Documente Academic

Documente Profesional

Documente Cultură

Soil Nailing in Germany

Încărcat de

Jose MartinezDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Soil Nailing in Germany

Încărcat de

Jose MartinezDrepturi de autor:

Formate disponibile

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G.

Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

1

Soil Nailing in Germany: Development, Design, Execution

[Eigene Dateien\Brasilia Powerpoint\Soil Nailing in Germany-63-Brasilia.ppt]

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

2

2. Design: Verification of stability of a nailed wall

2.1 General design considerations

2.2 Example: Verification of stability of a 10 m high wall

1.1 Principle static analyses

1.2 Model tests

1.3 Field tests

Summary and conclusions

3. Execution: Several examples in soil and soft rock

3.1 Practical cases of nailed cuts near to the vertical

3.2 Practical cases of nailed slopes

3.3 Quality control and warnings

Scope of Presentation

Introduction

1. Development: German research programme

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

3

Introduction

Soil nailing: is a technique of reinforcing natural ground

by the insertion of slender tension-carrying elements called nails.

Applications: excavation pits, permanent retaining structures and (natural) slopes.

Origin and idea of in situ reinforcing cuts or slopes:

1972: First recorded case of a nailed wall in France:

temporary stabilising of a 70 cut in cohesive sand

(commercial project, no subsequent research!)

1975 - 1981: Research and development project

Soil Nailing in Germany (Univ. of Karlsruhe

in joint venture with the contractor BAUER)

1979: First international publication on soil nailing

by the Univ. of Karlsruhe and BAUER (In this

publication the term Soil nailing was created)

1986 1990: National Research Project Clouterre in France

1976 - 1981: Research and development project

Lateral Earth Support System (Univ. of Cal.)

Fig.: First test wall in history of soil

nailing pushed to failure (1976)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

4

Construction method

(2) face stabilization using shotcrete

(3) installation of nails and grouting

The procedure is repeated until

the required depth is reached.

Three basic processes are involved in

soil nailing:

(1) excavation in steps

h

0.5-0.7 h

(1)

.

.

.

.

.

(2)

(3)

(1)

Fig. 1: Installed temporary nail of a test

wall in sand (digged out after test)

Fig. 2: Temporary nail after German

approval (System BAUER)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

5

tension!

slip surface

displacement

small

STEEP CUTS:

TENSION NAILS

1

te

n

s

io

n

!

d

i

s

p

l

a

c

e

m

e

n

t

s

m

a

l

l

2a

TENSION NAILS

2

FLAT SLOPES

bending!

s

l

i

p

s

u

r

f

a

c

e

d

i

s

p

l

a

c

e

m

e

n

t

l

a

r

g

e

!

w

e

a

t

h

e

r

e

d

t

o

p

l

a

y

e

r

s

o

l

i

d

g

r

o

u

n

d

2b

DOWEL NAILS

Principle mode of operation of soil nails

Remark: Nails in case 1 and 2a act also as bending elements carrying shear forces at the slip line;

but: These shear forces are of secondary order and are neglected in the following design example!

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

6

1. German research and development programme

comprised:

4. Derivation of partial safety factors on

a statistic-probabilistic basis

and

Development of a practical design

method

2. Model tests in sand

1. Static analyses on the basis of kinematical

failure mechanisms of rigid earth blocks

3. Field tests in sand and clay

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

7

Single wedge

(may be chosen for low nailing

densities or rough calculations)

Note: For given parameters (soil, load, nailing) the most unsafe failure mode is the one that, under vari-

ation of the slip lines, requires the absolute maximum of the pull-out resistance per unit nail length T

m,k

!

1.1 Static analyses on the basis of kinematical failure mechanisms of rigid earth blocks

Several kinematic failure models for nailed walls were investigated.

An overview is given on the four different potential failure mechanisms that turned out to be critical.

Note: the following failure modes were - theoretically investigated by stability analyses but also

- verified in model tests and full scale tests

Two-part wedge with circular slip lines

(theoretically the least safe mechanism in case of

very high surcharge in the rear or in case of

earthquake

Two-part wedge with

straight slip lines

(shall be chosen in

non-cohesive soils)

Slip circle

(shall be chosen in cohesive

soils as well as in non-cohe-

sive soils)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

8

1.2. Model tests

1.2.1 Simple wedge failure mechanism with a straight slip line

Fig.: Model test in Sand with low nailing density

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

9

Fig. 1: Observed 2-part-wedge mechanism with straight

slip lines in a model box filled with sand

Fig. 2: Kinematics of earth block (1) and (2)

1.2.2 The 2-part-wedge failure mechanism with straight slip lines

This failure mode was observed in a model test, where the rigid facing of the nailed construction (h = 40

cm) in dense sand was progressively moved to the air side.

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

10

a) Observed 2-part-block with circular slip lines

in a model box filled with sand

b) Kinematics of earth block (1) and (2) with centre

points and radii of the three slip circles

Fig.: Model test of a nailed wall in sand with a high load beyond the nailed zone

1.2.3 The 2-part-wedge failure mechanism with curved slip lines

This failure mode was observed in a model test, where a nailed wall (h = 40 cm) was progressively

surcharged by a water pressure cushion beyond the nailed zone until failure occurred.

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

11

What is the explanation for this special failure mode?

Answer: The high earth pressure force E of wedge (2) due to the high area load, acting upon the nailed

block in its upper part, leads to an overturning moment

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

12

1.3 Field tests

Fig.: Field tests in sand and clay

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

13

Fig. 1: Front view of the first test wall in history of

soil nailng with measuring facilities

Height: 6.0 m; Nail lengths: 3.0 m to 4.0 m

Load: Strip load in the rear (hydraulic jackets)

Fig. 2: Seperation of the proper test wall fromthe

surrounding ground by thin slurry walls to

achieve 2-D conditions

Test A: Strip load in the rear

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

14

Fig. 1: Cross-section of test wall A with inclino-

meter boreholes to locate the slip lines

Fig. 2: Cross-section of test wall A in moment of failure

(Wall was weakened by further excavation and

pulling-out of bottom nail row)

Failure mode: Two-part wedge mechanism with

straight slip lines

Test A: Measuring results

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

15

Test A

Fig.: Field test A: Nailed wall after failure: total displacement ca. 20 cm

(Movement of wall during failure parallel to itself is clearly to be seen)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

16

Measurements: 1 Displacements using inclinometer

and geodetic instruments

2 Earth pressures using hydaulic cells

3 Nail forces using electr. strain gauges

Fig. 1: Cross-section of instrumented test wall B

Test B: Strip load near the crest

Fig. 2: Cross-section of wall B with horizontal defor-

mation after completion (under dead weight)

u = horizontal displacement

h = height of the wall

Non-cohesive soils u/h 2.5 - 3

(Cohesive soils u/h 3 - 5 )

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

17

Fig. 3: Test B: Earth pressure after completion

(i. e. dead weight)

Fig. 4: Test B: Earth pressure due to loading

until failure (failure load 150 kN/m)

Test B: Strip load near the crest

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

18

Test B: Strip load near the crest

Fig. 6: View of test wall B after failure from the

side (Movement of wall during failure in

rotation clearly to be seen)

Fig. 5: Test B: Cross-section with rupture

line located in the inclinometer

boreholes after failure

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

19

Fig.: Cross-section of test wall B with axial nail forces

after completion and during loading until failure

Test B

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

Test D: Nailed edge in sand

1.3 Field tests (continuation)

Fig.: 2nd excavation step just finished

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

21

Test G in clay

Fig.: View at test wall G in slightly overconsolidated clay with loading equipment

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

22

Test G

B1, B2, B3 .... Boreholes for inclinometer measurements (horiz. & vertical deformations)

Fig.: Test G in overconsolidated clay: Measured horizontal and vertical deformations of facing

and nailed soil after completion (i. e. under dead weight)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

23

2.1 Presenting the design example: cross-section and soil parameters

2.2 Preconsiderations on the type of design approach

2.3 Derivation of design values

2.4 Identification of the unsafest failure mechanism

2.5 Determination of the required characteristic nail resistance

2.6 Further stability checks for the total structure

2. Design: Verification of stability of a nailed wall with shotcrete facing

Scope:

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

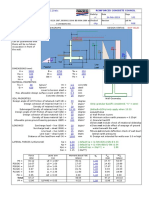

2.1 Design example: Permanent nailed wall in sand with a transient surface load

Given geometric data:

Height of the wall: h = 10 m;

Horizontal nail length at the bottom: l = 6.0 m

Wall inclination (to the vertical): = 10;

Nail inclination: = 10

Vertical nail spacing: s

v

= 1.10 m

Horizontal nail spacing: s

h

= 1.25 m

Acting characteristic parameters:

Transient surface load: q

k

= 23 kN/m

Unit weight of soil:

k

= 18 kN/m

Resisting characteristic parameters:

Friction angle of soil:

k

= 35; cohesion: c

k

= 0

Lowest value in a series of pulling-out tests of nails in-situ:

F

P

= 160 kN (Index P denotes Proof load)

Bonded length of all test nails: l

b

= 5.0 m

Hence: the ultimate pull-out resistance per unit nail length

is yielded by: T

Pm,k

= F

P

l

b

= 160 / 5.0 = 32 kN/m

Question: Is this nailed wall safe after EC-7 and DIN 1054?

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

25

2.2 Preconsiderations on the type of design approach

Eurocode 7 clearly states: Verification of total stability has to be performed in ultimate limit state

However: there are several options in EC 7 for the design approach!

DIN 1054 recommends the application of Design Approach DA1-2 of EC 7 for soil nailing.

Note: For all verifications the principle procedure after EC 7 provides a strict rule:

seperation of actions (e. g. loads) fromresistances (e.g. friction angle )

2.3 Derivation of the design values from the characteristic values

Resistances: friction angle

k

(given in the foundation report)

|

|

.

|

\

|

=

k

d

tan

arctan

Definition of partial factor

after EC 7 sec. 2.4.6.2:

25 . 1

tan

tan

= =

d

k

~ =

|

.

|

\

|

= 29 3 . 29

25 . 1

35 tan

arctan

d

/ 30 23 30 . 1 m kN q q

k Q d

= = =

/ 18 m kN

k d

= =

Definition of partial

factor

Q

after EC 7 sec.

2.4.6.2:

30 . 1 = =

k

d

Q

q

q

00 . 1 = =

k

d

G

Actions:

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

26

2.4 Identification of the unsafest failure mechanismfor the given example

As shown above, the stability proof of a nailed wall with conditions as given in the example can be based on

- the two-part wedge mechanism with straight slip lines,

or as well as on - the slip circle

NOTE: As the two-part wedge failure mechanism is more comprehensible for a presentation,

it will be used in the following design procedure!

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

27

h' = 5,8 m

0

(1)

= 35

q

d

1

st

Variation 0

(1)

= 35

Actions or driving forces:

W

d

W

d

= 694 kN/m

K

a

: active earth pressure coefficient

K

a

= 0,308

P

d

= q

d

b = 30 4.2 = 126 kN/m

P

d

b = 4.2 m

E

a,d

= h ( h + 2q

d

) K

a

(

d

)

d

= 29

E

a,d

E

a,d

= 5.8 (18 5.8 + 2 30) 0.308 = 147 kN/m

?

?

?

?

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

Z

d

=

2

3

0

k

N

/m

Q

0

(1)

= 35

6

7

8

9

W

d

P

d

d

= 29

E

a,d

N

6,d

N

7,d

N

8,d

N

9,d

intersection axial force of nail i:

N

i,d

= T

m,d

l

i

Resistances or resisting forces:

N

i,d

= T

m,d

l

i

9

6

Z

d

= T

m,d

(1.4 + 2.8 + 4.0 + 5.4)

Z

d

= T

m,d

13.6

Z

d

=

Z

d

l

9

=

5

.4

m

l

6

=

1

.4

m

l

8

=

4

.0

m

l

7

=

2

.8

m

230 = T

m,d

13.6

T

m,d

= 230 13.6 = 16.9 kN/m/m

for 0

(1)

= 35

Q

d

W

d

=

694 kN/m

P

d

=

126

d

E

a,d

= 147 kN/m

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

29

0

(2)

= 40

6

7

8

9

5

Z

d

Q

d

Z

d

= T

m,d

(0.8 + 2.0 + 3.2 + 4.3 + 5.6)

Z

d

= T

m,d

l

i

9

5

275 = T

m,d

15.9

T

m,d

= 275 15.9 = 17.3 kN/m/m

fr 0

(2)

= 40

Z

d

=

2

7

5

k

N

/m

Q

W

d

=

649 kN/m

P

d

=

126

d

E

a,d

= 115 kN/m

l

9

=

5

.6

m

l

6

=

2

.0

m

l

8

=

4

.3

m

l

7

=

3

.2

m

l

5

=

0

.8

m

W

d

P

d

d

= 29

E

a,d

h = 5.0 m

2

nd

Variation 0

(2)

= 40

0 = 5

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

0

(3)

= 45

6

7

8

9

5

4

Z

d

d

Z

d

=

3

0

0

k

N

/m

Q

W

d

P

d

E

a,d

l

9

=

5

.6

m

l

6

=

2

.6

m

l

8

=

4

.6

m

l

7

=

3

.6

m

l

5

=

1

.6

m

W

d

P

d

E

a,d

h = 4.0 m

3

rd

Variation 0

(3)

= 45

l

4

=

0

.6

m

16.1 18.6 300 45

17.3 = MAX! 15.9 275 40

16.9 13.6 230 35

[kN/m/m] [m] [kN/m] []

T

m,d

= Z

d

/ l

i

l

i

Z

d

0

design pull-out resistance: T

m,d,max

= 17.3 kN/m/m

characteristic pull-out resistance:

with partial safety

factor (DIN 1054,

Table 3)

N

=

T

m,k

T

m,d

T

m,k,max

=

N

T

m,d

T

m,k,max

= 1.40 17.3

T

m,k,max

= 24.2 kN/m/m

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

31

Remember: established horizontal spacing was: s

h

= 1.25 m

Thus, the required characteristic pull-out resistance per unit nail length of the physical

nail is yielded by:

T

m,k

= 24.2 1.25 = 30.25 kN/m

Remember: ultimate pull-out resistance, verified in a series of load tests was:

Result of slip line variation:

T

m,k,max

= 24.2 kN/m/m (i.e. per unit length of a virtual nail per unit width of the wall)

T

Pm,k

= 32 kN/m (P indicates: Proof load)

It can be seen: T

m,k,max

< T

Pm,k

which is OK!

The maximum ultimate pull-out resistance per unit nail length in the design is less than ultimate

pull-out resistance per unit nail length in the load test in-situ.

Conclusion: 1. The design is safe!

2. The design is also economic, as

the utilisation factor for the nails: T

m,k

/ T

Pm,k

= 30.25 / 32 = 0.95 or 95%

2.5 Determination of the required characteristic nail resistance

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

(a) Groundfailure

(a) Groundfailure

(c) Overall (or external) stability

(c) Embankment

failure

M

(b) Failure against horizontal sliding (often involved in varia-

ion of slip staight lines)

(b) Horizontal sliding

2.6 Further stability checks for the nailed wall

After DIN 1054, sec. 12.4.4 (2) the nailed (or reinforced) part of

the soil has to be considered as a solid block or gravity wall.

If in doubt, the following stability checks have to be made:

NOTE: Verification of nails and facing cannot be presented here (please, see publications!)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

33

DC-Nail

www.dc-software.com

Munich/ Germany

Fig.: Checking internal stability by two-wedge failure mechanisms with straight slip lines and

external stability by slip circles using German computer programDC-Nail

Anlisis de Suelos Enclavados

Program DC-Nail

Anlisis de suelos enclavados de acuerdo a

DIN 1054:2005 (basado en EUROCODE 7),

DIN 1054:1976

Diseo de revestimiento de hormign

lanzado de acuerdo a DIN 1045, DIN 1045-1

Anlisis con factores de seguridad parcial o

con seguridad global

Versiones del programa en Alemn, Ingls,

Francs, Italiano, Espaol

Anlisis de acuerdo con el mtodo general de

deslizamiento de bloques

Determinacin de la estabilidad interior y

exterior

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

34

3. Execution: Several examples in soil and soft rock or weatherd rock

3.1 Practical cases of nailed cuts near to the vertical

a) Auger drilling for the nails b) Pull-out test of a nail

Fig. 1: One of the first permanent nailed walls near to the vertical in sand/ gravel,

executed by the German contractor BAUER near Stuttgart, 1985

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

35

3.1 Practical cases of nailed cuts near to the vertical (1

st

continuation)

a) Shotcreting b) Drainage provided by drain

mats (System ENKA)

Fig. 2: Permanent nailed wall near to the vertical in sand/ gravel as before

(Nails coverd by shotcrete to prevent corrosion)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

36

a) Permanent soil nail with corrugated plastic sheath

for complete corrosion protection

Fig. 2: Permanent nail (System BAUER, Germany)

b) Permanent nail on site

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

37

a) b)

Fig. 2: Cross-section of the nailed cut (a) after completion,

(b) in final state with a revetment wall to be greened

Fig. 1: Permanent nailed cut in mountaineous area

in Southern Germany (Nails heads covered

by shotcrete, only weep hole pipes to be seen)

(National Road widening scheme project)

Permanent nailed wall with revetment wall

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

38

Fig. 3: Wall shortly after completion: Greening yet to come

Fig. 1: Mounting of the prefabricated concrete

elements by a crane

Permanent nailed wall with revetment wall

Fig. 2: Fixing of

concrete elements

at the top

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

39

Fig.: Permanent cutting slope in Keuper marl (South-West Germany) for a new National Road;

due to significant creeping property of marl: nail lengths 23 m; calculation by slip circles

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

40

Fig 1: Permanent nails without plastic sheath; corrosion protection

only by in-situ grouting; diameter of GEWI tendon: 50 mm

(Degradation due to corrosion incorporated in the design)

Fig. 2: Permanent facing with double reinforce-

ment layers (earth-sided and air-sided)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

Landslide is a nightmare for every geotechnical engineer!

3.2 Practical cases of nailed slopes

Fig.: Landslide due to fossil slip surfaces reactivated in a cutting (Marlstone)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

42

Fig.: Reinforcing a 30 cut in marlstone to prevent sliding on potential geologic slip

surfaces possibly reactivated by excavation in front of a tunnel portal of the

German high speed railway line Mannheim - Stuttgart

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

43

INCLINOMETRE

BOREHOLE

SOIL-

NAILS

2

0

m

1

5

m

2

4

m

GEOLOGIC-

SLIP-

SURFACES

10

DRAIN TUBES

EXTENSO-

METRE

(GREENED) (GREENED)

NATURAL GROUND LEVEL

FREE SURFACE

1

:

1

,

7

5

1

:

1

,

1

5

NATURAL GROUND LEVEL

FREE SURFACE

1

:

1

,

7

5

1

:

1

,

1

5

1

:

1

,

1

5

Fig.: Cross-section of the 30 cut (i.e. 1:1.75) in marlstone to prevent sliding on potential

geologic slip surfaces reactivated by excavation

(Slip surfaces were not localized but expected due to the experienced landslide shown before)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

44

Fig.: View at geologic slip surface found in reality during excavation process:

Nailing absolutely necessary for reasons of safety!

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

Fig.: Special drilling rig for 18 m long nails constructed by BAUER

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

46

Nail setting

Fig. 3

Fig. 2

Fig. 5

Fig. 1

Fig. 4

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

47

Fig. 1

Fig. 2 Fig. 3

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

48

Fig. 2: Setting of instrumented nail for pulling-out

test to verify the assumptions of design

Fig. 1: Analysis for the worst case: Geologic slip surface assumed at the

bottomof the slope (assumed failure: two-part wedge mechanism)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

49

Question: Assumption of mean pull-out resistance per unit nail length T

m

(kN/m) correct?

Fig. 2: Test loading facilities

Fig. 1: Axial force distribution along the instrumented test nail

for different loads (soil: weathered Keuper Marl)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

Fig.: Completed nailed slope with hidden nails under green surface

(Picture taken few months before opening to traffic, 1991)

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

51

Quality control:

- Work: according to the plans?

- Excavation steps: following the

admissible depth and the time sequence?

- Free standing of boreholes?

(if not: casing!)

- Nails: Length correct?

Diameter of the steel

tendon correct?

- Soil conditions: according to geotechnical report?

Put the following questions on the site:

Missing quality control:

Nails too short! Facing too thin! =>

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

52

Quality control:

- Work: according to the plans?

- Excavation steps: following the

admissible depth and the time sequence?

- Free standing of boreholes?

(if not: casing!)

- Nails: Length correct?

Diameter of the steel tendon correct?

- Grouting water-cement-factor correct?

- Shotcrete: thickness?

- Mounting of mats: sufficient overlapping?

- Soil conditions: according to geotechnical report?

Put the following questions on the site:

- Pull-out tests of nails: performance correct?

results according to the design?

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

53

Benefits of Soil Nailing:

- Economic advantage

- Construction flexibility

- Small construction equipment

- Special solutions: Remedial work

Fig.: Restoring and stabilizing historic

masonry walls using soil nails

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

54

Limitations and Warnings:

- No excavations in groundwater!.

- Attention to layer groundwater!

- Attention to existing buildings near to the excavation!

- No underpinning without special measures!

- Do not underestimate the first excavation step!

Fig.: Temporary excavation using nails

near to a settlement-sensitive house

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

2. The ultimate limit state design of nailed walls and slopes is based on kinematic

failure mechanisms proved in model and field tests of the research programme.

Summary and Conclusions:

1. The research and development programme in Germany (1976 1981) yielded

numerous results on the bearing behaviour and the stability of nailed walls.

3. The application of the principles of new European Standard EC 7-1 Geotechnical

Design combined with the detailed rules in German Standard DIN 1054

provides a safe and practicable limit state design of soil nail constructions.

4. Execution of soil nailed constructions needs experience and good knowledge of the

ground conditions.

5. Soil nailing involves numerous benefits but also some limitations.

6. Today soil nailing is a well established construction method in many contries all

over the world.

There is a wide field for its application in Brazil, too!

University of Applied Sciences Munich / Germany Prof. Dr.-Ing. G. Gssler

Department of Civil Engineering Presentation at Universidade de Braslia 03/2010

Not guys doing it like that:

Last but very important conclusion:

Soil nailing needs experienced engineers!

Thank you very much for your attention!

Cartoon by courtesy of

Sddeutsche Zeitung,

Germany

S-ar putea să vă placă și

- A Century of Design Methods For RetainingDocument20 paginiA Century of Design Methods For RetainingOmar M. Luque100% (1)

- Numerical Analysis of Displacements of A Diaphragm Wall PDFDocument5 paginiNumerical Analysis of Displacements of A Diaphragm Wall PDFHenry AbrahamÎncă nu există evaluări

- Numerical Analysis of Performance of Soil Nail Walls in Seismic ConditionsDocument10 paginiNumerical Analysis of Performance of Soil Nail Walls in Seismic ConditionsDeepthiÎncă nu există evaluări

- Secant Pile Wall Design For Deep ExcavationsDocument1 paginăSecant Pile Wall Design For Deep ExcavationsHorace Prophetic DavisÎncă nu există evaluări

- Soil NailDocument305 paginiSoil Nailosamosa33% (3)

- Jet Grouting PresentationDocument132 paginiJet Grouting PresentationMatthew KarabelaÎncă nu există evaluări

- Shallow Foundations - Settlement and EC7Document18 paginiShallow Foundations - Settlement and EC7Ashik Rehmath ParambilÎncă nu există evaluări

- Foundations-7-Diaphragm WallsDocument69 paginiFoundations-7-Diaphragm WallsElizhabet Flores PaucarÎncă nu există evaluări

- 17 Analysis of Horizontal Bearing Capacity of A Single Pile 1Document8 pagini17 Analysis of Horizontal Bearing Capacity of A Single Pile 1jasamnajÎncă nu există evaluări

- Slope Stability Analysis Using 2D and 3 D Methods Thesis MADocument143 paginiSlope Stability Analysis Using 2D and 3 D Methods Thesis MAbinhÎncă nu există evaluări

- FE Modeling of Embedded Cantilever Sheet Pile Retaining WallDocument10 paginiFE Modeling of Embedded Cantilever Sheet Pile Retaining WalllollazzoÎncă nu există evaluări

- FHWA - Design and Construction Monitoring of Soil Nail Walls DemoDocument44 paginiFHWA - Design and Construction Monitoring of Soil Nail Walls DemoDaniela Quinteros100% (1)

- HK Soil Nail DesignDocument20 paginiHK Soil Nail DesignDaltonWong100% (1)

- POS St1 structural analysis and designDocument2 paginiPOS St1 structural analysis and designpperic13Încă nu există evaluări

- Interim Report Soil NailDocument11 paginiInterim Report Soil Nailalex_rav17Încă nu există evaluări

- Some Comments On Modelling Deep Excavation Problems With PlaxisDocument5 paginiSome Comments On Modelling Deep Excavation Problems With Plaxisabfso5010100% (1)

- Design and Construction of Circular Secant Pile Walls in Soft ClaDocument11 paginiDesign and Construction of Circular Secant Pile Walls in Soft ClaHumza Mubarik100% (1)

- Factor of Safety of A Consolidated SlopeDocument33 paginiFactor of Safety of A Consolidated SlopeMadan RamuÎncă nu există evaluări

- Deep Excavation via Soil Nailing Saves CostsDocument19 paginiDeep Excavation via Soil Nailing Saves CostsgahsoonÎncă nu există evaluări

- Two Case Histories of Basement Excavation With Influence On Groundwater-Kl - 02Document19 paginiTwo Case Histories of Basement Excavation With Influence On Groundwater-Kl - 02Hoo Yen How100% (1)

- Analysis of reinforced soil slopes using limit equilibrium and finite element methodsDocument23 paginiAnalysis of reinforced soil slopes using limit equilibrium and finite element methodsHari RamÎncă nu există evaluări

- Slope StabilityDocument32 paginiSlope StabilityMohammed Alkhateeb100% (2)

- Design Methods Forthe Reinforcement of Highway Slopes by Reinforced Soil and Soil Nailing TechniquesDocument108 paginiDesign Methods Forthe Reinforcement of Highway Slopes by Reinforced Soil and Soil Nailing TechniquesNita BogdanÎncă nu există evaluări

- Design of Soil Nail HeadsDocument8 paginiDesign of Soil Nail HeadsHuy Le QuangÎncă nu există evaluări

- Prefabricated Vertical DrainsDocument26 paginiPrefabricated Vertical DrainsMayank Prakash100% (1)

- Mohr Coulomb Envelope: Edited by Sdr. Wan Mohd Azri 2009919835Document3 paginiMohr Coulomb Envelope: Edited by Sdr. Wan Mohd Azri 2009919835WanÎncă nu există evaluări

- Soil Nailing PDFDocument123 paginiSoil Nailing PDFAnonymous fE2l3Dzl83% (6)

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 24-Feb-2019 101 CHG - R68Document11 paginiSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 24-Feb-2019 101 CHG - R68Gertjan DuniceriÎncă nu există evaluări

- Micro Pile SpecificationsDocument3 paginiMicro Pile SpecificationsAnonymous 5VwQ0KC3Încă nu există evaluări

- Negative skin friction and load testing on pilesDocument3 paginiNegative skin friction and load testing on pilesNithin SudersananÎncă nu există evaluări

- A Study of Building Foundations in Malaysia PDFDocument130 paginiA Study of Building Foundations in Malaysia PDFpatricklim1982Încă nu există evaluări

- Compressibility & Consolidation (Autosaved)Document48 paginiCompressibility & Consolidation (Autosaved)KhalilluqmanÎncă nu există evaluări

- Principles and Practices of Soil Mechanics and Foundation Engineering by V N S MurthyDocument1.050 paginiPrinciples and Practices of Soil Mechanics and Foundation Engineering by V N S MurthyAbdelaziz Ibrahim Abdelaziz100% (1)

- Rock Bolting Techniques and ApplicationsDocument17 paginiRock Bolting Techniques and ApplicationsMarkusMakuAldoÎncă nu există evaluări

- Earth WorkDocument4 paginiEarth WorkNurali MamenÎncă nu există evaluări

- Tutorial 23 Anchored Sheet Pile WallDocument22 paginiTutorial 23 Anchored Sheet Pile WallHuitzilopochtli Quetzalcóatl0% (1)

- Titan MicropilesDocument12 paginiTitan Micropilesmunain_gÎncă nu există evaluări

- Retaining Walls with Geotextile ReinforcementDocument18 paginiRetaining Walls with Geotextile ReinforcementjoverevocalÎncă nu există evaluări

- C3 Slope StabilityDocument54 paginiC3 Slope StabilityLeo LaiÎncă nu există evaluări

- Numerical Modeling of Laterally Loaded PilesDocument6 paginiNumerical Modeling of Laterally Loaded PilesMatteo Izzi100% (1)

- Micro Piling and Soil Nailing For Ground ImprovementDocument5 paginiMicro Piling and Soil Nailing For Ground ImprovementIJARTETÎncă nu există evaluări

- SPREW Part 3 of 3 PDFDocument122 paginiSPREW Part 3 of 3 PDFhz135874Încă nu există evaluări

- Earthquake Resistant Building ConstructionDocument3 paginiEarthquake Resistant Building ConstructionKristine SantosÎncă nu există evaluări

- Wick Drain LectureDocument21 paginiWick Drain LectureChrisWaltzÎncă nu există evaluări

- Modelling of Negative Skin Friction On Bored Piles in ClayDocument64 paginiModelling of Negative Skin Friction On Bored Piles in ClayLordM00nÎncă nu există evaluări

- Design Report For Power House Rock SupportDocument9 paginiDesign Report For Power House Rock Supportsudhajagannathan100% (1)

- Shallow Foundation 1Document48 paginiShallow Foundation 1Nimas Az-zahra SofaÎncă nu există evaluări

- ConsolidationDocument13 paginiConsolidationthuaiyaalhinaiÎncă nu există evaluări

- L - 09 - Soil Nailing For Slope StrengtheningDocument9 paginiL - 09 - Soil Nailing For Slope StrengtheningTu Tu DarÎncă nu există evaluări

- Earthquake Design of Tied-Back Retaining WallDocument15 paginiEarthquake Design of Tied-Back Retaining WallEverson BoyDayz PetersÎncă nu există evaluări

- Underpinning Solutions of Historical Constructions PDFDocument10 paginiUnderpinning Solutions of Historical Constructions PDFRose Carla GuerrierÎncă nu există evaluări

- Educational Session Geosynthetics in Reinforced Soil StructuresDocument62 paginiEducational Session Geosynthetics in Reinforced Soil Structureskunalji_jainÎncă nu există evaluări

- David White: Relevant Experience and ProjectsDocument2 paginiDavid White: Relevant Experience and ProjectsDavid WhiteÎncă nu există evaluări

- gs13 Obrzud Preisig PDFDocument11 paginigs13 Obrzud Preisig PDFRaúl Bernal LunaÎncă nu există evaluări

- PC - 01 Concept 2023 04 05Document50 paginiPC - 01 Concept 2023 04 05Tamás NAGY-GYÖRGYÎncă nu există evaluări

- GeoTechnical DB Report 2203216Document8 paginiGeoTechnical DB Report 2203216wafikmh4Încă nu există evaluări

- Delft University of Technology: DOI Publication Date Document Version Published inDocument11 paginiDelft University of Technology: DOI Publication Date Document Version Published inRachad BouarourouÎncă nu există evaluări

- Analysis of Tunnel-Induced Settlement Damage To Surface Structures Analyse Des Dégâts Créés Par Tunnels Sur Les Constructions en SurfaceDocument6 paginiAnalysis of Tunnel-Induced Settlement Damage To Surface Structures Analyse Des Dégâts Créés Par Tunnels Sur Les Constructions en SurfaceLTE002Încă nu există evaluări

- Slide TutorialManualDocument207 paginiSlide TutorialManualrlprÎncă nu există evaluări

- Groundwater VerificationManual Slide PDFDocument48 paginiGroundwater VerificationManual Slide PDFJuan PabloÎncă nu există evaluări

- ASTM D1586 - 11, Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils PDFDocument9 paginiASTM D1586 - 11, Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils PDFMarcos67% (3)

- Win Wenger Einstein Factor GuidebookDocument87 paginiWin Wenger Einstein Factor GuidebookMihpaula100% (6)

- Neuro GymDocument13 paginiNeuro Gymrobert Friou80% (5)

- A Test in Phonetics 500 Questions and Answers On English Pronunciation - Dr. B. SiertsemaDocument91 paginiA Test in Phonetics 500 Questions and Answers On English Pronunciation - Dr. B. SiertsemaTrasgu Viajero67% (3)

- EM 1110-2-2502-Retaining and Flood WallsDocument448 paginiEM 1110-2-2502-Retaining and Flood WallsGlister Dhar100% (1)

- Concrete Test Equipment PDFDocument40 paginiConcrete Test Equipment PDFJose MartinezÎncă nu există evaluări

- Geotechnical Laboratory Measurements For Engineers - Germaine, John T - Germaine, Amy V (2009)Document359 paginiGeotechnical Laboratory Measurements For Engineers - Germaine, John T - Germaine, Amy V (2009)Muhammad Yunus86% (7)

- Seismic Design of Reinforced Concrete & Masonry Buildings - T Paular & Priestley PDFDocument765 paginiSeismic Design of Reinforced Concrete & Masonry Buildings - T Paular & Priestley PDFJose MartinezÎncă nu există evaluări

- The Top 5 Missed Opportunities for HappinessDocument33 paginiThe Top 5 Missed Opportunities for Happinessara1bescaÎncă nu există evaluări

- Geopier Soil ImprovementDocument8 paginiGeopier Soil ImprovementJose MartinezÎncă nu există evaluări

- Market Organic FT CoffeeDocument19 paginiMarket Organic FT CoffeeJose MartinezÎncă nu există evaluări

- Financial Analysis For The PEDocument36 paginiFinancial Analysis For The PEJose MartinezÎncă nu există evaluări

- Al Ries & Jack Trout - The 22 Immutable Laws of BrandingDocument8 paginiAl Ries & Jack Trout - The 22 Immutable Laws of BrandingDana IvanÎncă nu există evaluări

- Applications of Vinyl Sheet PilesDocument92 paginiApplications of Vinyl Sheet PilesJose MartinezÎncă nu există evaluări

- Entrepreneurship Motivation Performance and Risk Business Issues CompeDocument215 paginiEntrepreneurship Motivation Performance and Risk Business Issues CompeJose Martinez100% (1)

- Shotcrete Design GuidelinesDocument36 paginiShotcrete Design GuidelinesJose MartinezÎncă nu există evaluări

- Engineering in GermanyDocument32 paginiEngineering in GermanyJose MartinezÎncă nu există evaluări

- Trade State Sustainable CoffeeDocument198 paginiTrade State Sustainable CoffeeJose MartinezÎncă nu există evaluări

- Trade State Sustainable CoffeeDocument198 paginiTrade State Sustainable CoffeeJose MartinezÎncă nu există evaluări

- 2011 Coffee in The NetherlandsDocument4 pagini2011 Coffee in The NetherlandsJose MartinezÎncă nu există evaluări

- Market Organic FT CoffeeDocument19 paginiMarket Organic FT CoffeeJose MartinezÎncă nu există evaluări

- Anchored Sheet-Pile WallsDocument68 paginiAnchored Sheet-Pile WallsJose MartinezÎncă nu există evaluări

- Stairways and LaddersDocument16 paginiStairways and Laddersmohammad_reza_49Încă nu există evaluări

- Brian Tracy - Psychology of Achievement Course BookDocument23 paginiBrian Tracy - Psychology of Achievement Course BookAnonymous oTtlhP100% (1)

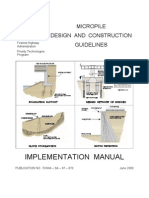

- Micropile Design and Construction Guidelines Implementation ManualDocument380 paginiMicropile Design and Construction Guidelines Implementation ManualJose MartinezÎncă nu există evaluări

- Design of Recreation AreasDocument107 paginiDesign of Recreation AreasJose Martinez100% (1)

- Q04Document9 paginiQ04Anonymous 1TTYYaÎncă nu există evaluări

- Revised Syllabus for B.E. in Civil EngineeringDocument95 paginiRevised Syllabus for B.E. in Civil EngineeringTaufique AhmedÎncă nu există evaluări

- Core Orientation Best Practice 1 3 John Wilson PDFDocument14 paginiCore Orientation Best Practice 1 3 John Wilson PDFFakhri ZakariaÎncă nu există evaluări

- Seismic Imaging and Inversion - by Robert H. Stolt & Arthur B WegleinDocument1 paginăSeismic Imaging and Inversion - by Robert H. Stolt & Arthur B WegleinArthur B WegleinÎncă nu există evaluări

- Physical Properties of The SoilDocument13 paginiPhysical Properties of The SoilAsrianti Putri LestariÎncă nu există evaluări

- Micro-Regions of The Lepenski Vir Culture, Padina in The Upper Gorge and Hajducka Vodenica in The Lower Gorge of The DanubeDocument36 paginiMicro-Regions of The Lepenski Vir Culture, Padina in The Upper Gorge and Hajducka Vodenica in The Lower Gorge of The DanubeJelena WehrÎncă nu există evaluări

- Bearing SettlementDocument4 paginiBearing SettlementBahaismail100% (1)

- MPLT logging by SDI: Analyze fluid flow profilesDocument25 paginiMPLT logging by SDI: Analyze fluid flow profilesISPÎncă nu există evaluări

- (Quantitative Geology and Geostatistics 19) J. Jaime Gómez-Hernández, Javier Rodrigo-Ilarri, María Elena Rodrigo-Clavero, Eduardo Cassiraga, José Antonio Vargas-Guzmán (eds.) - Geostatistics Valencia .pdfDocument949 pagini(Quantitative Geology and Geostatistics 19) J. Jaime Gómez-Hernández, Javier Rodrigo-Ilarri, María Elena Rodrigo-Clavero, Eduardo Cassiraga, José Antonio Vargas-Guzmán (eds.) - Geostatistics Valencia .pdfMaría Fernanda RamírezÎncă nu există evaluări

- Bai Bao Xac Dinh ModulDocument9 paginiBai Bao Xac Dinh ModulThái Trân LêÎncă nu există evaluări

- High Impact Energy Dynamic Compaction applications for ground improvement and earthworksDocument10 paginiHigh Impact Energy Dynamic Compaction applications for ground improvement and earthworkssezaitanyoluÎncă nu există evaluări

- Geology of landslide areaDocument2 paginiGeology of landslide areakrishnawijayaÎncă nu există evaluări

- Dispelling The Alaska Fear FactorDocument243 paginiDispelling The Alaska Fear FactorKLR71Încă nu există evaluări

- HB Wick Drain Case Study Alaska Oil PlatformDocument2 paginiHB Wick Drain Case Study Alaska Oil PlatformJimmy JauÎncă nu există evaluări

- Prehistoric Period Upsc Note 15Document3 paginiPrehistoric Period Upsc Note 15Rohit KumarÎncă nu există evaluări

- Coastal Landforms Caused by Deposition and ErosionDocument19 paginiCoastal Landforms Caused by Deposition and Erosionesteban duranÎncă nu există evaluări

- Distribusi TSS Di Teluk LampungDocument12 paginiDistribusi TSS Di Teluk LampungHesti ApriantiÎncă nu există evaluări

- Earths History Timeline LabDocument3 paginiEarths History Timeline Labapi-2622192730% (1)

- Use of Waste Marble in ConcreteDocument44 paginiUse of Waste Marble in ConcreteGaurav JethleÎncă nu există evaluări

- Artificial Lift Methods, Vol 4 - Production Optimization of Oil and Gas Wells by Nodal Systems PNGE420Document5 paginiArtificial Lift Methods, Vol 4 - Production Optimization of Oil and Gas Wells by Nodal Systems PNGE420Rama NathanÎncă nu există evaluări

- Optimizing Surface Mine Haul Road DesignDocument12 paginiOptimizing Surface Mine Haul Road Designfrans batakÎncă nu există evaluări

- Criteria For Selection of Board On Pillar Method in IndiaDocument9 paginiCriteria For Selection of Board On Pillar Method in IndiaSanthosh AkashÎncă nu există evaluări

- FMC Mining WorkingDocument19 paginiFMC Mining WorkingChandan Kumar100% (3)

- This Dynamic EarthDocument77 paginiThis Dynamic EarthPablo AlejoÎncă nu există evaluări

- Analysis of Lead OreDocument17 paginiAnalysis of Lead OrePutoy ItoyÎncă nu există evaluări

- CO2 Storage in Johansen FormationDocument13 paginiCO2 Storage in Johansen FormationahmedÎncă nu există evaluări

- Latest ReportDocument439 paginiLatest Reportanon_366624306Încă nu există evaluări

- The Sahara: Facts About the Largest Hot DesertDocument6 paginiThe Sahara: Facts About the Largest Hot DesertEsperanza M. GarciaÎncă nu există evaluări

- HDS-6 River EngineeringDocument646 paginiHDS-6 River EngineeringAnthony AlvaradoÎncă nu există evaluări

- Tectonostratigraphic Terranes in Colombia: An Update First Part: Continental TerranesDocument27 paginiTectonostratigraphic Terranes in Colombia: An Update First Part: Continental TerranesEsteban Giraldo ZuluagaÎncă nu există evaluări

- Nickel Laterite Ore Deposits: Weathered Serpentinites: Charles R. M. Butt and Dominique CluzelDocument6 paginiNickel Laterite Ore Deposits: Weathered Serpentinites: Charles R. M. Butt and Dominique Cluzelalan sapoetraÎncă nu există evaluări