Documente Academic

Documente Profesional

Documente Cultură

Compaction

Încărcat de

Chandan BleeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Compaction

Încărcat de

Chandan BleeDrepturi de autor:

Formate disponibile

Compaction, Excavation and Earthwork

Compaction, Excavation and Earthwork Publications Available for Downloading

NAVFAC 7.02 - Foundations and Earth Structures. Main topics includes excavations,

compaction/ earthwork/ hydraulic fills, analysis of walls/ retaining structures, shallow

foundations and deep foundations. This manual includes guidelines for braced excavations,

excavation stabilization, embankment compaction, underwater fills, cofferdams, uplift resistance,

foundation waterproofing and lateral load capacity on deep foundations.

NAVFAC 7.03 - Soil Dynamics and Special Design Aspects. Main topics include soil dynamics,

earthquake engineering and special design aspects. Information pertaining to these topics include

machine foundations, impact loadings, dynamic soil properties, slope stability, bearing capacity,

settlement, vibratory compaction, pile driving analysis and field testing, ground anchor systems,

seismic design parameters, liquefaction, sheet pile walls and laboratory testing.

USACE TM 5-852-4 - Arctic and Subarctic Construction - Foundations for Structures. The

main topics are site investigations, foundation design, construction considerations and

monitoring for structures in cold weather. Includes material considerations, excavation, backfill,

inspection, slope stability, retaining walls, creep and bearing capacity.

USACE TM 5-818-4 - Backfill for Subsurface Structures

USACE EM 1110-2-2906 - Design of Pile Foundations. Note: This publication does not have an

appendix. For link to appendix, click here.

USACE ETL 1110-1-185 - Guidelines on Ground Improvement for Structures and Facilities

USACE TM 5-822-5 - Pavement Design for Roads, Streets, Walks and Open Storage Areas

USACE EM 1110-2-2502 - Retaining and Flood Walls. Note: This publication does not have an

appendix. For link to appendix, click here.

USACE EM 1110-1-2908 - Rock Foundations

USACE TM 5-822-14 - Soil Stabilization for Pavements

USACE TM 5-818-1 - Soils and Geology Procedures for Foundation Design of Buildings and

Other Structures (Except Hydraulic Structures)

References to Compaction, Excavation and Earthwork in other Publications

Canadian Society for Civil Engineering, Cold Climate Utilities Manual, Canadian Society for

Civil Engineering, Montreal, 1986. An in-depth publication concerning water facilities. Also has

excellent information pertaining to foundations, roadways, runways, dams, earthwork and soil

properties.

Teng, W.C., Foundation Design, Prentice Hall International,1962.

Johnson, S.M. and Kavanaugh, T.C., The Design of Foundations for Buildings, McGraw Hill

Book Company, 1968.

Peck, R.B., Hanson, W.E., and Thornburn, T.H., Foundation Engineering, John Wiley and

Sons, Inc., 1974.

TECHNICAL GUIDANCE

Detailed specifications and guidance can be found at your local State Department of

Transportation Specifications for Roads and Bridges. Some of these principles may apply to

building structures, retaining walls and slope stability. Most State Departments have a wealth of

information on-line. See calculations for compaction, earthwork and phase diagrams below:

COMPACTION

Example #1: A project requires fill to be compacted to 95% relative density with relation

to the standard Proctor (ASTM D698). Laboratory results for the standard Proctor

indicated that the soil has a maximum dry density of 19.0 kN/m

3

(121 lb/ft

3

), and an

optimum moisture content of 8.9%.

After compaction of the fill soils with a vibratory roller, field testing with a sand cone,

nuclear densiometer, or other appropriate method indicated that the compacted fill soils

have an in-place unit weight of 18.76 kN/m

3

(124.4 lb/ft

3

), and a moisture content of 7.5%.

Calculate the relative compaction, and does the compacted fill exceed project

requirements?

Given

m

= 19.0 kN/m

3

(121 lbs/ft

3

) maximum dry density

m

o

= 8.9% optimum moisture content

= 19.54 kN/m

3

(124.4 lbs/ft

3

) in-situ density

m = 7.5% in-situ moisture content

R

d

= 95% required relative compaction per project specifications

Solution

Verify that compacted fill meets or exceeds compaction requirements,

R

d

> 95%

R

d

= d

m

d

= - (m) dry density of the in-situ soil

100

d

=19.54 kN/m

3

- 19.54 kN/m

3

(7.5%) = 18.07 kN/m

3

metric

100

d

=124.4 lb/ft

3

- 124.4 lb/ft

3

(7.5%) = 115.1 lb/ft

3

standard

100

R

d

= 18.07 kN/m

3

= 95.1% > 95% o.k. metric

19.0 kN/m

3

R

d

= 115.1 lb/ft

3

= 95.1% > 95% o.k. standard

121 lb/ft

3

Conclusion

The compacted fill exceeds project requirements of at least 95% relative density.

*****************************

Example #2: A project requires fill to be compacted to 100% relative density with

relation to the standard Proctor (ASTM D698). The fill has been vigorously compacted to a

relative density of 96.9%. Subsequent compacting does not increase the relative density.

What could be the problem?

Solution

1) Check the moisture content of the compacted fill. Depending on the soil type, an in-situ

moisture content deviating 2% to 4% from the optimum moisture content as determined from the

Proctor test, may create impossible conditions to achieve the required compaction. If this is the

case, scarify soil and add moisture (or let dry), and re-compact at the optimum moisture content.

Sometimes, complete removal and replacement of the soil is necessary.

2) Verify the maximum dry density as determined from the Proctor test still holds true for the

'un-compactible' soils. Sometimes the maximum dry density changes as different soils are

excavated from the borrow pit. If this is the case, use the new maximum dry density value when

determining the relative density.

3) Check compaction methods. Type of equipment used for compaction and the depth of

compacted lifts make a difference in the relative compaction.

4) Check for inadequate compaction in underlying lifts. Sometimes achieving adequate relative

density is impossible when compacting soils on top of loose or unconsolidated soils.

*******************************

EARTHWORK/ COMPACTION/ PHASE DIAGRAM

Example #3: This is in part, a phase diagram problem. A project requires fill to be

compacted to 95% relative density with relation to the standard Proctor (ASTM D698).

Laboratory results for the standard Proctor indicated that the soil has a maximum dry

density of 19.49 kN/m

3

(124 lb/ft

3

), and an optimum moisture content of 9.5%. Borrow soil

from another location that will be used as compacted fill for this project has a moisture

content of 12%, a void ratio of 0.6, and a specific gravity of 2.65.

Assuming that no moisture is lost during transport, what is the volume of borrow required

that is needed for 28.32 m

3

(1000 ft

3

) of compacted fill?

Given

m

= 19.49 kN/m

3

(124 lbs/ft

3

) maximum dry density

m

o

= 8.9% optimum moisture content

e = 0.6 void ratio of borrow soil

G

s

= 2.65 specific gravity of soil

m = 12.0% moisture content of soil

R

d

= 95% required relative compaction per project specifications

V

T

= 28.32 m

3

(1000 ft

3

) total soil volume of required fill

e

= 9.81 kN/m

3

(62.4 lbs/ft

3

) unit weight of water (constant)

Solution

Find dry unit weight,

o

, of soil required for 95% compaction.

o

= Rd

m

100

= 0.95(19.49 kN/m

3

) = 18.52 kN/m

3

metric

= 0.95(124.0 lb/ft

3

) = 117.8 lb/ft

3

standard

Calculate the weight of the soil solids, W

s

, required for 95% compaction. The weight of the soil

solids will be equal for both the fill and borrow material because only volume changes via

compaction.

W

s

=

o

(V

T

) *see notes within conclusion

= 18.52 kN/m

3

(28.32 m

3

) = 524.5 kN metric

= 117.8 lb/ft

3

(1000 ft

3

) = 117,800 lb standard

Determine the volume of soil solids, V

s

, required for 95% compaction.

V

s

= Ws

G

s

(

e

)

= 524.5 kN = 20.18 m

3

metric

2.65(9.81 kN/m

3

)

= 117,800 lb = 712.4 ft

3

standard

2.65(62.4 lb/ft

3

)

Find the volume of voids, V

v

, for the borrow material

V

v

= e (Vs)

= 0.6(20.18 m

3

) = 12.11 m

3

metric

= 0.6(712.4 ft

3

) = 427.4 ft

3

standard

Calculate the total volume, V

T

, of the borrow soil

V

T

= V

v

+ V

s

= 12.11 m

3

+ 20.18 m

3

= 32.3 m

3

metric

= 427.4 ft

3

+ 712.4 ft

3

= 1140 ft

3

standard

Conclusion

The volume of soil required from the borrow pit is 32.3 m

3

(1140 ft

3

). Equations used for this

problem are standard phase diagram relationships shown here. Other phase diagram equations

may be required depending on the situation.

COMPACTION

Below are a few powerpoint presentations that you can download. The original author of these

powerpoints is unknown. The original versions were slightly edited afterwards.

o Review of Compaction Principles powerpoint

o Relative Density powerpoint

S-ar putea să vă placă și

- CohesionDocument2 paginiCohesionChandan Blee100% (1)

- Paper CommunicatedDocument1 paginăPaper CommunicatedChandan BleeÎncă nu există evaluări

- Pile Foundations PhotosDocument26 paginiPile Foundations PhotosChandan Blee100% (1)

- The Post-Vaccination Syndrome - Post-Vaccination Syndrome - Homeopathy, Vaccination and Autism Website Dr. Tinus SmitsDocument58 paginiThe Post-Vaccination Syndrome - Post-Vaccination Syndrome - Homeopathy, Vaccination and Autism Website Dr. Tinus SmitsChandan BleeÎncă nu există evaluări

- Aditya Hridayam-Meaning in EnglishDocument9 paginiAditya Hridayam-Meaning in EnglishChandan BleeÎncă nu există evaluări

- Unit II-Dewatering and Drainage - GT-II Study Material-Nagaraj.H.BDocument27 paginiUnit II-Dewatering and Drainage - GT-II Study Material-Nagaraj.H.BChandan BleeÎncă nu există evaluări

- Sustainable Utilization of Quarry By-ProductsDocument80 paginiSustainable Utilization of Quarry By-ProductsChandan Blee100% (1)

- Absorption Water Content and Liquid LimitDocument7 paginiAbsorption Water Content and Liquid LimitChandan BleeÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Asme Wec Chapter Annual ReportDocument12 paginiAsme Wec Chapter Annual ReportManazar HussainÎncă nu există evaluări

- Softening N Penetration Test BitumenDocument11 paginiSoftening N Penetration Test BitumenEdwin LeonÎncă nu există evaluări

- ChemCAD and ConcepSys AIChE Spring 09Document28 paginiChemCAD and ConcepSys AIChE Spring 09ConcepSys Solutions LLCÎncă nu există evaluări

- State ManagementDocument16 paginiState Managementnegikamal703Încă nu există evaluări

- Water Treatment Process Disinfection PDFDocument6 paginiWater Treatment Process Disinfection PDFAriff JasniÎncă nu există evaluări

- zx350lc 3 InglesDocument6 paginizx350lc 3 InglesLuis Nahuelhuaique LemusÎncă nu există evaluări

- Write An Algorithm and Flowchart For Computing The Average Number of The Default 4 NumbersDocument3 paginiWrite An Algorithm and Flowchart For Computing The Average Number of The Default 4 NumbersMark Jelan100% (1)

- Panel 01-Eldora-Grand-1500V-2021-R01 - G1Document2 paginiPanel 01-Eldora-Grand-1500V-2021-R01 - G1DHAVAL SHAHÎncă nu există evaluări

- DT NotesDocument117 paginiDT NotestessÎncă nu există evaluări

- Problems PDFDocument9 paginiProblems PDFEduarGelvezÎncă nu există evaluări

- Structured ProgrammingDocument31 paginiStructured ProgrammingkakaboomÎncă nu există evaluări

- Help - Translating A CAD Stewart Platform - Computer-Aided Design Translation (SimMechanics™ Link)Document8 paginiHelp - Translating A CAD Stewart Platform - Computer-Aided Design Translation (SimMechanics™ Link)ĐinhĐứcAnhÎncă nu există evaluări

- Eramus Bridge PDFDocument10 paginiEramus Bridge PDFBabaO.Riley100% (1)

- HiraDocument30 paginiHiravijay kumar singhÎncă nu există evaluări

- AHRLACDocument18 paginiAHRLACVictor Pileggi100% (1)

- 01 GeoStrucAnal Cylinder Elastic PDFDocument12 pagini01 GeoStrucAnal Cylinder Elastic PDFSiddhant KaushikÎncă nu există evaluări

- 03-1 Synchronous Machines 1 DNDocument25 pagini03-1 Synchronous Machines 1 DNsaif thuraonÎncă nu există evaluări

- HARGA REFERENSI B2S PapuaDocument6 paginiHARGA REFERENSI B2S PapuaAbiyoga AdhityaÎncă nu există evaluări

- Woodworking Plans - Wheelbarrow PlanterDocument3 paginiWoodworking Plans - Wheelbarrow PlanterMirel HotescuÎncă nu există evaluări

- Huawei ACU2 Wireless Access Controller DatasheetDocument12 paginiHuawei ACU2 Wireless Access Controller Datasheetdexater007Încă nu există evaluări

- Mauser 98K - Model 48 Rifle ManualDocument20 paginiMauser 98K - Model 48 Rifle ManualMeor Amri96% (28)

- Turbin 1Document27 paginiTurbin 1Durjoy Chakraborty100% (1)

- 2019 All PDFDocument27 pagini2019 All PDFvishesh bhatiaÎncă nu există evaluări

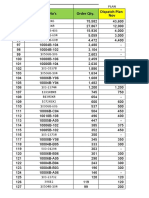

- Order Qty Vs Dispatch Plan - 04 11 20Document13 paginiOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPÎncă nu există evaluări

- Valve Body PDFDocument9 paginiValve Body PDFTimur TOT100% (2)

- The Right Stuff PDFDocument4 paginiThe Right Stuff PDFNeelank Tiwari100% (1)

- SQ Presentation 2021-r2Document43 paginiSQ Presentation 2021-r2nadeem4ahmed-805026Încă nu există evaluări

- Dynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass DcpsDocument2 paginiDynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass Dcpsd'Hell CaesarÎncă nu există evaluări

- High Integrity Aluminum (GENERAL)Document140 paginiHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)