Documente Academic

Documente Profesional

Documente Cultură

Mixed-Mode Fatigue Crack Propagation in Thin

Încărcat de

Omar Alejandro SalazarDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mixed-Mode Fatigue Crack Propagation in Thin

Încărcat de

Omar Alejandro SalazarDrepturi de autor:

Formate disponibile

The Journal of Strain Analysis for Engineering Design http://sdj.sagepub.

com/

Mixed-mode fatigue crack propagation in thin T-sections under plane stress

A. R Gowhari-Anaraki, S J Hardy and R Adibi-Asl The Journal of Strain Analysis for Engineering Design 2003 38: 557 DOI: 10.1243/030932403770735917 The online version of this article can be found at: http://sdj.sagepub.com/content/38/6/557

Published by:

http://www.sagepublications.com

On behalf of:

Institution of Mechanical Engineers

Additional services and information for The Journal of Strain Analysis for Engineering Design can be found at: Email Alerts: http://sdj.sagepub.com/cgi/alerts Subscriptions: http://sdj.sagepub.com/subscriptions Reprints: http://www.sagepub.com/journalsReprints.nav Permissions: http://www.sagepub.com/journalsPermissions.nav Citations: http://sdj.sagepub.com/content/38/6/557.refs.html

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:12am

Page 557 of 576

557

Mixed-mode fatigue crack propagation in thin T-sections under plane stress

A R Gowhari-Anaraki1 , S J Hardy2 * and R Adibi-Asl3 1 Department of Mechanical Engineering, Iran University of Science and Technology, Tehran, Iran 2 School of Engineering, University of Wales, Swansea, UK 3 Department of Mechanical Engineering, University of Tehran, Iran

Abstract: Data that can be used in the fatigue analysis of at T-section bars subjected to axial loading and local restraint are presented. The paper describes how nite element analysis has been used to obtain stress elds in the vicinity of a crack or crack-like aw introduced into the llet (i.e. high-stress) region of the component. The effect of both the position and inclination of the crack has been investigated. The inclination of the crack to the transverse direction is varied in such a way that a combination of mode I (tension opening) and mode II (in-plane shear) crack tip conditions are created in the component when subjected to axial loading which is applied to the entire at shoulder of the projection. Linear elastic fracture mechanics nite element analyses have been performed, and the results are presented in the form of J integrals and notch and crack conguration factors for a wide range of component and crack geometric parameters. These parameters are chosen to be representative of typical practical situations and have been determined from evidence presented in the open literature. The extensive range of notch and crack conguration factors obtained from the analyses are then used to obtain equivalent prediction equations using a statistical multiple non-linear regression model. The accuracy of this model is measured using a multiple coefcient of determination, R2 , where 0 < R2 < 1. This coefcient is found to be greater than or equal to 0.98 for all cases considered in this study, demonstrating the quality of the model t to the data. Predictive equations for stress intensity factors and J-integral values, which are based on the elastic stress concentration factor, are also developed. A crack propagation methodology, based on existing theory coupled with these predictive equations, is then presented for this type of component and loading. Keywords: mixed mode, fatigue, loaded projections, conguration factors, crack initiation and propagation

NOTATION a ac a0 b c0 d E F Fc F c,e crack length critical crack length initial crack length shoulder width constant 3 4n for plane stress and 3 n1 n for plane strain plate width Youngs modulus geometrycrack conguration factor crack conguration factor effective crack conguration factor

The MS was received on 9 May 2003 and was accepted after revision for publication on 5 August 2003. * Corresponding author: School of Engineering, University of Wales, Singleton Park, Swansea SA2 8PP, Wales, UK.

S03603 # IMechE 2003

F c,I F c,II Fn G h J JIc Jm ax Jth J45 k0 Keff Kt Ktm KI KII L n0

mode I crack conguration factor mode II crack conguration factor notch conguration factor shear modulus projection length J-integral value critical J-integral value maximum J-integral value threshold J-integral value J-integral value for a crack angle of 458 cyclic strength coefcient effective stress intensity factor elastic stress concentration factor total mixed-mode stress intensity factor mode I stress intensity factor mode II stress intensity factor plate length strain hardening exponent

J. Strain Analysis Vol. 38 No. 6

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 558 of 576

558

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

Ni Np Nt P Q r r, y R2 t Tk w W x, y x0 , y0 a b D u, D v De D e0 Ds D s0 e0f yc n sx, y s0 s0f txy j

initiation fatigue life propagation fatigue life total fatigue life uniform pressure vectors llet (notch) radius polar coordinates associated with the crack tip multiple coefcient of determination component thickness traction vector projection width strain energy density crack coordinate system global coordinate system crack angle material constant relative displacement of points along opposite sides of the crack face strain range at the notch nominal (axial) strain range stress range at the notch nominal stress range fatigue ductility coefcient crack growth direction Poissons ratio directional stresses nominal (axial) stress fatigue strength coefcient shear stress position around the llet

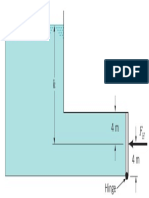

Fig. 1

Typical stepped at bar geometries

INTRODUCTION

Projections on plates, bars and tubes are often used as a means of transmitting axial load between two components, e.g. T-shaped at bars, shouldered plates/shafts/ tubes, wide grooves, lleted transitions and many other geometric shapes with similar stress concentration features (see examples in Fig. 1). For remote loading conditions, the point of application of the load is usually far removed from the region of stress concentration (see Fig. 2a) and does not inuence that local stress eld. However, when the load or the reaction of the loading is applied at or near to the region of high stress gradient, such as for these `loaded projections, the stress intensity factors can be signicantly higher than for the equivalent remote loading case (see Fig. 2b). This is because there is both a tensile component and a bending component of load at the projection, as illustrated in Fig. 2c.

J. Strain Analysis Vol. 38 No. 6

Fig. 2

Typical example of a loaded projection and remote loading

Fatigue failure is a major consideration in mechanical design. Nearly all fatigue failures initiate at stress concentration features, i.e. at the point of highest stress under cyclic or repeated loading conditions. In general, the initial crack (or any crack-like aw, void, defect, etc.) will develop in three stages, as presented in reference [1], namely initiation, propagation and fracture. Crack initiation is analysed at the microscopic level, while for crack propagation the continuum mechanics approach based on a macroscopic scale is used. Paris [2] showed that the stress intensity factor and

S03603 # IMechE 2003

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 559 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

559

J-integral are very important controlling factors in the fatigue crack growth of cracked components. In order to predict the strength of the cracked component, the crack growth rate and the critical crack size, an accurate value for stress intensity factor along the crack front has to be known. Many experimental, numerical and analytical solutions for the three basic stress intensity factors Ki (i I, II, III) have been deduced for varying crack sizes for relatively simplistic structures with basic loading conditions. Paris and Sih [3] present a comprehensive handbook of such results. In spite of wide-ranging applications of loaded projections, relatively very little information on the resulting stress intensity factors is available and, for the more realistic complex shapes encountered in practice, further general data are still required. Part of the reason for this lack of systematic information is due to difculties involved in obtaining analytical solutions. Whereas the stress intensity factor in a remotely loaded cracked component is controlled by the notch radius, r, projection length, t, crack length, a, and the remotely applied load, P, as shown in Fig. 2a, for cracked components with loaded projections the projection length, h, and the combined effect of tensile and bending loading also affect the stress intensity factor, as illustrated in Figs 2b and c. For the equivalent remote loading case, however, crack tip stress elds have previously been studied, and data on elastic stress intensity factors are readily available (e.g. reference [4]). Also, the crack tip stress solution for anked notches can be found in reference [5], for example. In the present paper, nite element analysis is used to predict stress intensity factors for an external inclined crack in a stepped at plate under complex projectionloaded conditions, as shown in Fig. 3. This geometry contains a stress concentration feature in the llet,

exacerbated by the projection loading, which is an obvious source of crack initiation and propagation under fatigue loading conditions. Modes I and II and mixed-mode conditions are created by varying the inclination of the crack, a, in the range 0908, and stress intensity factors and J-integral values are presented for these modes under linear elastic conditions. The results of the parametric survey are then used to develop predictive equations that enable the notch and crack conguration factors to be determined for the range of geometric parameters considered in this study. These results are then used to obtain predictive equations for stress intensity factor and J-integral values that are based on the elastic stress concentration factor for the geometry being considered. Thus, a direct link is provided between the notch parameter (which can be easily determined either from the predictive equations presented here or via elastic nite element analysis) and crack parameters, which normally require the use of complicated linear elastic fracture mechanics analysis. A methodology for determining fatigue life of components with loaded projections is described that is based on established theory coupled with these predictive equations.

GEOMETRY, LOADING AND BOUNDARY CONDITIONS

Four dimensions are used to dene the geometry, as shown in Fig. 3. They are the projection length, h, the projection width, w, the plate width, d, and the llet radius, r. Three non-dimensional parameters are formed by normalizing with respect to the plate width, d, i.e. h=d , w=d and r=d .

Fig. 3

S03603 # IMechE 2003

Component geometry and loading

J. Strain Analysis Vol. 38 No. 6

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 560 of 576

560

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

The range of dimensions selected for the parametric study is consistent with the geometric cases covered by Engineering Sciences Data Unit (ESDU) data item 69020 [6], and is considered to present a range of practical interest. The selected ranges are h 50:5 d w 3 5 51:5 d r 0:2 5 50:05 d 35 The plate length, L, is made long enough to ensure that uniform stress conditions are achieved away from the llet. A plane stress assumption (i.e. thin plate) is made for all geometries considered. The loading condition consists of a remotely applied axial stress, s0 , reacted by a uniform pressure, P, across the entire at section of the shoulder as shown in Fig. 3. The at section of the shoulder has a width, b, where b1 w d r 2 and the nominal stress in the plate is given by s0 w 2Pb r P 2 1 d d d 2 1

conditions is created, i.e. 0 4 a 4 90 . A range of crack lengths, a, is considered on the basis of the observations of surface cracks in fractured standard NDT (nondestructive testing) test specimens [7], i.e. a 0.5 2.5 mm. Many engineering components contain, or are assumed to contain, such cracks for life assessment purposes at the design stage. Such cracks may grow owing to fatigue, corrosion, creep, etc.

FINITE ELEMENT ANALYSIS OF THE CRACKED COMPONENTS

An edge through-crack or crack-like external aw is assumed to emanate from the high-stress region around the llet. It was found [1] that the maximum total mixedmode stress intensity factor, as well as the maximum Jintegral value, corresponded to a crack emanating from a point around the llet located at j 25 from the plate/llet intersection (see Fig. 3). The inclination of the crack to the transverse direction, a, is selected in such a way that a combination of mode I and mode II crack tip

Finite element predictions have been obtained using the standard linear elastic fracture mechanics facilities within the ANSYS suite of programs [8]. Six- and eight-noded, reduced integration, plane stress, triangular and quadrilateral elements were used with the crack tip singularity represented by moving nodes to the quarter-point positions [8]. A typical nite element mesh is shown in Fig. 4. In preliminary work, solutions were obtained with and without crack tip elements. The results indicated that large discrepancies (*15 per cent) in the predicted stress intensity factors were obtained if crack tip elements were not used. The results presented in this paper were therefore obtained using crack tip elements. The results of a preliminary nite element analysis under remote loading conditions were compared with results obtained by Gray et al. [9]. This comparison conrmed that the level of mesh renement and crack tip elements used in the current study would provide accuracy to within +2 per cent. Values for Youngs modulus and Poissons ratio of 209 GPa and 0.3 respectively have been used throughout the analysis.

Fig. 4

J. Strain Analysis Vol. 38 No. 6

Typical nite element mesh

S03603 # IMechE 2003

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 561 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

561

4 4.1

RESULTS J-integral values based on numerically determined stresses and displacements

Expressions for KI and KII can be obtained in terms of the nodal stresses ahead of the crack tip (i.e. sy and txy ), i.e. p KI lim sy 2pr r! 0 p KII lim txy 2pr

r!0

3 4

Similarly, expressions for KI and KII in terms of the relative displacement of points, on opposite faces of the crack, along the line of the crack, Du, and perpendicular to it, Dv, are r ! E 2p KI lim Du r! 0 8 r r ! E 2p KII lim Dv r!0 8 r 5 6

Fig. 5

Stresses and coordinate systems in the vicinity of a crack

the stress y 0) and displacement y +180 results, rather than use predictions at the crack tip. The elastic J-integral value is then calculated by substituting KI and KII values into the following equations for plane stress (i.e. thin plate) conditions [10]: J p

2 KI2 KII E q

These stress components and relative displacements are dened with respect to the coordinate system attached to the crack tip, as shown in Fig. 5. A typical plot of KI and KII is shown in Fig. 6 for a typical geometry (i.e. h/d 0.5, w/d 3, r/d 0.05, a 0 and crack length a 0.5 mm) with a crack position around the llet, j, of 258 (for reasons discussed later in this section). KI and KII values have been extrapolated to r 0 for each of

7 8

JE

2 K KI2 KII tm

where Ktm is referred to here as the total mixed-mode stress intensity factor.

Fig. 6

Typical nite element results based on stress and displacement extrapolation for h=d 0:5, w=d 3 and r=d 0:05 with a 0 , a 0:5 mm and P 100 MPa

Downloaded from sdj.sagepub.com by guest on May 21, 2011

S03603 # IMechE 2003

J. Strain Analysis Vol. 38 No. 6

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 562 of 576

562

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

It is very important not to confuse Ktm with the effective stress intensity factor, Keff, where, for this component, the effective stress intensity factor can be roughly dened as q 2 Keff KI2 bKII 9 where b is a material constant, which reects the sensitivity of the material to mode II. Further work on the calculation of the b parameter and the validation of equation (9) is in progress and will be reported at a later date. The variations of KI , KII and J-integral values [from equation (7)] around the llet are shown in Fig. 7 for the same typical geometry as Fig. 6. Although the crack is always perpendicular to the loading, the results show that both mode I and mode II contributions are present. This is due to the shear effect caused by the applied pressure loading in the llet region of the component. For all the geometries considered, it was found that the magnitude of the crack stress intensity factors varied considerably with both j and a, and the maximum value of KI occurred for a crack emanating from the position j&25 from the plate/projection intersection (see Fig. 3). It was also found that the maximum value of KII corresponded to j&50 . The maximum J-integral value occurred for a crack originating from j 308, but the value at j 258 is very close to the maximum. Also, the maximum meridional (i.e. surface) stress is found to occur at an angle j&25 (see section 4.3.1). Therefore, all the remaining results in this paper are for an edge

angle crack (with crack angle 0 4 a 4 90 ) originating from j 25 .

4.2

J-integral values based on the virtual crack extension method

It is recognized by the present authors that the method of calculation described in section 4.1, based on extrapolation, is not necessarily very accurate and that, to obtain reliable results, a highly rened mesh and tests to verify the mesh are necessary. In order to validate the predictions based on this method, J-integral values have also been obtained using a numerical procedure based on the virtual crack extension method (VCEM). This method only requires rather coarse meshes in order to obtain good results. In this section, elastic J-integral values have been derived by means of VCEM, as follows: quk J W dy T k d s, k 1, 2 10 qx G The VCEM procedure incorporated in the ANSYS nite element program [8] has been used to evaluate the J integrals. This evaluation was supported by a macro program, written by the authors, using ANSYS parametric design language (APDL). This program can conveniently be used as part of a post-processing program and uses stress and displacement data from a linear elastic fracture mechanics analysis to calculate the

Fig. 7

Variation in KI , KII and J integral with position around the llet for h=d 0:5, w=d 3 and r=d 0:05 with a 0 , a 0:5 mm and P 100 MPa

Downloaded from sdj.sagepub.com by guest on May 21, 2011

J. Strain Analysis Vol. 38 No. 6

S03603 # IMechE 2003

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 563 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

563

in section 4.1 has benets since it does not require the generation of a macro-program.

4.3

Notch and crack conguration factors

Notch and crack conguration factors are very important tools for fatigue crack initiation and fatigue crack propagation life predictions respectively. Information on stress intensity factors for anked notched components under simple loading conditions, e.g. remote loading, is readily available [11, 12]. Such data, however, are not available for loaded projections, and in this section simple parametric equations are presented to assist in the design life assessment of thin T-section plates, which eliminates the need for complex calculations of notch and crack conguration factors.

Fig. 8 J-integral contour paths

4.3.1 Notch conguration factors J-integral values. This procedure was carried out for four separate contours around the crack tip, which are shown in Fig. 8 for a typical geometry. Contour 1 is around the outside of the mesh, and contours 2 to 4 encircle the crack with progressively smaller enclosed areas. All contour integrals generally showed good path independence, as illustrated in Table 1 where the J values are normalized with respect to the value for the outermost contour 1. The only case that exceeds a 1 per cent deviation is the innermost contour, contour 4. Consequently, the values for contour 1 were used throughout this study. Table 2 shows a comparison of J values obtained by means of the numerically determined stresses with those calculated using VCEM, for a range of w/d values. It is seen that the agreement between the two approaches is very good, and this suggests that the method described

Table 1 Normalized J integrals for typical contour paths

1 1 2 0.998 3 0.992 4 0.974

The notch conguration factor (e.g. elastic stress concentration factor) is dened as a geometric correction factor, F n , which is a function of three nondimensional parameters, h/d, w/d and r/d, as follows: h w r Fn f Kt 11 , , d d d The elastic stress concentration factors, Kt, have been obtained by dividing the predicted maximum local elastic stress in the llet region by the nominal stress, s0 , from equation (2). For all geometries considered, the maximum stress was in the meridional direction and generally close to the intersection between the plate and the llet radius, where the J integral had a maximum value (i.e. j&25 ). Using these Kt values, useful prediction equations for F n have been derived, based on the denition in equation (11) and using a statistical multiple non-linear regression model [13], as follows: F n Kt 0:91h=d 2:11 0:26w=d 1:44 0:57r=d 0:92 0:14 h=d 1:68 w=d 0:25 r=d 0:49 12 The accuracy of this equation has been assessed using a multiple coefcient of determination [13], R2 , where 0 4 R2 4 1. This coefcient was found to be approximately 0.98, which demonstrates the accuracy of model t to the data. The values of Fn that are obtained from equation (12) compare favourably with direct nite element predictions for some typical geometries, as shown in Fig. 9. It can also be seen that they are very close (within 2 per cent) to experimental results from reference [14].

J. Strain Analysis Vol. 38 No. 6

Contour Normalized J

Table 2

Comparison of J-integral values obtained from stresses and VCEM for h/d 0.5, r/d 0.2, a 0.5 mm and a 408

J integral (N/mm)

w /d 1.9 2.3 2.7 3.0

S03603 # IMechE 2003

From stresses 0.97 4.37 12.20 22.47

VCEM 0.95 4.51 11.96 22.34

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 564 of 576

564

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

Fig. 9

Variation in notch conguration factor with w/d for h=d 0:5 and r=d 0:05

4.3.2

Crack conguration factors

The stress intensity factor KN (where N I, II and corresponds to the mode I and mode II stress elds) is usually written as p K N Fc s p a 13

where Fc is the crack conguration factor, which accounts for such things as proximity effects of boundaries, orientation of the crack, shape of the crack and the restraints on the structure containing the crack. It is with the determination of this geometrical crack conguration factor that fatigue crack growth analysis methods are concerned in the three stages of failure, namely initiation, propagation and fracture. The analysis of fatigue crack growth from its initial dimensions to its nal critical stages requires the accurate calculation of the instantaneous crack conguration factor. For the purpose of the initiation stage analysis of the shouldered plate with an axially loaded symmetrical projection, an initial angle crack (or crack-like external aw) emanating from a critical point along the llet radius (i.e. a point with a maximum J-integral value at j 25 as shown in Fig. 3) was assumed. The inclination of this initial crack to the transverse direction, a, was varied in the range 0 to 908, in such a way that mixed-mode KI and KII crack tip conditions were created. This kind of initial crack or crack-like aw can be created practically under strain cycle fatigue conditions or be introduced during manufacturing and assembly processes, or are inherent in the basic metal. Unfortunately, estimating this initial crack size involves non-destructive crack detection and sizing or proof testing, which is a very complicated engineering problem

J. Strain Analysis Vol. 38 No. 6

and beyond the scope of this paper. However, the denition of an initial crack has been the subject of much controversy. Unfortunately, no satisfactory solution to this problem exists. Fatigue cracks start with dislocation movement on the rst load cycle and end with fracture on the last. Crack initiation lies somewhere between the two. For the purposes of strain cycle fatigue analysis, crack initiation is dened as a crack in the structure or component that is the same size as the cracks observed in the strain cycle fatigue specimen. Frequently, this is the specimen radius, which is of the order of 2.5 mm [15]. Dowling [16] proposed that strain cycle fatigue data should be presented in terms of the number of cycles required to reach a crack of xed length. He found that, for steels with fatigue lives below the transition fatigue life, cracks 0.25 mm long were formed at approximately 50 per cent of the life required for specimen separation. For smooth specimens with longer lives, where the bulk behaviour of the material is primarily elastic, the rst crack is observed just prior to specimen fracture. Therefore, for design purposes, crack initiation is dened as the formation of cracks between 0.25 and 2.5 mm long. It should be noted that the cyclic behaviour of small cracks (less than 0.25 mm) is different to that of long cracks under equal stress intensities [17]. As a result, the analysis described in this study does not apply to these very small cracks. However, in this part of the present study, a reasonable initial crack length, a 0.52.5 mm, was assumed throughout the analysis. These crack sizes, which are easily seen at 610 to 620 magnication, can be related to engineering dimensions and can represent a small microcrack. Using the methodology described in section 4.1, mode I and mode II stress intensity factors (KI , KII ) have been obtained from the nite element predictions for more

S03603 # IMechE 2003

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 565 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

565

Fig. 10

Variation in KI and KII with crack angle for h=d 0:5, w =d 1:5 and 3 and r=d 0:05 with a 0:5 mm and P 100 MPa

than 2000 combinations of crack length (a 0.5 2.5 mm), crack angle (a 0908) and different component geometries h=d , w=d , r=d , as dened in section 2). As an example, the variation in KI and KII with crack angle is presented in Figs 10 to 12 for a range of geometric parameters and a crack length of 0.5 mm. In all cases, j 258. The lled-in symbols in Figs 10 to 12 are for the same geometric parameters and enable direct comparison

between the three gures. A number of signicant features can be identied: 1. For all geometries considered in this study, the mode I stress intensity factor becomes equal to the mode II stress intensity factor (i.e. KI KII ) when the crack angle is 458. According to equation (7), this means that the J integral also reaches a maximum when the crack angle a 45 .

Fig. 11

S03603 # IMechE 2003

Variation in KI and KII with crack angle for h=d 0:5 and 3, w=d 3 and r=d 0:05 with a 0:5 mm and P 100 MPa

Downloaded from sdj.sagepub.com by guest on May 21, 2011

J. Strain Analysis Vol. 38 No. 6

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 566 of 576

566

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

Fig. 12

Variation in KI and KII with crack angle for h=d 0:5, w=d 3 and r=d 0:05 and 0.2 with a 0:5 mm and P 100 MPa

2. The crack angle a 45 was observed to coincide with the direction of the perpendicular to the maximum principal stress at the critical point in the llet (i.e. j 25 , the origin for the worst crack). 3. For all geometries considered, the maximum mode I stress intensity factor, KI , occurs at the crack angle a&30 , whereas the maximum mode II stress intensity factor, KII , occurs at a&60 . 4. For all geometries considered, the mode II stress intensity factor at crack angle a is equal to the mode I stress intensity factor at crack angle 90 a. 5. For all geometries, the ratio KI /KII is greater than unity (mode I dominant) when the crack angle is less

than 458 and less than unity (mode II dominant) when the crack angle is greater than 458. 6. The ratios KI /KII 0 and ?, which correspond to pure mode I and mode II conditions respectively, are not observed at either a 0 or 908, as might be expected for simple axial loading. This is due to the additional shear effect of the applied pressure loading in the llet region of the components. 7. The difference between KI and KII decreases, for any crack angle, as the component elastic stress concentration factor decreases. 8. The variation in KI /KII with respect to crack angle is plotted in Fig. 13 for two typical geometries, e.g.

Fig. 13

Variation in KI =KII with crack angle for h=d 0:5, w=d 1:5 and 3 and r=d 0:05 with a 0:5 mm and P 100 MPa

Downloaded from sdj.sagepub.com by guest on May 21, 2011

J. Strain Analysis Vol. 38 No. 6

S03603 # IMechE 2003

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 567 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

567

h/d 0.5, r/d 0.05 and w/d 1.5 and 3. The results show that this ratio is w/d independent and is only crack angle dependent. This ratio can be expressed as KI =KII paq 14

where the constants p and q can be easily calculated from Fig. 13, using suitable boundary conditions. 9. KI and KII vary considerably with w/d (greatest variation), h/d and r/d (least variation) for the range of geometric parameters considered. This information is clearly important from a design viewpoint. KI and KII increase with increasing w/d. This is because an increase in the projection width and hence the radial width of the at section of the shoulder (over which the loading is applied) produces an increase in the bending component of load, as well as an increase in the nominal stress. It is also seen that KI and KII decrease with increasing h/d. This is because an increase in the projection length produces an increase in the bending resistance of the projection section (or an increase in section modulus of the projection) and hence provides extra constraints to bending. It is also observed that KI and KII increase with decreasing r/d, i.e. because of an increase in the elastic stress concentration factor. Using the KI and KII values obtained from the nite element predictions, J-integral values have been obtained using equation (7). The variation in the J integral with respect to crack angle for some typical geometries (e.g. h/d 0.5, r/d 0.05 and w/d 1.5 and 3) are presented in Fig. 14 for two crack lengths of 0.5 and 2.5 mm. It is observed that the maximum J-integral value occurs at a crack angle of a 45 for all

component geometries and all crack lengths considered in this study. Mode I and mode II stress intensity factor predictions for an extensive range of geometric parameters (e.g. h=d , r=d , w=d ), crack angles and crack lengths have been used to obtain useful prediction equations, using statistical multiple non-linear regression [13], in the following form: p KIa Fc,I s0 pa p KIIa F c,II s0 pa 15 16

F c,I and Fc,II are crack conguration factors corresponding to mode I and mode II situations respectively and are dened as

p a 0:669 0:041 0:021 sin 90 h 0:015 w 0:008 r 0:23 a 1:24 0:71 0:7 0:02 0:4 d d d d

Fc,I

17

Fc,II a Fc,I 90a

18

The accuracy of equation (17) has been measured by means of a multiple coefcient of determination, R2 , where 0 4 R2 4 1. This coefcient was found to be *0.98, which suggests a high level of accuracy of t between the prediction equation and the nite element data. By substituting equations (15) and (16) into equation (8), an effective crack conguration factor, corresponding to mixed-mode situations, is dened as below. This effective crack conguration factor is referred to as F c,e,

Fig. 14

Variation in the J integral with crack angle for h=d 0:5, w=d 1:5 and 3 and r=d 0:05 with a 0:5 and 2.5 mm and P 100 MPa

Downloaded from sdj.sagepub.com by guest on May 21, 2011

S03603 # IMechE 2003

J. Strain Analysis Vol. 38 No. 6

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 568 of 576

568

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

Fig. 15

Variation in effective crack conguration factor with crack angle for h=d 0:5, w=d 3 and r=d 0:05 with a 0:5 and 2.5 mm and P 100 MPa

where p and q Fc,e Fc, I 2 Fc, II 2 20 p JE Fc,e s0 pa 19

component and crack geometries, i.e.

KI 3:25 0:54 h p i 0:07KI p a 0:6 2:23 0:55 sin s0 pa 90 0:013 0 : 1 0:54 0:11 h w r a 0:017 0:15 d d d d 21

It is worth noting that the maximum J value can be calculated by substituting a 45 in equations (15) to (20), i.e. Jmax J45 . The J value provides an important controlling parameter in the fatigue crack propagation process under small-scale yielding conditions. Estimated values of Fc,e , calculated using equations (15) to (20), are plotted in Fig. 15 for a typical geometry h=d 0:5, w=d 3, r=d 0:05 and crack initiation lengths of 0.5 and 2.5 mm. The nite element predictions of Fc,e are also plotted in Fig. 15. It can be seen that, for both crack lengths, there is good agreement between the two sets of data (i.e. within 2 per cent).

and KII a KI 90a 22

The accuracy of equation (21) has been assessed using a multiple coefcient of determination [13], R2 , where 0 4 R2 4 1. This coefcient was found to be 0.985 in this case, which demonstrates the accuracy of the model t to the nite element data. Equations (21) and (22) can be used for any similar shaped component and crack geometries within the range 35 h 5 0:5 d w 3 5 5 1:5 d r 0:2 5 5 0:05 d 0:5 5 a 5 2:5 mm

5 5.1

PREDICTION EQUATIONS BASED ON Kt Stress intensity factors

The nite element predictions of the elastic stress concentration factor, Kt, and the mode I and mode II stress intensity factors, KI and KII respectively, have been used to develop useful analytical equations, based on the statistical multiple non-linear regression model [13], which can estimate KI and KII , knowing the

J. Strain Analysis Vol. 38 No. 6

0 5 a 5 90 The variation in KI , calculated using equation (21) and directly from the nite element predictions, with respect to crack angle is shown in Fig. 16 for a typical geometry h=d 0:5, w=d 3, r=d 0:05 and crack initiation

S03603 # IMechE 2003

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 569 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

569

Fig. 16

Variation in KI with crack angle for h=d 0:5, w=d 3 and r=d 0:05 with a 0:5 and 2.5 mm and P 100 MPa

lengths, a, of 0.5 and 2.5 mm. It can be seen that, in both cases, there is very good agreement between the two approaches (within a maximum of 2 per cent).

for Jm ax , i.e. R2 0.986, is presented: Jmax 0:41 36:9 s0 a w 0:75 r 0:17 a 0:068 d d d

Kt

h d

0:013

24

5.2

J-integral values

In a similar way, J-integral values obtained from the nite element analyses, for an extensive range of component and crack geometries, have been used to obtain useful equivalent prediction equations based on elastic stress concentration factor, using the statistical multiple non-linear regression method for the same range of parameters: 5:79 Kt J 0:41 7:79 1:79 sin s0 a h 0:017 w 0:79 r 0:15 d d d p a + 0:013 90 a 0:057 d 23 where the negative sign in the last numerator bracket is used for 45 5 a 5 0 and the positive sign is used for 90 5 a 5 45 . In this case, the multiple coefcient of determination, R2 , is 0.95, which is more than adequate at the preliminary design stage. It has been seen that the maximum J-integral values, Jm ax , which are an important controlling parameter in fatigue crack propagation analysis, occurred at a crack angle of a 45 . Therefore, an alternative, more accurate, predictive equation

S03603 # IMechE 2003

The variation in Jmax , obtained from equation (24) and directly from the nite element results, with respect to crack length is plotted in Fig. 17 for typical geometries h/d 0.5, w/d 1.5 and 3 and r/d 0.05. It can again be seen that in both cases there is very good agreement between the two methods (within 2 per cent). For engineering design purposes, an estimation of the stress intensity factors corresponding to mode I and/or mode II dominant situations is sometimes demanded. For example, it has been suggested [18] that, for some components, mode II has a larger contribution to fatigue crack growth than mode I or mixed-mode Jintegral values. It has been shown earlier that crack angles of 30 and 608 are considered to be representative of the highly dominant mode I and mode II loading conditions, respectively, for all geometries considered. Therefore, prediction equations are also presented for these highly dominant modes. For a 30 or 60 , J 0:41 37:99 s0a w 0:79 r 0:16 a 0:066 d d d

Kt

h d

0:013

25

A similar equation has been derived for J-integral

J. Strain Analysis Vol. 38 No. 6

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 570 of 576

570

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

Fig. 17

Variation in Jmax with crack length for h=d 0:5, w =d 1:5 and 3 and r=d 0:05 with P 100 MPa

predictions when a 0 or 908: J 0:41 44:88 s0 a 0:8 w r 0:132 a 0:037 d d d

F becomes h d 0:013 w d 0:79 r d 37:99 0:16 a d 0:066 29

Kt

h d

0:011

26

The accuracy of equations (25) and (26) is demonstrated by a multiple coefcient of determination, R2 0.99. The J-integral values predicted from these equations are more accurate than those obtained by substituting a 0, 30, 60 and 908 into equation (23). Equations (23) to (26) can be approximated in the following general form by replacing the exponent 0.41 with 0.5: p p J FKt s0 a 27

APPLICATION OF RESULTS TO CRACK INITIATION AND PROPAGATION

where F is a `geometrycrack conguration factor and is a function of h/d, w/d, r/d and a. By substituting equation (12) into equation (27), an alternative general equation for calculating the J-integral values can be written as

h 0:91 d 2:11 w 1:44 r 0:92 0:26 0:57 0:14 d d 1:68 0:25 0:49 h w r d d d 28

p 6F s0 a

where F can be dened, using equation (27) together with equations (23), (24), (25) or (26). For example, when using equation (25) for a crack angle of 30 or 608,

J. Strain Analysis Vol. 38 No. 6

Traditionally, fatigue analysis is separated into two parts, initiation and crack propagation. The initiation portion of fatigue life consists of crack nucleation caused by repeated plastic shear straining and a period of crystallographically oriented crack growth. Propagation consists of slow stable crack growth followed by rapid unstable crack growth to nal fracture. Initiation may be analysed using strain cycle fatigue concepts, and propagation by linear elastic fracture mechanics concepts. If the majority of the fatigue life is spent in crack formation and early growth (crack initiation), precise knowledge of the propagation life is unnecessary for reasonable estimates of the total fatigue life. Conversely, when the majority of the fatigue life is spent in crack propagation, the denition of the initial crack size is more important than the calculation of initiation life. However, good estimates of the total life of notch components, subjected to variable amplitude load histories, can be obtained if both crack initiation, Ni, and crack propagation, Np , are considered, i.e. Nt Ni Np 30

S03603 # IMechE 2003

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 571 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

571

6.1

Crack initiation

Neuber (for plane stress):

2 DsDe Fn D s 0 D e0

As the quest for cost effective nite life designs continues, there is an increasing requirement to quantify the failure performance of components. However, the conventional methods of achieving this objective (e.g. prototype testing) are very expensive and time consuming. A number of investigators (e.g. reference [19]) have suggested alternative approaches based on local strain and obtained fatigue data from simple uniaxial unnotched specimen tests, where it is assumed that smooth and notched specimens with the same local strain range, De, experience the same number of cycles to fatigue crack initiation, Ni . Smooth specimen fatigue life data, proposed by MansonCofn, may be expressed in the following form: De s0f 2Ni b e0f 2N ic 2 E 31

32

where Ds0 and De0 are the nominal stress and strain range respectively, Ds and De are the local maximum stress and strain range at the notch, and Fn is a notch conguration factor, which can be replaced by Kt from equation (12), for a stepped plate with loaded projection in order to predict the fatigue crack initiation life of such a component using the MansonCofn equation [equation (31)]. The local strain approach associated with the NSSC rules is a useful and powerful method for estimating the fatigue crack initiation life of a notched component. The local strain range is found from the intersection of equation (32) with the material cyclic stressstrain curve obtained from smooth specimen testing: De Ds Ds 2 2E 2K 0 1=n0 33

However, the problem of fatigue crack initiation life prediction based on a local strain approach becomes one of estimating the local strain amplitude at the notch. Local strain amplitude can be determined by prototype component testing, or can be predicted using nite element analysis or other numerical or analytical prediction methods. Prototype testing is very expensive and time consuming and, although nite element analysis is very powerful, there are some difculties when using the method for component design assessments. Therefore, various authors have proposed analytical relationships for predicting the local strain amplitude at the root of a notch (see reference [20]). These relationships, known as notch stressstrain conversion (NSSC) rules, are used to determine the non-linear and history-dependent stressstrain behaviour at the notch root in terms of the load history and the cyclic deformation properties of the metal. The commonly used conservative NSSC rules include

By replacing the relevant local strain range in equation (31), the fatigue crack initiation life, Ni, can be obtained, as shown in Fig. 18. It is worth recalling that crack initiation has previously been dened as the formation of a crack of 0.52.5 mm length.

6.2

Crack propagation

The most widely accepted correlation between constantamplitude fatigue crack growth and the applied load is that suggested by Paris [21]. The rate of crack propagation per cycle, da=dN , is directly related to the mode I cyclic stress intensity, DKI , for uniaxial specimen

Fig. 18

S03603 # IMechE 2003

Fatigue crack initiation life prediction procedure based on local strain approach

Downloaded from sdj.sagepub.com by guest on May 21, 2011

J. Strain Analysis Vol. 38 No. 6

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 572 of 576

572

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

testing, in the following way da C DKI n dN 34

Fatigue crack growth under mixed-mode loading has been studied since the 1960s (e.g. reference [22]). The research has mainly concentrated on two aspects: crack growth direction and crack growth rate. Many criteria have been proposed to predict crack growth direction, including maximum tangential stress, strain energy density, maximum tangential strain, the T criterion and the J criterion (e.g. references [10] and [23]). The parameters proposed for correlating the fatigue crack growth rate under mixed-mode loading include effective stress intensity factor, equivalent strain intensity factor and the J integral (e.g. references [24] and [25]). A detailed review of these theories, including advantages and limitations, has been presented in reference [26].

Fig. 19

Projection of the Q vector along the direction of crack growth

6.2.1

Crack growth direction

The criteria considered in this section are based on the Jintegral approach for the determination of crack growth direction and crack growth rate. Consider the vector Q for a two-dimensional elastic crack problem [10] as Q Q1 i Q2 j J1 i J2 j where Q1 and Q2 are given as W n j T k u k , j dS , Qj

S

The initiation of crack growth is governed by the hypothesis that the crack extends along the radial direction y yc on which J y becomes a maximum (see Fig. 19). This hypothesis may be expressed mathematically as qJ y 0, qy q2 J y <0 qy2 41

35

j 1, 2, 3

36

W is the strain energy density, n is a normal vector, Tk is the traction vector, u is the displacement eld, S is every closed surface bounding a region R which is assumed to be free of singularities, J1 is equal to the J integral according to equation (27) and J2 is expressed by 37 J2 W n2 T k uk,2 ds

G

and, using equations (38) and (39), the crack growth direction yc is expressed as 2KI KII 42 yc tan1 2 KI2 KII By substituting KI and KII from equations (15) to (18) into equation (42), the variation in crack extension angle with crack inclination for an initial crack length of a 0:5 mm is plotted in Figs 20 and 21 for some typical combinations of h=d , w=d and r=d . It is clear that the variation in yc is relatively small (i.e. 39.5458) and that it is virtually independent of component geometry and crack position. It is also seen that the maximum value of yc (for a crack angle of 458) is independent of crack length.

For a crack in a mixedmode stress eld governed by the values of stress intensity factors KI and KII, the integral J1 is given by J1 c0 1 2 2 KI KII 8G 38

6.2.2 Crack growth rate Many parameters have been proposed to correlate crack growth rates under mixed-mode loading conditions. These include effective stress intensity factors, effective strain intensity factors, strain energy density factor and the J integral. In this study, the J-integral criterion is assessed for its capacity to correlate fatigue crack growth rate under mixed-mode loading conditions. It is worth noting that, although the effective stress intensity factor criterion is commonly used, the denition

S03603 # IMechE 2003

The integral J2 can be calculated in a similar way: J2 c0 1 KI KII 8G 39

Consider the projection Qy of the vector Q along a direction making an angle y with the x axis, as shown in Fig. 19, where J y J1 cos y J2 sin y

J. Strain Analysis Vol. 38 No. 6

40

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 573 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

573

Fig. 20

Variation in crack extension angle with crack angle for h=d 0:5, w=d 1:5 and 3 and r=d 0:05 and 0.1 with a 0:5 mm and P 100 MPa

of a suitable model for determining effective stress intensities that accounts for load ratio, sequence and crack closure effects needs further work which is currently in progress for a later publication. However, a relationship of the form da ADJ B dN 43

which is analogous to the Paris law [e.g. equation (34)],

has been suggested for crack propagation life predictions under mixed-mode loading conditions [27]. The value of DJ below which no (measurable) amount of fatigue crack growth occurs is termed the threshold J integral, Jth . The implication for design is important since, if in a cracked structure DJ < Jth , then crack propagation will not occur, which is a crucial requirement for components that experience a very large number of loading cycles in service. However, rapid crack advance leading to catastrophic failure occurs

Fig. 21

Variation in crack extension angle with crack angle for h=d 0:5 and 3, w=d 3 and r=d 0:05 and 0.1 with a 0:5 mm and P 100 MPa

Downloaded from sdj.sagepub.com by guest on May 21, 2011

S03603 # IMechE 2003

J. Strain Analysis Vol. 38 No. 6

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 574 of 576

574

A R GOWHARI-ANARAKI, S J HARDY AND R ADIBI-ASL

when DJ JIc 44

substituted from p p DJE F c,e Ds0 pa

51

where Jth and JIc are material constants for a given thickness under specic environmental conditions. The critical values of Jth and JIc are related to the threshold stress intensity factor, Kth , and the critical strain intensity factor (fracture toughness), KIc , as follows [10]: Jth 1 v2 2 Kth E 1 v2 2 JIc KIc E 45 46

Equation (50) should be numerically integrated, as the value of F c,e is a function of crack length, a, i.e. !B ac 1 E da Np 52 B 2 2 A p D s 0 F a0 c, e a 5. The total fatigue life for the component is then given by equation (30), with the derivation of fatigue crack initiation life, Ni, as discussed in section 6.1, using equation (31). This process can be repeated for any crack angle by substituting the appropriate value of a into equation (17).

CRACK PROPAGATION METHODOLOGY 8 CONCLUSIONS 1. Stress intensity factors for components with loaded projections can be signicantly higher than the corresponding values for remote loading, and little relevant fatigue information is available for this type of severe loading. 2. In situations where the crack is perpendicular to the applied loading, a non-zero mode II stress intensity factor is predicted for these components owing to the shear effects caused by the pressure loading. 3. The maximum KI value, KII value and J-integral value occur when the crack originates from a point around the llet that is at angles of j&25, 50 and 308 respectively to the horizontal. 4. The maximum stress was in the meridional direction and generally close to the intersection between the plate and the llet radius, where the J integral had a maximum value (i.e. j&25 ). On the basis of this and conclusion 3, results are generally presented for j 25 . 5. The J-integral value predictions for this type of geometry and loading demonstrate good path independence, and there is good agreement between values obtained from stresses and those based on the virtual crack extension method. 6. Equation (12) can be used to estimate the notch conguration (elastic stress concentration) factor for geometrically similar components with loaded projections with a high degree of condence. 7. For all geometries considered: (a) KI is a maximum when the crack angle is approximately 308; (b) KII is a maximum when the crack angle is approximately 608; (c) KI KII when the crack angle is 458; (d) KI for a is the same as KII for 90 a;

S03603 # IMechE 2003

As a typical example, in its simplest form, a fatigue crack propagation methodology for this plane loaded Tsection under constant-amplitude axial loading can be summarized as: 1. It is assumed that an initial crack size of a 0:5 mm is established owing to strain cycle fatigue (described in section 6.1). The crack angle is assumed to be a 45 (since it corresponds to the maximum J-integral value). The remotely applied constant-amplitude axial nominal stress range, Ds0 , is reacted by a uniform pressure across the entire at section of the shoulder. 2. The critical crack length, ac , is calculated using equation (19) p p Jc E Fc,e Ds0 pac 47 where JIc is determined from equation (46) and Fc,e comes from equation 20 [Fc,I and Fc,II can be calculated from equations (17) and (18) for the given geometry and with a 45 ]. 3. The value of DJ is then calculated, based on equation (19), i.e. p p 48 DJE F c,e Ds0 pa0 No crack growth occurs if DJ < Jth 49

where Jth is derived from equation (45). 4. If DJ > Jth , the fatigue crack propagation life, Np , can be calculated by integrating the equation ac da Np 50 B a 0 A D J where A and B are material constants and DJ is

J. Strain Analysis Vol. 38 No. 6

Downloaded from sdj.sagepub.com by guest on May 21, 2011

3B2 Version Number 7.51a/W (May 2 2001)

j:/Jobsin/M11069/S03603.3d

Date: 28/10/03

Time 09:14am

Page 575 of 576

MIXED-MODE FATIGUE CRACK PROPAGATION IN THIN T-SECTIONS UNDER PLANE STRESS

575

(e) KI and KII increase with decreasing h/d, increasing w/d and decreasing r/d; (f ) the maximum J-integral value occurs when the crack angle is 458. 8. Equations (17) and (18) can be used to estimate the mode I and mode II crack conguration factors for geometrically similar components with loaded projections with a high degree of condence. 9. Equations are presented that can provide estimates for crack initiation and propagation lives without the need to carry out extensive nite element linear elastic fracture mechanics analyses. 10. Equations (21) and (22) can be used to estimate mode I and mode II stress intensity factors from the elastic stress concentration factor and the crack angle for at bars and plates with loaded projections with a high level of con dence. 11. Similarly, equation (23) can be used to estimate the J-integral value for any crack angle with reasonable accuracy. Greater accuracy can been achieved by using equations (24) to (26) for the specic crack angles of 0 and 908 (which represent the extreme mode I and mode II cases), 30 and 608 (which are the dominant mode I and mode II angles respectively) and 458 (at which the maximum J-integral value is predicted). 12. The direction in which a crack will grow was not found to vary signi cantly with initial crack angle, crack length or component geometry. 13. The methodology presented in section 7 can be easily used to estimate the fatigue life of such components with a knowledge of the component geometry and loading, together with the initial crack angle and length.

10 11

12 13

14 15 16

17

18

19

20

REFERENCES

1 Hertzberg, R. W. Deformation and Fracture Mechanics of Engineering Materials, 1976 (John Wiley, New York). 2 Paris, P. C. FatigueAn Interdisciplinary Approach, 1964 (Syracuse University Press, Syracuse, New York). 3 Paris, P. C. and Sih, G. Fracture toughness testing and its application. In ASTM STP 381, 1965, pp. 3081 (American Society for Testing and Materials, Philadelphia, Pennsylvania). 4 Harris, D. O. Stress intensity factor for hollow circumferentially notch round bars. J. Basic Engng, 1967, 89, 4954. 5 Hellen, T. K. On the method of virtual crack extensions. Int. J. Numer. Meth. Engng, 1975, 9, 187207. 6 Engineering Sciences Data Unit, data sheet 69020. 7 BS 5447 Methods of Test for Plane Strain Fracture Toughness (KIc) of Metallic Material, 1977 (British Standards Institution, London). 8 ANSYS, Version 6.1, Data Preparation Manual, 1973 (ANSYS, Canonsburg, Pennsylvania). 9 Gray, T. G. F., Tournery, F. and Spence, J. Analysis of stress concentration factor for stepped plates based on a

S03603 # IMechE 2003

21

22

23

24

25

26

27

crack tip stress intensity approach. J. Strain Analysis, 1996, 31(3), 197204. Gdoutos,E. E. Fracture Mechanics Criteria and Applications, 1990 (Kluwer Academic Publishers, Boston and London). Tada, M., Paris, P. and Irwin, G. The Stress Analysis of Cracks Handbook, 1973 (Del Research Corporation, Hellertown, Pennsylvania). Peterson, R. E. Stress Concentration Design Factors, 1974 (John Wiley, New York). Gowhari-Anaraki, A. R. and Hardy, S. J. Design equations for elastic stress concentration factors in hollow tubes with axisymmetric internal projections subjected to axial loading. J. Strain Analysis, 2001, 36(5), 531534. Singh, S. Machine Design, 1999 (Khanna Publishers, Delhi, India). Socie, D. F. Fatigue life estimates for bluntly notched members. J. Engng. Mater. Technol., 1980, 102, 153158. Dowling, N. E. Crack growth during low-cycle fatigue of smooth axial specimens. In Cyclic StressStrain and Plastic Deformation Aspects of Fatigue Crack Growth, ASTM STP 637, 1977, pp. 97121 (American Society for Testing and Materials, Philadelphia, Pennsylvania). Haddad, M. H., Smith, K. N. and Topper, T. H. Fatigue crack propagation of short cracks. Trans. ASME, J. Engng Mater. Technol., 1979, 101(1), 573580. Smith, E. W. and Pascoe, K. J. Fatigue crack initiation and growth in a high strength ductile steel subject to in-phase biaxial loading. In ASTM STP 853, 1985, pp. 111134 (American Society for Testing and Materials, Philadelphia, Pennsylvania). Topper, T. H. and Gowda, C. V. B. G. Local stressstrain approach to fatigue analysis and design. In ASME Design Engineering Conference, Chicago, Illinois, 1970, paper 70DE-24. Hardy, S. J. and Gowhari-Anaraki, A. R. Stress and strain range predictions for axisymmetric and two-dimensional components with stress concentrations and comparisons with notch stressstrain conversion rule estimates. J. Strain Analysis, 1993, 28(3), 209221. Paris, P. C. The fracture mechanics approach to fatigue. In Proceedings of 10th Sagamore Conference, 1963 (Syracuse University Press, Syracuse, New York). Iida, S. and Kabayashi, A. S. Crack propagation rate in 7075-T6 plates under cyclic tensile and transverse shear loading. Trans. ASME, J. Basic Engng, 1969, 91, 764769. Theocaris, P. S., Kardomateas, G. A. and Andrianopoulos, N. P. Experimental study of the T-criterion in ductile fracture. Engng Fracture Mechanics, 1982, 17, 439447. Tanaka, K. Fatigue crack propagation from a crack inclined to the cyclic tensile axis. Engng Fracture Mechanics, 1974, 6, 493507. Socie, D. F., Hua, C. T. and Worthem, D. W. Mixed mode small crack growth. Fatigue and Fracture of Engng Mater. Struct., 1987, 10(1), 116. Bold, P. E., Brown, M. W. and Allen, R. J. A review of fatigue crack growth in steels under mixed mode I and II loading. Fatigue and Fracture of Engng Mater. Struct., 1992, 15(10), 965977. Begley, J. A. and Landes, J. D. The J-integral as a fracture criterion. In Fracture Toughness, ASTM STP 514, 1972, pp. 123 and 2439 (American Society for Testing and Materials, Philadelphia, Pennsylvania).

J. Strain Analysis Vol. 38 No. 6

Downloaded from sdj.sagepub.com by guest on May 21, 2011

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Workshop Practice Series - 01 - Hardening Tempering and Heat TreatmentDocument64 paginiWorkshop Practice Series - 01 - Hardening Tempering and Heat TreatmentChad Hunter100% (2)

- Continuous Casting of Lead-Antimony AlloysDocument7 paginiContinuous Casting of Lead-Antimony AlloysOmar Alejandro SalazarÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- E 122 - 09e1Document5 paginiE 122 - 09e1ruben carcamoÎncă nu există evaluări

- Computational Fluid Dynamics Fundamentals Course: Fluid Mechanics 101 Dr. Aidan WimshurstDocument51 paginiComputational Fluid Dynamics Fundamentals Course: Fluid Mechanics 101 Dr. Aidan WimshurstRaquel VelascoÎncă nu există evaluări

- D2671-13 Standard Test Methods For Heat-Shrinkable Tubing For Electrical UseDocument19 paginiD2671-13 Standard Test Methods For Heat-Shrinkable Tubing For Electrical UseOmar Alejandro SalazarÎncă nu există evaluări

- API 570 API 571 QuestionsDocument4 paginiAPI 570 API 571 QuestionsThomas Tucker100% (1)

- Aws D1.1welding Qualification.Document10 paginiAws D1.1welding Qualification.idealparrotÎncă nu există evaluări

- Structure and Bonding in Crystalline Materials - G. Rohrer (Cambridge, 2004) WW PDFDocument552 paginiStructure and Bonding in Crystalline Materials - G. Rohrer (Cambridge, 2004) WW PDFOmar Alejandro Salazar0% (1)

- Electrochemistry: Electrochemistry Chemistry and Energy Relations Lecture Notes 12 Chemistry For EngineersDocument46 paginiElectrochemistry: Electrochemistry Chemistry and Energy Relations Lecture Notes 12 Chemistry For EngineersAce Heart Rosendo AmanteÎncă nu există evaluări

- Great Minds of Carbon Equivalent - 1 PDFDocument3 paginiGreat Minds of Carbon Equivalent - 1 PDFSiva SubramaniÎncă nu există evaluări

- The Least Prime Number in A Beatty Sequence: Journal of Number TheoryDocument16 paginiThe Least Prime Number in A Beatty Sequence: Journal of Number TheoryOmar Alejandro SalazarÎncă nu există evaluări

- The Deformation and Ageing of Mild Steel PDFDocument9 paginiThe Deformation and Ageing of Mild Steel PDFOmar Alejandro SalazarÎncă nu există evaluări

- The Least Prime Number in A Beatty Sequence: Journal of Number TheoryDocument16 paginiThe Least Prime Number in A Beatty Sequence: Journal of Number TheoryOmar Alejandro SalazarÎncă nu există evaluări

- The Least Prime Number in A Beatty Sequence: Journal of Number TheoryDocument16 paginiThe Least Prime Number in A Beatty Sequence: Journal of Number TheoryOmar Alejandro SalazarÎncă nu există evaluări

- Physical Determinants of KarateDocument9 paginiPhysical Determinants of KarateOmar Alejandro SalazarÎncă nu există evaluări

- Accepted Manuscript: Electrochimica ActaDocument28 paginiAccepted Manuscript: Electrochimica ActaOmar Alejandro SalazarÎncă nu există evaluări

- Presentation TT PDFDocument66 paginiPresentation TT PDFOmar Alejandro SalazarÎncă nu există evaluări

- Monodisperse Sodium Oleate Coated Magnetite High Susceptibility Nanoparticles For Hyperthermia ApplicationsDocument8 paginiMonodisperse Sodium Oleate Coated Magnetite High Susceptibility Nanoparticles For Hyperthermia ApplicationsOmar Alejandro SalazarÎncă nu există evaluări

- Specific Absorption Rate Determination of Magnetic Nanoparticles Through Hyperthermia Measurements in Non-Adiabatic ConditionsDocument6 paginiSpecific Absorption Rate Determination of Magnetic Nanoparticles Through Hyperthermia Measurements in Non-Adiabatic ConditionsOmar Alejandro SalazarÎncă nu există evaluări

- Impact of Magnetic Field Parameters and Iron Oxide NanoparticleDocument11 paginiImpact of Magnetic Field Parameters and Iron Oxide NanoparticleOmar Alejandro SalazarÎncă nu există evaluări

- Magnetization of Single Magnetic ParticlesDocument2 paginiMagnetization of Single Magnetic ParticlesOmar Alejandro SalazarÎncă nu există evaluări

- Hydrogen Bonding-New InsightsDocument535 paginiHydrogen Bonding-New InsightsOmar Alejandro SalazarÎncă nu există evaluări

- Size Dependence of The Magnetic Relaxation and Specific Power Absorption in Iron Oxide NanoparticlesDocument11 paginiSize Dependence of The Magnetic Relaxation and Specific Power Absorption in Iron Oxide NanoparticlesOmar Alejandro SalazarÎncă nu există evaluări

- Free Energy Analysis On Perpetual Motion MachineDocument6 paginiFree Energy Analysis On Perpetual Motion MachineOmar Alejandro SalazarÎncă nu există evaluări

- Improvement of The Mechanical Properties of Al-Si AlloysDocument6 paginiImprovement of The Mechanical Properties of Al-Si AlloysOmar Alejandro SalazarÎncă nu există evaluări

- Improvement of The Mechanical Properties of Al-Si AlloysDocument6 paginiImprovement of The Mechanical Properties of Al-Si AlloysOmar Alejandro SalazarÎncă nu există evaluări

- DSCDocument9 paginiDSCgaurav thakur100% (1)

- Evaluation and Assessment of The Nfatigue in The Architectural Artwork On The Lighting Poles in The Anzac Drive BridgeDocument29 paginiEvaluation and Assessment of The Nfatigue in The Architectural Artwork On The Lighting Poles in The Anzac Drive BridgeFabrizio BisernaÎncă nu există evaluări

- Design of Connectors in Web-Flange Beam or Girder SplicesDocument8 paginiDesign of Connectors in Web-Flange Beam or Girder SplicesChewfy150% (2)

- BrazeLet BNi Family 2182HOGDocument2 paginiBrazeLet BNi Family 2182HOGMASOUDÎncă nu există evaluări

- MTE 314 Mechanical Vibrations: Report Experiments 2Document3 paginiMTE 314 Mechanical Vibrations: Report Experiments 2Yomna EmadÎncă nu există evaluări

- 2.pH, Buffers and Isotonic Solutions AbDocument48 pagini2.pH, Buffers and Isotonic Solutions AbPasham Venkat ReddyÎncă nu există evaluări

- 2023 - New Control Method of Casing Deformation in Shale Gas Slip Fault Based On Solid Expandable TubularDocument13 pagini2023 - New Control Method of Casing Deformation in Shale Gas Slip Fault Based On Solid Expandable TubularOmar S Al-AbriÎncă nu există evaluări

- Break The Tension A Water ExperimentDocument3 paginiBreak The Tension A Water ExperimentDeyann ZoldyckÎncă nu există evaluări

- LDA Jaywant ArakeriDocument38 paginiLDA Jaywant ArakerirajuvadlakondaÎncă nu există evaluări

- Edexcel A Level Chemistry Book 2 - OCRDocument268 paginiEdexcel A Level Chemistry Book 2 - OCREdcademiaÎncă nu există evaluări

- Tamura Solder Paste GP 216 HF 17Document5 paginiTamura Solder Paste GP 216 HF 17luthfiÎncă nu există evaluări

- CADE Technologybrochure AccumulatorsDocument24 paginiCADE Technologybrochure AccumulatorsJose francisco Lazo castroÎncă nu există evaluări

- Chapter 4. Heat Treatment by InductionDocument1 paginăChapter 4. Heat Treatment by InductionKamil IbraÎncă nu există evaluări

- Thermodynamics Table (Enthalpy and Entropy of Common Substances and Compound)Document2 paginiThermodynamics Table (Enthalpy and Entropy of Common Substances and Compound)francesca castilloÎncă nu există evaluări

- Fluid Statics: F I G U R E P2.69Document1 paginăFluid Statics: F I G U R E P2.69andres bernalÎncă nu există evaluări

- Name:Sajeel Khan Roll#:M.phil-SSP-03-F19 Class:M.phil-SSP (Morning) Subject: Defect in Solids Submitted TO:Dr. Ijaz Mujtaba Ghauri SBDocument10 paginiName:Sajeel Khan Roll#:M.phil-SSP-03-F19 Class:M.phil-SSP (Morning) Subject: Defect in Solids Submitted TO:Dr. Ijaz Mujtaba Ghauri SBAnonymous f7wV1lQKRÎncă nu există evaluări

- Proprietary & Confidential: PM AuthorisationDocument55 paginiProprietary & Confidential: PM AuthorisationMuhammad Najam AbbasÎncă nu există evaluări

- CIV312 Assignment 2Document4 paginiCIV312 Assignment 2louisÎncă nu există evaluări

- DRAFT - : Fracture Properties and Fatigue Cracking Resistance of Asphalt BindersDocument58 paginiDRAFT - : Fracture Properties and Fatigue Cracking Resistance of Asphalt BindersEsra'a AlhajÎncă nu există evaluări

- Lab Report 1Document11 paginiLab Report 1Haziq HakimiÎncă nu există evaluări

- MS327 SyllabusDocument1 paginăMS327 SyllabuspratÎncă nu există evaluări

- Cam Analysis ManualDocument4 paginiCam Analysis ManualNishant B MayekarÎncă nu există evaluări

- Off Budgell FRCR - VerificationDocument46 paginiOff Budgell FRCR - VerificationAmr MuhammedÎncă nu există evaluări

- SBT 200 Plant Ecologykenyatta UniversityDocument85 paginiSBT 200 Plant Ecologykenyatta Universityvincent onsaseÎncă nu există evaluări

- Liquid CrystalDocument18 paginiLiquid CrystalNanditha AÎncă nu există evaluări

- Robot Actuators:: Actuators Are Used For Converting The Hydraulic, Electrical orDocument12 paginiRobot Actuators:: Actuators Are Used For Converting The Hydraulic, Electrical orNani KumarÎncă nu există evaluări

- RanikhetDocument2 paginiRanikhetAbhishikta BhattacharjeeÎncă nu există evaluări