Documente Academic

Documente Profesional

Documente Cultură

Airlift Basic Calculation

Încărcat de

Mohammed EljammalDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Airlift Basic Calculation

Încărcat de

Mohammed EljammalDrepturi de autor:

Formate disponibile

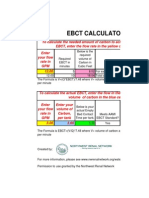

Enter data in green cells only Pumping rate Pipe diameter submergence lift % submergence cross-sectional area of pipe

Pipe volume Pipe volume/cu.ft. Vl (Flow rate) A (Pipe area) L (Lift) D (Pipe diameter) Lf (density of fluid) S (submergence) Lg (Gas density) Value of Ordinate Value of Abscissa

Calculations for an air

12,000 gallon/day 2.00 inch 7.0 ft 1.5 ft 82%

0.022 ft2 0.15 ft3 7.48 gallon Input data Results from left gal/day 12,000 gal/hr 500.00 gal/min

8.33

8.33 GPM

0.022 1.5 2 100 7.00 0.0765 45,196 100<Y<10,225 10,225<Y<73,637 73,637<Y<117,690 117,690<Y<123.645 123,645<Y<128,308 128,308<Y<99,018 5.23 ft2 ft inch ft Don't change anything

4.52E+04 5.50 5.23 5.15 0.01 0.00 5.77

There are two major sections to this spre number. 2. On the right will calculate the maximum. This is a theoretical maximum it would be 33 gal/min

I have entered my basic pumping needs i

Graph reading Vg (Gas flow) Pressure

The bottom, yellow cells show the CFM a at its maximum, and therefore, limit that

ft3/min Answer psi

1.03 3.03

The convention I follow is to enter data in

If you enter a set of data where the air lif occurs, change the sizes or gallons to twe formulas complete properly.

This spreadsheet is built off other person the calculator on the right based on form Please give proper attribution.

The calculator on the right is adapted fro expressing the formulas from:

F.A. Zenz from "Explore the Potential of A

ations for an air lift assembly

Calculate needed gals/day 500 gal/hr 12,000 gal/day

total length submergence pipe diameter water flow

Calculation of maximum air lift pump capacity 8.5 feet 259.08 cm feet of water 82 % 0.82 feet of rise 2 inches 5.08 cm 126.240 liter/min 33.352 gal/min 48,027.59

6.97 1.53

gal/day

optimal air flow range for these parameters 8% 116.89 liter/min 4.13 cfm 9% 115.82 liter/min 4.09 cfm pressure

3.02

PSI

o major sections to this spreadsheet. They fill two different niches. 1. on the left figures from a known, desired gal/day On the right will calculate the maximum capacity for a given scenario. There are a lot of variables that might lower that his is a theoretical maximum. It will not be grossly in error. My test demonstrated a flow of 30 gal/min and the calculator said

ed my basic pumping needs in the calculators.

yellow cells show the CFM and the pressure needed to overcome the head. An air pump would need to match this and not um, and therefore, limit that would make it prone to failure.

ion I follow is to enter data in green cells and the formulas are completed in other colored cells.

a set of data where the air lift assembly will not work, there will be odd characters appear within the calculations. If this ge the sizes or gallons to tweak your desired assembly. For instance, if a 2" pipe will not work, then try a 3" and see if the mplete properly.

heet is built off other persons' work . It must not be distributed for profit. It is for education and design purposes only. I built or on the right based on formulas found on an engineer ing site for air lift assemblies.

proper attribution.

or on the right is adapted from one found on http://www.airliftpump.com/ap_calc.htm by Dr. Sam Kondo, Ph.D. who is he formulas from:

m "Explore the Potential of Air-lift Pumps and Multiphase", Chemical Engineering Progress, Aug., 1993

ulator said

not be

see if the

es only. I built

who is

S-ar putea să vă placă și

- 3114 3116 3126 Disassembly and Assembly PDFDocument253 pagini3114 3116 3126 Disassembly and Assembly PDFAnonymous DgrLAHZ98% (40)

- Enter data in green cells to calculate air lift pump parametersDocument3 paginiEnter data in green cells to calculate air lift pump parametersStircu Florian60% (5)

- Calculate EBCT and carbon volume neededDocument3 paginiCalculate EBCT and carbon volume neededWael FawzyÎncă nu există evaluări

- Velocity Pressure Method Calculation SheetDocument7 paginiVelocity Pressure Method Calculation SheetPhyu Mar Thein Kyaw100% (1)

- Airlift Basic CalculationDocument3 paginiAirlift Basic CalculationFadhilah Suroto100% (1)

- Air BlowerDocument10 paginiAir Blowerewanz89100% (2)

- Modeling Cyclone PerformanceDocument4 paginiModeling Cyclone PerformancesergioÎncă nu există evaluări

- Airlift Basic CalculationDocument1 paginăAirlift Basic Calculationcumpio425428Încă nu există evaluări

- Principle of Air-Lift PumpDocument1 paginăPrinciple of Air-Lift PumpPierre TÎncă nu există evaluări

- Airlift PumpDocument5 paginiAirlift PumpAnoop NimkandeÎncă nu există evaluări

- Enviraj MBBR CalculatorDocument3 paginiEnviraj MBBR Calculatorankur100% (2)

- Wastewater Treatment Sizing Calculations for 50 Person FacilityDocument41 paginiWastewater Treatment Sizing Calculations for 50 Person FacilityJohn TauloÎncă nu există evaluări

- Reciprocating Compressor Performance CalculationDocument1 paginăReciprocating Compressor Performance Calculationsafald100% (1)

- WWT Secondary Clarifier PDFDocument15 paginiWWT Secondary Clarifier PDFdzari6738Încă nu există evaluări

- Hopper Calulation For ClarifierDocument1 paginăHopper Calulation For ClarifierHemantk8731100% (1)

- Cálculos Osmosis InversaDocument26 paginiCálculos Osmosis InversabetzabeÎncă nu există evaluări

- Hydraulics worksheet Rev (2) optimizedLength10570 ft450 ft180 ft150 ftDocument9 paginiHydraulics worksheet Rev (2) optimizedLength10570 ft450 ft180 ft150 ftShivaram SuppiahÎncă nu există evaluări

- Venturi Scrubber Design Equations Formulas CalculatorDocument2 paginiVenturi Scrubber Design Equations Formulas Calculatorblueboy33% (3)

- MBR DesignDocument52 paginiMBR Designpragatheesk100% (2)

- Dual Media FilterDocument4 paginiDual Media FilterPandiaraj MkÎncă nu există evaluări

- Venturi ScrubbersDocument47 paginiVenturi ScrubbersAnoop SharmaÎncă nu există evaluări

- Chain CalculationsDocument3 paginiChain CalculationsTeguh Nugraha KusnanÎncă nu există evaluări

- Conveyor Design-DraftDocument42 paginiConveyor Design-Draftmkchy1295% (21)

- Din 2576 Manufacture Din2576 Flange and Flanges Plate of Din 2576 Pn10, PN 10Document3 paginiDin 2576 Manufacture Din2576 Flange and Flanges Plate of Din 2576 Pn10, PN 10Mohammed EljammalÎncă nu există evaluări

- Rectangular Tank Design PDFDocument71 paginiRectangular Tank Design PDFPrajwal Shetty87% (15)

- Berg SystemDocument390 paginiBerg SystemMohamed Mohamed100% (1)

- Enter data in green cells to calculate air lift pump parametersDocument5 paginiEnter data in green cells to calculate air lift pump parametersTuan NguyenÎncă nu există evaluări

- Air Lift PumpDocument4 paginiAir Lift PumpFoxty67% (3)

- Design of Flocculator PaddlesDocument1 paginăDesign of Flocculator Paddlessumitanurag100% (1)

- AirliftDocument6 paginiAirliftAlina PlescanÎncă nu există evaluări

- Airlift PumpDocument18 paginiAirlift Pumptushar patelÎncă nu există evaluări

- Advanced airlift pumping technologyDocument5 paginiAdvanced airlift pumping technologyzarkima100% (1)

- Design Spreadsheet Calculation For SBR Sequential Biological ReactorDocument12 paginiDesign Spreadsheet Calculation For SBR Sequential Biological ReactorHenry SPÎncă nu există evaluări

- Screen and SBR v1.0Document3 paginiScreen and SBR v1.0Richard Magadia Jr0% (1)

- 371hw06s (Rapid Mix Tank Design-Sample 1)Document5 pagini371hw06s (Rapid Mix Tank Design-Sample 1)Yang Ching HianÎncă nu există evaluări

- Design and Calculation UASB Reactor For Sludge TreatmentDocument3 paginiDesign and Calculation UASB Reactor For Sludge TreatmentDavid LambertÎncă nu există evaluări

- Airlift Pump Article 1987Document14 paginiAirlift Pump Article 1987lychekÎncă nu există evaluări

- Annex 31 Tool Design Extended AerationDocument5 paginiAnnex 31 Tool Design Extended AerationAnonymous QiMB2lBCJLÎncă nu există evaluări

- Process Design CalcDocument9 paginiProcess Design Calckiran raghukiranÎncă nu există evaluări

- SBR DesignDocument25 paginiSBR DesignConya Smathel100% (1)

- De NitrificationDocument3 paginiDe Nitrificationkiran raghukiranÎncă nu există evaluări

- De NitrificationDocument3 paginiDe Nitrificationkiran raghukiranÎncă nu există evaluări

- Activated Sludge Calculations With Excel QuizDocument2 paginiActivated Sludge Calculations With Excel Quiztrantrunghoa290784Încă nu există evaluări

- Air Lift Pump Wiki PDFDocument4 paginiAir Lift Pump Wiki PDFsteeluisÎncă nu există evaluări

- Tube Settler DesignDocument4 paginiTube Settler DesignKrishna Winx100% (1)

- Air Lift Design Pumps PDFDocument5 paginiAir Lift Design Pumps PDFinggerman100% (1)

- Wetscrubber VenturiDocument10 paginiWetscrubber Venturiakifah100% (1)

- Process Calculations 1 MLD SBRDocument168 paginiProcess Calculations 1 MLD SBRAngelo EndozoÎncă nu există evaluări

- Grit Removal DesignDocument5 paginiGrit Removal Designnassif75Încă nu există evaluări

- Design Spread Sheet For W&WWDocument18 paginiDesign Spread Sheet For W&WWsuinsas75% (8)

- Pond Discharge Calculation Worksheet: Step 1 - Calculate Storage NeededDocument3 paginiPond Discharge Calculation Worksheet: Step 1 - Calculate Storage Needednassif75Încă nu există evaluări

- Clariflocculator TypesDocument7 paginiClariflocculator TypesdexterÎncă nu există evaluări

- Sand Filter vs Disc Filter: Comparing Space, Cost and MaintenanceDocument1 paginăSand Filter vs Disc Filter: Comparing Space, Cost and MaintenanceKailash ThapliyalÎncă nu există evaluări

- Peak Flow Calculations XYZ Dec 16,2003Document7 paginiPeak Flow Calculations XYZ Dec 16,2003Amit BhamreÎncă nu există evaluări

- Grit Removal Mechanism: (Detritor and Classifier Mechanism)Document2 paginiGrit Removal Mechanism: (Detritor and Classifier Mechanism)Kaustav Patnaik100% (1)

- Aeration TankDocument18 paginiAeration TankKamod RaiÎncă nu există evaluări

- Activated-Sludge-Aeration-Tank-Calculations-Si-Units-Final-Locked (For Student)Document30 paginiActivated-Sludge-Aeration-Tank-Calculations-Si-Units-Final-Locked (For Student)Johnclaude Chamandi50% (2)

- Jet Pump EngineeringDocument43 paginiJet Pump EngineeringRohit Sharma50% (2)

- Computational Fluid Dynamics Investigation of Air Cooled Heat ExchangersDocument6 paginiComputational Fluid Dynamics Investigation of Air Cooled Heat ExchangersCarlos VegaÎncă nu există evaluări

- Ac Sizing - Duct SizingDocument9 paginiAc Sizing - Duct SizingHarpreet SinghÎncă nu există evaluări

- Compressed Piping Related Docs - 1Document5 paginiCompressed Piping Related Docs - 1Ashik HasanÎncă nu există evaluări

- Ashrae Duct PDFDocument3 paginiAshrae Duct PDFAnonymous XhkjXCxxsTÎncă nu există evaluări

- Compressed Air Systems PipingDocument5 paginiCompressed Air Systems PipingAnonymous DJrec250% (2)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDe la EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsÎncă nu există evaluări

- Heat Exchanger Design for Distillation Column Energy RecoveryDocument22 paginiHeat Exchanger Design for Distillation Column Energy Recoverykirandevi1981Încă nu există evaluări

- Hydraulic Hose Sizing NomographDocument3 paginiHydraulic Hose Sizing NomographFILID MADÎncă nu există evaluări

- WRD Ot Clarifier Calculations 445211 7Document118 paginiWRD Ot Clarifier Calculations 445211 7royal inÎncă nu există evaluări

- Seconardy TreatmentDocument43 paginiSeconardy TreatmentMohammed EljammalÎncă nu există evaluări

- Activated Sludge ModelDocument30 paginiActivated Sludge Modelvikas2504Încă nu există evaluări

- Influence of Local Wall Thinning On Elastic Shakedown Boundary of Pipe BendDocument9 paginiInfluence of Local Wall Thinning On Elastic Shakedown Boundary of Pipe BendMohammed EljammalÎncă nu există evaluări

- PV Quick StartDocument30 paginiPV Quick StartMinh Nguyen VanÎncă nu există evaluări

- Shakedown and Limit Load of Pipe Bends With Local Wall Thinning Under Combined Internal Pressure and Cyclic In-Plane Bending Moment PDFDocument24 paginiShakedown and Limit Load of Pipe Bends With Local Wall Thinning Under Combined Internal Pressure and Cyclic In-Plane Bending Moment PDFMohammed EljammalÎncă nu există evaluări

- Fourier Series TutorialDocument80 paginiFourier Series TutorialJose VillegasÎncă nu există evaluări

- SC PDFDocument10 paginiSC PDFMohammed EljammalÎncă nu există evaluări

- CA46S Austenitic Stainless Steel Air and Gas Trap DN40 and DN50Document3 paginiCA46S Austenitic Stainless Steel Air and Gas Trap DN40 and DN50Mohammed EljammalÎncă nu există evaluări

- ModiconPremium ScraperChain PDFDocument6 paginiModiconPremium ScraperChain PDFMohammed EljammalÎncă nu există evaluări

- BS6399 P 1Document16 paginiBS6399 P 1Gopan PillaiÎncă nu există evaluări

- Pages 285-295 From Complete Idler Roller Catalog-6 PDFDocument11 paginiPages 285-295 From Complete Idler Roller Catalog-6 PDFMohammed EljammalÎncă nu există evaluări

- Leak DetectionDocument36 paginiLeak Detectionliyana_anuar_3Încă nu există evaluări

- 2Document18 pagini2Beny AbdouÎncă nu există evaluări

- 2012Sept-IPC2012-90582 OvalityDocument13 pagini2012Sept-IPC2012-90582 OvalityMohammed EljammalÎncă nu există evaluări

- Using The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureDocument15 paginiUsing The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureMohammed EljammalÎncă nu există evaluări

- Asme PVP2011 57108 Final PDFDocument12 paginiAsme PVP2011 57108 Final PDFMohammed EljammalÎncă nu există evaluări

- 2012Sept-IPC2012-90582 OvalityDocument13 pagini2012Sept-IPC2012-90582 OvalityMohammed EljammalÎncă nu există evaluări

- ULC UL142 Comparison SpreadsheetDocument43 paginiULC UL142 Comparison SpreadsheetMohammed EljammalÎncă nu există evaluări

- Weights CalculationDocument10 paginiWeights CalculationMohammed EljammalÎncă nu există evaluări

- Effect of Internal Pressure and Shape Imperfections On Plastic Loads of Pipe Bends Under In-Plane Closing MomentDocument46 paginiEffect of Internal Pressure and Shape Imperfections On Plastic Loads of Pipe Bends Under In-Plane Closing MomentMohammed EljammalÎncă nu există evaluări

- NT-BELT CONVEYOR TRANSPORTS SOLIDS IN WATER TREATMENTDocument2 paginiNT-BELT CONVEYOR TRANSPORTS SOLIDS IN WATER TREATMENTMohammed EljammalÎncă nu există evaluări

- WHP-East Piatu-Roark Calc & Stiffener-Rev0Document18 paginiWHP-East Piatu-Roark Calc & Stiffener-Rev0namasral100% (4)

- 005 - CAT-6040 - Tank, Main Pumps + PMSDocument27 pagini005 - CAT-6040 - Tank, Main Pumps + PMS----Încă nu există evaluări

- LCS Series: Integrated Engine Speed ControlDocument2 paginiLCS Series: Integrated Engine Speed ControlBashar ZakariaÎncă nu există evaluări

- Mission 3D Inverter Series Service Manual 2016Document90 paginiMission 3D Inverter Series Service Manual 2016pastilhasÎncă nu există evaluări

- INDICATED MALFUNCTION: Engine Has Low RPM, Exhaust Gas Temperature, andDocument6 paginiINDICATED MALFUNCTION: Engine Has Low RPM, Exhaust Gas Temperature, andRaul DeonarainÎncă nu există evaluări

- Manual For Moyno Pump 28022007Document32 paginiManual For Moyno Pump 28022007Chozha RajanÎncă nu există evaluări

- ECON Quick Closing Valves and Accessories: Installation & Operation ManualDocument15 paginiECON Quick Closing Valves and Accessories: Installation & Operation ManualСергей ДенисенкоÎncă nu există evaluări

- Shuang Liang Chiller (H2 Series IOM)Document66 paginiShuang Liang Chiller (H2 Series IOM)Adi KurdiÎncă nu există evaluări

- 795F AC Off-Highway Truck Air SystemDocument2 pagini795F AC Off-Highway Truck Air SystemEugenio Pizarro MondacaÎncă nu există evaluări

- MegaCPK Curvas 50 HZDocument142 paginiMegaCPK Curvas 50 HZFlores AlbertoÎncă nu există evaluări

- 070.610-Iom Rwfii 2017-04 PDFDocument72 pagini070.610-Iom Rwfii 2017-04 PDFyoye1968100% (1)

- 5251200Document17 pagini5251200jabeer_aÎncă nu există evaluări

- Dimensions: Glanded Standard Pump Atmos GIGA-N 125/200-11/4Document3 paginiDimensions: Glanded Standard Pump Atmos GIGA-N 125/200-11/4Daney RockerzÎncă nu există evaluări

- Juntas SMC MQR PDFDocument10 paginiJuntas SMC MQR PDFhexapodoÎncă nu există evaluări

- Hvaci 0543 UsDocument14 paginiHvaci 0543 UsRami ReddyÎncă nu există evaluări

- 2014-15 PetroSkills Facilities CatalogDocument84 pagini2014-15 PetroSkills Facilities CatalogMichael MorrisonÎncă nu există evaluări

- (TDB) VRF Idu Duct For La (Drain Pump Integrated, R410a, 50 - 60hz, HP - HR) - Ver.1.1 Slim DuctDocument59 pagini(TDB) VRF Idu Duct For La (Drain Pump Integrated, R410a, 50 - 60hz, HP - HR) - Ver.1.1 Slim DuctJaime A. AlvarezÎncă nu există evaluări

- 4 PumpsDocument219 pagini4 PumpsVũ QuangÎncă nu există evaluări

- SEVO 1230 Fill & Recharge StationDocument2 paginiSEVO 1230 Fill & Recharge StationAli OsmanÎncă nu există evaluări

- N2000 Spec SheetDocument2 paginiN2000 Spec SheetJavier GarciaÎncă nu există evaluări

- Reciprocating Compressor PDFDocument16 paginiReciprocating Compressor PDFshan4600Încă nu există evaluări

- PG 6 - 14 Basis of Support StandardDocument10 paginiPG 6 - 14 Basis of Support StandardPankaj SahuÎncă nu există evaluări

- Leaning The Eaction ELL: Figure 5-10. Photolytic Lamp Assembly ReplacementDocument105 paginiLeaning The Eaction ELL: Figure 5-10. Photolytic Lamp Assembly ReplacementEdwar Vicente Moreno AsmatÎncă nu există evaluări

- Production ProgrammeDocument24 paginiProduction ProgrammejsabreuÎncă nu există evaluări

- 01 Chemical ProcessDocument333 pagini01 Chemical ProcessDavid ValladaresÎncă nu există evaluări

- Practical Rotordynamics For Centrifugal PumpsDocument52 paginiPractical Rotordynamics For Centrifugal PumpsRavi Shankar100% (1)

- Scania Engine DocumentDocument43 paginiScania Engine DocumentMsnanda100% (5)

- (File 1) Pf1033 Iom enDocument284 pagini(File 1) Pf1033 Iom enCristian VegaÎncă nu există evaluări