Documente Academic

Documente Profesional

Documente Cultură

ENV.04 Multi-Project Costing and Reporting Techniques: Erin Bognar and Chris Schoenbauer

Încărcat de

lalouniDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ENV.04 Multi-Project Costing and Reporting Techniques: Erin Bognar and Chris Schoenbauer

Încărcat de

lalouniDrepturi de autor:

Formate disponibile

1999 AACE INTERNATIONAL TRANSACTIONS

ENV.04 Multi-Project Costing and Reporting Techniques

Erin Bognar and Chris Schoenbauer

aiser-Hill Company, L.L.C. (Kaiser-Hill) has accepted the challenge of managing an environmental cleanup project that is multifaceted, with execution performance and responsibility assigned to multiple companies. Ensuring the successful integration and control of the Rocky Flats Environmental Technology Site (Rocky Flats or site) Closure Project is reliant on innovative costing and reporting techniques. The closure project consists of over 17,000 schedule activities and over 80,000 integrated resource records, each with a full basis of estimate. Kaiser-Hill manages and integrates five core subcontractors, who are tasked with the execution of these activities. All planning, scheduling, and budgeting (funding-constrained execution year budgets and out-year plans) reside in the closure project baseline (CPB) database. This baseline provides a single integrated reporting and planning system that supports the US Department of Energy (DOE) and community goals and objectives for the closure of Rocky Flats. Industry standard project control techniques establish the framework for the site scheduling, costing, and reporting systems. The site has advanced these techniques to facilitate multicompany business and project costing and reporting. All core subcontractors responsible for accomplishing the cleanup tasks use a central cost accounting, reporting, and project control system. This dynamic and flexible system allows Kaiser-Hill to respond to changing performance reporting requirements from our customer (DOE, Rocky Flats Field Office) and our core subcontractors while maintaining configuration control of the closure project baseline (CPB). This article describes the reporting systems and techniques implemented by Kaiser-Hill to manage the multicompany, multitask $7.3 billion dollar closure of Rocky Flats. SYSTEM SELECTION CRITERIA In selecting and implementing an integrated reporting system to manage the closure project, Kaiser-Hill established the following system criteria: total replacement of the legacy mainframe system; use of a modern client server approach; use of relational databases;

use of commercial off-the-shelf applications, where possible, to minimize cost; and year 2000 (Y2K) compliance.

The resulting system had to meet the above while maintaining focus on the end-users ability to get to data! INTEGRATED REPORTING SYSTEM Applying the above criteria, Kaiser-Hill selected/developed a control system that consists of five major systems or databases: a scope database, a baseline scheduling system, a basis of estimate database, a performance report database, and a work breakdown structure (WBS) database. When integrated with the sites accounting system, Kaiser-Hill has a reporting system (see figure 1), which supports the closure project mission, management, and customer/stakeholder needs. This suite of systems was developed and integrated in a near real-time basis with no impact to work in progress. The systems/databases are integrated and share data. They are designed to maintain the integrity of the baseline data that is under change control, while allowing flexibility for what-if analysis and work-around planning. Currently, the systems are being used to develop a what-if plan to accelerate closure from the year 2010 to 2006. WORK BREAKDOWN STRUCTURE The common thread used to integrate these systems/databases (scope, schedule, basis of estimate, performance reports, and the accounting system) is a configuration controlled work breakdown structure (WBS). The closure project WBS was completed in 1996 and defines the scope of the closure project consistent with the Rocky Flats Cleanup Agreement, until the scheduled completion in 2010. The WBS is expandable, as the scope is refined over the life of the project. DOE controls levels 1 to -5 of the WBS. The WBS controls the creation and status of charge numbers. The WBS coding structure is used as the link between the scope, schedule, and estimate tools. The WBS is maintained in a lookup table that links the WBS code to the:

ENV.04.1

1999 AACE INTERNATIONAL TRANSACTIONS

Figure 1Integrated Reporting System various project-reporting levels (project, subproject, cost account, and work package); various DOE financial-code reporting levels (budget and reporting, project reporting number (PRN), etc.); to the company responsible for managing the scope of work; and to the charge numbers used by the accounting system. gorization of hazards and risks, planned or implemented controls to mitigate and prevent hazards/risks, and the identification of the work performance feedback and improvement process that will be implemented during work execution. Subproject interface identification is essential to scope management. Although subproject interfaces are often identified as logic ties between activities on the project schedule, the need exists to identify these interfaces within the scope document. The closure project scope documents are used frequently by the general public, who may not have the technical expertise to understand interrelationships as defined on a detailed project schedule. Therefore, specific fields are provided within the scope database to capture the subproject internal interfaces, in addition to identification of external interfaces. Examples of two recent external interfaces affecting the closure project scope and completion are the delivery of a government furnished plutonium packaging system and the opening of the New Mexico Waste Isolation Pilot Project. The scope database is linked to the cost estimates in the basis of estimate software tool (BEST) database, the milestones in the baseline schedule system, and historical WBS cost data from the performance reports database via the WBS code. This link allows the production of closure project description documents that contain life-cycle scope schedule and cost information, which may be produced in any desired customer format. This scope database also produces the core baseline scope documents for the closure project. These documents, when approved, provide the contractual fiscal year statements of work between Kaiser-Hill and DOE (see figure 3). The data is also used as the basis for the Kaiser-Hill contracts with the five performing Kaiser-Hill Team companies. In addition, it is the source database for all government budget submissions, whatif exercises and special reports.

By using the WBS code in a reporting lookup table, Kaiser-Hill has maintained the ability to respond to changing regulatory and DOE financial and project reporting requirements without effecting the integrity of the WBS. By linking the WBS code to the company assigned to manage and/or perform the work, company-level performance measurement reporting capability is obtained. Scope Database The closure project scope is dynamic and subject to changes depending upon government and regulatory requirements. Kaiser-Hill is challenged with managing and communicating the closure project scope requirements, ensuring clear communication between the five companies that make up the core Kaiser-Hill Team. In order to manage and communicate the closure project scope, a scope management SQL-server database was developed. For each subproject (known as project baseline description, or (PBD) in Rocky Flats vernacular), cost account (known as a work authorization document), and work package within the closure project, the database clearly identifies the life-cycle scope, technical strategy, deliverables, and assumptions (see figures 2 and 3). A paramount concern is the identification and management of safety related concerns and issues and their potential effect to the closure project scope. As illustrated above, the database captures this information by requiring the identification and cate-

ENV.04.2

1999 AACE INTERNATIONAL TRANSACTIONS

Figure 2PBD (Subproject) Database Screen

Figure 3WAD (Cost Account) Screen

ENV.04.3

1999 AACE INTERNATIONAL TRANSACTIONS sure project scheduling standard requires that all schedules be Baseline Schedule System developed using a uniform coding structure within Primavera. As seen in figure 1, Kaiser-Hill manages the closure project This ensures that company detail working schedules summarize by using an industry standard software application for schedulto the Kaiser-Hill project summary schedule. Compliance to ing (Primavera). Primavera software supports the multiproject the closure project scheduling standard is contractually required environment and facilitates the various levels of schedules of all companies. required to manage the project. The implementation of a clo-

Figure 4Schedule Example

Schedule dates from Primavera Database

Figure 5Basis of Estimate ENV.04.4

1999 AACE INTERNATIONAL TRANSACTIONS

Company Identifier: R= Rocky Mountain Remediation Services K= Kaiser-Hill

Figure 6Basis of Estimate Two primary schedules are maintained: a target schedule and an active schedule. The target schedule is the basis for all commitments, as stated in the scope database. It also contains all milestones used for contract performance measurement. This target schedule is under change control. The active schedule is used to report progress, and the data date is moved monthly (see figure 4). These two schedules are compared to each other in order to perform critical path analysis on milestone and project completions. Schedule resources (as required by the Primavera schedule software) are obtained from the basis of estimate database and time-phased (spread) by Primavera to create manpower profiles and fiscal year budgets. Summarizing the two primary schedules creates the KaiserHill executive-level summary schedule. The executive-level schedule status is obtained monthly from the active schedule. This summary schedule is used for presentation purposes to the US Congress, the DOE, and project stakeholders (the city of Broomfield, etc.). Basis of Estimate Database Since the closure project consists of many subprojects whose scope includes such diverse activities as building construction, building demolition, fire protection services, laundry services, waste processing, waste packaging and waste shipments, a customized activity-based estimating tool (BEST) was developed. The estimate for each activity on the schedule is linked to the scheduling system via the WBS code and activity identifier (see figure 5). This link allows the scheduler to access the resources for time phasing and provides the estimator with schedule information as the estimate is being developed. This activity-based estimating tool was developed in Microsoft Access and SQL Server and allows cost estimates to be developed easily for a variety of project types including construction, demolition, production, service, and distribution. Since the database is used for all estimate types, the cost estimate learning curve associated with a project team transitioning from a completed production subproject to a demolition subproject is minimized. A standardized estimating tool for all project types facilitated the implementation of an integrated reporting system, ensuring that all project teams developed their estimates using a common cost code structure. The common cost coding structure ensures that actual costs collected can be compared to the cost estimate. This common cost code structure not only includes industry standard estimating data elements (labor/nonlabor, hours, quantity, units, department codes, skill codes, etc.) but also identifies the performing company (see figure 6). Having this identifier in the cost estimate and in the financial system enables Kaiser-Hill to monitor a service contractor who provides services such as laundry and building maintenance. These costs are collected for performance measurement in the work package of the Kaiser-Hill team company benefiting from the work being performed. This venue of cost reporting provides another mechanism for Kaiser-Hill to evaluate the service contractors performance. In managing the closure project , Kaiser-Hill has retained accountability for allocating the union work force to the various core companies. The performing company identifier in the cost estimate facilitates the forecasting of union labor requirements by company and is crucial in the allocation process of these limited resources. Including the company identifier enables company-level resource forecasting, facilitates the development of

ENV.04.5

1999 AACE INTERNATIONAL TRANSACTIONS

Figure 7Samples of Risk Codes company-specific statements of work, and enables companylevel performance reporting. Each basis of estimate is evaluated and assigned risk factors for scope, schedule, and cost to monitor the quality and uncertainty of the estimate. This information is used to evaluate and quantify the risks associated with each subproject. Management can then focus attention on risk issues that require mitigation. Examples of several of the risk codes captured in the basis of estimate database are indicated in figure 7. Performance Reports Kaiser-Hills performance reports mirror industry standard methodology for cost and schedule evaluation and reporting. These reports integrate the budget spreads (or budgeted cost of work scheduled) from the Primavera target schedule, the progress (or budgeted cost of work performed) for the Primavera active schedule and the actual costs of the work performed from the accounting system. Project labor cost data is updated weekly in the system; official performance measurement reports are updated monthly. Electronic performance reports are available for all levels of the project, for DOE, for the functional organizations, and for the individual companies. Accounting System In managing the closure project, Kaiser-Hill uses an industry-recognized leader in software applications for financial management (Peoplesoft). The Peoplesoft financial software supports multicompany financial reporting and multiproject cost collection and reporting. Kaiser-Hill manages the site application used by both Kaiser-Hill and the five primary contractors. The financial system provides cost information to the project control system for performance reporting and analysis. ENSURING EASE OF USE The key success criterion for any integrated reporting system is its ease of use. All elements of the integrated reporting system (scope, schedule, cost estimating, performance reports, or financial details) can be accessed via one application. The systems users are not just limited to Kaiser-Hill and its core companies but include the DOE and special agencies, at DOEs request. Today the system has approximately 300 users with access to information controlled via the WBS and the sites responsibility assignment matrix. Reports are standardized so that all levels of project managers (project, subproject, cost account, and work package) receive similar reports. Reports (performance, cost estimate, statements of work, schedules, etc.) are provided online via the reporting system and can be printed or migrated to Microsoft Excel at the discretion of the user. The reporting system windows are customized to the user-level (project manager, subproject manager, cost account manager, work package manager, functional manager, company-level, DOE, etc.). Users can access the reporting system onsite, 24-hours a day, from any terminal connection to the site client-server system. n integrated reporting system provides the contractor with the ability to respond to the annual government budget submissions, what-if requests, and special report requests while minimizing the effect to the sites project managers. Investment in customizing and integrating industry standard reporting systems to meet the demands of a multiproject, multicompany environment has paid off; specifically this integrated reporting tool has shortened learning curves, provided a multicompany standard for project costing and reporting, minimized the reporting demands on the project manager, received stakeholder and customer acceptance, and is easy to understand and use.

ENV.04.6

1999 AACE INTERNATIONAL TRANSACTIONS Erin Bognar Kaiser-Hill Company, L.L.C. Project Controls Division PO Box 464 Golden, CO 80402 Phone: 303-966-7526 or 303-966-8091 Fax: 303-966-6335 Chris Schoenbauer Kaiser-Hill Company, L.L.C. Project Controls Division PO Box 464 Golden, CO 80402 Phone: 303-966-7526 or 303-966-8091 Fax: 303-966-6335

ENV.04.7

S-ar putea să vă placă și

- EVMGuideDocument31 paginiEVMGuidefranciscobolognesi79Încă nu există evaluări

- Transfer Budgets From Oracle Plan and Budget Cloud To Erp Cloud Whitepaper PDFDocument25 paginiTransfer Budgets From Oracle Plan and Budget Cloud To Erp Cloud Whitepaper PDFBeatrice RousselinÎncă nu există evaluări

- Market Research & Business Strategy: Profile SummaryDocument1 paginăMarket Research & Business Strategy: Profile Summaryideation12345Încă nu există evaluări

- Project Cost Control Jul 02Document23 paginiProject Cost Control Jul 02Dexter DuronÎncă nu există evaluări

- Downstream Schedule Analysis for Non-SchedulersDocument15 paginiDownstream Schedule Analysis for Non-SchedulersplannersuperÎncă nu există evaluări

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideDe la EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideEvaluare: 5 din 5 stele5/5 (2)

- Drilling Data Management - SPE PetrowikiDocument6 paginiDrilling Data Management - SPE PetrowikiWanambwa SilagiÎncă nu există evaluări

- Engineering Change Management Aberdeen ReportDocument20 paginiEngineering Change Management Aberdeen ReportthehappytrollÎncă nu există evaluări

- Cost and Schedule Control For Engineering Contracts: Kenneth R. Davey, CCEDocument7 paginiCost and Schedule Control For Engineering Contracts: Kenneth R. Davey, CCElalouniÎncă nu există evaluări

- CAPEX Planning Overview & Tutorial GuideDocument10 paginiCAPEX Planning Overview & Tutorial GuidePrashantRanjan2010Încă nu există evaluări

- CM-PE-902 Procedure For Progress and Performance MeasurementDocument7 paginiCM-PE-902 Procedure For Progress and Performance MeasurementSam_1_Încă nu există evaluări

- Manage Construction Projects & Accounting with Integrated ModulesDocument14 paginiManage Construction Projects & Accounting with Integrated ModulesOvais990Încă nu există evaluări

- Managing Conversion of Legacy Data To Oracle FinancialsDocument20 paginiManaging Conversion of Legacy Data To Oracle FinancialsamitvohraÎncă nu există evaluări

- TOGAF® 10 Level 2 Enterprise Arch Part 2 Exam Wonder Guide Volume 2: TOGAF 10 Level 2 Scenario Strategies, #2De la EverandTOGAF® 10 Level 2 Enterprise Arch Part 2 Exam Wonder Guide Volume 2: TOGAF 10 Level 2 Scenario Strategies, #2Evaluare: 5 din 5 stele5/5 (1)

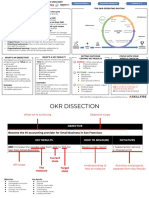

- Okr Cheat Sheet: Objective (Ideally 1) Key Results (Ideally 3-5) Initiatives ( 1)Document2 paginiOkr Cheat Sheet: Objective (Ideally 1) Key Results (Ideally 3-5) Initiatives ( 1)Tùng Hoàng50% (2)

- ISO 9001 Checklist Website Legal Compliance ProcedureDocument5 paginiISO 9001 Checklist Website Legal Compliance ProcedureCandiceÎncă nu există evaluări

- Integrated Project Planning and Construction Based on ResultsDe la EverandIntegrated Project Planning and Construction Based on ResultsÎncă nu există evaluări

- Event ManagementDocument3 paginiEvent ManagementAlexandru Dan GheorghiuÎncă nu există evaluări

- Project Execution Planning For Cost and Schedule Managers: Technical PaperDocument8 paginiProject Execution Planning For Cost and Schedule Managers: Technical Papermy_khan20027195Încă nu există evaluări

- Primavera Project Manager Deployment & Implementation Including But Not Limited To The FollowingDocument9 paginiPrimavera Project Manager Deployment & Implementation Including But Not Limited To The Followingtopriyeshpp50% (2)

- EVM PocketGuide PDFDocument36 paginiEVM PocketGuide PDFDilip KumarÎncă nu există evaluări

- Cost Code & WBSDocument8 paginiCost Code & WBSsprinter792100% (1)

- Oracle ProjectsDocument15 paginiOracle ProjectsKaran Kunwar singhÎncă nu există evaluări

- PRIME-HRM Action Plan - TEMPLATEDocument4 paginiPRIME-HRM Action Plan - TEMPLATEalikutegak67% (3)

- Earned Value Project Management (Fourth Edition)De la EverandEarned Value Project Management (Fourth Edition)Evaluare: 1 din 5 stele1/5 (2)

- 4 IT 35 Prototyping and Quality AssuranceDocument7 pagini4 IT 35 Prototyping and Quality Assurancemichael pascuaÎncă nu există evaluări

- SAP Project Systems OverviewDocument11 paginiSAP Project Systems OverviewKiran Thatikonda50% (2)

- REVPRO 3.0 ASC606 ConfigurationBRDDocument32 paginiREVPRO 3.0 ASC606 ConfigurationBRDBeverly Baker-HarrisÎncă nu există evaluări

- 200 Organization: Project Control System ManualDocument11 pagini200 Organization: Project Control System ManualRafael Fernandez SanchezÎncă nu există evaluări

- Module 4 PDFDocument22 paginiModule 4 PDFJerin MathewÎncă nu există evaluări

- Business Management QuizDocument6 paginiBusiness Management QuizSeckin UzunÎncă nu există evaluări

- AVEVA's Open PLM Platform For ShipbuildingDocument13 paginiAVEVA's Open PLM Platform For Shipbuildingguru4lifegmailcomÎncă nu există evaluări

- Making Project Historical Data UsefulDocument7 paginiMaking Project Historical Data UsefulegglestonaÎncă nu există evaluări

- Free PMI-SP AnswersDocument14 paginiFree PMI-SP Answerslalouni100% (1)

- As Built ScheduleDocument7 paginiAs Built ScheduleDayana Romero MonroyÎncă nu există evaluări

- Integrating Earned Value Management With CC ExecutionDocument12 paginiIntegrating Earned Value Management With CC ExecutionAntonio CalcinaÎncă nu există evaluări

- Introduction to Project Management: The Quick Reference HandbookDe la EverandIntroduction to Project Management: The Quick Reference HandbookÎncă nu există evaluări

- Advanced Work PackagesDocument24 paginiAdvanced Work Packagescfsolis100% (1)

- Integrated Cost and Schedule Control in Project ManagementDe la EverandIntegrated Cost and Schedule Control in Project ManagementEvaluare: 2 din 5 stele2/5 (1)

- Introduction To Primavera P6Document18 paginiIntroduction To Primavera P6MUUTHUKRISHNAN100% (1)

- Model-Driven Online Capacity Management for Component-Based Software SystemsDe la EverandModel-Driven Online Capacity Management for Component-Based Software SystemsÎncă nu există evaluări

- Front End LoadingDocument10 paginiFront End LoadingRnD2013Încă nu există evaluări

- Project Planning ProcessDocument23 paginiProject Planning ProcessNero ShaÎncă nu există evaluări

- QA-QC Work PlanDocument11 paginiQA-QC Work PlanWilliam l. Cabato100% (1)

- The Fake People PDFDocument7 paginiThe Fake People PDFFaizullahshahÎncă nu există evaluări

- Zenotis Boyd: 11008-J Sugar Pines Ct. Florissant, MO 63033 Phone: 314-831-8939Document4 paginiZenotis Boyd: 11008-J Sugar Pines Ct. Florissant, MO 63033 Phone: 314-831-8939zboydjr802Încă nu există evaluări

- JCEPMS13002 Hyunjoo KimDocument9 paginiJCEPMS13002 Hyunjoo Kimuday64668Încă nu există evaluări

- E V M Paper PDFDocument18 paginiE V M Paper PDFabdouÎncă nu există evaluări

- Dominic Robinson CV 042013Document6 paginiDominic Robinson CV 042013dominicrobinsonÎncă nu există evaluări

- AIS Project Plan Document - v1.0Document14 paginiAIS Project Plan Document - v1.0mcheyouwÎncă nu există evaluări

- Source: - Downloaded: 2005-04-14T12:33Z Check The Source To Verify That This Is The Current Version Before UseDocument6 paginiSource: - Downloaded: 2005-04-14T12:33Z Check The Source To Verify That This Is The Current Version Before UsejmbourvenÎncă nu există evaluări

- ProjectHistoricalDatabasesForTheCanadianOilSands PDFDocument5 paginiProjectHistoricalDatabasesForTheCanadianOilSands PDFbharathaninÎncă nu există evaluări

- 3.2 Work Breakdown StructureDocument4 pagini3.2 Work Breakdown StructureNadeem AhmadÎncă nu există evaluări

- Cocomo IiDocument7 paginiCocomo Iimeme2001.bashÎncă nu există evaluări

- PT&C'S Approach To Total Cost ManagementDocument6 paginiPT&C'S Approach To Total Cost ManagementRadwa El-HodaibyÎncă nu există evaluări

- Projects R12 New FeaturesDocument7 paginiProjects R12 New Featureshemanthp1212Încă nu există evaluări

- KRICE Kuali Rice: Kuali Rice RoadmapDocument23 paginiKRICE Kuali Rice: Kuali Rice RoadmapJosé Victor Hugo Arevalo PacoraÎncă nu există evaluări

- Project planning and operations improvementDocument12 paginiProject planning and operations improvementMohammed AfzaalÎncă nu există evaluări

- LBNL EVMS Reference Guide Final Rev0Document22 paginiLBNL EVMS Reference Guide Final Rev0orjuanÎncă nu există evaluări

- Cognos Administrator ResumeDocument3 paginiCognos Administrator ResumeChris D'MelloÎncă nu există evaluări

- Web Concepts Oct03 060104Document40 paginiWeb Concepts Oct03 060104kamlÎncă nu există evaluări

- Procedure 12.Pm-001 WBS, Obs, RamDocument11 paginiProcedure 12.Pm-001 WBS, Obs, RamTaha SalihÎncă nu există evaluări

- Earned Value Analysis: An Introduction ToDocument12 paginiEarned Value Analysis: An Introduction ToManuel Ortiz0% (1)

- Robert F. NiemoellerDocument4 paginiRobert F. NiemoellerPhaniVenkatÎncă nu există evaluări

- IADC/SPE-201088-MS Well Design and Engineering Process AutomationDocument12 paginiIADC/SPE-201088-MS Well Design and Engineering Process AutomationAleksey SolominÎncă nu există evaluări

- Standardized Multidimensional Wbs Cbs For Hospital Construction PDFDocument22 paginiStandardized Multidimensional Wbs Cbs For Hospital Construction PDFAndre de MontreuilÎncă nu există evaluări

- INNOVATION AND PROGRAM MANAGEMENTDocument7 paginiINNOVATION AND PROGRAM MANAGEMENTWajdi Jalal Osman KambalÎncă nu există evaluări

- 003 Converting Linear Schedules To CPM 27.10.12Document5 pagini003 Converting Linear Schedules To CPM 27.10.12Sunil Varma DanthuluriÎncă nu există evaluări

- WBS for project managementDocument8 paginiWBS for project managementrenshagullÎncă nu există evaluări

- Benefits of Project ControlDocument3 paginiBenefits of Project ControlPadma PatilÎncă nu există evaluări

- AIS Project Plan Document - v1.0Document15 paginiAIS Project Plan Document - v1.0Candy SpiceÎncă nu există evaluări

- Construction Management Polices and & Procedures SupplementDocument3 paginiConstruction Management Polices and & Procedures SupplementhiteshcparmarÎncă nu există evaluări

- Gaining Competitive Advantage Through Reducing Project Lead TimesDocument6 paginiGaining Competitive Advantage Through Reducing Project Lead TimeslalouniÎncă nu există evaluări

- Corresponding Schedule Reserve AnalysesDocument6 paginiCorresponding Schedule Reserve AnalyseslalouniÎncă nu există evaluări

- Delivering Benefits - Who, What and How! Project Value ChainDocument5 paginiDelivering Benefits - Who, What and How! Project Value ChainlalouniÎncă nu există evaluări

- Characterizing Unknown UnknownsDocument5 paginiCharacterizing Unknown UnknownslalouniÎncă nu există evaluări

- Webinar Introduction To AIPMO Certifications v1Document24 paginiWebinar Introduction To AIPMO Certifications v1lalouniÎncă nu există evaluări

- Exploration and Mining Explained E Book Metals Minerals and GeologyDocument6 paginiExploration and Mining Explained E Book Metals Minerals and GeologylalouniÎncă nu există evaluări

- 12v3 Project Portfolio Management PDFDocument6 pagini12v3 Project Portfolio Management PDFlalouniÎncă nu există evaluări

- Schedule Risk Analysis PDFDocument40 paginiSchedule Risk Analysis PDFicq4joyÎncă nu există evaluări

- CostMgmt 000 PDFDocument112 paginiCostMgmt 000 PDFupendrasÎncă nu există evaluări

- How Much Risk Is Too Much Risk - Understanding Risk AppetiteDocument6 paginiHow Much Risk Is Too Much Risk - Understanding Risk AppetitelalouniÎncă nu există evaluări

- Measuring Portfolio Strategic Performance Using Ke PDFDocument11 paginiMeasuring Portfolio Strategic Performance Using Ke PDFlalouniÎncă nu există evaluări

- Emad Mohamed Asal PDFDocument95 paginiEmad Mohamed Asal PDFlalouniÎncă nu există evaluări

- Work Breakdown Structure ProcedureDocument29 paginiWork Breakdown Structure ProcedurelalouniÎncă nu există evaluări

- Draft Def Aust 5664 Wbs 1Document53 paginiDraft Def Aust 5664 Wbs 1lalouniÎncă nu există evaluări

- 2011 01 01 Pharmaceutical Engineering RiskDocument6 pagini2011 01 01 Pharmaceutical Engineering RisklalouniÎncă nu există evaluări

- 4D SchedulingDocument6 pagini4D SchedulinglalouniÎncă nu există evaluări

- TRN33NA2011 editedJC 08082011Document8 paginiTRN33NA2011 editedJC 08082011lalouniÎncă nu există evaluări

- Risk Analysis in FS Higway ProjectsDocument4 paginiRisk Analysis in FS Higway ProjectslalouniÎncă nu există evaluări

- Strategic Risk Factors in ProjectsDocument21 paginiStrategic Risk Factors in ProjectslalouniÎncă nu există evaluări

- 4D SchedulingDocument6 pagini4D SchedulinglalouniÎncă nu există evaluări

- PMI Lexicon FinalDocument0 paginiPMI Lexicon Finaltuku67100% (1)

- An Introduction To The Management Principles of SchedulingDocument43 paginiAn Introduction To The Management Principles of SchedulingelsayedamrÎncă nu există evaluări

- State of The PMO 2012 Research ReportDocument12 paginiState of The PMO 2012 Research ReportlalouniÎncă nu există evaluări

- John K. Hollmann, PE CCE: 2002 AACE International TransactionsDocument7 paginiJohn K. Hollmann, PE CCE: 2002 AACE International TransactionslalouniÎncă nu există evaluări

- 2013 Salary SurveyDocument38 pagini2013 Salary SurveylalouniÎncă nu există evaluări

- Internship Report On Recruitment and Retention Process of Hup Lun BD LTDDocument42 paginiInternship Report On Recruitment and Retention Process of Hup Lun BD LTDTonmoy Kabiraj100% (1)

- HR Admin DutiesDocument2 paginiHR Admin Dutiesdtr17Încă nu există evaluări

- Multiple Choices - Quiz - Chapter 1-To-3Document21 paginiMultiple Choices - Quiz - Chapter 1-To-3Ella SingcaÎncă nu există evaluări

- 1 Information System ConceptsDocument35 pagini1 Information System ConceptsSushila SinghÎncă nu există evaluări

- AcumaticaERP InvMgmtDocument247 paginiAcumaticaERP InvMgmtcrudbugÎncă nu există evaluări

- Credit Management - A Study On Mercantile Bank Limited, Sheikh Mujib Road Branch, Chittagong.Document37 paginiCredit Management - A Study On Mercantile Bank Limited, Sheikh Mujib Road Branch, Chittagong.SharifMahmudÎncă nu există evaluări

- Seminar Topic: Software Reuse, Reengineering, Reverse EngineeringDocument29 paginiSeminar Topic: Software Reuse, Reengineering, Reverse EngineeringSHAIK CHAND PASHAÎncă nu există evaluări

- IBM Banking: IBM and Norkom Lead in Information Security SolutionsDocument4 paginiIBM Banking: IBM and Norkom Lead in Information Security SolutionsIBMBankingÎncă nu există evaluări

- CVP Formulas SummaryDocument2 paginiCVP Formulas SummaryNitish VermaÎncă nu există evaluări

- Inventory Control FinalDocument13 paginiInventory Control Finalamrendrakr09243460% (5)

- TMC PepsiCo 03Document3 paginiTMC PepsiCo 03snafarooqiÎncă nu există evaluări

- The Contribution Margin Ratio Will DecreaseDocument7 paginiThe Contribution Margin Ratio Will DecreaseSaeym SegoviaÎncă nu există evaluări

- IC Stock Inventory Control 8566Document7 paginiIC Stock Inventory Control 8566khalil baizarÎncă nu există evaluări

- Objectives of Study Scope of Study Research Methodology Limitation of Study - 7Document76 paginiObjectives of Study Scope of Study Research Methodology Limitation of Study - 7Anand SagarÎncă nu există evaluări

- Solution File MGT 402 Session-3Document11 paginiSolution File MGT 402 Session-3mc0902030450% (1)

- RAJEEV Summer Training Report SgiDocument38 paginiRAJEEV Summer Training Report SgichinkidimpiÎncă nu există evaluări

- Principles of Risk ManagementDocument19 paginiPrinciples of Risk ManagementJL FavÎncă nu există evaluări

- Job Costing: True / False QuestionsDocument232 paginiJob Costing: True / False QuestionsElaine GimarinoÎncă nu există evaluări

- BSBPMG522 1 SummaryDocument5 paginiBSBPMG522 1 SummarySergio OliveiraÎncă nu există evaluări

- SkykkelParts, Inc. Portfolio Project Managment PlanDocument10 paginiSkykkelParts, Inc. Portfolio Project Managment PlanKnowNaimÎncă nu există evaluări

- Chapter 2 - Describing The JobDocument44 paginiChapter 2 - Describing The JobRoshan ZamirÎncă nu există evaluări