Documente Academic

Documente Profesional

Documente Cultură

Bedding Specs (DM & Water)

Încărcat de

ganmosesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bedding Specs (DM & Water)

Încărcat de

ganmosesDrepturi de autor:

Formate disponibile

Project R999/1: Extension of Business Bay Canal Phase 1 - Sheikh Zayed Road Bridges Dubai Sewerage and Drainage

Master Plan Standard Specifications

Volume 2 Part III

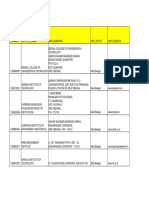

All thermoplastic pipes shall be shaded/protected from direct sunlight during handling, transportation, storage and laying. The Contractor shall ensure that thermoplastic pipes do not come into contact with bituminous or other hydrocarbon based materials. Determination of Ring Stiffness of Thermoplastic Pipes shall be tested at Dubai Central Laboratory in accordance with BS EN ISO 9969:2007 (Mechanical Testing) 4.3 GRANULAR MATERIAL FOR PIPE BEDDING Granular material for pipe bedding shall be free-draining, hard, clean, chemically stable gravel or crushed stone to BS EN 12620 and shall be graded in accordance with BS EN 12620 as shown in the following table:Table 4-3. Grading of Granular Material for Pipe Bedding Test Sieve ( mm) 63 37.5 20 14 10 5 2.36 Notes: 1) 2) For pipes 400 mm to 600 mm diameter, either grading is acceptable. Total acid soluble content of the material when tested in accordance with BS1377 shall not exceed 0.3 percent by weight of sulphate expressed as SO3 (sulphur trioxide). The material shall have a Compaction Fraction value not exceeding 0.15. For uPVC pipes only rounded aggregates will be permitted but for all other pipe materials crushed aggregates may also be used. Percentage by Weight Passing Sieve For Pipe For Pipe Diameters Diameters upto 600 mm 400 mm and above 100 100 85 - 100 85 - 100 0 - 50 0 - 25 0 - 10 0- 5 -

3)

4) 4.3.1

Stone for Land Drains Stone for land drains shall be nominal single size 20 mm in accordance with the following table or the manufacturers recommendations if different, and placed as shown on the drawings. The stone shall also comply with the general requirements of Clause 4.3.

August 2013

Tender Documents

Page 4/13

Project R999/1: Extension of Business Bay Canal Phase 1 - Sheikh Zayed Road Bridges Dubai Sewerage and Drainage Master Plan Standard Specifications

Volume 2 Part III

Table 4-4. Grading of Stone for Land Drains Test Sieve (mm) 75 63 37.5 20 14 10 5 2.36 4.3.2 Compaction Fraction Test For testing pipe bedding material, a representative sample of about 40 kg shall be heaped onto a clean surface and quartered to obtain approximately 10 kg. The moisture content of the sample should not differ materially from that of the main body of material, at the time of use in the trench. A 150 mm internal diameter open ended cylinder 250 mm high, shall be placed on a firm flat surface and loosely filled, without tamping, from the 10 kg sample. Any surplus material shall be struck off level with the top of the cylinder. The area around the filled cylinder shall be cleared of all surplus material and the cylinder then lifted clear of its contents and placed alongside the material. Approximately one quarter of the material shall then be replaced into the cylinder and compacted by tamping vigorously with a 40 mm diameter metal rammer weighing about 1 kg until no further compaction can be obtained. This operation shall then be repeated for each of the remaining quarters, tamping the final surface as level as possible. The distance from the top of the cylinder to the surface of final layer shall then be measured and this value, divided by the height of the cylinder, shall be taken as the Compaction Fraction. 4.4 4.4.1 CONVENTIONAL (OPEN TRENCH) PIPELINE CONSTRUCTION General This section applies to conventional open-trench pipe works. Nonconventional pipeworks have been detailed in Sections 14 and 16. 4.4.2 Nominal Trench Widths Nominal trench widths for single pipelines shall be defined as 1.50 times the diameter plus 500 mm, subject to a minimum trench width of 750 mm. Nominal trench widths for two or more pipes in the same trench (laid in parallel with similar invert levels) shall be defined as the sum of the internal diameters plus 450 mm between the pipes, plus 750 mm. Percentage by Weight Passing Sieve 100 85-100 0 - 25 0- 5 -

August 2013

Tender Documents

Page 4/14

Project R999/1: Jumeirah Creek Sheikh Zayed Road Crossing Particular Specifications

Volume 2 Part IIA

When supported horizontally over a span of 1.0 meter with the climbing face uppermost and with a load of 1000N applied at the center of the span, the ladder shall not deflect more than 15mm at the point of application of the load and shall show no permanent deflection after removal of the load. Each ladder fixing shall be capable of withstanding shear and pull-out loads of 5000N. Safety cages shall be provided where the distance between landing exceeds 3500mm. These shall be constructed of three vertical flats, minimum size 50mm by 8mm supported by flat hoops with a diameter of 750mm. The hoops shall be at a maximum of 900mm center and the first hoop shall be 2400mm above lowest platform level. No single hoops shall be used. All welds shall be ground flush and smoothed and ladders hot-tip galvanized after fabrication. Connections to concrete or masonry walls shall be secure with accurately positioned stainless steel anchor bolts. Ladders shall be mounted to produce a finished appearance that is plumb, straight and true to dimensions. Each ladder shall be coated with two coats of polyurethane painting system compatible with the galvanized surface strictly in accordance with the paint manufacturers instructions and as directed by the Engineer. PS 6/60.8 Granular Material for Pipe Bed and Surrounds Granular material for pipe bedding shall be free draining, hard, clean, chemically stable gravel or crushed stone to BS 882 and shall be graded in accordance with BS 882: Part 2 as shown in the following table:Table 2: Granular Material for Pipe Bedding Test Sieve (mm) 63 37.5 20 14 10 5 2.36 Notes: 1. For pipes 400mm to 800mm diameter, either grading is acceptable. Percentage by Weight Passing Sieve For Pipe Diameters up to 1200mm 100 85 - 100 0 - 25 0-5 For Pipe Diameters 1200mm and above 100 85 100 50 85 10 50 0 - 10

August 2013

Tender Documents

PS 6/68

Project R999/1: Jumeirah Creek Sheikh Zayed Road Crossing Particular Specifications

Volume 2 Part IIA

2. Refer clause 3/6.2 of General Specifications for the test method of acid soluble sulphate content and for other chemical requirements. 3. Total acid soluble content of the material when tested in accordance with BS1377 shall not exceed 0.3 percent by weight of sulphate expressed as SO 3 (Sulphur Trioxide). 4. The material shall have a compaction fraction value not exceeding 0.15. 5. For uPVC pipes only rounded aggregates will be permitted but for all other pipe materials crushed aggregate may also be used. Pipelines on Granular Beds Where granular beddings to pipelines are detailed the minimum thickness of bedding material beneath the pipe shall be: 150mm (minimum 100mm under sockets) for pipes not exceeding 300mm internal diameter. 200mm (minimum 100mm under sockets) for pipes exceeding 300mm internal diameter. The time internal between placing bedding material on the trench formation and commencing pipe laying shall be as short as is practicable.

The bedding material shall extend to the full width of the trench and shall be compacted in layers not exceeding 200mm. The bedding material shall carefully compacted using a plate vibrator or other approved equivalent mechanical method. Sufficient passes of a plate vibrator or other approved mechanical method are required to achieve positive deflection of flexible pipes to ensure that final deflections are within the specified limits. Hand tamping or punning will only be permitted where insufficient space is available to allow the use of mechanical plant. Recesses shall be formed in the bedding to accommodate pipe joints while ensuring continuous even support along the pipe length. Bedding material shall be prevented from entering pipe joints. After the joint has been made bedding material shall be carefully placed and hand compacted beneath the joint barrel to close any void left by the recess. Where the formation of the trench is of silt or soft clay and is below the natural water table, a 75mm blinding layer of sand shall be substituted for the specified bedding material directly above formation and carefully compacted if directed on site.

PS 6/60.9

Geotextile Filter Fabric Filter fabric used for subsurface drainage works shall consist of longchain synthetic polymer fibers composed of at least 85 percent by mass polyolefins, polyesters or ployamids. They shall be formed into a network that the filaments or yarns retain dimensional stability relative to each other including selvedges.

August 2013

Tender Documents

PS 6/69

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Heavy PlatesDocument41 paginiHeavy PlatesganmosesÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDocument3 paginiAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Road Geometric Design Manual PDFDocument690 paginiRoad Geometric Design Manual PDFganmosesÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Epoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidDocument4 paginiEpoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidganmosesÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Underpass DWGDocument1 paginăUnderpass DWGganmosesÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- DCL Test ChargesDocument1 paginăDCL Test ChargesganmosesÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Nitomortar FC PDFDocument2 paginiNitomortar FC PDFganmosesÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Cement Stablize - StudyDocument21 paginiCement Stablize - StudyganmosesÎncă nu există evaluări

- Iso 6361 2 1990 en PDFDocument8 paginiIso 6361 2 1990 en PDFganmoses0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Crosshole Sonic LoggingDocument2 paginiCrosshole Sonic LoggingganmosesÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Umwd 06516 XD PDFDocument3 paginiUmwd 06516 XD PDFceca89Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- EPAS 11 - Q1 - W1 - Mod1Document45 paginiEPAS 11 - Q1 - W1 - Mod1Alberto A. FugenÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Buried PipelinesDocument93 paginiBuried PipelinesVasant Kumar VarmaÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- QSP 04bDocument35 paginiQSP 04bakrastogi94843Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Algoritm BackTracking EnglezaDocument6 paginiAlgoritm BackTracking Englezaionutz_67Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Systems Analysis and Design in A Changing World, Fourth EditionDocument41 paginiSystems Analysis and Design in A Changing World, Fourth EditionKoko Dwika PutraÎncă nu există evaluări

- Congenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementDocument87 paginiCongenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementJZÎncă nu există evaluări

- 15 Day Detox ChallengeDocument84 pagini15 Day Detox ChallengeDanii Supergirl Bailey100% (4)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- 2014 - A - Levels Actual Grade A Essay by Harvey LeeDocument3 pagini2014 - A - Levels Actual Grade A Essay by Harvey Leecherylhzy100% (1)

- Bom Details FormatDocument6 paginiBom Details FormatPrince MittalÎncă nu există evaluări

- Injections Quiz 2Document6 paginiInjections Quiz 2Allysa MacalinoÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Micro Lab Midterm Study GuideDocument15 paginiMicro Lab Midterm Study GuideYvette Salomé NievesÎncă nu există evaluări

- 2022 Mable Parker Mclean Scholarship ApplicationDocument2 pagini2022 Mable Parker Mclean Scholarship Applicationapi-444959661Încă nu există evaluări

- Quiz 140322224412 Phpapp02Document26 paginiQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriÎncă nu există evaluări

- Guyana and The Islamic WorldDocument21 paginiGuyana and The Islamic WorldshuaibahmadkhanÎncă nu există evaluări

- Jackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairDocument65 paginiJackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairTeamMichael100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- NCP - Major Depressive DisorderDocument7 paginiNCP - Major Depressive DisorderJaylord Verazon100% (1)

- Genetics Icar1Document18 paginiGenetics Icar1elanthamizhmaranÎncă nu există evaluări

- Where We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Document1 paginăWhere We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Safia-umm Suhaim- FareedÎncă nu există evaluări

- Pityriasis VersicolorDocument10 paginiPityriasis Versicolorketty putriÎncă nu există evaluări

- Dwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFDocument35 paginiDwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFmirthafoucault100% (8)

- Sample Resume For Supply Chain Logistics PersonDocument2 paginiSample Resume For Supply Chain Logistics PersonAmmar AbbasÎncă nu există evaluări

- WBDocument59 paginiWBsahil.singhÎncă nu există evaluări

- Astm B19Document6 paginiAstm B19Davor IbarraÎncă nu există evaluări

- Baseline Scheduling Basics - Part-1Document48 paginiBaseline Scheduling Basics - Part-1Perwaiz100% (1)

- Deep Hole Drilling Tools: BotekDocument32 paginiDeep Hole Drilling Tools: BotekDANIEL MANRIQUEZ FAVILAÎncă nu există evaluări

- The Covenant Taken From The Sons of Adam Is The FitrahDocument10 paginiThe Covenant Taken From The Sons of Adam Is The FitrahTyler FranklinÎncă nu există evaluări

- JIS G 3141: Cold-Reduced Carbon Steel Sheet and StripDocument6 paginiJIS G 3141: Cold-Reduced Carbon Steel Sheet and StripHari0% (2)

- Application Form InnofundDocument13 paginiApplication Form InnofundharavinthanÎncă nu există evaluări

- Friction: Ultiple Hoice UestionsDocument5 paginiFriction: Ultiple Hoice Uestionspk2varmaÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)