Documente Academic

Documente Profesional

Documente Cultură

72.5 420kV CVT Crompton Greaves

Încărcat de

bcqbaoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

72.5 420kV CVT Crompton Greaves

Încărcat de

bcqbaoDrepturi de autor:

Formate disponibile

CAPACITIVE VOLTAGE TRANSFORMER (72.

5 TO 420 kV)

S W I T C H G E A R

C O M P L E X

SWITCHGEAR COMPLEX

CAPACITIVE VOLTAGE TRANSFORMER

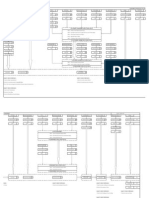

FIG. 1

1 2 22 21 3 4

More than 9500 Crompton Greaves Capacitive Voltage Transformers upto 420 kV have been put into service in various environments in over 60 countries all over the world since 1984 where they are operating satisfactorily. Our CVTs adhere to the requirements of the International quality standards and our quality and environment management systems are certified to ISO 90012000 and ISO 14001 respectively.

DESIGN AND CONSTRUCTION

Figure 1 shows the schematic view as well as the construction of a single stack CVT. Each CVT consists of a coupling capacitor (CC) which acts as a voltage divider and an Electro Magnetic Unit (EMU) which transforms the medium voltage to standard low voltage. Depending on the system voltage the CC can be a single or a multi stack unit. The CC and the EMU are individually hermetically sealed to ensure accurate performance and high reliability.

C1

C2

6 20 7 8 19 18 23 9 24 Name plate 17 10 16 11 15 12 14 13

Coupling Capacitor The Coupling Capacitor (CC) acts as a voltage divider and converts the system voltage to a medium voltage. The active part of the CC consists of a large number of oil impregnated paper (or paper and film) capacitor elements connected in series. Supercalendered capacitor tissue paper and pure aluminium foils are used to make the capacitor elements. The capacitor elements are pressed and held in insulating supports to ensure a stable capacitance even for large temperature variations. The electrical connections between the capacitor elements are designed for a natural frequency much above 600 Hz in order to avoid interference with carrier communication. The processed capacitor stack is assembled inside a porcelain insulator with corrosion resistant aluminium alloy end fittings. Brown glazed porcelain insulators with shed profile as per IEC 815 are used. The insulators are cemented to aluminium alloy flanges for improved strength. Oil volume changes due to temperature variations are compensated by a stainless steel bellow installed at the upper end of the CC. The unit is completely filled with degassed insulated oil under vacuum. The bellow is pressurised by inert gas

CAPACITOR VOLTAGE TRANSFORMER

1 2 3 4 5 6 7 8 9 10 11 12 H.V. Terminal 3080 Hood for L.T. Pedestal Mount. Porcelain Flange S.S. Bellow Porcelain Insulator Oil Filling Plug (For EMU) Lifting Lugs Secondary Terminal Box Varistor L.V. Terminal Block Gland Plate Surge Arrestor 13 14 15 16 17 18 19 20 21 22 23 24 EMU Tank Oil Sampling Valve Earthing Pads Compensating Choke M.V. Tap Terminal Oil level Indicator (For EMU) NHF Terminal Tank Cover Bellow Level Indicator (for capacitor unit) Chamber For Indicator Earthing Switch (Optional) Drain Coil (Optional)

SWITCHGEAR COMPLEX

(from the top surface) to maintain a positive oil pressure even at lowest ambient temperatures. The CVT thus has very low PD levels even at low ambient temperatures. Electromagnetic Unit The Electromagnetic Unit (EMU) consists of a medium voltage transformer, compensating reactor, damping element and surge protection device. The unit is housed inside a steel tank which is filled with insulating oil leaving a largely dimensioned air cushion at the top in order to take care of changes in the oil volume due to fluctuations in the ambient temperature. An oil level indivator is mounted on the side wall of the tank. The CC unit is mounted on the EMU tank and the insulated earth terminal of the CC (marked as NHF in Fig.1) is also accessible for connecting to power line carrier communication equipment. A surge arrester across this terminal and earth serves as the surge protection device. The NHF terminal must always be connected to earth if the CVT is not connected to carrier equipment. The secondary terminal box is provided on the EMU tank. Secondary leadouts, NHF lead and earth leads are all terminated inside the secondary terminal box. The EMU is caliberated and adjusted at factory for all burden and accuracy requirements. No site adjustments or measurements are neccessary. The EMU is given adequate surface treatment for corrosion protection for life long service.

FIG. 2

A - HV Terminal Zd V D S N - Damping Device - Varistor - Drain Coil - Surge Arestor - Neutral Terminal Of Intermediate Transformer

C1 - Pri. Capacitance C2 - Sec. Capacitance NHF- HF Terminal L Tr F - Compensating Choke - Intermediate Voltage Transformer - HRC Fuse

ES - Earthing Switch

ARCING DISTANCE

ARCING DISTANCE

C1

C2

NHF L Link

F F

Tr

D S ES 1a 1n 2a 2n f v g N Link

Za

MAINTENANCE

The product is self contained, maintenance free and requires no spares over its entire life span. We recommend regular and periodic checks as per pre-specified schedules (specified in the Instruction Manuals supplied with the CVTs).

FIG. 3

W

BOTTOM VIEW

W

BOTTOM VIEW

OPTIONALS / ACCESSORIES

Terminal Connector (Aluminium/Bimetallic, NEMA or as per customer specs) Three element Carrier Protection Device Level (comprising Drain Coil, surge Arrester & Earth Switch) Cable Glands

BELLOW POSITION INDICATOR

OIL LEVEL INDICATOR ON EMU

SWITCHGEAR COMPLEX

1. TYPE DESIGNATION 2. APPLICABLE STANDARDS 3. HIGHEST SYSTEM VOLTAGE 4. ONE MIN POWER FREQUENCY VOLTAGE 5. LIGHTNING IMPULSE 6. SWITCHING IMPULSE 7. RATED FREQUENCY 8. AMBIENT TEMPERATURE 9. SEISMIC ACCELERATION 10. RATED VOLTAGE FACTOR 11. ONE MIN. POWER FREQUENCY VOLTAGE ON SECONDARY 12. SECONDARY VOLTAGE 13. TOTAL CREEPAGE DISTANCE 14. EQUIVALENT CAPACITANCE

: UNIT : : : kV kV

CVE CVE CVE CVE CVE CVE CVE CVE 72.5/325/50 145/650/50 145/650/50 170/750/50 245/1050/50 300/1050/50 362/1300/50 420/1425/50

IEC 44-2; IEC 186 (1987) IEC 358 (1990); IEC 44-2 : IEC 44-5; IEC 44-5 72.5 140 325 123 230 550 145 275 650 NA 50/60 -25 TO 50 0.3/0.5 1.2 (CONT) / 1.5 (30 SEC) 3 100, 100/3, 110, 110/ 3 , 120 , 120/ 3. 1810 8800 3075 6000 3625 6000 4250 6000 6125 4400 7500 4400 9050 4400 10500 4400 170 325 750 245 460 1050 300 510 1050 850 362 570 1300 950 420 630 1425 1050

: kVp : kVp : : : : : : Hz C g kV V

: mm : pF VA kg

15. TOTAL SIMULTANEOUS BURDEN / ACCURACY : 16. TOTAL THERMAL BURDEN 17. CANTILEVER LOAD 18. ARCING DISTANCE 19. TOTAL HEIGHT (H) 20. MAXIMUM DEPTH (A) 21. MOUNTING DIMENSIONS (W) 22. TOTAL WEIGHT 23. QTY OF OIL 24. OIL VOLUME COMPENSATION (CC UNIT) 25. ALTITUDE : :

200VA / CL 0.5 500VA 125 820 1950 785 450 315 75 1215 2350 785 450 360 90 200 1215 2350 785 450 430 95 1415 2550 785 450 450 100 1930 3410 785 450 575 115 2180 3655 785 450 600 125 750VA 250 2630 4175 850 450 810 200 2830 4370 850 450 825 210

: mm : mm : mm : mm : : : : kg kg m

STAINLESS STEEL BELLOW UPTO 1000

OPTIONALS

TYPE DESIGNATION 1. HIGHEST SYSTEM VOLTAGE 2. VOLTAGE FACTOR 3. CREEPAGE DISTANCE : UNIT : : kV CVE 72.5 CVE 123 CVE 145 CVE 170 1.9 FOR 30 SEC 25, 31, 35 200 VA / CL 0.2 CVE 245 CVE 300 CVE 362 CVE 420 25 100 VA /CL 0.2

: mm/kV

4. TOTAL SIMULTANEOUS BURDEN / ACCURACY :

These parameters are typical values. For other specifications, please contact us.

Switchgear Complex A-3, MIDC, Ambad, Nashik - 422 010 India Tel : (+91) 253 2301661 to 674 Fax : (+91) 253 2381247 E-mail : ranjan.pendharkar@cgl.co.in URL : www.cglonline.com Regd. Office : 6th Floor, CG House, Dr. Annie Besant Road, Worli, Mumbai - 400 030, India.

Data subject to change Cat.No. CVT-112 (7/07/5K)

S-ar putea să vă placă și

- CVT O & M ManualDocument12 paginiCVT O & M ManualAgaram VenkateshÎncă nu există evaluări

- DISCUSSION ON MEASURING CVT TAN DELTADocument11 paginiDISCUSSION ON MEASURING CVT TAN DELTAỐng KhóiÎncă nu există evaluări

- Transformer Oil&DgaDocument70 paginiTransformer Oil&DgaBasudev PatraÎncă nu există evaluări

- Instrument Transformers CatalogueDocument12 paginiInstrument Transformers CatalogueGanesh DuraisamyÎncă nu există evaluări

- Crompton Greaves Limited: 12kV Indoor Vacuum Circuit BreakerDocument3 paginiCrompton Greaves Limited: 12kV Indoor Vacuum Circuit BreakerRamesh AnanthanarayananÎncă nu există evaluări

- Capacitive Voltage Transformer 040126Document4 paginiCapacitive Voltage Transformer 040126dharmendra.prp100% (6)

- Install and Maintain CVTs and CCsDocument20 paginiInstall and Maintain CVTs and CCsedgard100% (1)

- CVT TandeltaDocument5 paginiCVT Tandeltakishansai100% (2)

- Outdoor live tank SF6 circuit breaker 245-550kVDocument6 paginiOutdoor live tank SF6 circuit breaker 245-550kVRindah Tandiono100% (1)

- Omega Acb Catalogue PDFDocument135 paginiOmega Acb Catalogue PDFUmesh kumar100% (1)

- Product Guide Trip Circuit Supervision Relay TSR-BDocument2 paginiProduct Guide Trip Circuit Supervision Relay TSR-BPiyush OjhaÎncă nu există evaluări

- ALSTOM Reverse Power Relay CCUM 21 High ResDocument4 paginiALSTOM Reverse Power Relay CCUM 21 High ResArun KumarÎncă nu există evaluări

- 3ap1fg 72 eDocument2 pagini3ap1fg 72 efelipe_rodrigos80% (5)

- VTXDocument6 paginiVTXHari Krishna.MÎncă nu există evaluări

- DAVR Series Automatic Voltage Regulator Users ManualDocument20 paginiDAVR Series Automatic Voltage Regulator Users ManualriyantoÎncă nu există evaluări

- Trip Circuit Supervision Relay Explained in Detail !!!!!!!Document6 paginiTrip Circuit Supervision Relay Explained in Detail !!!!!!!Manali PrajapatiÎncă nu există evaluări

- Presentation DGADocument63 paginiPresentation DGAMuhammad Ahmed100% (2)

- MC31ADocument5 paginiMC31APuneet RanaÎncă nu există evaluări

- REF542 plus Bay Protection and Control UnitDocument24 paginiREF542 plus Bay Protection and Control UnitAbode OlusegunÎncă nu există evaluări

- User Manual Accuchek ERS MeterDocument39 paginiUser Manual Accuchek ERS MeterBashir Ahmad100% (5)

- Generator ProtectionsDocument50 paginiGenerator ProtectionsHari Krishna.MÎncă nu există evaluări

- Oil Filling To Transformers With Conservator, Aircell Inside ODT - MPTDocument17 paginiOil Filling To Transformers With Conservator, Aircell Inside ODT - MPTAnonymous Qoh9Tz5Ub100% (3)

- OLTC Control Diagram PDFDocument20 paginiOLTC Control Diagram PDFThant ZinÎncă nu există evaluări

- Standard Documentation for Float Cum Boost ChargerDocument12 paginiStandard Documentation for Float Cum Boost Chargerpitamberverma100% (1)

- Ses-12 TDPSDocument31 paginiSes-12 TDPSbaljeetjatÎncă nu există evaluări

- OVB VBF - O&M ManualDocument63 paginiOVB VBF - O&M ManualTetiana100% (2)

- Secure E3m051 Meter User ManualDocument6 paginiSecure E3m051 Meter User ManualSindhu Pandre0% (1)

- MiCOM P54 X - Current Diff Prot Relays - CT RequirementDocument5 paginiMiCOM P54 X - Current Diff Prot Relays - CT RequirementpayÎncă nu există evaluări

- ADR133A ManualDocument70 paginiADR133A ManualRitesh JaiswalÎncă nu există evaluări

- Technical Data Sheet (33-11kV Substation Construction) - Rev.0Document109 paginiTechnical Data Sheet (33-11kV Substation Construction) - Rev.0elsayedÎncă nu există evaluări

- Approved ProDoc sheets as of 13-okt-04 manufacturer model description doc typeDocument25 paginiApproved ProDoc sheets as of 13-okt-04 manufacturer model description doc typekhoshnama50% (2)

- Flat, Trofoil & TriplexDocument12 paginiFlat, Trofoil & Triplexphanibarama100% (1)

- Stub protection for one and a half circuit breaker schemeDocument2 paginiStub protection for one and a half circuit breaker schemesamlash100% (1)

- T09849 - CTR Fire Systems Rev.2Document30 paginiT09849 - CTR Fire Systems Rev.2Rudra Dash88% (8)

- CDG RelayDocument6 paginiCDG RelayAli AhmadÎncă nu există evaluări

- VAJ ManualDocument6 paginiVAJ Manualshailesh28467% (3)

- Battery Charger Manual - HBL PDFDocument12 paginiBattery Charger Manual - HBL PDFDSG0% (1)

- MVAPM32Document6 paginiMVAPM32rahul50% (2)

- Trip circuit supervision relays protect power gridsDocument6 paginiTrip circuit supervision relays protect power gridsishak789Încă nu există evaluări

- SubstationControl InterlockingDocument14 paginiSubstationControl Interlockingdundi_kumarÎncă nu există evaluări

- DGA & Oil Parameter TestingDocument98 paginiDGA & Oil Parameter Testingsibasis mohapatra100% (1)

- Fuse Failure RelayDocument12 paginiFuse Failure RelayHoangÎncă nu există evaluări

- MR TapChangerDocument76 paginiMR TapChangervertextsc100% (1)

- 3AK6 VCB Tech Description PDFDocument3 pagini3AK6 VCB Tech Description PDFArunava Basak50% (2)

- MBAS 9400 CatalogueDocument2 paginiMBAS 9400 CataloguebalajiÎncă nu există evaluări

- SOP for Troubleshooting LT ACB IssuesDocument9 paginiSOP for Troubleshooting LT ACB IssuesAkhilesh Kumar SinghÎncă nu există evaluări

- Transformer ProtectionDocument18 paginiTransformer ProtectionTanmayÎncă nu există evaluări

- Online Drying Systems With MoistureDocument51 paginiOnline Drying Systems With MoisturePrasanna MohandossÎncă nu există evaluări

- DC Time Constant EstimationDocument6 paginiDC Time Constant Estimationrasheed313Încă nu există evaluări

- ETL41 Manual enDocument199 paginiETL41 Manual enAnonymous PVKq1hZ5wÎncă nu există evaluări

- ALSTOM Instntneous Voltage Relay VAGM HighResDocument4 paginiALSTOM Instntneous Voltage Relay VAGM HighResMorgan Brooks0% (1)

- IEC61850-8-1 GOOSE - Basic ENaDocument19 paginiIEC61850-8-1 GOOSE - Basic ENayasadik9Încă nu există evaluări

- 72.5 - 420kV Capacitive Voltage TransformerDocument4 pagini72.5 - 420kV Capacitive Voltage TransformerRAPRATSINÎncă nu există evaluări

- TCVT and TCC - International BrochureDocument8 paginiTCVT and TCC - International Brochureseltonjapao0% (1)

- CCVT Products l3 Otcf Ansi 71508 v1 enDocument8 paginiCCVT Products l3 Otcf Ansi 71508 v1 enZeeshan HayatÎncă nu există evaluări

- Capacitor Voltage TransformerDocument12 paginiCapacitor Voltage TransformerThangco HutÎncă nu există evaluări

- Specification For 3 MVA TransformerDocument16 paginiSpecification For 3 MVA Transformervishwadeep_sinha100% (1)

- Current Transformers (72.5 kV to 420 kV) SpecificationsDocument4 paginiCurrent Transformers (72.5 kV to 420 kV) SpecificationsPaulo CardosoÎncă nu există evaluări

- 220KV CVT 0 2 Metering AccuracyDocument12 pagini220KV CVT 0 2 Metering AccuracyJAY PARIKHÎncă nu există evaluări

- Instrument Transformer CVT TransformerDocument6 paginiInstrument Transformer CVT Transformerkajrare_1947Încă nu există evaluări

- Power Factoring Surge ArrestersDocument2 paginiPower Factoring Surge Arrestersdacow22Încă nu există evaluări

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceDocument36 paginiCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoÎncă nu există evaluări

- Zero Lead Length Configuration PDFDocument2 paginiZero Lead Length Configuration PDFfourwheelerÎncă nu există evaluări

- Application Note: Determining Harmonic DirectionDocument5 paginiApplication Note: Determining Harmonic DirectionAnton MatzÎncă nu există evaluări

- ArresterWorks Facts-001 Arrester Lead LengthDocument11 paginiArresterWorks Facts-001 Arrester Lead Lengthnshj196Încă nu există evaluări

- Test Voltages For CablesDocument3 paginiTest Voltages For CablesMahmoud EidÎncă nu există evaluări

- Test Procedure of Surge ArresterDocument6 paginiTest Procedure of Surge Arrestersmi1989100% (3)

- Arrester Disconnector PDFDocument7 paginiArrester Disconnector PDFipraoÎncă nu există evaluări

- Testing of High Voltage CablesDocument7 paginiTesting of High Voltage CablesYogi Rungi100% (2)

- Monitor Lightning Arresters OnlineDocument5 paginiMonitor Lightning Arresters OnlineJoshi DhvanitÎncă nu există evaluări

- DOE Diagnostic Testing of Underground Cable Systems CDFI - Phase - 1 - Final-ReportDocument323 paginiDOE Diagnostic Testing of Underground Cable Systems CDFI - Phase - 1 - Final-ReportGustavo AguayoÎncă nu există evaluări

- 2 - 14 Experiences EuroDoble MeetingsDocument22 pagini2 - 14 Experiences EuroDoble Meetingsbcqbao100% (1)

- IEEE Guide For Fault Locating Techniques On Shielded Power Cable SystemsDocument37 paginiIEEE Guide For Fault Locating Techniques On Shielded Power Cable SystemsbcqbaoÎncă nu există evaluări

- Diagnostic AG en US1Document5 paginiDiagnostic AG en US1bcqbaoÎncă nu există evaluări

- Test Voltages For CablesDocument3 paginiTest Voltages For CablesMahmoud EidÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- IM-1 Doble Case Studies LewandDocument21 paginiIM-1 Doble Case Studies LewandbcqbaoÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Be On Guard For Effective Testing: 5 KV and 10 K Insulation TestingDocument8 paginiBe On Guard For Effective Testing: 5 KV and 10 K Insulation TestingKarthikÎncă nu există evaluări

- Above1kV UG en V04Document36 paginiAbove1kV UG en V04Amal MohanÎncă nu există evaluări

- Diagnostic AG en US1Document5 paginiDiagnostic AG en US1bcqbaoÎncă nu există evaluări

- Oil Revised)Document78 paginiOil Revised)shhansikaÎncă nu există evaluări

- SF6 Technical PaperDocument2 paginiSF6 Technical PaperbcqbaoÎncă nu există evaluări

- 5kV DiagnosticTestingDocument41 pagini5kV DiagnosticTestingkl_tsoÎncă nu există evaluări

- IM-1 Doble Case Studies LewandDocument21 paginiIM-1 Doble Case Studies LewandbcqbaoÎncă nu există evaluări

- Mineral Insulating OilDocument96 paginiMineral Insulating OilnbhawyaÎncă nu există evaluări

- Western Mining Electric Association Presentation on Transformer Testing and Maintenance ServicesDocument51 paginiWestern Mining Electric Association Presentation on Transformer Testing and Maintenance ServicesPrabhu Koppal100% (1)

- Efficient Method To Accelerate Resistance Measurement of Transformer LV WindingDocument8 paginiEfficient Method To Accelerate Resistance Measurement of Transformer LV WindingbcqbaoÎncă nu există evaluări

- Guide To Low Resistance Booklet-CROPICODocument39 paginiGuide To Low Resistance Booklet-CROPICObcqbaoÎncă nu există evaluări

- Rectify Binary Plate Efficiency BubblesDocument4 paginiRectify Binary Plate Efficiency BubblesCsaba AndrásÎncă nu există evaluări

- Solution 2 AntennaDocument7 paginiSolution 2 Antennaabdulwahab12100% (1)

- Fassmer Freefall - Lifeboat Type CFL (-T) 49 ManualDocument55 paginiFassmer Freefall - Lifeboat Type CFL (-T) 49 Manualkayhan aytugÎncă nu există evaluări

- Brandt M FR Btd500blnDocument74 paginiBrandt M FR Btd500blnStéphane JoussetÎncă nu există evaluări

- International Log Building StandardsDocument19 paginiInternational Log Building Standardsursind100% (1)

- Adobe Photoshop: The EditingDocument10 paginiAdobe Photoshop: The EditingMer Cjielo BalloonsÎncă nu există evaluări

- Online Quiz System DocumentationDocument92 paginiOnline Quiz System DocumentationSultan Aiman100% (1)

- FTS ScaleoEUserManualEN 10 1082177Document2.044 paginiFTS ScaleoEUserManualEN 10 1082177JÎncă nu există evaluări

- STP of Ethifen SyrupDocument5 paginiSTP of Ethifen SyrupBejoy KarimÎncă nu există evaluări

- A Practical Introductory Guide On Using Satellite Technology For CommunicationsDocument15 paginiA Practical Introductory Guide On Using Satellite Technology For CommunicationsJohan PrinslooÎncă nu există evaluări

- Android Tutorial - Broadcast ReceiversDocument15 paginiAndroid Tutorial - Broadcast ReceiversTrieu Ngo HuyÎncă nu există evaluări

- Multi-disciplinary profile of IS/IT outsourcing researchDocument47 paginiMulti-disciplinary profile of IS/IT outsourcing researchIsabel MirandaÎncă nu există evaluări

- SQL Server 2008 R2 Express Installation GuideDocument53 paginiSQL Server 2008 R2 Express Installation GuideGersonGamas100% (2)

- Explorador Ww90j6410cwec Version 02Document13 paginiExplorador Ww90j6410cwec Version 02Cristi PopescuÎncă nu există evaluări

- Data Collector 2.03.00Document20 paginiData Collector 2.03.00vyaskingÎncă nu există evaluări

- XXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorDocument5 paginiXXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorGilbert MartinezÎncă nu există evaluări

- Sant Gadge Baba Amravati University: Backlog From Session Winter-2019Document2 paginiSant Gadge Baba Amravati University: Backlog From Session Winter-2019Prashant pandeÎncă nu există evaluări

- The B-GON Solution: To Mist EliminationDocument20 paginiThe B-GON Solution: To Mist EliminationDimitris Sardis LÎncă nu există evaluări

- BTSDocument75 paginiBTSgyanesh198450% (2)

- (Mamoru Hosaka (Auth.) ) Modeling of Curves and SuDocument363 pagini(Mamoru Hosaka (Auth.) ) Modeling of Curves and Suamalendu_biswas_1Încă nu există evaluări

- NASA ERAST Program Develops High-Altitude UAVsDocument17 paginiNASA ERAST Program Develops High-Altitude UAVsEgz AguilarÎncă nu există evaluări

- Oracle E-Business Suite Release 11i Upgrade To R12.1Document60 paginiOracle E-Business Suite Release 11i Upgrade To R12.1Vladimir PacotaipeÎncă nu există evaluări

- 3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureDocument4 pagini3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureMohammed MustafaÎncă nu există evaluări

- Nurul Ain - nurulain@gmail.comDocument32 paginiNurul Ain - nurulain@gmail.comMuhamad FarhanÎncă nu există evaluări

- American English File Starter Ichecker - File 3Document3 paginiAmerican English File Starter Ichecker - File 3Daniel AugustoÎncă nu există evaluări

- Core 3Document2 paginiCore 3RidhiÎncă nu există evaluări

- Process Level ChartDocument2 paginiProcess Level ChartzaidinÎncă nu există evaluări

- Introduction to Generators, Protection Schemes, Relays and MaintenanceDocument44 paginiIntroduction to Generators, Protection Schemes, Relays and MaintenancerahulNrana100% (1)

- P1125P1/P1250E1: Output RatingsDocument6 paginiP1125P1/P1250E1: Output Ratingsmohsen_cumminsÎncă nu există evaluări

- Windmill ABB MachinesDocument6 paginiWindmill ABB MachinesRadu BabauÎncă nu există evaluări