Documente Academic

Documente Profesional

Documente Cultură

Mne 312 Report

Încărcat de

Afolabi Oluwadara CalebDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mne 312 Report

Încărcat de

Afolabi Oluwadara CalebDrepturi de autor:

Formate disponibile

CHAPTER THREE 3.

0 CANNED FOODS Canning is a method of preserving food in which the food contents are processed and sealed in an airtight container. Canning is a form of heat treatment in which the product is enclosed in hermetically sealed (air - tight) container such as impervious containers e.g. tin coated steel. Canning provides a shelf-life typically ranging from one to five years. The properties of the tin used must be such as to be inert to the acidic conditions of the products in the tin. The canned processing of food is used for preservation. Foods are sterilized by heating the cans or containers that can be sealed such that no microbes can enter. The time and temperature for heating vary with the type of food, the acid content and the ease with which sterilization can be achieved. Canning usually is adjusted to prevent nutritional destruction of food such as vitamins and other important food components. For canning to be accomplished, the foods are first cleaned washed and blanched to soften tissues and destroy enzymes. The softening of tissues allows easy canning. The cans after been filled are exposed to a vacuum system to remove dry excess air. The process called is thermal exhaustion, then sealed cans are exposed or cooled in cold water. The temperature and time of canning is dependent on the type of food being canned. Canning is use to preserve foods like fish, meat, fruits, vegetables etc. The following rules must be adhered to in canning: (i) Product should be taken in its prime. (ii) Product must be prepared as quickly as possible before the onset of deterioration. (iii) Enclosed in a container which could be hermetically sealed e.g. glass and tin cans. (iv) Heat the cold container sufficiently to keep the contents good.

3.1

METAL AS PACKAGING MATERIAL

Metal containers commonly used in the food industry include steel drums, tins with push-

on or screw-on closures, sanitary cans (the tin can), composite cans (usually a combination of paper board and steel), aerosols, aluminum cans and aluminum foil made into dishes, etc.(AYINDE,2002). The level of technology involved in filling into aluminum cans (used for beers and carbonated beverages) is high and as generally it is only applicable to large production units. There are three main methods of making cans, the most common produces the traditional three-piece sanitary can that consist of a body and two end pieces that are joined together to provide a hermeticor perfect seal while most commonly used for foods that are heat processed they also find application in packaging powders, syrups, etc. that are non-heat-processed. The most common shape is a round but square and oval flat cans are used, particularly for fish processing. The other two methods, which produce a two-piece, can (integral body and base plus a lid) have become increasingly common in recent years. Two-piece cans require less metal and thus are lighter and cheaper.

3.2 TYPES OF CANNING

There are two kinds of canning both of which use high temperatures to create a vacuum seal that prevents air and bacteria from forming on food. (i) Canning in a water bath: this is done by immersing sterile jars filled with high- acid foods (more on this in a minute) in enough boiling water to cover them and boiling for the required amount of time. (ii) Pressure canning: that involves a special piece of equipment, a pressure canner (not a pressure cooker) designed to achieve higher temperatures than boiling water can. This is for food that is not acidic enough to prevent of a growth of a particular toxin, botulism, which can kill you.

Examples of foods that are canned includes fruits and vegetables , milks and sauces, beans and legumes, meat and fish, soups and other prepared items. 3.3 FOOD CANNING PROCESSES In the preparation of canned food from vegetables, fish and meat, there are main operations that are common to all(for example heat treatment) and other main operations that are characteristics of the type of raw material being processed (gutting, peeling, mincing). The general unit operations of production processes in the food industry normally consist of the following stages: washing of the raw material, elimination of the non-edible part, preparation of the food product and canning. The process stages are applicable to any canning industry and what makes them characteristic in relation to the rest of the food industries in the heat treatment, sterilization or pasteurization process that is applied after canning to destroy microbes. The preparation of canned foods starts with a raw material, either fruit, vegetables, fish or meat, which is prepared by applying different treatments such as washing, peeling or skinning and chopping. Once it is prepared, the product is packed in metal or glass containers together with a control juice in most cases that optimizes and protects the foodstuff from any subsequent treatment.

3.3.1 The general process in the canning industry

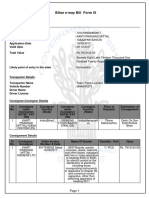

Raw material reception

Preparation of the raw material

Addition of covering liquid

Elimination of trapped air

Sealing of containers

Sterilization/Pasteurisation

Cooling and drying of containers

Labelling and packing

Pelleting

Storage

Fig 3.1 Process in Canning Industry

3.4

Unit operations OF FOOD CANNING

Washing of the containers

It is usually necessary to wash the containers before they are filled, even though they are normally supplied clean. For washing to be effective, it must be done using hot water sprinklers with the container upside-down because a jet steam is sufficient for correct cleaning.

Preparation of the covering liquid

Most canned foods are filled with hot sweet syrup solutions, brines or sauces that must be at the highest possible temperature at the time that the container is being filled. This helps to optimize the sterilization process because the container starts at an initially high temperature, and at the same time it helps to eliminate air from the headroom in the container.

Filling of the containers and elimination of any trapped air

Once the containers have been washed, they are uniformly filled with the appropriate quantity of the product in order to expel any unwanted gases, especially oxygen. Here a covering liquid is added that can be brine, a sauce, juice according to the type of preserved food.Once the containers are filled and before they are sealed, they are preheated to eliminate any air trapped inside of the containers so that there is a partial vacuum that prevents alterations occurring during storage and to reduce the sterilization time, at the same time that the pressure inside the container is reduced during the period of sterilization.

Sealing the containers

It is an essential part of the canning process because incorrect sealing would lead to recontamination of the foodstuff once it has been sterilized. There are various sealing alternatives according to the type of container. Glass jars are normally vacuum sealed while tins are closed

with a double seam on the seal side and they can also be vacuum sealed. Sealing can be done either manual equipment or very modern, efficient machinery that can seal over a thousand cans a minute.

Sterilization

It is an operation in which the foodstuff is heated to a sufficiently high temperature and during a sufficiently high temperature and during a sufficiently long period of time to destroy all microbial and enzymatic activity in the food and it also lengthens the life of the product. Nowadays the different sterilization techniques are classified into two systems, in batches and continuously.

Pasteurisation

This treatment involves the application of temperatures that are lower than in sterilization (lower than 100 c) and of a low intensity to stabilize the product in a way that respects its organoleptic qualities. There are two systems of pasteurization: Low temperature during a long period of time (LTLT: low temperature-long time). This system can work with batches or continuously, for all types of product presentation (liquid or solid, bulk, packaged). High temperature during a short period of time (HTST: high temperature-short time). In this case, the system is only applied to liquid products in continuous processes.

Final preparation (cooling, labeling, packing, palletizing)

Once it has been given the heat treatment, the product is cooled. The object of this operation is to avoid the harmful effects of over baking which softens the foodstuff excessively and produces negative changes in the flavour and colour. Many of the heat treatment systems explained in the previous section include the cooling phase of the product in the same system. The water used to carry out this cooling is chlorinated and does not pollute microbiologically. The container reaches 38 40 C and retains sufficient heat to dry because a wet container is dangerous. Once they are dry, the containers are labelled, packed and put on pallets

REFERENCES Ayinde, F.A. (2002). Basic food packaging. Oyez-Gilgal Company, Lagos. Pyke, M. (1970). Food science and Technology. John Murray, London. Olaleye, O.N. (2007).Basic microbiology.A Food perspective. Telletes Publishing House, Lagos.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Binet Kamat Test For General Mental AbilitiesDocument54 paginiBinet Kamat Test For General Mental AbilitiesSana Siddiq100% (14)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Action Analysis For Animators by Chris WebsterDocument409 paginiAction Analysis For Animators by Chris WebsterThomas Yandex100% (8)

- Differential Geometry of Curves and Surfaces 3. Regular SurfacesDocument16 paginiDifferential Geometry of Curves and Surfaces 3. Regular SurfacesyrodroÎncă nu există evaluări

- Antoine Constants PDFDocument3 paginiAntoine Constants PDFsofiaÎncă nu există evaluări

- Chemical Bonds WorksheetDocument2 paginiChemical Bonds WorksheetJewel Mae MercadoÎncă nu există evaluări

- Statistics and Probability Module 3Document3 paginiStatistics and Probability Module 3Eftychia LeegleeÎncă nu există evaluări

- Top Coat-200 - Data PDFDocument4 paginiTop Coat-200 - Data PDFLiliana GeorgianaÎncă nu există evaluări

- CE Review GEOMETRY 2Document6 paginiCE Review GEOMETRY 2Paul Gerard AguilarÎncă nu există evaluări

- Southwest Airlines Final ReportDocument16 paginiSouthwest Airlines Final Reportapi-427311067Încă nu există evaluări

- Stanley B. Alpern - Amazons of Black Sparta - The Women Warriors of Dahomey-New York University Press (2011)Document308 paginiStanley B. Alpern - Amazons of Black Sparta - The Women Warriors of Dahomey-New York University Press (2011)georgemultiplusÎncă nu există evaluări

- Bolt Action Italian Painting GuideDocument7 paginiBolt Action Italian Painting GuideTirmcdhol100% (2)

- Energy Transfer in Cell During Exercise and Oxygen Metabolism and Transport - PalakDocument85 paginiEnergy Transfer in Cell During Exercise and Oxygen Metabolism and Transport - Palakpalooo4Încă nu există evaluări

- Earth Science (Metamorphic Rocks)Document8 paginiEarth Science (Metamorphic Rocks)MA. ALEXIS LAURENÎncă nu există evaluări

- c083c282a43655ec69532f2704c3993aDocument12 paginic083c282a43655ec69532f2704c3993aAneilRandyRamdialÎncă nu există evaluări

- The Wild T1 TheodoliteDocument61 paginiThe Wild T1 TheodoliteCJLara100% (1)

- Cell Wall Synthesis InhibitorsDocument6 paginiCell Wall Synthesis InhibitorsRPh Krishna Chandra JagritÎncă nu există evaluări

- 1.1 The Prescription of Blood ComponentsDocument9 pagini1.1 The Prescription of Blood ComponentsagurtovicÎncă nu există evaluări

- Active Faults in MalaysiaDocument52 paginiActive Faults in MalaysiaHazim HaÎncă nu există evaluări

- Igcse Revision BookDocument23 paginiIgcse Revision BookJo Patrick100% (2)

- Iron Ore ProcessDocument52 paginiIron Ore Processjafary448067% (3)

- Product Stock Exchange Learn BookDocument1 paginăProduct Stock Exchange Learn BookSujit MauryaÎncă nu există evaluări

- YellowstoneDocument1 paginăYellowstoneOana GalbenuÎncă nu există evaluări

- ANS: (2.59807m/s2 Horizontal) (1.5m/s2 Vertical) (12.93725 Degree Angle That The Water Surface Makes With The Horizontal)Document5 paginiANS: (2.59807m/s2 Horizontal) (1.5m/s2 Vertical) (12.93725 Degree Angle That The Water Surface Makes With The Horizontal)Lolly UmaliÎncă nu există evaluări

- Science Involved in Floating Paper Clip Science Experiment GuidelinesDocument4 paginiScience Involved in Floating Paper Clip Science Experiment GuidelinesSHIELA RUBIOÎncă nu există evaluări

- LighthouseDocument4 paginiLighthousejaneborn5345Încă nu există evaluări

- Recycling Mind MapDocument2 paginiRecycling Mind Mapmsole124100% (1)

- Ge Fairchild Brochure PDFDocument2 paginiGe Fairchild Brochure PDFDharmesh patelÎncă nu există evaluări

- 1ST SUMMATIVE TEST FOR G10finalDocument2 pagini1ST SUMMATIVE TEST FOR G10finalcherish austriaÎncă nu există evaluări

- Multiple Choice Enzymes Plant and Animal NutritionDocument44 paginiMultiple Choice Enzymes Plant and Animal Nutritionliufanjing07Încă nu există evaluări