Documente Academic

Documente Profesional

Documente Cultură

McCabe Thiele!!!!!

Încărcat de

Chokri ChakiirDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

McCabe Thiele!!!!!

Încărcat de

Chokri ChakiirDrepturi de autor:

Formate disponibile

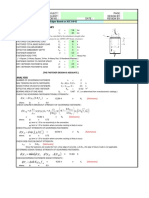

06-361 page 1 Spring, 2001

Review of Lectures 13-24

Chapters 8-13 oI Notes

OUNTERCURRENT ASCADES

Equal Molar Overflow Assumption

Neglecting sensible heat eIIects and assuming molar latent heat oI

vaporization is the same Ior both components, then

H

x,i

0

and H

v,i1

The main consequence is that the molar Ilowrates oI liquid and vapor are

constant throughout the cascade

J

a

J

1

J

2

...J

N

J

b

( J, say)

L

a

L

1

L

2

...L

N

L

b

( L, say)

Operating Line

a relationship between the mole Iraction oI the more volatile component

in the vapor v

i1

and the mole Iraction oI the more volatile component in the adjacent liquid

stream x

i

, which is imposed by mole balances around a subset oI the cascade. Eor example, a

mole balance around the top i stages in the cascade ( line in the Iigure above) yields

v

i1

(L/J)x

i

|v

a

-(L/J)x

a

|

where we have also applied the assumption oI equal molar overIlow.

Equilibrium Curve

v*(x) - a relationship between the mole Iraction oI the more volatile component in the vapor v

and the mole Iraction oI the more volatile component in the liquid x, when the two phases are in

thermodynamic equilibrium

v v*(x)

06-361 page 2 Spring, 2001

Ideal Stage

The dashed line in the Iigure at right connects vapor and liquid streams

leaving a given stage which are usually assumed to be in

thermodynamic equilibrium with each other. Eor the n

th

stage this

means

v

n

v*(x

n

)

x

R

+1

x

QL

CABEHIELE ETHOD

Rectifying Operating Line (ROL)

- relationship between v

n1

and x

n

imposed by mole balances in the rectiIying cascade oI a

distillation column.

v

L

J

x

D

J

x

n n D

= +

1

To draw the operating line, you need either one point and the slope or two points:

slope:

L

J

R

R

=

+1

2 points: (x

D

, x

D

) and (0,

x

R

1

)

06-361 page 3 Spring, 2001

Reflux ratio

deIinition: R

L

D

=

II (x, v) is any point on the ROL, then the reIlux ratio can be computed Irom

R

x v

v x

D

=

'

' '

Q-Line

- locus oI points oI all possible intersections (x,v) between the operating lines Ior two adjacent

cascades:

v

q

q

x

:

q

F

=

1 1

To draw the Q-line, you need one point and a slope:

slope oI Q-line

q

q 1

one point on Q-line: (:

F

, :

F

)

q is a dimensionless number characterizing the thermal condition oI the Ieed:

q

H H

H H

J F

J L

=

energy required to completely vaporize Ieed

latent heat oI vaporization

When the Ieed is a two-phase mixture (oI vapor and liquid), q is also the (molar) Iraction oI the

Ieed which is liquid. Using a enthalpy balance (assuming equal molar overIlow), q also

represents the Iraction oI Ieed which adds to the vapor Ilowrate (Irom the cascade below the

Ieed) and the Iraction oI Ieed which adds to the liquid Ilowrate (Irom the cascade above the

Ieed):

L -L qF and J-J (1-q)F

06-361 page 4 Spring, 2001

Flow Rates

Mole balances can be used to relate the distillate, Ieed and bottoms Ilowrates:

D

F

: x

x x

F B

D B

=

Knowing the distillate Ilowrate, we can use the deIinition oI the reIlux ratio to calculate the

liquid and vapor rates in the rectiIying section

L RD and J (R1)D

The Ilowrates in the stripping section are determined Irom

L L qF and J J (q-1)F

Stripping section operating line

- relationship between v

n1

and x

n

imposed by mole balances in the stripping cascade oI a

distillation column.

1 n n B

L B

v x x

J J

=

To draw the operating line, you need two points:

intersection oI Q-line and ROL and (x

B

, x

B

)

Note that the slope oI the SOL also is the ratio oI liquid-to-vapor Ilowrates (in moles per time)

Ior that section oI the column.

Kremser`s Equation

- when both the operating line and equilibrium curve can

be approximated by a straight line over some range oI

mole Iractions, the number oI steps between them can be

calculated Irom

N

v v

v v

v v

v v

a a

b b

a b

a b

=

log

log

*

*

* *

,

,

,

06-361 page 5 Spring, 2001

In distillation, the equilibrium curve lies above the operating line: v

a

* ~ v

a

and v

b

* ~ v

b

. To

obtain N~0, you must have v

a

~ v

b

. II you inadvertently (but consistently) interchange the

subscripts a and b, you will obtain negative values Ior N, although dropping the negative sign

gives the correct result.

Plate (1ray) Efficiency

- the length oI a 'real step divided by the length oI an

ideal step

q

Mv

n n

n n

v v

v v

=

1

1

*

q

Mx

n n

n n

x x

x x

=

1

1

*

ULTICOMPONENT ISTILLATION

Key Components

Eor a sharp split, components heavier than the heavy key have negligible mole Iraction in the

distillate and components lighter than the light key have negligible mole Iraction in the bottoms.

Fenske`s Equation

Eor total reIlux, constant molar overIlow, and constant relative volatilities, the number oI

ideal steps can be calculated Irom

min

ln

ln

Di Bi

Df Bf

if

x x

x x

N

| |

|

|

\ .

=

o

OI course, iI the reboiler only partially vaporizes the bottom liquid, one oI these steps is the

reboiler. Eor purpose oI calculating the minimum number oI steps, we usually choose i LK

and f HK. Once N

min

is known, this equation can be used to x

D

or x

B

Ior other components.

Underwood`s Method

Assuming constant molar overIlow and constant relative volatilities, the minimum reIlux

ratio can be estimated Irom

06-361 page 6 Spring, 2001

R

x

i Di

i

i

min

+ =

1

o

o |

where is that root oI

o

o |

i Fi

i

i

:

q

1

which lies in the interval o | o

HK LK

< <

Gilliland`s Correlation

Once estimates are available Ior N

min

and R

min

, the number oI ideal stages N Ior some

operating reIlux ratio R ~ R

min

can be estimated Irom the Iollowing empirical correlation (see

page 113 oI 2000 Notes):

SE OF HEMSEP

Chemsep vs. McCabe-1hiele

In the McCabe-Thiele graphical method, you speciIy the Ieed, the composition oI the product

streams, and the reIlux ratio; then Mc-T gives you the number oI stages required (no trial-and-

error)

given: x

D

, x

B

and R

Mc-T Iinds: N

E

and N

S

In constrast, Chemsep is a simulator: you must speciIy the number oI trays in each section and

one detail about the distillate and one detail about the bottoms. Then Chemsep solves Ior the

remaining details:

given N

E

, N

S

, x

D

(or R) and x

B

Chemsep Iinds: R (or x

D

)

06-361 page 7 Spring, 2001

Determining the Reflux Ratio

ChemSep does not report the reIlux ratio directly, but it can be calculated Irom the Ilowrates

which can be tabulated.

Generally the liquid and vapor Ilowrates on the line Ior stage n are the rates oI the streams

leaving stage n, except that stage 1 reIers to the stage 1 plus the condenser and the stream splitter

Iollowing it. The liquid leaving 'stage 1 is the reIlux stream while the 'vapor leaving stage 1

reIers to the distillate product (regardless oI whether it is vapor or liquid). Thus the reIlux ratio

is

R

L

D

= = =

7 463

0 7654

9 75

.

.

.

Sfage Tempeafue Pessue I1oW afes |mo1/s}

|K} |afm} L1qu1d vapou Ieed Poducf

1 411.9 1.000 7.463 0.7654 0.7654 L

2 412.0 1.000 7.463 8.229

3 412.0 1.000 7.462 8.228

4 412.0 1.000 7.461 8.227

5 412.0 1.000 7.461 8.227

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Wichita Clutch Spring Set BrakesDocument12 paginiWichita Clutch Spring Set Brakesayman akrab100% (1)

- Surge Tank DesignDocument15 paginiSurge Tank Designdharanimadala100% (3)

- SludgeDocument53 paginiSludgeRaajiv Menon100% (2)

- Commissioning Plan Preparation Guide 0Document16 paginiCommissioning Plan Preparation Guide 0Chokri ChakiirÎncă nu există evaluări

- Net Positive Suction Head or NPSHDocument4 paginiNet Positive Suction Head or NPSHsateesh chandÎncă nu există evaluări

- Designing A MixerDocument12 paginiDesigning A MixerPrasanna KumarÎncă nu există evaluări

- Industrial WastewaterDocument32 paginiIndustrial WastewaterAldo Martinez100% (1)

- Sludge Age Calculation PDFDocument1 paginăSludge Age Calculation PDFChokri ChakiirÎncă nu există evaluări

- MBBR DesignDocument68 paginiMBBR DesignQuốc Tuyên80% (15)

- Dimensioning and Design of Nitrogen - Stefan RettigDocument33 paginiDimensioning and Design of Nitrogen - Stefan RettigNguyen Phuc PhamÎncă nu există evaluări

- Blower Testing StandardsDocument13 paginiBlower Testing StandardsChokri ChakiirÎncă nu există evaluări

- Journey To The Edge of The UniverseDocument27 paginiJourney To The Edge of The UniverseApoorva JnanaÎncă nu există evaluări

- Testing and Commissioning Procedure: 2007 EDITIONDocument38 paginiTesting and Commissioning Procedure: 2007 EDITIONChokri ChakiirÎncă nu există evaluări

- SayDocument1 paginăSayChokri ChakiirÎncă nu există evaluări

- 1260868Document10 pagini1260868Hashem Mohamed HashemÎncă nu există evaluări

- Tefsa Belt Filter Presses BrochureDocument8 paginiTefsa Belt Filter Presses BrochureMashudi FikriÎncă nu există evaluări

- Tunisia 2012 State of The Water ReportDocument129 paginiTunisia 2012 State of The Water ReportChokri ChakiirÎncă nu există evaluări

- B10 12 1Document10 paginiB10 12 1Chokri ChakiirÎncă nu există evaluări

- Pumping Stations GuideDocument1 paginăPumping Stations GuideChokri ChakiirÎncă nu există evaluări

- International Journal of EngineeringDocument10 paginiInternational Journal of EngineeringChokri ChakiirÎncă nu există evaluări

- 115doc PAA 1et2Document2 pagini115doc PAA 1et2Chokri ChakiirÎncă nu există evaluări

- 9101CGM4Document198 pagini9101CGM4Chokri ChakiirÎncă nu există evaluări

- Dewatering TechnologiesDocument31 paginiDewatering TechnologiesChokri ChakiirÎncă nu există evaluări

- CE 428 Wastewater Grit SediDocument4 paginiCE 428 Wastewater Grit SediChokri ChakiirÎncă nu există evaluări

- Natural Gas CompressionDocument49 paginiNatural Gas CompressionArjun Pratap SinghÎncă nu există evaluări

- AquaAero2 0 ManualDocument89 paginiAquaAero2 0 ManualAlper NuhogluÎncă nu există evaluări

- Basic Formula Water DemandsDocument4 paginiBasic Formula Water DemandsArfah MpÎncă nu există evaluări

- TEG Unit DesignDocument1 paginăTEG Unit DesignChokri ChakiirÎncă nu există evaluări

- Hydraulic Profile CalculationDocument1 paginăHydraulic Profile CalculationChokri ChakiirÎncă nu există evaluări

- Simulation and Optimization of Full Scale Reverse Osmosis Desalination PlantDocument6 paginiSimulation and Optimization of Full Scale Reverse Osmosis Desalination PlantLuis RamirezÎncă nu există evaluări

- M1 Part3Document88 paginiM1 Part3Chokri ChakiirÎncă nu există evaluări

- Aeration Tank CalculationDocument1 paginăAeration Tank CalculationChokri ChakiirÎncă nu există evaluări

- Science ReviewerDocument3 paginiScience ReviewerLily CollinsÎncă nu există evaluări

- WORKSHEET 3.7 Active TransportDocument4 paginiWORKSHEET 3.7 Active TransportFadhliana UzalliÎncă nu există evaluări

- The Physics of WeldingDocument8 paginiThe Physics of WeldingnitinÎncă nu există evaluări

- Jan 07Document16 paginiJan 07Evelyn L-XingÎncă nu există evaluări

- Cambridge IGCSE: Physics 0625/21Document16 paginiCambridge IGCSE: Physics 0625/21Thiru VeleyudhamÎncă nu există evaluări

- Coupled PendulumDocument5 paginiCoupled PendulumSubhasis PandaÎncă nu există evaluări

- ANSYS Structural Analysis Guide Table of Contents (UP19980818)Document29 paginiANSYS Structural Analysis Guide Table of Contents (UP19980818)sunpnairÎncă nu există evaluări

- 4e3 A Maths Prelim Exam Paper 2Document4 pagini4e3 A Maths Prelim Exam Paper 2ahmedzaki1234Încă nu există evaluări

- Atoms Pyq 2023Document10 paginiAtoms Pyq 2023SREE GANESHÎncă nu există evaluări

- Computer Simulation of Vapor-Liquid Equilibrium in Mixed Solvent Electrolyte SolutionsDocument10 paginiComputer Simulation of Vapor-Liquid Equilibrium in Mixed Solvent Electrolyte SolutionsJoseCastilhoÎncă nu există evaluări

- Spinodal Decomposition PDFDocument3 paginiSpinodal Decomposition PDFOmar VillanuevaÎncă nu există evaluări

- HSAB TheoryDocument3 paginiHSAB Theorykaran113Încă nu există evaluări

- Paper-2: Cumulative Test-1 (Ct-1)Document44 paginiPaper-2: Cumulative Test-1 (Ct-1)vikram2002Încă nu există evaluări

- Chapter 3c X Ray DiffractionDocument51 paginiChapter 3c X Ray DiffractionDeependra Kumar Ban100% (1)

- Proof of Earth's ShapeDocument15 paginiProof of Earth's ShapeVinayaka RamÎncă nu există evaluări

- Atomic Model WorksheetDocument2 paginiAtomic Model WorksheetTelle Telle100% (1)

- 2nd Half Book Ist Year PHYSICSDocument4 pagini2nd Half Book Ist Year PHYSICSranaateeq100% (1)

- Class 11 Physics Practice Paper 2022-23Document11 paginiClass 11 Physics Practice Paper 2022-23Curiosity SatisfiedÎncă nu există evaluări

- 2017 National Exam Part I PDFDocument11 pagini2017 National Exam Part I PDFNguyễn Đức TrọngÎncă nu există evaluări

- Chemistry Final Exam Review KEY: Practice ProblemsDocument7 paginiChemistry Final Exam Review KEY: Practice ProblemsZetrix JensenÎncă nu există evaluări

- AFS 2211 - FUNDAMENTALS OF FOOD CHEMISTRY - Water PDFDocument40 paginiAFS 2211 - FUNDAMENTALS OF FOOD CHEMISTRY - Water PDFderrickÎncă nu există evaluări

- PDC Lecture Notes 7 - Stability of Closed-Loop Systems 2018Document56 paginiPDC Lecture Notes 7 - Stability of Closed-Loop Systems 2018R-A PascualÎncă nu există evaluări

- TW 14792Document2 paginiTW 14792crisplebeuÎncă nu există evaluări

- Structural Analysis of Differential Gearbox: Daniel Das.ADocument5 paginiStructural Analysis of Differential Gearbox: Daniel Das.ASivateja NallamothuÎncă nu există evaluări

- 09 Science Notes Ch10 GravitationDocument4 pagini09 Science Notes Ch10 Gravitationdvrao_chowdaryÎncă nu există evaluări

- B2 Stability of Structures 2nded Dover2003Document9 paginiB2 Stability of Structures 2nded Dover2003nicu1212Încă nu există evaluări

- Fusha Magnetike Dhe Forca MagnetikeDocument40 paginiFusha Magnetike Dhe Forca Magnetikefatjonmusli2016Încă nu există evaluări

- Single Tension Fastener Away From Edges Based On ACI 318-02Document2 paginiSingle Tension Fastener Away From Edges Based On ACI 318-02civixxÎncă nu există evaluări