Documente Academic

Documente Profesional

Documente Cultură

Layout Power

Încărcat de

Stephanie McintyreDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Layout Power

Încărcat de

Stephanie McintyreDrepturi de autor:

Formate disponibile

MWM GmbH Carl-Benz-Strae 1 D-68167 Mannheim Phone: +49(0)621 384-0 Fax: +49(0)621 384-8612 www.mwm.

net

Power plants layout

with

Gas and

Diesel Engines

(Planning and Installation Notes)

06-2012

Chapter_00 - Contents.docx Page 1 / 4 MWM GmbH 2012 / VD-S

This handbook including all illustrations is protected by copyright. All rights for it are reserved, including rights

to the extracts. Any use outside of the limits prescribed by copyright legislation is prohibited without written

approval and is l iable t o prosecution. This applies in par ticular to r eproductions, t ranslations, microfilming

and storage and processing via electronic systems.

MWM GmbH Mannheim 2012

The r eproduction of t rademarks, ut ility names, t rade names, des criptions of goods, et c. in t his doc ument,

even where not specifically marked, does not justify the assumption that such names may be considered to

be f ree within the meaning of t he l aws governing the pr otection of t rademarks and brand names and may

therefore be used by anyone.

Should any reference be made, directly or indirectly, in this document to or quotations cited from any laws,

regulations or directives (e.g. DIN,VDI, VDE) neither the authors nor MWM can accept any guarantee with

regard to correctness, completeness or currency. It is recommended, should your own work require it, that

you read the complete regulations or directives in the currently applicable version.

Figures, drawings, diagrams and circuit diagrams within the handbook represent general information for the

project planning. The relevant order documentation is binding for orders.

There is no revision service for the drawings of the installation guidelines. They will only be updated with the

next edition of the installation guidelines.

Chapter_00 - Contents.docx Page 2 / 4 MWM GmbH 2012 / VD-S

FOREWORD

The guidelines of this handbook are not operating instructions for the final machine user. They apply to all

designers an d m anufacturers of pr oducts who us e a M WM gens et. T hus t he g uidelines ar e not us er

information as defined by DIN standard 8418, but fulfil a similar purpose, because their observance ensures

the engine functioning and thus protects the product user from danger which could result from genset use.

Operating s afety and a l ong s ervice l ife c an on ly be ex pected f rom per fectly installed gensets. This a lso

allows maintenance work to be c arried o ut s imply a nd qu ickly. T hese gu idelines pr ovide i nformation f or

mounting and give information about limit values to be observed.

The wide range of installation options does not allow for generally applicable and strict rules. Experience and

special k nowledge ar e n ecessary i n or der t o ens ure opt imum i nstallation. T he s tandards, di rectives an d

regulations listed have no claim to completeness. Therefore the local requirements must be investigated and

duly taken into account in each individual case.

Therefore we r ecommend an installation consultation with MWM or an authorised sales partner during the

planning stage.

MWM does not accept warranty claims and is not responsible for damage or loss occurring from failure to

comply with the information and instructions given in this handbook.

Your suggestions on how to enhance or supplement these guidelines are always highly appreciated.

MWM GmbH

VD-S, 06-2012

Chapter_00 - Contents.docx Page 3 / 4 MWM GmbH 2012 / VD-S

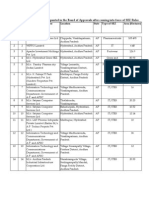

Contents

Chapter Title

1 Layout of diesel /gas engi ne-powered gensets

2 Genset output

3 CHP gensets

4 Requirements for installi ng the genset

5 Engine room ventilation

6 Engine cooling systems

7 Fuel system

8 Lubricating oil system

9 Combustion air system

10 Exhaust system

11 Compressed ai r system

12 Measuring, monitoring and limiting devices

13 No content in chapter

14 Electrical switch gear systems

15 Isolated operation mode with gas engines

16 Load steps

17 Cabling

18 Transport and positioning of gensets

19 Genset instal lation and al ignment instructions

20 Piping

21 Health and safety at work, accident prevention, environmental protection

MWM GmbH Carl-Benz-Strae 1 D-68167 Mannheim Phone: +49(0)621 384-0 Fax: +49(0)621 384-8612 www.mwm.net

1

Power plants layout

Chapter 1

Layout of diesel/gas engine-powered gensets

for combined power and heat generation at power

plants (CHP's)

06-2012

Chapter_01 - Layout of CHPs.docx Page 2 / 6 MWM GmbH 2012 / VD-S

Contents

1. Layout of diesel /gas engi ne-powered installations for combined power and heat

generation at power plants (CHP's) .......................................................................................... 3

1.1 Types of use .................................................................................................................................. 3

1.1.1 Heat-led operation ......................................................................................................................... 3

1.1.2 Electricity-led operation ................................................................................................................. 4

1.1.2.1 Mains parallel operation ................................................................................................................ 4

1.1.2.2 Island mode ................................................................................................................................... 4

1.1.2.2.1 Emergency power mode ............................................................................................................... 4

1.1.2.2.2 Black start ...................................................................................................................................... 5

1.1.3 Operation dependent on the availability of fuel gas ...................................................................... 5

1.1.4 Dual gas operation ........................................................................................................................ 5

Chapter_01 - Layout of CHPs.docx Page 3 / 6 MWM GmbH 2012 / VD-S

1. Layout of diesel/gas engine-powered installations for combined power and

heat generation at power plants (CHP's)

A di esel or gas engine-powered genset c omprises a c ombustion engine, generator, c oupling, base f rame

and mounting arrangement. The engine and generator ar e r igidly mounted on t he base frame. This uni t is

described as a CHP set and is used to generate electricity and heat.

A CHP set comprises a CHP genset and the following components:

Cooling water heat exchanger

Exhaust gas heat exchanger

Exhaust gas silencer

Exhaust gas cleaning system

Fuel tank or gas supply

Lube oil supply

Monitoring system

A CHP plant may comprise one or more CHP sets: the electrical switch gear with management system, the

air supply system and the exhaust gas system.

The basic pr inciples, requirements, components, implementation and maintenance of electricity generating

sets are described in DIN 6280, Part 14 (see Fig. 1.1).

Attention !

It is not allowed to change any parts in the gensets, components and control cabinets which are delivered by

manufacturer. It is also not allowed to install external parts.

To av oid EMC problems, t he p arts on t he plant s ide, e. g. f requency c onverters, must be c onnected with

shielded cables. The manufacturing specification must observed. See also Chapter 14 and 17.

1.1 Types of use

Depending on its application, the plant may be primarily used to generate either electricity or heat.

1.1.1 Heat-led operation

In the case of heat-led operation, the demand for heat is the lead factor which determines the output of the

CHP plant. To cover the demand for heat during peaks, the CHP plant may be supported by other heating

systems.

Chapter_01 - Layout of CHPs.docx Page 4 / 6 MWM GmbH 2012 / VD-S

1.1.2 Electricity-l ed operation

With electricity-led genset operation, the demand of electric power is the command variable for the

power output of the CHP plant.

1.1.2.1 Mains parallel operation

When oper ating i n par allel w ith t he m ains, t he C HP pl ant s upplies c onsumers e. g. unt il t he m aximum

electrical out put i s r eached ac cording t o t he nom inal c apacity of t he eng ine. A ny f urther add itional

requirement is covered from the mains power supply. During peak tariff periods, the gensets can be used to

offset peak loads.

In the event of a mains fault, the CHP plant can be operated in island mode.

1.1.2.2 Island mode

When operating in island mode, the CHP plant supplies the power needs of the consumers by itself.

The gens ets ar e r equired to s upply t he p ower f or al l c onnected l oads a t an y time of oper ation. T his i s

applicable for switching on and rejecting loads.

The control system's load-management has to ensure that the gensets are never overloaded. The required

load steps should not exceed the maximum load steps as specifically determined for each engine type (refer

to Chapter " Load s teps f or gas en gines"). T his r efers bot h t o load ac ceptance an d l oad s hedding. T he

required switch-on power i s of par ticular consideration her e, not t he nominal power ( See also Chapter 15

Isolated operation mode and Chapter 16 Load steps).

1.1.2.2.1 Emergency power mode

Taking due ac count of t he appr opriate add itional measures r equired, t he CHP pl ant c an a lso be used t o

provide an emergency power supply, covering the demand for power in the event of a mains power failure as

per :

DIN VDE 0100-710 and DIN VDE 0100-560

DIN EN 50172 and DIN VDE 0100-718

The emergency power mode must be clarified in each individual case. Not all generator sets are capable of

providing an em ergency power s upply as s tated per t he s tandards mentioned above. The engine-specific

load steps must be adhered to.

The heat energy simultaneously produced by the CHP plant should, if possible, be utilised (e.g. for heating or

refrigeration), for which purpose heat accumulators should be employed where necessary. When providing

an emergency power supply, heat dissipation must be guaranteed under all circumstances, if necessary with

the aid of dump cooling facilities and/or accumulators.

Chapter_01 - Layout of CHPs.docx Page 5 / 6 MWM GmbH 2012 / VD-S

1.1.2.2.2 Black start

The bl ack s tart i s an emergency f unction of t he g as gens et an d s hould be us ed only f or e mergency

situations. I f a gas engine is " black-started", i t starts without auxiliary power for prelubrication and cooling

pumps. The gas engi ne i s s tarted di rectly after t he T EM demand c ontact has been c losed. T he c ooling

pumps start as soon as the auxiliary power supply is available. The gas genset will be started without prior

leak monitoring of the gas pressure regulation unit.

The engines of the series TCG 2016 and TCG 2020 are capable of back-starting. The engines of the series

TCG 2032 cannot be black-started. (See also Chapter 15 Isolated operation mode).

1.1.3 Operation dependent on the availability of fuel gas

With this type of operation, the lead factor is the available supply of fuel gas (e.g. landfill gas, sewage gas,

bio-gas, etc.). In the case of multi-engine plants, gensets are switched on or off depending on t he amount of

gas available. For single engine plants, the engine power is adjusted to the available gas amount.

1.1.4 Dual gas operation

For special applications, the gas gensets can be equipped with two gases for the operation. If, for example,

natural gas and sewage gas are available, it is possible to change over from sewage gas to natural gas if

sewage gas is lacking. For the changeover between the two gases, the genset must be stopped.

Chapter_01 - Layout of CHPs.docx Page 6 / 6 MWM GmbH 2012 / VD-S

Fig. 1.1

Definition and demarcation of CHP components as per DIN 6280-14

A Combined heat and power plant (CHP)

B CHP module

C CHP genset

1 Reciprocating internal combustion engine 8 Exhaust gas cleaning system

2 Generator 9 Fuel tank or gas supply

3 Coupling and flexible mounting 10 Lube oil supply

4 Combustion air filter

(optionally installed s eparately f rom t he

engine)

11 Monitoring system

5 Exhaust gas heat exchanger 12 Switch board with controls

6 Cooling water heat exchanger 13 Ventilation inlet

7 Exhaust gas silencer 14 Ventilation outlet

MWM GmbH Carl-Benz-Strae 1 D-68167 Mannheim Phone: +49(0)621 384-0 Fax: +49(0)621 384-8612 www.mwm.net

Power plants layout

Chapter 2

Genset output

06-2012

Chapter_02 - Genset output.docx Page 2 / 6 MWM GmbH 2012 / VD-S

Contents

2. Genset output .............................................................................................................................. 3

2.1 Demand for heating ....................................................................................................................... 3

2.2 Demand for electricity ................................................................................................................... 3

2.3 Available fuel supply ..................................................................................................................... 3

2.3.1 Gas ................................................................................................................................................ 3

2.3.2 Liquid fuel ...................................................................................................................................... 4

2.4 Performance data on the rating plates .......................................................................................... 4

2.4.1 Rating plate of the engine ............................................................................................................. 4

2.4.1.1 Diesel engines ............................................................................................................................... 4

2.4.1.2 Gas engines .................................................................................................................................. 4

2.4.2 Rating plate of the generator ......................................................................................................... 5

2.4.3 Rating plate of the genset ............................................................................................................. 5

Chapter_02 - Genset output.docx Page 3 / 6 MWM GmbH 2012 / VD-S

2. Genset output

To plan the size of the genset, it is necessary to determine the demand for electricity and heat on the basis

of annual consumption curves.

2.1 Demand for heating

The heating demand curve can be used to determine the size and number of gensets required for heat-led

operation. However, w ith heat -led o peration, i t i s e ssential t o c onsider t he g eneration and d emand f or

electricity. The choice of operating mode may lead to negative feed or to power being drawn from the mains.

2.2 Demand for electricity

The electricity demand curve is decisive in determining the demand for electricity when operating in parallel

with t he mains. At t he s ame t ime, i t i s nec essary t o i nvestigate whether it is appropriate to s plit the t otal

output bet ween s everal g ensets. For the emergency power s upply s ervice, i n addition t o t he demand f or

electricity when operating in par allel with t he mains, t he emergency electricity s upply output must al so be

considered. A di stinction must be dr awn between " important" a nd "non-important" c onsumers and t heir

permitted downtimes.

Not al l c onsumers ar e connected or ac hieve t heir m aximum c urrent c onsumption s imultaneously

(simultaneity factor).

Some consumers pur ely c onsume r eal power, ot hers have merely an apparent power dr aw ( power f actor

cos phi). Particular consumers such as, for example, those with impulse load characteristics or which make

extreme demands in terms of constant voltage and frequency must be taken into account.

Under s pecial c limatic s ite c onditions ( high a ltitude, high ai r t emperatures and humidity) t he e ngine and

generator are unable to produce their normal output (reduction in output as per ISO 8528-1, DIN VDE 0530

and DIN EN 60034).

2.3 Avail able fuel suppl y

2.3.1 Gas

The genset output and number of gensets will be dependent on the available gas volume. The gensets must

be operated only in t he 50 100 % output r ange. For c ontinuous oper ation, t he out put s hould be above

70%.

Chapter_02 - Genset output.docx Page 4 / 6 MWM GmbH 2012 / VD-S

2.3.2 Liquid fuel

In this case, fuel tank capacity must be designed in accordance with the output and number of gensets.

2.4 Performance data on the rating plates

In case of a generator-genset, engine, generator and genset have each their own rating plate.

2.4.1 Rating plate of the engine

2.4.1.1 Diesel engines

The rating plate of the engine lists the mechanical output according to DIN 3046-7. The output is given in kW

(Kilowatt).

Exemplarily outputs labelled SCXN and SFN can be indicated on the rating plate.

The following mean here:

S operating output

C continuous output

X 10% overload per hour within 12 hours

N power efficiency

F blocked power

2.4.1.2 Gas engines

In case of gas engines, the output SCN (continuous output, cannot be overloaded) is outlined according to

DIN 3046-7. On the test bench gas engines are run with natural gas. In case of engines, which are run with

other t ypes of gas es l ater on i n t he ac tual o peration phas e, t he ou tput f or t he t ype of gas i s addi tionally

outlined on the rating plate. The type of gas is considered by the extension behind the output description.

Exemplarily the following outputs can be indicated on the rating plate.

SCN n: continous output during operation with natural gas; n means natural gas; the output

is run on the test bench.

SCN b: continuous output during operation with bio-gas; b means bio-gas

Further extensions may be:

m mine gas

s sewage gas

l landfill gas

Chapter_02 - Genset output.docx Page 5 / 6 MWM GmbH 2012 / VD-S

2.4.2 Rating plate of the generator

The rating plate of the generator lists the apparent power of the specific type according to IEC 60034 and the

power factor (cos Phi) of the generator. The specification is given in kVA (Kilo Volt-Ampere), the power factor

is dimensionless.

2.4.3 Rating plate of the genset

The electric capacity of the genset is given on the rating plate. The name of the output category is outlined

according to DIN 8528-1. The output is given in KWel (Kilowatt electric). The output descriptions are:

COP continuous output of the genset

PRP variable continuous output of the genset

LTP temporary continuous output of the genset

Gensets with gas e ngines ar e des igned f or c ontinuous oper ation, t herefore t he un it r ating pl ate al ways

shows the power category COP-output. Depending on the individual case, the output t ypes PRP and LTP

may also apply to diesel gensets.

Chapter_02 - Genset output.docx Page 6 / 6 MWM GmbH 2012 / VD-S

MWM GmbH Carl-Benz-Strae 1 D-68167 Mannheim Phone: +49(0)621 384-0 Fax: +49(0)621 384-8612 www.mwm.net

Power plants layout

Chapter 3

CHP sets

06-2012

Chapter_03 - CHP set.docx Page 2 / 22 MWM GmbH 2012 / VD-S

Contents

3. CHP sets ....................................................................................................................................... 3

3.1 Genset design ............................................................................................................................... 3

3.2 Genset ........................................................................................................................................... 3

3.2.1 Engine monitoring and cabling ...................................................................................................... 3

3.2.2 Genset examples ........................................................................................................................ 14

3.3 Generators .................................................................................................................................. 19

3.3.1 General ........................................................................................................................................ 19

3.3.2 Generator voltage regulation ....................................................................................................... 20

3.3.2.1 Basic function of the voltage regulator ........................................................................................ 21

3.3.2.2 Set point adjustment of the voltage regulator ............................................................................. 21

3.3.3 Generator protection ................................................................................................................... 21

3.3.3.1 Monitoring facilities for generators as per ISO 8528, Part 4 ....................................................... 21

3.3.4 Earthing ....................................................................................................................................... 22

Chapter_03 - CHP set.docx Page 3 / 22 MWM GmbH 2012 / VD-S

3. CHP sets

3.1 Genset design

Gensets comprise the following main components:

Diesel or gas engine

Generator

Torsionally elastic coupling

Base frame

Elastic mounting (resilient seatings)

Engine and generator are linked by a torsionally elastic coupling and rigidly mounted to the base frame. The

base frame is elastically mounted to the foundation by resilient seatings.

All flexible connections for the operating media are installed at the genset. Auxiliary units such as

prelubricators and lubricating oil level monitors are mounted to the base frame.

Preheating must be provided for every engine. Dependent on the design of the plant, this may be installed

either at the genset or in the plant.

3.2 Genset

3.2.1 Engine monitoring and cabling

The gas engine is equipped with sensors for monitoring and control purposes. The sensors are wired to a

multifunction rail at cylinder rows A and B. Bus cable run from each multifunction rail to the TEM system

(TEM see Chapter 14.1). At the engine, all parts needing to be earthed are connected to the copper rail. This

rail must therefore be connected to the earthing system of the switchboard. An overview of the monitoring

facilities is shown in the following engine drawings.

The diesel engine is likewise equipped with monitoring and control sensors. These are wired to a terminal

box on the genset.

Chapter_03 - CHP set.docx Page 4 / 22 MWM GmbH 2012 / VD-S

Fig. 3.1a Engine TCG 2016 V08 C, V12 C and V16 C Sensor arrangement

1 Mixture temperature sensor before exhaust turbocharger

2 Ignition coil

3 Coolant temperature sensor (low-temperature circuit, inlet)

4 Actuator

5 Starter relay

6 Flywheel sensor installation location depending on version

7 Starter

8 Knock sensor

One sensor for every two cylinders

9 Lubricating oil level sensor

10 Camshaft sensor

11 Coolant temperature sensor (engine outlet)

12 Crankcase pressure sensor

13 Stepping motor gas-air mixer

Chapter_03 - CHP set.docx Page 5 / 22 MWM GmbH 2012 / VD-S

Fig. 3.1b Engine TCG 2016 V08 C, V12 C and V16 C Sensor arrangement

1 Charging mixture temperature sensor after mixture cooler

2 Ignition control unit

3 Multifunction rail cylinder row B

4 Combustion chamber temperature sensor

One sensor for every cylinder

5 Coolant temperature sensor (high-temperature circuit)

6 Prelubrication pump

7 Lube oil temperature sensor

8 Lube oil pressure sensor

Chapter_03 - CHP set.docx Page 6 / 22 MWM GmbH 2012 / VD-S

Fig. 3.2a Engine TCG 2020 V12(K) and V16(K) Sensor arrangement

1 Coolant temperature sensor before mixture cooler

2 Knock sensor

One sensor for every cylinder

3 Combustion chamber temperature sensor

One sensor for every cylinder

4 Starter

5 Starter relay

6 Crankcase pressure sensor

7 Lubricating oil level sensor

8 Prelubrication pump

9 Lube oil pressure sensor

10 Camshaft sensor

11 Multifunction rail cylinder row A

12 Proximity switch gas-air mixer

13 Inlet temperature sensor

V16 engine

14 Inlet temperature sensor

V12 engine

15 Ignition coil

One ignition coil for every cylinder

Chapter_03 - CHP set.docx Page 7 / 22 MWM GmbH 2012 / VD-S

Fig. 3.2b Engine TCG 2020 V12 and V16 Sensor arrangement

1 Multifunction rail cylinder row B

2 Coolant temperature sensor (engine outlet)

3 Mixture temperature sensor

4 Coolant temperature sensor (engine inlet)

5 Lube oil temperature sensor

6 Lube oil pressure sensor

7 Knock sensor

One sensor for every cylinder

8 Combustion chamber temperature sensor

One sensor for every cylinder

9 Flywheel pulse sensor

10 Ignition control unit

11 Actuator

12 Stepper motor gas-air mixer

13 Ignition coil

One ignition coil for every cylinder

14 Exhaust turbocharger speed sensor

15 Exhaust turbocharger temperature sensor

Chapter_03 - CHP set.docx Page 8 / 22 MWM GmbH 2012 / VD-S

Fig. 3.3a Engine TCG 2020 V20 Sensor arrangement

1 Exhaust turbocharger temperature sensor

2 Inlet temperature sensor

3 Ignition coil

One ignition coil for every cylinder

4 Starter relay

5 Combustion chamber temperature sensor

One sensor for every cylinder

6 Knock sensor

One sensor for every cylinder

7 Crankcase pressure sensor

8 Camshaft sensor

Chapter_03 - CHP set.docx Page 9 / 22 MWM GmbH 2012 / VD-S

Fig. 3.3b Engine TCG 2020 V20 Sensor arranagement

1 Exhaust turbocharger speed sensor

2 Coolant temperature sensor (engine outlet)

3 Mixture temperature sensor

4 Coolant temperature sensor (engine inlet)

5 Lube oil temperature sensor

6 Lube oil pressure sensor

7 Knock sensor

One sensor for every cylinder

8 Combustion chamber temperature sensor

One sensor for every cylinder

9 Actuator

10 Flywheel pulse sensor

11 Temperature sensor before mixture cooler

12 Ignition control unit

13 Proximity switch gas-air mixer

14 Stepping motor gas-air mixer

Chapter_03 - CHP set.docx Page 10 / 22 MWM GmbH 2012 / VD-S

Fig. 3.4a Engine TCG 2032 V12 und V16 Sensor arrangement

1 Coolant temperature sensor (high-temperature circuit inlet)

2 Proximity switch gas-air mixer

One switch for each gas-air mixer

3 Coolant temperature sensor (high-temperature circuit outlet)

4 Mixture temperature sensor

One sensor for each gas-air mixer

5 Stepping motor gas-air mixer

One stepping motor for each gas-air mixer

6 Depending on version Base bearing temperature sensor

7 Multifunction rail cylinder row A

8 Camshaft sensor

9 Crankcase pressure sensor

10 Electric pump for preheating unit (coolant)

11 Electrical preheater

for coolant and lubricating oil

12 Electric pump for preheating unit (lubricating oil)

Chapter_03 - CHP set.docx Page 11 / 22 MWM GmbH 2012 / VD-S

Fig. 3.4b Engine TCG 2032 V12 and V16 Sensor arrangement

1 Lube oil temperature sensor

2 Start backup for engine turning device

3 Solenoid valve for air starter

4 Flywheel sensor installation location depending on version

5 Multifunction rail cylinder row B

6 Charging mixture temperature sensor

One sensor each for A and B side

V12 engine: Between cylinder A4 and A5 as well as before B6

V16 engine: Between cylinder A6 and A7 as well as before B8

Chapter_03 - CHP set.docx Page 12 / 22 MWM GmbH 2012 / VD-S

Fig. 3.4c Engine TCG 2032 V12 and V16 Sensor arrangement

1 Exhaust turbocharger speed sensor

One sensor for every exhaust turbocharger

2 Actuator

3 Coolant temperature sensor (high-temperature circuit inlet)

4 Lubricating oil level sensor

5 Lube oil pressure sensor

(Lube oil pressure before lubricating oil filter)

6 Coolant temperature sensor (low-temperature circuit, inlet)

7 Charging mixture pressure sensor A side, mixture cooler Depending on

version

Chapter_03 - CHP set.docx Page 13 / 22 MWM GmbH 2012 / VD-S

Fig. 3.4d Engine TCG 2032 V12 and V16 Sensor arranagement

1 Flywheel sensor installation location depending on version

2 Lube oil pressure sensor

(Lube oil pressure after filter)

3 Ignition coil

One ignition coil for every cylinder

4 Ignition control unit

5 Combustion chamber temperature sensor

One sensor for every cylinder

6 Knock sensor

One sensor for every cylinder

7 Charging mixture pressure sensor

One sensor each for A and B side

Chapter_03 - CHP set.docx Page 14 / 22 MWM GmbH 2012 / VD-S

3.2.2 Genset examples

Figures 3.6 to 3.9 illustrate gensets with Series of the gas engines 2016, 2020, 2032.

Binding genset dimensions are contained in the contract-specific genset drawing.

Chapter_03 - CHP set.docx Page 15 / 22 MWM GmbH 2012 / VD-S

Fig. 3.5 Engine TCG 2016 V16 C with Marelli generator MJB 400 LC 4

Genset weight approx. 7140 kg

Chapter_03 - CHP set.docx Page 16 / 22 MWM GmbH 2012 / VD-S

Fig. 3.6 Engine TCG 2020 V16 with Marelli generator MJB 500 MC4

Genset weight approx. 13900 kg

Chapter_03 - CHP set.docx Page 17 / 22 MWM GmbH 2012 / VD-S

Fig. 3.7 Engine TCG 2020V20 with Marelli generator MJB 560 LA 4

Genset weight approx. 19000 kg

Chapter_03 - CHP set.docx Page 18 / 22 MWM GmbH 2012 / VD-S

Fig. 3.8 Engine TCG 20232 V16 with Marelli generator MJH 800 MC6

Genset weight approx. 53700 kg

Chapter_03 - CHP set.docx Page 19 / 22 MWM GmbH 2012 / VD-S

3.3 Generators

3.3.1 General

The types used as standard are brushless synchronous generators, which, depending on the application,

may be suitable for mains-parallel and/or islands power supply operation.

Depending on output and the available mains supply, these may be 400 V to 690 V three-phase generators

or medium-voltage generators in the range from 3 kV to 15 kV.

The efficiency of the generators dependent upon size and power factor value (cos phi) is between 95.0 %

and 97.8 %.

Thus, for example, a 494 kVA generator with a power factor of 0.8 has an efficiency level of 95.5 % and a

5336 kVA medium-voltage generator with a power factor of 0.8 is 97.2 % efficient. If the generator is

operated at a power factor of 1, efficiency is increased by approx 1-1.5 %.

As per DIN VDE 0530 / DIN EN 60034 the generators are designed for an ambient temperature of 40 C and

a site altitude of 1000 m. At higher ambient temperatures or higher altitude, the output must be reduced in

accordance with the manufacturer's specifications.

These generators can operate as standard in a power factor range of 0.8 - 1 inductive (lagging). Thus in the

case of mains-parallel operation, it is possible to improve the mains handover power factor in the event that

the generators are to be used as "phase shifters".

Generators must be specially designed for use in the capacitive range! There are different country-specific

regulations for static and dynamic mains support, which have to be considered when designing the gas

engine gensets.

In island operation mode, the max. permissible unbalanced load for the generator must be taken into

account. (Dependent upon generator output and manufacturer, 30 % between maximum and minimum

phase current)

Fig. 3.9 Generator

Chapter_03 - CHP set.docx Page 20 / 22 MWM GmbH 2012 / VD-S

3.3.2 Generator voltage regulation

The voltage regulator keeps the generator voltage on a constant level. The voltage regulator is either

installed in the generator's terminal box or also may be installed in a switch cabinet within the switch gear.

The principle function of the voltage regulator is shown in Figure 3.10.

Fig. 3.10 Generator voltage regulation

1 Setpoint adjuster

2 Voltage regulator

3 Rotor

4 Stator

G1 Three-phase main machine

G2 Three-phase exciter

G3 Auxiliary exciter

U V W N

G1 G2

G3

Spannungs-

Regler

Sollwerteinsteller

s t

Stator

G1 = Drehstrom-

Hauptmaschine

G2 = Drehstrom-

Erregermaschine

G3 = Hilfs-

Erregermaschine

Rotor

1

3

2

4

Chapter_03 - CHP set.docx Page 21 / 22 MWM GmbH 2012 / VD-S

3.3.2.1 Basic function of the voltage regulator

The power supply of the voltage regulator is provided from the auxiliary exciter G3. The brushless rotary

current exciter G2 receives its voltage supply from the actuating element of the voltage regulator. The

voltage delivered from the three-phase rotor winding of the exciter G2 is rectified and supplied as direct

current to the rotor of the generator G1. In order to obtain a constant voltage level at the generator terminals

with alternating load, it is necessary to adjust the current supply to the rotor accordingly. This function is

assumed by the voltage regulator.

3.3.2.2 Set point adjustment of the voltage regulator

The inputs to the voltage regulator are the voltage set point from the set point adjuster and the actual

generator voltage measured at the terminals U,V and W. The readjustment of the generator voltage is done

via adjustment of the current supply to the rotor. The amount of difference between the voltage set point and

the actual voltage is the defining parameter for the size of the adjustment of the direct current supply to the

rotor.

The adjustment of the voltage set point has to be done at site with regard to the voltage level at the local

conditions. The range for the voltage adjustment is normally within 5% to 10% of the generator's nominal

voltage.

3.3.3 Generator protection

To protect the generators, monitoring facilities as per ISO 8528 must be employed.

Those monitoring facilities are not included in the TEM system.

3.3.3.1 Monitoring facilities for generators as per ISO 8528, Part 4

The following generator monitoring facilities are absolutely essential and must be provided in the switch gear:

Protection in case of short-circuit

Protection in case of overload

Chapter_03 - CHP set.docx Page 22 / 22 MWM GmbH 2012 / VD-S

The following protection facilities are urgently recommended:

Protection in case of time-delayed overcurrent

Protection in case of voltage-related overcurrent

Protection in case of directionally dependent overcurrent

Reverse power protection

Mains isolation facility

Reactive current restriction

Differential current protection

Also the following protection facilities are recommended:

System earth fault protection

Stator earth fault protection

Unbalanced load protection

3.3.4 Earthing

The generator is connected to the base frame by an earthing wire. The earthing connection of the genset

must be connected to the earthing system for the CHP plant.

The local power supply company rules or safety regulations must be complied with in order to ensure that the

genset earthing is correct.

MWM GmbH Carl-Benz-Strae 1 D-68167 Mannheim Phone: +49(0)621 384-0 Fax: +49(0)621 384-8612 www.mwm.net

Power plants layout

Chapter 4

Requirements for genset installation

06-2012

Chapter_04 - Requirements for genset installation.docx Page 2 / 12 MWM GmbH 2012 / VD-S

Contents

4. Requirements for genset installation ............................................................................................. 3

4.1 Engine room ....................................................................................................................................... 3

4.1.1 Location .............................................................................................................................................. 3

4.1.2 Requirements for the engine room ..................................................................................................... 3

4.2 Foundations and vibration damping ................................................................................................... 5

4.2.1 Foundation block ................................................................................................................................ 5

4.2.2 Elastic support .................................................................................................................................... 6

4.2.3 Assessing vibrations........................................................................................................................... 7

4.2.4 Cable and pipe ducts.......................................................................................................................... 7

4.3 Questions of noise .............................................................................................................................. 7

4.3.1 Acoustic dependencies ...................................................................................................................... 8

4.3.2 Possible means of mitigating noise .................................................................................................. 10

Chapter_04 - Requirements for genset installation.docx Page 3 / 12 MWM GmbH 2012 / VD-S

4. Requirements for genset installation

4.1 Engine room

Having carefully selected and established the output of the power plant, there are a series of preconditions

which must be fulfilled by the client to achieve a safe, low-maintenance, and defect-free operation.

The most important questions associated with the erection and installation of the genset must therefore be

clarified at t he t ime w hen bui ldings i ntended t o ho use t he e nergy ge neration uni ts ar e be ing p lanned.

Alterations and special solutions introduced at a later date are generally expensive and often unsatisfactory.

Right from the start, consideration should be given to possible future expansion.

4.1.1 Location

The planning process begins with the selection of the site at which to erect the genset. In order to minimise

losses i n t he t ransmission of ener gy t o t he c onsumer, i t makes pr actical s ense t o ar range t he unit i n t he

vicinity of the consumer. However, requirements in terms of noise and vibration often lead to power plants

being set up far away from residential properties.

Where a bu ilding is r eserved f or ener gy generation, t he pr oblems of v entilation, vibration damping, f uel

supplies and storage, and also of bringing in and providing access to the unit are generally easier to resolve.

Engine rooms inside large buildings such as e.g. department stores, hospitals and administration buildings

should be l ocated as nea r as pos sible t o an o utside wall, s o t here i s no difficulty i n drawing i n an d

discharging air for cooling and ventilation. The genset room can be designed at ground level, below ground,

or in the case of smaller units, even on one of the upper floors.

The choice of building materials must take account of the need for sound and vibration damping.

4.1.2 Requirements for the engine room

The engine room should be of adequate size. Aside from the added complication of operation and

maintenance, the problem of ventilation in small rooms is also not easy to resolve.

For TCG/TCD 2016 and 2020, a c lear space of approx. 1 m i n width should, under all circumstances, be

allowed for all round the genset, increasing to 2 m for bigger engines. Care must be taken to ensure that the

starter batteries are arranged as close as possible to the electric starter. For installations with engines TCG

2032, i t i s n ecessary t o p rovide a f ree area of 2 m eters b y 5 m eters s uitable f or ac ceptance of hea vy

weights. Preferably, this area should be arranged close to the engine in order to achieve access by the same

crane b oth f or t he pr e-assembly area and t he e ngine itself. F urthermore, t he s ize of the r oom w ill be

determined by the other components to be installed, such as e.g. heat utilisation unit, switchgear, gas control

unit, fuel tank, lube oil tank, batteries, exhaust pipe and silencer. The silencers for the inlet and exhaust air

Chapter_04 - Requirements for genset installation.docx Page 4 / 12 MWM GmbH 2012 / VD-S

for ex ample, require enough av ailable r oom.It i s es sential t o design s ufficiently openinmgs t o br ing i n t he

genset, and to draw in and discharge air to ventilate the plant (see Chapter 5, Engine room ventilation).

No eng ine r oom s hould b e without p ermanently installed lifting g ear ( crane), t he l oad-bearing c apacity of

which corresponds to the heaviest single item in the room. It must, however, in all cases be guaranteed that

when carrying out maintenance works, dependent on the engine type, e.g. pistons, con-rods, cylinder heads

or ev en a c omplete eng ine c an be l ifted. Both er ection a nd s ubsequent maintenance c an be c arried out

quickly and practically.

The engi ne r oom s hould be of s ufficient hei ght t o allow p istons a nd c onnecting r ods t o b e withdrawn

upwards, t aking i nto ac count t he l ifting g ear. T he s ize of t he r oom must per mit works t o be c arried o ut

unobstructed at all points around the genset and there must be space to park individual genset components

and spares.

Together with the planning of the engine room, the elastic mounting, the design of the foundation block, the

pipe and cable work must be clarified. Also to be considered in the early stages of planning is the

implementation of any special noise protection and anti-vibration insulation measures.

At s maller in stallations, t he gens et an d t he s witchgear c an g enerally be er ected i n on e r oom. For l arger

installations, it may be more practical to install the switchgear in a separate, sound-proofed and maybe air-

conditioned operating room.

When planning the engine room, consideration must also be given to the transport route, so that if necessary

an engine or generator can be dismantled and reinstalled (floor loading and space available).

The following example illustrates a practical and proven genset set-up in Figure 4.1.

If t he ac cess t o t he ge nset and its c omponents i s heavily r estricted d ue t o t he en gine r oom not be ing

designed large e nough, t he pr oducer may c laim addi tional c osts when do ing maintenance or r epair work

within the scope of the warranty of the producer.

Chapter_04 - Requirements for genset installation.docx Page 5 / 12 MWM GmbH 2012 / VD-S

Fig. 4.1 Typical set-up TCG 2016 V16 C

Before detailed planning work starts, the pr oducer would also assist prospective clients with further

documentation on s tandard s et-ups. For major pl anning t asks, c onstruction or dr aft construction dr awings

are requested by us.

4.2 Foundations and vibration damping

In the case of reciprocation gensets with piston engines, gravity forces and moments of inertia cannot, in all

cases, be completely balanced. The transmission to the foundation of the vibration and noise thus created

can be significantly r educed by the use of elastic mountings. When erecting gensets, the elastic mounting

elements must therefore always be provided between the base frame and the foundation block.

4.2.1 Foundation block

For the base of the foundation, which must be implemented with special care, it is recommended that a soil

investigation be carried out by an expert. The costs for this bear no relation to the expense involved in the

subsequent work r equired, i f, f or example, it is found t hat vibration is being transmitted to the surrounding

neighbourhood.

There must be no groundwater veins either beneath or in the vicinity of the foundation block, as these can

transmit vibrations over very l ong distances. This al so applies t o a high gr oundwater l evel which l eads t o

Chapter_04 - Requirements for genset installation.docx Page 6 / 12 MWM GmbH 2012 / VD-S

stronger transmission of vibration than occurs in dry ground. Depending on local conditions, the foundation

block may have to be set on a sole plate or pilework.

Sinking and basing the foundation are in any case the responsibility of the construction company or architect.

The latter must assess the load-bearing capacity of the soil and determine the solidity of the foundation block

by specifying the requisite concrete mix and reinforcements to suit the local conditions.

For calculation purposes, clients will be pr ovided with dat a on t he foundation l oad imposed by t he genset

and the natural frequencies of the elastic bearings.

The foundation block as built must have no contact with the foundation walls of the building or with the floor.

The gap bet ween t he f oundation block and t he f loor can be sealed with an elastic material. To accept the

elastic bearing elements, the surface of the foundation must be horizontal and disked, without being

smoothed with a t rowel. The foundation s urface must be f lat t o a t olerance of max. 2 mm. I t i s n ot

permissible to mount the genset on tiles or pavement.

4.2.2 Elasti c support

In order to insulate the genset as far as possible from the foundation in terms of vibration and structure-borne

noise, steel spring bearing elements are used. These bearing elements reduce the transmission of dynamic

forces t o t he foundation. The i nsulation of l ow f requencies i n buildings i s of gr eat i mportance. This t oo i s

achieved with a s oft s teel spring be aring ar rangement. Structure-borne n oise insulation i s guar anteed b y

means of reflection from the footplate of the bearing, thanks to the isolation effect of the steel / rubber plate

arrangement.

The el astic bear ing ar rangement must be r ecalculated f or eac h appl ication. T he nat ural f requency of t he

system constituted by the genset / elastic bearing must be sufficiently far below the operating speed of the

genset.

Insulation levels of approx. 88 - 94 % are achieved with the bearing elements used.

To meet es pecially high r equirements, t here is t he possibility of us ing a d ouble f oundation i ncorporating

elastic bearings.

The spring elements which are used in gensets can be adjusted in hight over a certain range. They have to

be pr operly a djusted; meaning t he l oad on eac h e lement has t o be equal . A wrong s etting of t he s pring

elements l eads t o t heir destruction on a l ong t erm basis and t he oscillations cannot be isolated anymore.

Spring elements can compensate unevenness of the foundation only to some extent. Due to an uneven load,

too great unevenness of the foundation and a wrong setting of the spring elements lead to the deformation of

the gensets base frame. As a consequence the alignment between the genset and the engine is no longer

efficient. This can result in an incalculable destruction of the components.

Chapter_04 - Requirements for genset installation.docx Page 7 / 12 MWM GmbH 2012 / VD-S

4.2.3 Assessing vibrations

DIN ISO 8528 - 9 must be applied for gensets. This standard deals with the measurement and evaluation of

the mechanical vibrations in electricity generating units with reciprocating piston combustion engines.

4.2.4 Cable and pipe ducts

Cooling water and exhaust pipes can be laid in ducts beneath the floor. The requisite dimensions must be

adapted to the size of the pipes and to local conditions.

In gener al, c are m ust be t aken t o ens ure t hat duc ts for pi pes and duc ts f or c ables ar e i mplemented

separately from one another, whereby a further distinction must be drawn between power cables and control

cables and signal cables. Ducts are laid with a fall leading away from the foundation block, with drains fitted

with oil separators provided at the lowest points. The ducts can be covered with treadplate or grilles. Ducts

and covers must always be provided by the client.

4.3 Questions of noise

Since t he acoustic r equirements i mposed by various l aws and r egulations on t he er ection of gensets with

combustion e ngines ar e c onstantly increasing, a br ief r eference i s appr opriate her e t o t he c ontexts and

possible solutions to noise problems.

Noise s ources mainly include the c ombustion noise of the en gine, mechanical e ngine no ises a nd the a ir

intake and exhaust noises from the engine. The fans, pumps and other ancillaries can also be the cause of

nuisance noise.

Likewise, excessive air speeds can cause noise (see Chapter 5.4, Planning notes).

There i s not hing t hat ef fective r esources c an do t o c hange t he s ources of noi se t hemselves. T hus most

measures t o mitigate noi se ar e di rected t owards r educing t he t ransmission of noise outside of t he genset

room.

Chapter_04 - Requirements for genset installation.docx Page 8 / 12 MWM GmbH 2012 / VD-S

4.3.1 Acoustic dependenci es

Noise is made up of pressure waves of varying frequencies. All measurements of noise are thus frequency

dependent pr essure measurements. Lower-frequency noises ar e more eas ily t olerated b y human bei ngs

than t hose of hi gher f requencies. S ound waves ab ove 16,000 - 20,000 H ertz, on t he other han d, ar e

generally beyond detection by the human ear.

The need t o c ompare t he l oudness of s ound ev ents at di fferent l ocations h as l ed t o t he de velopment of

objective measuring procedures. Assessments are conducted in accordance with specific frequency curves,

as defined in DIN EN 61672-1 and DIN EN 6167-2. These are assessment curves A, B, C and D (Table 4.1).

The as sessment c urves r eplicate in a s omewhat s implified manner t he f requency r esponse of t he ear t o

narrow-band noises. Curve A applies to the low-volume range, Curves B and C cover the range of loud and

very loud noises, whilst D applies to aircraft noise.

Table 4.1

Frequency Assessment curve

Hz A

dB

B

dB

C

dB

D

dB

31.5 -39.4 -17.1 -3.0 -16.5

63 -26.2 -9.3 -0.8 -11.0

125 -16.1 -4.2 -0.2 -6.0

250 -8.6 -1.3 0.0 -2.0

500 -3.2 -0.3 0.0 0.0

1000 0.0 0.0 0.0 0.0

2000 1.2 -0.1 -0.2 8.0

4000 1.0 -0.7 -0.8 11.0

8000 -1.1 -2.9 -3.0 6.0

Chapter_04 - Requirements for genset installation.docx Page 9 / 12 MWM GmbH 2012 / VD-S

Engine noises are normally assessed in dB (A).

measured value at 125 Hz is for example perceived as 16.1 dB quieter than the same value at 1000 Hz.

The strength of the noise is dependent on the range at which it is measured and on the erection site. When

measured a s hort distance f rom t he source, t he sound pr essure level is hi gher, and at long distance i t i s

lower. This reduction in sound level is referred to as dispersion damping.

For point sources, the foll owing applies:

2

) 1 ( ) 2 (

1

2

log 10

=

r

r

L L

r r

L(r1) = sound pressure level 1 L(r2) = sound pressure level 2

r1 = distance 1 r2 = distance 2

Exampl e:

L(r1) = 70 dB r1 = 10 m r2 = 20 m

As the distance doubles, the sound pressure level falls by 6 dB.

For installations comprising several gensets, the total noise level may be determined according to the laws of

acoustics:

L

Li

i

n

=

=

10 10

10

1

log

L

= total level L

i

= individual level

Exampl e:

L

= + + + +

= 10 10 10 10 10 10 811

705

10

715

10

72 5

10

755

10

77 0

10

log ,

, , , , ,

dB

L

1

= 70.5 dB L

2

= 71.5 dB L

3

= 72.5 dB

L

4

= 75.5 dB L

5

= 77.0 dB

Chapter_04 - Requirements for genset installation.docx Page 10 / 12 MWM GmbH 2012 / VD-S

In simplified terms, when adding n equal levels L, the following applies:

L L n

= +10log

When 2 equal sound levels are added, the level rises by 3 dB.

Where a gens et i s er ected i n a c losed r oom, t he noi se i s gr eater t han i n t he o pen a ir as a r esult of t he

impeded d ispersal of t he noise. I n s mall r ooms with no acoustic material, t he noi se d istribution i s equal

almost everywhere.

Large rooms with sound-absorbent walls offer acoustic benefits; tiles or similar construction materials should

be avoided.

4.3.2 Possibl e means of mitigating noise

Normal wall thicknesses of 24 cm or 36 cm damp the noise coming from within by 40 to 50 dB. Nevertheless,

silencer sections 2 to 3 m in length must be provided for the air inlet and exhaust ducts, with approx. 40 dB

noise reduction. Taking into account the volume of cooling air (see Chapter 5, Machine room ventilation), in

the silencer section, the air speed should not exceed approx. 8 m/s on the delivery side and approx. 6 m/s on

the extraction side.

If acoustic materials such as sound insulating panels are installed in the engine room, the noise level can be

reduced by approx. 3 dB, and indeed at considerable expense even by approx. 10 dB. Particular care should

be taken to control the exhaust noise. With suitable silencers, reductions in noise levels of up to approx. 60

dB can be achieved here.

Questions of sound insulation can only be solved on an individual basis, as they are highly dependent on

local c ircumstances. B y way of as sistance, t he producer pr ovides oc tave a nalyses of ex haust gas a nd

engine noises.

Sound insulation measures should be designed in collaboration with specialist firms.

Such measures might, for example, include :

Exhaust silencing with the aid of reflection silencers, absorption silencers, active sound

deadening

Erecting the genset so as to insulate against structure-borne noise

Arrangement of absorption baffles for the engine room air inlet and outlet apertures

Housing the genset inside a sound-insulating enclosure

Fitting the engine room with sound insulation and installing a floating floor (tasks for

specialist firms).

Chapter_04 - Requirements for genset installation.docx Page 11 / 12 MWM GmbH 2012 / VD-S

No f ibre materials ( e.g. Heraklit) may be used t o clad t he interior of t he r oom. Vibrations i n t he air cause

particles to be released which then block the air filters and can even destroy the engine.

When sound-proofing the building, it is necessary to consider not only the walls but also the windows, doors

and so on.

Technical sound-proofing considerations should al so extend t o additional sound sources such as auxiliary

drives or horizontal-type radiators which are located outside of the engine room. Also gas control lines, pre-

pressure control lines or zero-pressure control lines, which are installed outside the engine room or outside a

sound c apsule, c an r epresent an additional no ise s ource and m ust be c onsidered i n t he s ound t echnical

design.

Chapter_04 - Requirements for genset installation.docx Page 12 / 12 MWM GmbH 2012 / VD-S

MWM GmbH Carl-Benz-Strae 1 D-68167 Mannheim Phone: +49(0)621 384-0 Fax: +49(0)621 384-8612 www.mwm.net

Power plants layout

Chapter 5

Engine room ventilation

06-2012

Chapter_05 - Engine room ventilation.docx Page 2 / 16 MWM GmbH 2012 / VD-S

Contents

5. Engine room ventilation ............................................................................................................. 3

5.1 Ventilation systems ....................................................................................................................................... 4

5.1.1 Pressurised system (recommended) ............................................................................................................ 4

5.1.2 Extraction system (not recommended) ......................................................................................................... 4

5.1.3 Combined system (recommended) ............................................................................................................... 4

5.1.4 Ventilation by use of frequency-controlled ventilator fans ............................................................................. 5

5.1.5 Circulating air temperature control ................................................................................................................ 5

5.2 Determining the demand for air .................................................................................................................... 8

5.2.1 Combustion air requirement.......................................................................................................................... 8

5.2.2 Cooling air requirement for the engine and components .............................................................................. 8

5.3 Determining the radiation heat ...................................................................................................................... 9

5.3.1 Radiation from the engine ............................................................................................................................. 9

5.3.2 Radiation from the generator ........................................................................................................................ 9

5.3.3 Radiation from auxiliaries ........................................................................................................................... 10

5.3.4 Radiation from the heat recovery unit ......................................................................................................... 10

5.3.5 Total radiated heat ...................................................................................................................................... 10

5.3.6 Required ventilation air (excluding the combustion air for the engine) ........................................................ 11

5.4 Ventilation system components .................................................................................................................. 12

5.4.1 Weather protection grilles ........................................................................................................................... 13

5.4.2 Silencers ..................................................................................................................................................... 13

5.4.3 Louvres ....................................................................................................................................................... 14

5.4.4 Filters .......................................................................................................................................................... 14

5.4.5 Ventilators ................................................................................................................................................... 14

5.4.6 Air ducts ...................................................................................................................................................... 14

5.5 Planning notes ............................................................................................................................................ 15

5.5.1 Changes of air ............................................................................................................................................ 15

5.6 Notes on operating ventilation systems for gas engines ............................................................................. 15

Chapter_05 - Engine room ventilation.docx Page 3 / 16 MWM GmbH 2012 / VD-S

5. Engine room ventilation

An engine room is heated by convection and radiation from the engines, generators, heat recovery system

and pipework systems installed therein.

To avoid unacceptably high temperatures for the machinery, components and switchgear, this heat must be

dispersed with the aid of a ventilation system.

Also, for power plants operating in areas with extraordinary low ambient temperatures it must be taken care

that t he minimum c ombustion ai r temperatures as g iven p er t he g enset data sheet ar e k ept. F or t hose

applications it is recommended to utilise the radiation heat of the engine and its auxiliaries for the heating of

the e ngine r oom. I n t his case, t he engine r oom w alls m ust be t ight an d a thermal i solation s hould b e

provided.

In this respect, the design of the ventilation system is of particular importance; on the one hand, the removal

of the radiation heat in summer, and on the other hand, the utilisation of the radiation heat for engine room

heating in winter.

General note: Combusti on air temperatures (design and minimum temperatures) must be kept as

given per genset data sheets.

It must be assured that the combustion air temperature does not fall below the permitted starting

temperature. See also Chapter 9.2, requirements for the combustion air.

The kind of ventilation systems feasible for engine rooms may be divided into three types (see Fig. 5.1):

Chapter_05 - Engine room ventilation.docx Page 4 / 16 MWM GmbH 2012 / VD-S

5.1 Ventilation systems

5.1.1 Pressurised system (recommended)

Air at ambient t emperature i s dr awn i n f rom t he out side b y a f an, f orced t hrough t he eng ine r oom and

returned to the environment via exhaust vents. An overpressure prevails inside the engine room.

The use of this system is especially recommended in environments with a high dust content (desert regions,

etc.). The overpressure inside the engine room prevents dust from penetrating into the room through leaks in

the walls of t he b uilding o r t hrough op en doors or windows. T he v entilation s ystems must be f itted with

appropriate f ilters t o s eparate ou t t he d ust, e. g. i nertia c yclone f ilters, dr y t ype f ilters, et c. T he f iltration

efficiency of the applied filters for the ventilation system must be of the degree achieved by filters class G3.

See also Chapter 5.4.4.

5.1.2 Extraction system (not recommended)

Outside air is sucked into the engine room via the inlet air system (weather protection grille, filter, silencer

and l ouvre); i t t hen f lows through t he engine r oom before bei ng ex tracted b y a f an and r eturned t o t he

environment. Negative pressure prevails inside the engine room.

The extraction side of the ventilation system must be so designed that the negative pressure created in the

engine room is well below 1 mbar. If the negative pressure in the engine room is excessive, especially in the

case of gas engine plants which draw combustion air from inside the engine room, there can be difficulties

with starting (see al so Chapter 5.5, Notes on operating ventilation systems for gas engines). In addition, if

the negative pressure is excessive, it will be difficult to open the external doors of the engine room, which in

an emergency must serve as escape door s. The ventilation s ystem i s working l ike a bi g vacuum cleaner.

Secondary air will be sucked through leakages in the wall and the windows. In the course of time, this will

lead t o an increased pollution of t he eng ine r oom. T he filtration ef ficiency of t he app lied f ilters f or t he

ventilation system must be of the degree achieved by filters class G3. See also Chapter 5.4.4.

5.1.3 Combined system (recommended)

The ai r t o ventilate t he e ngine r oom i s bl own into t he en gine r oom b y an air inlet f an an d ex tracted b y

another f an on t he exhaust side. By suitably t uning t he i nlet and exhaust systems, t he ai r pr essure i n t he

engine room is approximately equal to the external ambient pressure.

This system must definitely be used for plants which exhibit significant pressure losses at both the inlet side

and the exhaust side. This is particularly the case where the air for the engine room must be drawn in and

discharged aga in o ver gr eat di stances and t he pr essure l oss i s c ompounded b y c omponents s uch as

weather protection grilles, sound-proofing baffles, louvres and filters.

Chapter_05 - Engine room ventilation.docx Page 5 / 16 MWM GmbH 2012 / VD-S

5.1.4 Ventilation by use of frequency-controll ed ventilator fans

When operating gas engines, the combustion air temperature must be kept in a comparable narrow range.

The minimum ai r t emperature i ndicated i n t he dat a s heet m ust not b e f allen bel ow, as ot herwise t he

compressor of the exhaust turbocharger will pump. Engines with exhaust wastegate permit a further area of

the intake air temperature.

While us ing an en gine r oom v entilator with c onstant speed an d d esign air f low f or s ummer c onditions, i t

might not be possible to keep the minimum combustion air temperature in wintertime. By adjustment of the

flow rate and use of the radiation heat of the generator, the combustion air temperature can be kept in the

design range. The control of the combustion air temperature is via adjustment of the fan speed depending on

changing am bient c onditions. T he c ontrol of t he c ombustion ai r t emperature j ust b y a djustment of t he

ventilator fan speed is only suitable for ambient temperatures above about 0C. For ambient temperatures

lower than 0C, a re-circulating air system must be provided.

5.1.5 Circul ating air temperature control

To av oid u nacceptably low t emperatures i n t he e ngine r oom, t he r oom t emperature c an be c ontrolled b y

mixing exhaust air in with the inlet air.

With all systems, the air flow must be so designed as to ensure that the air flows through the entire engine

room; there must be no short-circuit currents from the inlet aperture to the exhaust aperture, thus ensuring

that there is adequate air circulation around the heat-producing components. If necessary, air ducts must be

installed which provide an air flow specifically targeted at the individual components in the engine room.

In or der t o minimise t he r adiated h eat oc curring i n t he eng ine r oom and t hus t he v olume of ai r required,

silencers and engine exhaust pi pes i nside t he engine room must be insulated. I t i s generally necessary to

insulate exhaust systems inside buildings.

In many cases, the combustion air for the engines is drawn from the engine room. This additional volume of

air must be taken into consideration when designing the inlet fan. Dependent on the design of the plant, the

engine air filters could be located in areas in which the air has already undergone considerable heating. In

such cases, cold air must be conducted to the air filters via separate ventilation ducts.

Chapter_05 - Engine room ventilation.docx Page 6 / 16 MWM GmbH 2012 / VD-S

Fig. 5.1a Ventilation systems

Pressurised system

Extraction system (not recommended)

1 Inlet air

2 Outlet air

3 Weather protection grilles

4 Filters

5 Sound-proofing baffles

6 Inlet air ventilator

7 Inlet air louvre

8 Outlet air louvre

9 Outlet air ventilator

6 5 8 7 3 3

1

4 5

2

5 9 7 3 3

1

4 5

2

8

Chapter_05 - Engine room ventilation.docx Page 7 / 16 MWM GmbH 2012 / VD-S

Fig. 5.1b Fig. Ventil ation systems

System with circulating air temperature control (recommended)

Combined system (recommended)

1 Inlet air

2 Outlet air

3 Weather protection grilles

4 Filters

5 Sound-proofing baffles

6 Inlet air ventilator

7 Inlet air louvre

8 Outlet air louvre

9 Outlet air ventilator

10 Circulating air channel

11 Circulating air louvre

7 5 9 3 3

1

4 5

2

8

6

3

1

4 5 6 5 8

2

7 3

11 10

Chapter_05 - Engine room ventilation.docx Page 8 / 16 MWM GmbH 2012 / VD-S

5.2 Determining the demand for air

The r equired volume of ai r t o be determined i n or der t o design t he ventilation system i s composed of t he

following individual requirements:

5.2.1 Combustion air requi rement

If the combustion air is drawn from inside the engine room, it must be included in the layout of the ventilation

air s ystem for t he engi ne r oom. The combustion ai r t emperature is one of t he f actors which i nfluence t he

location-dependent output achievable by the engine. It must therefore be guaranteed that the air temperature

in the area of the intake neither exceeds nor falls short of the value established to determine the location-

dependent output.

5.2.2 Cooling air requi rement for the engine and components

The r adiation he at f rom t he en gine, t he g enerator a nd / or other c omponents i n t he e ngine r oom which

radiate heat, such as e.g. auxiliaries, including pumps, separators, boilers, etc must be di scharged via t he

engine room ventilation system.

Consumers s uch as e. g. c ompressors which operate on ly intermittently ar e likely t o b e ne glected when

determining the demand for air.

Chapter_05 - Engine room ventilation.docx Page 9 / 16 MWM GmbH 2012 / VD-S

5.3 Determining the radi ation heat

To determine the demand for air, the heat radiated from the engine and generator must be found out first.

5.3.1 Radiation from the engine

The heat levels radiated from the engine are always stated in the actual data sheets.

As a rough estimate, the radiated heat from a di esel engine may be assumed to be a percentage proportion

x of the thermal output of the fuel supplied to the engine:

QM [kW] engine heat radiation

PM [kW] mech. output of the engine

[%] mech. efficiency of the engine

x [%] radiated proportion in %

Generally, for the Diesel engines, the heat amount by radiation can be assumed by 3% of the total heat for

the TCD 2016 engines and 2.5% of the total heat for the TCD 2020 engines. The total heat can be calculated

as a product of specific fuel consumption, lower calorific value of the fuel and the mechanical output.

5.3.2 Radiation from the generator

The heat radiated from the generator is calculated via the following equation:

QG [kW] heat radiated from the generator

PG [kW] generator output

PM [kW] engine output

Chapter_05 - Engine room ventilation.docx Page 10 / 16 MWM GmbH 2012 / VD-S

5.3.3 Radiation from auxili ari es

The heat radiated from piping, especially exhaust pipes, exhaust silencers, radiators and pump sets can be

determined only with considerable effort. Experience indicates that this radiated heat equates to approx. 10

% of the heat radiated from the engine.

Q =0,1 Q

H M

QH [kW] heat radiated from auxiliaries

QM [kW] heat radiated from the engine

5.3.4 Radiation from the heat recovery unit

If components ar e i nstalled i n t he engine r oom t o use t he heat energy, f rom experience t he heat r adiated

from t he cooling water and exhaust gas heat exchangers will be approx. 1.5 % of the respective available

heat as per data sheet.

QWN [kW] heat radiated from the heat recovery unit

QKW [kW] engine cooling water heat

QAbg [kW] available engine exhaust gas heat

5.3.5 Total radiated heat

The total radiated heat QS is the sum of the above-mentioned proportions:

Depending on am bient c onditions, par t of t he r adiated hea t i s di ssipated v ia t he eng ine r oom walls. This

proportion c an be determined only with gr eat difficulty o wing t o variable c ircumstances s uch as e. g. t he

ambient temperature or the design of the engine room walls, and is therefore not taken into account.

Chapter_05 - Engine room ventilation.docx Page 11 / 16 MWM GmbH 2012 / VD-S

5.3.6 Required ventilation air (excluding the combustion air for the engine)

Finally, the required air is a function of the total radiated heat, the permissible rise in air temperature in the

engine room and the specific heat capacity of the air:

mLerf [kg/h] required air mass flow for cooling

QS [kW] total radiated heat

T [K] permissible rise in temperature

cpL [kJ/kgK] specific heat capacity of the air (1.005 kJ/kgK)

The abo ve eq uation pr ovides t he r equired air mass f low. T o d etermine t he necessary volume f low, t he

density of the air must be taken into account.

The density depends on the air temperature, the air pressure and the relative humidity. The required volume

flow is:

mLerf [kg/h] required air mass flow

VLerf [m/h] required air volume flow

L [kg/m] air density (e.g. 1.172 kg/m at 1002 mbar and 25C)

The air pressure reduces as altitude above sea level increases. The following table indicates pressures and

densities depending on temperature and altitude above sea level.

The specified values apply to dry air. With moist air, the density falls as relative humidity rises. At a relative

humidity of 60 % the drop in density can be up to 10 %..

Chapter_05 - Engine room ventilation.docx Page 12 / 16 MWM GmbH 2012 / VD-S

Table 5.2

Al titude above sea level-dependent air pressure and air density at 25C

Geodetic

height

Temperature

Geodetic

height

Temperature

Geodetic

height

Temperature

in m 25 C in m 25 C in m 25 C

mbar kg/m mbar kg/m mbar kg/m

0 1013 1.184 700 940 1.099 1800 835 0.976

100 1002 1.172 800 930 1.087 2000 817 0.955

200 991 1.159 900 920 1.075 2200 800 0.935

300 981 1.147 1000 910 1.064 2400 783 0.915

400 970 1.135 1200 890 1.041 2600 766 0.896

500 960 1.122 1400 871 1.019 2800 750 0.877

600 950 1.11 1600 853 0.997 3000 734 0.858

The densities can be converted for other temperatures by applying the following equation:

t) + (273

25) + (273

* C) (25 = (t) L L

L(25C)[kg/m] air density at 25C

L(t) [kg/m] air density at temperature t

t [C] air temperature

In the c ase of pl ants which ex tract ai r f rom t he e ngine r oom, on t he i nlet side t he qu antity of ai r f or

combustion must also be taken into account. Chapter 9.2 contains guide values for the specific combustion

air volume required for the individual engine models.

5.4 Ventilation system components

The principal components of an engine room ventilation system are the weather protection grills, silencers,

louvres, filters, air ducts and fans.

Chapter_05 - Engine room ventilation.docx Page 13 / 16 MWM GmbH 2012 / VD-S

5.4.1 Weather protection grill es

Weather protection grilles are installed on the outside wall of the engine room at both the air inlet and the

outlet. They prevent r ain and s now f rom ent ering i nto t he ventilation s ystem. A bi rd s creen must al so be

integrated into the weather protection grille to stop small insects, etc., from entering the plant.

5.4.2 Silencers

Especially when pl ants ar e i nstalled in r esidential a reas or ar eas with r estricted no ise levels, s ignificant