results are not shown here. It is possible that because of the close spacing of the wick drains, localised horizontal connections between wick drains and the zone of the piezometer tip might have caused the piezometers not to be effective. Strength Increase After Stage 1 Consolidation Six piezocone tests and three field vane shear tests were carried out towards the end of Stage 1 consolidation. All tests show considerable improvement in the undrained shear strength of clay. For comparison, the profiles of the cone tip resistance of the original ground and after the Stage 1 consolidation are shown in Figure 6. On average the tests indicate a shear strength profile of about 20+3 D kPa, where D is the depth below the original ground surface in m. The measured increase in undrained shear strength was higher than predicted especially at depths. The increase in undrained shear strength was also assessed using the method of Stamatopoulos and Kotzias (1985). Based on soil mechanics principles, they present the following equation to estimate the increase in undrained shear strength for one dimensional consolidation:

Figure 5: Measured lateral displacement at Inclinometer No. 2

Figure 6: Comparison of cone tip resistances

1 + WN G S u = Su 0.434 C c

(2)

where, Su is the increase in undrained shear strength, Su is the original undrained shear strength, WN is the natural moisture content (in decimal), G is the specific gravity, Cc is the compression index, is the measured settlement and h is the thickness of the deposit. Using Equation (2), for the average properties of the clay and for the measured settlement, Su/Su is estimated to be 1.17. Thus, the undrained shear strength profile after Stage 1 consolidation will be 18.5 + 2.8 D kPa, where D is the depth below the original ground surface in metre. The strength increase predicted by Equation (2) is in reasonable agreement with the measured values, although the measured values are slightly higher. An attempt has also been made here to obtain a general guidance to assess the undrained shear strength increase due to consolidation. Generally the natural moisture content, WN in inorganic clays varies from 30% to 100%. Koppula (1981) shows that a simplistic correlation for the compression index of most of the inorganic clays can be given by Cc = 0.93 WN. Hence, for a specific gravity G of 2.7 and for WN of 30% to 100%, Equation (2) can be simplified to

S u = 9 to 15 Su h

(3)

where the lower factor is associated with the higher moisture content. However, it should be noted that Equation (2) is based on one dimensional consolidation does not account for the contribution of the lateral movement of soil and the settlement of the underlying stiffer soils in the measured settlement. The extent of the loaded area will also have an effect, especially where compressible soils extend to larger depths. Monitoring Results Stage 2 & 3 Based on the undrained shear strength measured after the Stage 1 consolidation, Stage 2 and Stage 3 (surcharge) of the embankment construction were combined. This provided a considerable reduction in construction period. The measured settlements at the survey monuments in the area of the maximum height of the embankment are shown in Figure 4. A maximum settlement of about 1.37 m (additional 370 mm from end of Stage 1) was measured at Survey Monument No. 27. The lateral displacements measured in Inclinometer No.2 are shown in Figure 5. A maximum lateral displacement of about 100 mm (additional 30 mm from end of Stage 1) was measured at about 5 m below the original ground surface. Surcharge Removal The time for surcharge removal was based on the following criteria outlined in the contract specification: The lateral movements measured in the inclinometers should be less than 2 mm per month. Under Stage 3 embankment 95% of the primary consolidation settlements should have occurred. An assessment of the degree of consolidation was carried out about 3 months after the construction of the combined Stage 2 and 3 construction. The degree of consolidation was assessed using Asaoka (1978) method. Tan and Chew (1996) indicate that the Asaoka method gives a better assessment of the 100% consolidation settlement, when assessing the settlement points approximately between 60% and 90% consolidation. This is because in a theoretical plot a linear segment is observed between these settlement points. However, because of the staged construction, the settlement readings for the last stage of loading were considered. The Asaoka plot for the settlements at Survey Monument No. 27 is shown in Figure 7.

Figure 7. Asaoka plot for Monument No.27

Adopting a back-calculated Cc of 0.35 from Stage 1, a 100% primary consolidation settlement of about 1400 mm was calculated. This is in reasonable agreement with that predicted by the Asaoka method. The degree of consolidation was also assessed using the log time plot. Based on the above methods, the degree of consolidation was assessed to be at least 95% after 3 months and the surcharge was removed by end of April 1999. However, concerns were expressed about the degree of consolidation because of the observed rate of settlement prior to surcharge removal, which was about 4 mm/week. This might have been primarily due to creep. Because of the concern, it was decided to continue monitor the settlement after the surcharge removal. Figure 5 also shows the settlement measurements after the surcharge removal and indicates no appreciable increase in settlements. CONCLUDING REMARKS Embankments on soft clays can be constructed successfully, by adopting a staged construction approach. The use of extensive instrumentation is highly desirable for this approach. The instrumentation provides valuable data to assess the performance of the embankment and its stability during staged construction. Monitoring of settlement, lateral movements and excess pore pressures can be considered either individually or collectively as reliable indicators of the performance of the embankment. The above case study indicates that piezometers may not be very effective in areas where vertical drains are installed at very close spacing, and indicates the need for redundancy in the type and extent of instrumentation. There are case histories in the literature where the wick drains did not accelerate the consolidation. However, at the My Thuan site wick drains were effective in accelerating the consolidation settlements. Equations (2) and (3) presented in the paper may be used to estimate the increase in undrained shear strength from measured settlement. However, a limited number of field tests are recommended to confirm the increase in strength. ACKNOWLEDGEMENT Authors would like to thank AusAID and Baulderstone Hornibrook Engineering Ltd for granting permission for publication of this paper. REFERENCES Asaoka, A. (1978). "Observational procedure of settlement predictions". Soils and Foundations, Vol. 18, No. 4, pp. 87-101. Bjerrum, L. (1972). "Embankments on Soft Ground". Proceedings of the ASCE specialty conference on Performance of Earth and Earth Supported Structures, Vol. 2, pp. 1-54. Koppula, S.D. (1981). "Statistical estimation of compression index". Geotechnical Testing Journal, ASTM, Vol. 4, No. 2, pp. 68 - 73. Stamatopoulos, A.C. and Kotzias, P.C. (1985). "Soil improvement by preloading". John Wiley series in geotechnical engineering. Tan, S.A. and Chew, S.H. (1996). "Comparison of the hyperbolic and Asaoka observational method of monitoring consolidation with vertical drains". ". Soils and Foundations, Vol. 36, No. 3, pp. 31-42. Yeung, A.T. (1997). "Design curves for prefabricated vertical drains". Journal of Geotechnical and Geoenvironmental Engineering, Vol. 123, No. 8, pp. 775 - 759.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- TM 2.4.5 Tunnel Structure Design R0 100729Document47 paginiTM 2.4.5 Tunnel Structure Design R0 100729mbikucoÎncă nu există evaluări

- Standard Us Lab ReportsDocument12 paginiStandard Us Lab ReportsmbikucoÎncă nu există evaluări

- Seismic Data (USGS, SNI, Etc)Document1 paginăSeismic Data (USGS, SNI, Etc)mbikucoÎncă nu există evaluări

- 4429 11330 1 SMDocument13 pagini4429 11330 1 SMmbikucoÎncă nu există evaluări

- AllPile ManualDocument103 paginiAllPile ManualcrnewsomÎncă nu există evaluări

- Standard Us Lab ReportsDocument12 paginiStandard Us Lab ReportsmbikucoÎncă nu există evaluări

- Classification Using - RobertsDocument1 paginăClassification Using - RobertsmbikucoÎncă nu există evaluări

- Subsurface Diagram SectionDocument1 paginăSubsurface Diagram SectionmbikucoÎncă nu există evaluări

- HSE DrillingDocument132 paginiHSE DrillingmbikucoÎncă nu există evaluări

- D2435 OnedimconsolidDocument10 paginiD2435 OnedimconsolidHilana OliveiraÎncă nu există evaluări

- Boring Number Bh1Document1 paginăBoring Number Bh1mbikucoÎncă nu există evaluări

- ManualDocument34 paginiManualmbikucoÎncă nu există evaluări

- CPT - L - 01 (BDMS) 4Document1 paginăCPT - L - 01 (BDMS) 4mbikucoÎncă nu există evaluări

- CPT - L - 01 (BDMS) 3Document1 paginăCPT - L - 01 (BDMS) 3mbikucoÎncă nu există evaluări

- GRL-Measurements and Analysis On Becker Penetration Tests SR-522 Cathcart Road Vicinity To US-2 WideningDocument156 paginiGRL-Measurements and Analysis On Becker Penetration Tests SR-522 Cathcart Road Vicinity To US-2 WideningmbikucoÎncă nu există evaluări

- UTM ConversionDocument1 paginăUTM ConversionaハタケÎncă nu există evaluări

- CPT - L - 01 (BDMS) 2Document1 paginăCPT - L - 01 (BDMS) 2mbikucoÎncă nu există evaluări

- CPT - y - 03 (BDMS)Document5 paginiCPT - y - 03 (BDMS)mbikucoÎncă nu există evaluări

- 7-4 Open Channel DesignDocument40 pagini7-4 Open Channel Designdliu88Încă nu există evaluări

- Road Design Manual Chapter One Road Design Process: Montana Department of TransportationDocument12 paginiRoad Design Manual Chapter One Road Design Process: Montana Department of TransportationufffyaarÎncă nu există evaluări

- 08 Hydrologic and Hydraulic Analysis Frick Springs BR (1) .Document15 pagini08 Hydrologic and Hydraulic Analysis Frick Springs BR (1) .mbikucoÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Seismic Risk in JordanDocument18 paginiSeismic Risk in JordanJihad TámímíÎncă nu există evaluări

- Room-And-pillar Method of Open Stope MiningDocument6 paginiRoom-And-pillar Method of Open Stope MiningIsmaelÎncă nu există evaluări

- Mus Phys PartDocument13 paginiMus Phys PartJAGDEV PANESARÎncă nu există evaluări

- Why The Moon's Orbit Is ConvexDocument2 paginiWhy The Moon's Orbit Is ConvexAnonymous e8BzOGqlawÎncă nu există evaluări

- Ian Palmer HTDocument33 paginiIan Palmer HTtassili17Încă nu există evaluări

- Cognitive Development and Conservation Tasks by Jean PiagetDocument3 paginiCognitive Development and Conservation Tasks by Jean Piagetteachersmanual100% (5)

- Telluric CurrentDocument4 paginiTelluric CurrentWassim HelouÎncă nu există evaluări

- 3.3bjhbbbb BattttttDocument14 pagini3.3bjhbbbb BattttttSipu GiriÎncă nu există evaluări

- #Richard HartshorneDocument558 pagini#Richard HartshorneJulián L. Gómez100% (1)

- Morgan Reflection EssayDocument2 paginiMorgan Reflection Essayapi-242968406Încă nu există evaluări

- Diversity of Seed Plants and Their Systematics by DR Nupur BhowmickDocument26 paginiDiversity of Seed Plants and Their Systematics by DR Nupur Bhowmickdapolra55100% (2)

- Approach To Political ScienceDocument17 paginiApproach To Political ScienceRandy Raj OrtonÎncă nu există evaluări

- NCERT Book Fundamentals of Human Geography Class XIIDocument112 paginiNCERT Book Fundamentals of Human Geography Class XIInikhilam.com100% (7)

- 2016 - Hassen Et Al - Journal of HydrologyDocument14 pagini2016 - Hassen Et Al - Journal of HydrologyAnonymous KxvIaYEEÎncă nu există evaluări

- Work DoneDocument2 paginiWork DonealexÎncă nu există evaluări

- Crypto Charted Newsletter June 2021Document6 paginiCrypto Charted Newsletter June 2021Preeti YadavÎncă nu există evaluări

- The Living World: Mind MapDocument12 paginiThe Living World: Mind MapPrince100% (1)

- ParajitDocument15 paginiParajitAbhishek ChandraÎncă nu există evaluări

- Etienne Szekely - The Living Atom TheoryDocument137 paginiEtienne Szekely - The Living Atom Theorydigger257Încă nu există evaluări

- SbciDocument112 paginiSbcimanikumar0Încă nu există evaluări

- 3 Theories of Solar SystemDocument2 pagini3 Theories of Solar SystemMonique Gk0% (1)

- Kamasutra Simplified and DetailedDocument830 paginiKamasutra Simplified and DetailedSpiritualHelp88% (8)

- GROSS Mystery of UFOs A PreludeDocument309 paginiGROSS Mystery of UFOs A PreludeTommaso MonteleoneÎncă nu există evaluări

- VanWees - 2D Numerical Modeling P-T-T Path: Dynamics of Extension & Inversion (Betics, Spain) - Tectonophysics 1992Document20 paginiVanWees - 2D Numerical Modeling P-T-T Path: Dynamics of Extension & Inversion (Betics, Spain) - Tectonophysics 1992Koen de JongÎncă nu există evaluări

- A Timeline For Planet FormationDocument2 paginiA Timeline For Planet FormationpianomagicianÎncă nu există evaluări

- Subjective CommunicationDocument38 paginiSubjective CommunicationDr.Varnisikha D NÎncă nu există evaluări

- McKenzie2007 Article ConnectivityAndScaleInCultural PDFDocument2 paginiMcKenzie2007 Article ConnectivityAndScaleInCultural PDFLolita UmarÎncă nu există evaluări

- Alonso 2003Document20 paginiAlonso 2003dave miltonÎncă nu există evaluări

- Chapter 01 - Diversity of LifeDocument27 paginiChapter 01 - Diversity of LifeMaryam AliÎncă nu există evaluări

- Famous Filipino Scientist AND Their ContributionDocument20 paginiFamous Filipino Scientist AND Their ContributionMary Angeline PasajeÎncă nu există evaluări