Documente Academic

Documente Profesional

Documente Cultură

Wcee2012 2303

Încărcat de

atulqweTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Wcee2012 2303

Încărcat de

atulqweDrepturi de autor:

Formate disponibile

International Guideline for Seismic Design of Low-Rise Confined Masonry Buildings in Regions of High Seismic Risk

Svetlana Brzev

Department of Civil Engineering, British Columbia Institute of Technology, Canada

Roberto Meli

Instituto de Ingeniera, UNAM, Mexico

SUMMARY: This paper presents an overview of the development and content of a global design guideline for confined masonry buildings sponsored by the Confined Masonry Network (www.confinedmasonry.org) under the auspices of EERI and IAEE. The authors of the paper co-chaired a committee of thirteen international experts responsible for the development of Seismic Design Guide for Low-Rise Confined Masonry Buildings which offers prescriptive design recommendations for low-rise buildings (one- and two-storey high). The design provisions are related to the building layout, wall density, and size of confined masonry structural components, as well as reinforcement size and detailing. The document addresses variations in seismic hazard and construction practices in various countries. The guideline is expected to be of interest to individuals and organizations interested to introduce confined masonry construction in countries and regions where this technology is currently not in use. Keywords: Confined masonry, seismic design, low-rise buildings

1. DEVELOPMENT OF THE GUIDE Poor performance of unreinforced masonry and poorly-built reinforced concrete (RC) frame construction in past earthquakes caused high human and economic losses and prompted a need for alternative building technologies with enhanced seismic performance. One such technology is confined masonry, which has emerged as a building system that offers an alternative to both unreinforced masonry and reinforced concrete (RC) frame construction. Confined masonry construction has evolved though an informal process based on its satisfactory performance in past earthquakes. The first reported use of confined masonry construction was in the reconstruction of buildings destroyed by the 1908 Messina, Italy earthquake (M 7.2), which killed over 70,000 people. Confined masonry construction has been practiced in Mediterranean Europe (Italy, Slovenia, Serbia), Latin America (Mexico, Chile, Peru, Argentina, and other countries), the Middle East (Iran), south Asia (Indonesia), and the Far East (China). It is important to note that confined masonry construction practice exists in countries and regions of extremely high seismic risk. Several examples of confined masonry construction around the world, from Argentina, Chile, Iran, Peru, Serbia and Slovenia, are featured in the World Housing Encyclopedia (EERI/IAEE 2000). In January 2008, an International Strategy Workshop on the Promotion of Confined Masonry was organized at Kanpur, India, by the National Information Centre of Earthquake Engineering, India, the World Housing Encyclopedia project of EERI and IAEE, and the World Seismic Safety Initiative. A group of international experts from India, the USA, Switzerland, Peru, Mexico, China, Indonesia, and Canada created a Confined Masonry Network with two major objectives: i) to improve the design and construction quality of confined masonry where it is currently in use, and ii) to introduce it in areas where it can reduce seismic risk. The web site www.confinedmasonry.org has been created as a growing repository of resources related to confined masonry construction, including training materials,

guidelines, and research papers. Besides compiling the existing resources on confined masonry, the group committed to developing global guides for seismic design and construction of confined masonry structures, state-of-the-art papers on confined masonry and research needs, and several awareness initiatives. The network provides a platform for discussion on issues related to confined masonry design and construction in seismic areas. Seismic Design Guide for Low-Rise Confined Masonry Buildings (EERI 2011), referred to as the Guide in this paper, was developed by a group of thirteen international experts in earthquake engineering and confined masonry structures. The recommendations in the Guide are based on design codes and research studies from countries and regions where confined masonry construction has been practiced for several decades, including Mexico, Peru, Chile, Argentina, Iran, Indonesia, China, Algeria and Slovenia. As the initial step in the development of the Guide, the committee performed a review and comparison of seismic design provisions related to confined masonry contained in international codes and standards from China, Mexico, Chile, Peru, Colombia, Iran, Algeria and Europe (Eurocode). The comparison covers structural design and construction requirements, including types of masonry units and mortar and their mechanical properties (e.g. minimum masonry compressive and shear strength); mechanical properties of concrete and steel; wall dimensions (height, thickness) and slenderness ratio (height/thickness ratio); wall density; and tie-columns and tie-beams (size and detailing requirements). Subsequently, the group developed the Guide which contains prescriptive design recommendations for low-rise buildings. The Guide addresses differences in seismic hazard level, construction materials (e.g. strength of masonry and reinforced concrete materials), and construction practices such as different floor/roof systems (light wooden roof versus reinforced concrete slabs). This paper presents an overview of the Guide and outlines the key recommendations.

2. PURPOSE AND SCOPE OF THE GUIDE The purpose of the Guide is to: Explain the mechanism of seismic response of confined masonry buildings for in- and out-ofplane seismic effects and other relevant seismic response issues, Recommend prescriptive design provisions for low-rise buildings related to the wall layout and density, and prescribe minimum size requirements for structural components of confined masonry buildings (tie-columns, tie-beams, walls), reinforcement size and detailing, and Provide a summary of the seismic design provisions for confined masonry buildings from relevant international codes. The Guide has been divided into three chapters. Chapter 1 provides an overview of confined masonry buildings and the key structural components, and discusses seismic performance of confined masonry buildings in past earthquakes. Chapter 2 presents general requirements related to confined masonry construction. Chapter 3 contains prescriptive recommendations for low-rise non-engineered confined masonry buildings (up to two stories high), which are built without input from qualified engineers and thus no design calculations or procedures are required. It is expected that many single-family dwellings are built in this manner. Note that rational analysis and design procedures for medium-rise engineered confined masonry buildings are outside the scope of this document, however a separate guideline is under development. Also, a construction guideline, a companion document to this design guideline is currently being developed. These two documents, as well as any future updated versions of the design guide which is the scope of this paper, are going to be published on the web site of the Confined Masonry Network (www.confinedmasonry.org). The intended audiences for the Guide are design engineers, academics, code development organizations and non-governmental organizations in countries that do not have seismic design provisions for confined masonry construction. However, it is expected that the Guide is going to be a

useful reference for design engineers and other professionals in those countries where confined masonry has been practiced and seismic design codes and standards addressing confined masonry construction are already in place.

3. CHAPTER 1: AN OVERVIEW OF CONFINED MASONRY CONSTRUCTION Chapter 1 of the Guide provides an overview of confined masonry construction, its components and performance in past earthquakes. This material is largely based on a NICEE publication (Brzev 2008) and is intended for readers without any background on the subject. Confined masonry construction consists of masonry walls and horizontal and vertical RC confining members built on all four sides of a masonry wall panel, as shown in Figure 1. Confined masonry walls can be constructed using different types of masonry units, but the most common types of units used in practice are solid clay bricks or hollow clay tiles, and concrete blocks. Vertical members, called tie-columns, resemble columns in RC frame construction, except that they tend to be of far smaller cross-sectional dimensions and are built after the masonry wall has been constructed. Horizontal elements, called tie-beams, resemble beams in RC frame construction. In worldwide applications, confined masonry is used for non-engineered low-rise construction (one- to two-storey high) and also for engineered construction such as mid-rise apartment buildings (up to six stories high). The application of confined masonry does not require advanced construction skills and can be used as an alternative for both unreinforced masonry and RC frame construction.

Figure 1. A typical confined masonry building (Blondet, 2005)

The appearance of a finished confined masonry building and a RC frame with masonry infills may look alike, however these two construction systems are substantially different, as illustrated in Figure 2. Note that Figure 2a) shows features of RC frames with infills, while Figure 2b) shows confined masonry construction. The main differences are related to i) the construction sequence, and ii) the manner in which these structures resist gravity and lateral loads. The differences related to the construction sequence are as follows: In confined masonry construction, masonry walls are constructed first, one storey at a time, followed by the cast in-place RC tie-columns. Finally, RC tie-beams are constructed on top of the walls, simultaneously with the floor/roof slab construction. In RC frame construction infilled with masonry wall panels, the frame is constructed first, followed by the masonry wall construction.

Seismic response of confined masonry buildings is different from RC frames with masonry infills for the following reasons: Due to smaller cross-sectional dimensions, RC tie-columns in confined masonry construction are slender and cannot provide an effective frame action. Tie-beam-to-tie-column connections are pinned (similar to post-and-beam timber construction), as opposed to the moment connections in RC frames. Tie-columns are cast against a rough (toothed and/or doweled) surface, and are integrated into the masonry wall in confined masonry construction, while infill walls are usually not integrated into an RC frame. Gravity loads in confined masonry construction are mostly carried by the masonry walls, while infills in RC frames carry mostly self-weight. When subjected to lateral seismic loads, walls in confined masonry buildings act as shear walls, similar to unreinforced or reinforced masonry walls or RC shear walls, while infill wall panels in RC frame buildings act as diagonal struts.

1 2

e tie-b am

beam

tie-column

column

ll l wa Infil

Loa

ear db

ing

l wal

Infill wall

Load bearing wall

a)

b)

Figure 2. A comparison of RC frames with masonry infills (a), and confined masonry construction (b): construction sequence (top); size of confining elements (middle), and the seismic response (bottom) (EERI, 2011)

Well built confined masonry buildings were able to survive the effects of major earthquakes without collapse, and in most cases without significant damage. Confined masonry tends to be quite forgiving of minor design and construction flaws, as well as material deficiencies provided that the buildings have regular floor plan and sufficient wall density. Confined masonry was exposed to several significant earthquakes, including the 2010 Maule, Chile earthquake (M 8.8). The earthquake-affected area was populated by many low-rise confined masonry buildings, which performed very well in the earthquake. Figure 3a) shows a two-storey confined masonry house in Curepto which remained virtually undamaged, while the adjacent adobe house collapsed; see Brzev, Astroza, and Moroni (2010) and Astroza et al. (2012) for more details on performance of confined masonry buildings in the 2010 Chile earthquake. A similar observation was made after the 2007 Pisco, Peru earthquake (M 8.0), where confined masonry buildings performed very well compared to other types of masonry

buildings which were badly damaged or collapsed. Figure 3b) shows a four-storey confined masonry building in Ica which remained virtually undamaged in the earthquake.

a) b) Figure 3. Performance of confined masonry buildings in recent significant earthquakes: a) the 2010 Maule, Chile earthquake (M.O. Moroni Yadlin), and b) the 2007 Pisco, Peru earthquake (D. Quiun)

It is important to understand how seismic forces are resisted by a confined masonry structure. Seismic behavior of a confined masonry wall panel can be explained by composite (monolithic) action of a masonry wall and adjacent RC confining elements. This composite action exists due to the toothing between the walls and the tie-columns - that is one of the key features of confined masonry construction. Shear resistance of a confined masonry wall panel (3) can be determined as the sum of contributions of the masonry wall (1) and the adjacent RC tie-columns (2), as shown in Figure 4. It can be seen that the stiffness and strength of a confined masonry panel decrease following the onset of diagonal cracking in the wall (point 1). However, the load-resisting capacity of the panel is maintained until the critical regions of the confining elements experience significant cracking (point 2). This shows that a significant lateral deformation and ductility can be attained before the failure of a properly designed and constructed confined masonry panel (point 3). It can be concluded that critical regions in a confined masonry structure are end zones of tie-columns (top and bottom region at each floor level). Proper detailing of these regions is critical for minimizing damage in confined masonry buildings, as evidenced by past earthquakes.

P V

Vc

Vm

3

Vm ' Vc

2

Vm

Shear force

1

Vc

Vm ' Displacement

Figure 4. Mechanism of shear resistance for a confined masonry wall panel: 1) diagonal cracking in the masonry wall; 2) diagonal cracks have propagated from the wall into the tie-columns, and 3) shear failure of the RC tiecolumns and the confined masonry wall panel

4. CHAPTER 2: GENERAL REQUIREMENTS Chapter 2 outlines a number of general requirements, including design and performance objectives, seismic hazard, general planning and design aspects, and materials. These requirements are summarized below: 1. Design and performance objectives: the recommendations of the Guide are based on the life safety performance objective, which means that building collapse should be avoided in the case of a major earthquake and occupants should be able to safely evacuate the building. 2. Seismic hazard: four seismic hazard levels have been considered in the Guide, based on the Global Seismic Hazard Program (GSHAP 1999): a. Low: peak ground acceleration (PGA) less than 0.08g b. Moderate: PGA in the range from 0.08 to less than 0.25g c. High: PGA in the range from 0.25 to 0.4g d. Very high: PGA exceeds 0.4g The focus of the Guide is on confined masonry construction in the regions of moderate and high seismic hazard. 3. General planning and design aspects: experience from past earthquakes has confirmed that the initial conceptual design of a building is critical for its satisfactory performance during an earthquake. Architects play an important role in developing conceptual design and defining the overall shape, size and dimensions of a building. Regular building layout is one of the key requirements for satisfactory earthquake performance. Both desirable and undesirable solutions are presented in the Guide. 4. Materials: this section discusses the properties of masonry materials, concrete, and steel, which are acceptable for confined masonry construction. The key mechanical properties of masonry, including the unit compressive strength, mortar strength, masonry compressive and shear strength, are also discussed, and minimum requirements are specified. It is expected that material testing is unlikely for non-engineered masonry construction, however simple field tests can be used to confirm that the minimum material requirements have been met.

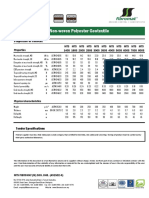

5. CHAPTER 3: PRESCRIPTIVE RECOMMENDATIONS FOR NON-ENGINEERED LOWRISE CONFINED MASONRY BUILDINGS This chapter contains recommendations for low-rise (one or two-storey high) non-engineered confined masonry buildings. The key building components, masonry walls and confining elements, are addressed in detail. 5.1. Masonry walls The items related to confined masonry walls include: wall density requirements, spacing of crosswalls, dimensions and height/thickness ratio, parapets and gable walls, walls with openings, and toothing at the wall-to-tie-column interface. Wall density is one of the key parameters influencing the seismic performance of confined masonry buildings. Evidence from past earthquakes has shown that confined masonry buildings which had adequate wall density, were able to sustain the effects of major earthquakes without collapse. Wall density index is a ratio of the total wall area in each orthogonal direction and the building plan area, and its required value depends on seismic hazard, soil type, number of stories, building weight, and masonry shear strength. Three soil types have been considered in the Guide: i) rock or firm soil, ii) compact granular soil, and iii) soft clay. Gravity load-bearing capacity has been considered in determining the wall density requirements. The key wall recommendations contained in Chapter 3 are summarized in Table 5.1.

Table 5.1. Recommendations for Confined Masonry Walls Item Wall density index Spacing of transverse walls Wall dimensions Wall height/thickness ratio Walls with openings Recommendation Depends on number of stories, type of masonry units and mortar, and type of soil (ranges from 1 to 9.5 %) Buildings with flexible diaphragms: 4.5 to 6.0 m Minimum 110 mm Maximum 25 The effect of opening can be ignored, provided that the opening area is less than 10% of the panel surface area and that it is located outside the diagonals

Good bonding between a masonry wall and adjacent RC tie-columns is important for satisfactory earthquake performance, and for delaying undesirable cracking and separation at the wall-to-tiecolumn interface. Bonding is an essential feature of confined masonry construction and it can be achieved by toothing at the wall-to-tie-column interface, as shown in Figure 5. Toothed edges should be left on each side of the wall at the interface with the tie-columns. Toothing length should be equal to one-quarter of the masonry unit length, but not less than 50 mm, as shown in Figure 5 a) and b). Horizontal reinforcement anchored into tie-columns, also known as dowels, can be used instead of toothing, as shown ( in Figure ) p 5c). q

2.5 cm 5 cm 3 cm

2.5 cm Shear connectors or dowels

40 cm

40 cm

Details of the toothed wall edges

a) b) c) Figure 5. Toothing in confined masonry walls: a) machine-made hollow units, b) hand-made solid units, and c) provision of horizontal reinforcement when toothing is not possible (EERI, 2011).

5.2. Confining elements The Guide contains recommendations regarding spacing, dimensions, and reinforcement requirements for confining elements (tie-columns and tie-beams). Spacing requirements are summarized in Figure 6. Reinforcement requirements are related to size and detailing of longitudinal and transverse reinforcement in tie-columns and tie-beams. Although RC confining elements are predominantly axially loaded and there is no moment transfer in the tie-beam-to-tie-column connections, proper detailing of these connections is very important for satisfactory earthquake performance.

tie-beam in parapets 500 mm tie-beam spacing 3.0 m tie-columns in parapets

slab

t

Ti 6. e 4. 0 m sp -co 5 a ( c i lu m m m (h od ng: n ig er h at se e ism se ici ism ty) ici ty

H

H / t 25 t 110 mm

confining elements around openings

Tie-columns at wall intersections

Figure 6. Key recommendations for non-engineered confined masonry buildings (EERI, 2011, adapted from NTC-M, 2004).

6. CONCLUSIONS This paper outlines the first-of-a-kind effort to develop a global design guide for confined masonry buildings in regions of high seismic risk. The consensus-based recommendations were developed by an international group of experts and are based on the review of international design codes and guidelines and the state-of-the-art body of knowledge on the subject. The expected audience includes design engineers, academics, code development organizations and non-governmental organizations in countries where seismic design provisions for confined masonry construction are not available. This is a public domain document and it can be used and translated by interested parties free of charge. As of this writing, there is an ongoing initiative to translate the guide in Gujarati language in India and promote its use in Gujarat through a government agency called Gujarat State Disaster Management Authority.

ACKNOWLEDGMENT The authors would like to acknowledge the contribution of their colleagues who participated in the development of the Guide, including Miha Tomazevic (Slovenia), Maximiliano Astroza (Chile), Daniel Quiun (Peru), Luis Yamin (Colombia), Junwu Dai (China), Mohammed Farsi (Algeria), Teddy Boen (Indonesia), A.S. Moghadam (Iran), Tim Hart (USA), Ahmed Mebarki (France), and Francisco Crisafulli (Argentina). Financial support for the development of the Guide provided by the Earthquake Engineering Research Institute and the Risk Management Solutions is gratefully acknowledged. Continuous support and encouragement by Marjorie Greene, Special Projects Manager, EERI, are gratefully acknowledged. Special thanks are due to Leonardo Flores and Miguel Angel Pacheco, research engineers at the National Centre for Disaster Prevention, Mexico City, who compiled many of the codes that were reviewed during the development of this document, conducted some of the analyses, and prepared the drawings and figures.

REFERENCES Blondet, M. (2005). Construction and Maintenance of Masonry Houses For Masons and Craftsmen, Pontificia Universidad Catolica del Peru, Lima, Peru (www.world-housing.net) Brzev, S., Astroza,M. and Moroni,M.O. (2010). Performance of Confined Masonry Buildings in the February 27, 2010 Chile earthquake, Confined Masonry Network, Earthquake Engineering Research Institute, Oakland, California (www.confinedmasonry.org). Brzev, S. (2008). Earthquake-Resistant Confined Masonry Construction, National Information Center for Earthquake Engineering, Kanpur, India (www.nicee.org)

EERI (2011). Seismic Design Guide for Low-Rise Confined Masonry Buildings, Earthquake Engineering Research Institute, Oakland, California (www.confinedmasonry.org). EERI/IAEE (2000). World Housing Encyclopedia, Earthquake Engineering Research Institute and the International Association for Earthquake Engineering (www.world-housing.net). GSHAP (1999). Global Seismic Hazard Assessment Program, International Lithosphere Program (www.seismo.ethz.ch/GSHAP/global/). Astroza, M., Moroni,O., Brzev, S., and Tanner, J. (2012). Seismic Performance of Engineered Masonry Buildings in the 2010 Maule Earthquake. Special Issue on the 2010 Chile Earthquake, Earthquake Spectra, Vol. 28:S1, 250-267. NTC-M (2004). Normas Tcnicas Complementarias para Diseo y Construccin de Estructuras de Mampostera (Technical Norms for Design and Construction of Masonry Structures), Mexico D.F. (in Spanish and English).

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Is 800:2007Document150 paginiIs 800:2007crajtry100% (2)

- Komatsu SAA6D114E-3D Engine ManualDocument634 paginiKomatsu SAA6D114E-3D Engine ManualLuzioNetoÎncă nu există evaluări

- Hotpoint Service Manual Fridge FreezerDocument36 paginiHotpoint Service Manual Fridge FreezerMANUEL RODRIGUEZ HERRERA100% (1)

- Sabita Manual 2Document79 paginiSabita Manual 2Carel De Jager0% (1)

- Project Report On Automobile Workshop..Document42 paginiProject Report On Automobile Workshop..atulqwe69% (49)

- Concrete Tech Test PaperDocument7 paginiConcrete Tech Test PaperatulqweÎncă nu există evaluări

- MAMPOSTERIAConstruction and Maintenance of Masonry Houses - Masons and CraftsmenDocument92 paginiMAMPOSTERIAConstruction and Maintenance of Masonry Houses - Masons and CraftsmenAle CruzÎncă nu există evaluări

- ResPaper GATE 2011 - Civil EngineeringDocument15 paginiResPaper GATE 2011 - Civil EngineeringatulqweÎncă nu există evaluări

- Wcee2012 2303Document9 paginiWcee2012 2303atulqweÎncă nu există evaluări

- Dissertation2007 AsinariDocument177 paginiDissertation2007 AsinariatulqweÎncă nu există evaluări

- 145 79 1 SM Adobe - ConfinadoDocument11 pagini145 79 1 SM Adobe - ConfinadoPankhuri Rai BahadurÎncă nu există evaluări

- Peru Confined Masonry HouseDocument26 paginiPeru Confined Masonry HouseatulqweÎncă nu există evaluări

- Wcee2012 2303Document9 paginiWcee2012 2303atulqweÎncă nu există evaluări

- Resume: Vivek KumarDocument3 paginiResume: Vivek KumaratulqweÎncă nu există evaluări

- Dissertation2007 AsinariDocument177 paginiDissertation2007 AsinariatulqweÎncă nu există evaluări

- MEE08171 Lourdes Ana Maria Cardenas Paredes 2009Document6 paginiMEE08171 Lourdes Ana Maria Cardenas Paredes 2009atulqweÎncă nu există evaluări

- Cover LetterDocument1 paginăCover LetteratulqweÎncă nu există evaluări

- Teaching SkillDocument3 paginiTeaching SkillatulqweÎncă nu există evaluări

- Higher Algebra - Hall & KnightDocument593 paginiHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Ce1a3q E1a3qDocument5 paginiCe1a3q E1a3qapi-239041842Încă nu există evaluări

- Classification of Breast Cancer Histopathological ImagesDocument20 paginiClassification of Breast Cancer Histopathological Imagesdolar singhÎncă nu există evaluări

- Data Scrambling: A Net 2000 Ltd. White PaperDocument12 paginiData Scrambling: A Net 2000 Ltd. White PapernassarsubÎncă nu există evaluări

- Face Recognization and Detection System For Attendance.Document39 paginiFace Recognization and Detection System For Attendance.Deepanshu Sharma33% (3)

- Price ListDocument2 paginiPrice ListCHeng SOngco TAlosigÎncă nu există evaluări

- Pneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingDocument4 paginiPneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingYi WUÎncă nu există evaluări

- Um String Code 2 0 eDocument46 paginiUm String Code 2 0 ehydrasearchÎncă nu există evaluări

- Activate &sap - Edit in Se16n (Sap Ecc 6Document4 paginiActivate &sap - Edit in Se16n (Sap Ecc 6raovijay1976Încă nu există evaluări

- ION Enterprise 6.0 System RequirementsDocument2 paginiION Enterprise 6.0 System RequirementsAlberto SalazarÎncă nu există evaluări

- Cantonk HD-Analog Cameras Price List V201407BDocument7 paginiCantonk HD-Analog Cameras Price List V201407BCatalin StefanutÎncă nu există evaluări

- Mine Design and SchedulingDocument10 paginiMine Design and SchedulingLeandro FagundesÎncă nu există evaluări

- Best Practices in PL/SQL: Karthikeyan MDocument15 paginiBest Practices in PL/SQL: Karthikeyan MranusofiÎncă nu există evaluări

- Problem Statement: Designing of Pump System For Multi Story Residential BuildingDocument23 paginiProblem Statement: Designing of Pump System For Multi Story Residential Buildingmehtab ul hassanÎncă nu există evaluări

- PHCbi Refrigerators MPRS163 MPRS313Document2 paginiPHCbi Refrigerators MPRS163 MPRS313Eslam HassanÎncă nu există evaluări

- FibrotexDocument2 paginiFibrotexMan ChupingÎncă nu există evaluări

- Squashing Commits with RebaseDocument4 paginiSquashing Commits with RebaseDavid BeaulieuÎncă nu există evaluări

- A Review of Heat Transfer Enhancement Using Twisted Tape With and Without PerforationDocument9 paginiA Review of Heat Transfer Enhancement Using Twisted Tape With and Without PerforationIJIERT-International Journal of Innovations in Engineering Research and TechnologyÎncă nu există evaluări

- Unit-4 (Wireless Communication)Document15 paginiUnit-4 (Wireless Communication)Anonymous EjQbY1CÎncă nu există evaluări

- NJAPA-PaveXpress V2 PresentationDocument75 paginiNJAPA-PaveXpress V2 PresentationLuis MogrovejoÎncă nu există evaluări

- Espectrómetro FT-IR Nicolet Is 10Document1 paginăEspectrómetro FT-IR Nicolet Is 10Adriano BludegardÎncă nu există evaluări

- CLC Blocks ProposolDocument5 paginiCLC Blocks ProposolGyi TawÎncă nu există evaluări

- Barco RLM g5 PDFDocument114 paginiBarco RLM g5 PDFRainer AdelsbergerÎncă nu există evaluări

- Cutting Guide: Integrated Seat Post (ISP)Document4 paginiCutting Guide: Integrated Seat Post (ISP)Anand sÎncă nu există evaluări

- Image Similarity Measure Using Color Histogram, Color Coherence Vector, and Sobel MethodDocument6 paginiImage Similarity Measure Using Color Histogram, Color Coherence Vector, and Sobel MethodIjsrnet EditorialÎncă nu există evaluări

- Sika PDS - E - Sika FastFix - 138 TPDocument2 paginiSika PDS - E - Sika FastFix - 138 TPlwin_oo2435Încă nu există evaluări

- Traffic Engineering Bachelor of Science in Civil EngineeringDocument22 paginiTraffic Engineering Bachelor of Science in Civil EngineeringDaisy AstijadaÎncă nu există evaluări

- Pai Ch03 ArrayDocument33 paginiPai Ch03 ArrayanonÎncă nu există evaluări