Documente Academic

Documente Profesional

Documente Cultură

NH3 Syn Flowsheet

Încărcat de

pepepopoooDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NH3 Syn Flowsheet

Încărcat de

pepepopoooDrepturi de autor:

Formate disponibile

Ammonia Synthesis

Flowsheet

Operator Training

By

Gerard B. Hawkins

Managing Director, CEO

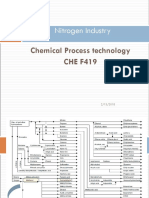

Introduction

Most modern ammonia processes are

based on steam-reforming of natural

gas or naphtha.

The 3 main technology suppliers are

Uhde (Uhde/JM Partnership), Topsoe

& KBR.

The process steps are very similar in all

cases.

Other suppliers are Linde (LAC) &

Ammonia Casale.

Simplified - NH

3

Plant

H

2

O

H/C

feed

H/C

purification

Removes

impurities (S,

Cl, metals)

Primary

reforming

Converts to

H

2

, CO, CO

2

+

H

2

O + CH

4

CO

Shift

WGS

reaction

Secondary

reforming

Combustion +

Adiabatic Reforming

+ Adds Nitrogen

Air

Ammonia

synthesis

NH

3

Converts N

2

+

H

2

=> NH

3

Syngas

compression

Purification

CO2 Removal

& Methanation

Ammonia Synthesis Loop

Synthesis reaction is equilibrium limited,

typically 15 20% NH3 at converter exit.

Therefore recycle in a loop is required.

Multi-stage complex converters are

required to control bed temperatures.

Various designs are used depending on

contractor.

Liquid Ammonia is recovered by

refrigeration.

Simplified Flowsheet for a Typical Ammonia

Plant

Natural

Gas

Steam

superheater

Air

Steam

30

bar

Steam

Steam

raising

350 C

200 C

Heat

Recovery

Steam

raising

Cooling

Cooling

Reboiler

CO

Cooling

Preheater

Heat

Recovery

Steam

Boiler

Process

Condensate

Quench

Quench

Liquid Ammonia

H

Hydrodesulphuriser Primary

Reformer

Secondary

Reformer

High

Temperature

Shift

Low

Temperature

Shift

Ammonia Synthesis Methanator

Carbon Dioxide

Purge Gas

Cooling

400 C

o

390 C

o

2

790 C

o

550 C

o

1000 C

o

o

420 C

o

150 C

o

400 C

o

470 C

o

o

220 C

o

290 C

o

330 C

o

2

CO Removal

2

220 bar

Refrigeration

Condensate

Cooling

Ammonia

Catchpot

Ammonia Plant Steam & Power

System

Waste Heat recovery is used to raise

HP steam, 100 120 bar

Steam is used to drive the main

compressors

Process air

Syn gas compression + circulator

Refrigeration

Pass-out steam is used for process.

Ammonia Flowsheet Variations

1. Uhde

Top fired reformer

Cold outlet manifold design

Secondary reformer with internal riser

H P loop (200 bar) with radial flow

converter

1 or 2 converters

Once-through synthesis section upstream

of main synthesis loop for very large

capacities (dual pressure Uhde process)

Ammonia Flowsheet Variations

2. KBR

Top-fired reformer

With internal risers

Several synthesis loop options:

Conventional 140 bar loop with 4bed

quench converter

Higher pressure for large-scale plants

Horizontal converter on modern plants.

KAAP design 100 bar loop with Ru/C

catalyst

Braun Purifier flowsheet

Excess air with cryogenic purifier to

remove excess N2 and inerts from MUG

Ammonia Flowsheet Variations

3. Topse

Side-fired reformer

Radial flow converter

S-100 2 bed quench

S-200 2 bed intercooled

S-250 = S-200 + boiler + 2

nd

converter

(1 bed)

S-300 3 bed intercooled

Ammonia Flowsheet Variations

4. Linde LAC (Linde Ammonia

Concept)

Hydrogen plant + N2 addition from

air separation unit

Ammonia Casale synthesis loop

Ammonia Flowsheet Variations

5. ICI (JM)

AMV

Large-scale process with excess air,

low pressure loop (80 110 bar)

LCA

Small-scale plant based on GHR

technology

AMV / LCA technology is now part

of JMs background in ammonia

Ammonia Synthesis Mechanism

Dissociative adsorption of H

2

Dissociative adsorption of N

2

-

Believed to be the Rate Determining

Step (RDS)

Multi-step hydrogenation of

adsorbed N

2

Desorption of NH

3

Typical Uhde Synthesis Loop

Uhde Dual-Pressure Process

C.W. Make up gas

from frontend

C.W.

Steam

Once

through

converter

Synthesis

Loop

Purge

NH

3

NH

3

NH

3

1 2 3 R

C.W. Make up gas

from frontend

C.W.

Steam

Once

through

converter

Synthesis

Loop

Purge

NH

3

NH

3

NH

3

1 2 3 R

Effect of Pressure on Ammonia

Equilibrium Concentration

0

10

20

30

40

50

60

50 75 100 125 150 175 200 225 250 275 300

N

H

3

c

o

n

c

e

n

t

r

a

t

i

o

n

%

Pressure bara

380 C

400 C

420 C

Ammonia Equilibrium Diagram

300

(572)

350

(662)

400

(752)

450

(842)

500

(932)

550

(1022)

600

(1112)

650

(1202)

0

10

20

30

40

Equilibrium

Max Rate

Temperature C (F)

A

m

m

o

n

i

a

c

o

n

t

e

n

t

%

Effect of Catchpot Temperature on

Ammonia VLE

0.0

2.0

4.0

6.0

8.0

10.0

12.0

50 75 100 125 150 175 200 225 250 275 300

N

H

3

c

o

n

c

e

n

t

r

a

t

i

o

n

%

Pressure bara

0 C

minus 20 C

Synthesis Loop Principles:

Mass Balance

Overall Loop Mass Balance

On a mass basis:

NH3 = MUG Purge

On a molar basis:

NH3 = (MUG Purge) / 2

because 4 mol -> 2 mol in the NH3

reaction.

Converter balance, on a molar basis:

NH3 = Inlet gas Outlet gas

Synthesis Loop Principles:

Mass Balance

Converter Molar balance:

NH3 = Circ Flow x (NH3

out

- NH3

in

)

1 + NH3

out

NH3

in

is set by P & T of final

separator

+ position of MUG addition (before or

after separator).

Synthesis Loop Principles:

Effect of Purge

Circulating composition is the same

as the purge composition (like a

stirred-tank reactor).

Inerts (CH

4

+ Ar) build-up in loop.

Circulating gas H / N ratio is very

sensitive to MUG H / N ratio because

the reaction consumes gas in a 3 : 1

ratio.

Synthesis Loop Principles:

H2 : N2 ratio example

H / N = 3 : 1

MUG NH3 Purge

H2 3000 2700 300

N2 1000 900 100

H / N 3.0 3.0 3.0

H / N = 2.95 : 1

H2 2950 2700 250

N2 1000 900 100

H / N 2.95 3.0 2.50

Synthesis Loop Principles :

Inerts Balance

Inerts (CH4 + Ar) concentrate in the loop,

typically by a factor of about 10.

Note that some of the inerts (10 20% of

the total) dissolve in the product NH3.

A few loops with purified make-up gas

have a self-purging loop where all the

inerts are removed in solution in the

product.

The NH3 content of the purge at the

flowmeter position is required to check the

loop mass balance.

Synthesis Loop Principles :

Effect of H2 Recovery

Most modern loops have H2 recovery.

2 systems are used, cryogenic or

membrane.

The overall effect is similar, typically 90%

H2 recovery at 90% purity.

Overall loop H2 conversion to NH3

increases from about 92% to 98%.

MUG H / N ratio changes from 3.0 to

approx. 2.85, and returns to 3.0 after H2

addition.

Synthesis Loop Principles :

Control of Catalyst Bed Temperatures

Multi-bed design :

2, 3, or 4 catalyst beds with

intermediate cooling.

Synthesis Loop Principles :

Converter Heat Balance

Older converter designs usually had an

interchanger after the final bed to contain

high temperatures within the converter.

Modern designs typically have no overall

interchanger because this gives better

heat recovery (heat available at a higher

temperature)

Split converter designs further increase

the heat recovery temperature.

3 Bed Converter Example

450 C

1. Optimum Catalyst

Temperatures

410 C

520 C

415 C

480 C

410 C

3 i/c design

Cold Converter

410 C

520 C

415 C

480 C

410 C

450 C

120 C

335 C

2 i/c design

410 C

520 C

415 C

480 C

410 C

450 C

Hot Converter

235 C

1 i/c design

410 C

520 C

415 C

480 C

410 C

450 C

Split Converter

305 C

Converter Heat Recovery Example

In all cases the amount of heat recovered

is the same, only the available

temperatures are different.

In all cases, the catalyst bed temperatures

are the same:

Bed 1 410 520 dT = 110

Bed 2 415 480 dT = 65

Bed 3 410 450 dT = 40

Total Bed dT = Converter dT = 215

Comparison of 74 & 35 Series

30

40

50

60

70

80

90

100

110

120

0 2 4 6 8 10 12 14

Time on line (years)

R

e

l

a

t

i

v

e

A

c

t

i

v

i

t

y

Severnside LCA

Standard Catalyst

Effect of Size on Activity

Particle Diameter (mm)

14 12 10 8 6 4 2

0

R

e

l

a

t

i

v

e

A

c

t

i

v

i

t

y

120

100

80

60

40

0

20

Effect of Size on Activity

Smaller pellets = high activity

Therefore high production rate or

smaller catalyst volume

But pressure drop will rise

Either axial-radial or radial flow

beds are used to minimise

pressure drop

Radial flow is the basis of many

converter internal retrofits

Deactivation

Clean Gas

Thermal sintering

Contaminated Gas

Both Temporary and Permanent

Poisoning

Oxygen induced sintering

By water, CO and CO

2

Site blocking/Sintering

Typical Operating Conditions

Temperature (

o

C) 360-520

Pressure (bar) 80-600

Space velocity (hr

-1

)1000-5000

Poisons oxygen and oxygen

compounds

normally < 3ppm

Catalyst Size

Grade Size

A 1.5-3.0 mm

B 3.0-4.5 mm

C 3.0-6.0 mm

D / E 6.0-10.0 mm

G 14.0-20.0 mm

Catalyst Reduction

Max water in outlet gas during

reduction (ppm)

Formation of water during

reduction of 1te of Catalyst (kg)

Pre-reduced Oxidized

1000 3000

25 280

End

Ammonia Converter

Designs

Converter Designs

Objectives for modern designs are;

- low pressure drop with small catalyst

particles.

- high conversion per pass with high grade

heat recovery.

Principal types are designed by:

Uhde

Kellogg (KBR) - conventional, Braun,

KAAP

Topsoe

Ammonia Casale

JM (I C I)

Uhde

Uhde design a range of converters:

Modern designs use radial flow

with inter-cooling & 'split

converters' with heat recovery

between,

- Converter 1 : 2-bed, 1

interchanger

- Heat recovery (boiler)

- Converter 2 : 3rd bed.

Uhde 3 bed

NH3 Converter

M W Kellogg Converter Types

'Conventional' make-up gas and loop

layout, refrigeration to low temperature (-

25 C),

loop pressure typically 140 - 180 bar.

Converters:

4 bed quench ; conventional Kellogg

design.

Horizontal converter ;

lower cost, low pressure drop, easier

installation

2 bed inter-cooled layout with small catalyst

Kellogg Ammonia Quench Converter

Outlet

Inlet

Kellogg Horizontal Converter

Bed 1 Bed 2A Bed 2B

Inlet

Outlet

KBR KAAP

Converter is made up of 4 beds

First bed uses magnetite catalyst

Ru can not be used since

temperature rise is too large

Lower beds use Ru catalyst

Ru catalyst has a carbon support

Catalyst developed by BP

Very high activity even at low pressure

Braun Converter Types

Purifier Process gives pure make-up gas

- low levels of poisons; H2O, CO, CO2

- Low inerts; no purge from loop

Converters :

Basically 2-bed intercooled with each

catalyst bed in a separate vessel

Modern designs may use 3 converters

&/or radial flow

Haldor Topse S- Series

S-100 :Radial flow 2-bed quench

S-200 :Radial flow 2-bed inter cooled

S-250 : S-200, heat recovery, 2nd

converter with 1 radial flow bed

S-300 :Radial flow 3-bed inter cooled

Topse S-200 Converter

Inlet

Outlet

Cold

Bypass

Ammonia Casale

Ammonia Casale - 'axial-radial'

concept

- radial flow without a top cover on

the beds

- simpler mechanical design

No. of beds & type of inter-bed

cooling varies;

typically 3 bed, 2 interchanger.

ICI Types

Lozenge quench converter :

single bed divided into 3 parts by quench

addition

simple concept but suffered high pressure

drop

ICI AMV Process :

Low pressure loop with H2 recovery at loop

pressure

range of converters in use

Terra: ICI 3-bed, 1 quench + 1 intercooler

axial flow

ICI LCA Process :

Tube-cooled + adiabatic design.

ICI Lozenge Quench Converter

ICI Tube Cooled Converter

ICI TCC Equilibrium Plot

300

(572)

350

(662)

400

(752)

450

(842)

500

(932)

550

(1022)

600

(1112)

650

(1202)

0

10

20

30

40

Equilibrium

Max Rate

Converter Profile

Temperature C (F)

A

m

m

o

n

i

a

c

o

n

t

e

n

t

%

S-ar putea să vă placă și

- Ammonia ProductionDocument44 paginiAmmonia ProductionBalamurali BalamÎncă nu există evaluări

- Successful Installation and Startup of An S-300 Ammonia Converter BasketDocument12 paginiSuccessful Installation and Startup of An S-300 Ammonia Converter Basketgharibi.ali98486Încă nu există evaluări

- Ammonia Traniee Manual (General Theory)Document22 paginiAmmonia Traniee Manual (General Theory)Kvspavan Kumar100% (1)

- Ammonia TechnologyDocument13 paginiAmmonia TechnologyMihaela Popescu-NeagoeÎncă nu există evaluări

- BY Prem Baboo Sr. Manager (Prod) National Fertilizers LTD, Vijaipur, IndiaDocument74 paginiBY Prem Baboo Sr. Manager (Prod) National Fertilizers LTD, Vijaipur, IndiaAlbertoÎncă nu există evaluări

- KSFL ReportDocument56 paginiKSFL ReportAbhishek KumarÎncă nu există evaluări

- Aiche-36-021Equipment Performance of AmmoniaDocument9 paginiAiche-36-021Equipment Performance of AmmoniaHsein WangÎncă nu există evaluări

- Kres KBRDocument33 paginiKres KBRrenitadyahÎncă nu există evaluări

- Reformer Sagar PresentationDocument43 paginiReformer Sagar Presentationsagarlambariya123456Încă nu există evaluări

- KBR Ammonia PDFDocument10 paginiKBR Ammonia PDFsadsnd-1100% (1)

- TOPSOE Seminar - Catalysts and Reactions PDFDocument132 paginiTOPSOE Seminar - Catalysts and Reactions PDFAhmad Nakash100% (3)

- 100 Years of Ammonia Synthesis Technology: Ib DybkjærDocument10 pagini100 Years of Ammonia Synthesis Technology: Ib DybkjærGrootÎncă nu există evaluări

- Ammonia Synthesis ConverterDocument26 paginiAmmonia Synthesis ConverterKvspavan Kumar100% (1)

- Ammonia PDFDocument49 paginiAmmonia PDFmfruge7Încă nu există evaluări

- Failure of Inner Shell of Double Walled Atmospheric Ammonia TankDocument9 paginiFailure of Inner Shell of Double Walled Atmospheric Ammonia Tankvaratharajan g rÎncă nu există evaluări

- Topsoe Steam Reforming CatDocument6 paginiTopsoe Steam Reforming CatKhairul HadiÎncă nu există evaluări

- Casale Advanced Ammonia TechnologiesDocument35 paginiCasale Advanced Ammonia TechnologiesMaribel ParragaÎncă nu există evaluări

- Ammonia Energy - EfficiencyDocument4 paginiAmmonia Energy - Efficiencyanupam01013787Încă nu există evaluări

- Delivering: Optimal PerformanceDocument20 paginiDelivering: Optimal PerformanceNathalia Delgado100% (1)

- Commissioning of The First Ammonia-Urea Complex: A Challenging Venture For The Vietnamese EconomyDocument13 paginiCommissioning of The First Ammonia-Urea Complex: A Challenging Venture For The Vietnamese Economyvaratharajan g rÎncă nu există evaluări

- Workshop On Energy Efficiency and CO2 ReductionDocument124 paginiWorkshop On Energy Efficiency and CO2 ReductionvirginiaucvÎncă nu există evaluări

- Revamp of Liaohes Ammonia Plant With KRES Technology To Reduce Natural Gas UsageDocument10 paginiRevamp of Liaohes Ammonia Plant With KRES Technology To Reduce Natural Gas UsageHussain FakhruddinÎncă nu există evaluări

- Ammonia: A Company of Thyssenkrupp TechnologiesDocument28 paginiAmmonia: A Company of Thyssenkrupp Technologiesenghisham100% (1)

- 06 Ammonia Synthesis Catalyst in Action - March 2015Document49 pagini06 Ammonia Synthesis Catalyst in Action - March 2015Kvspavan KumarÎncă nu există evaluări

- Catacarb Section, Dawood Hercules Fertilizers LimitedDocument16 paginiCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (1)

- Uop Benfield DatasheetDocument2 paginiUop Benfield DatasheetSusan Monteza GrandezÎncă nu există evaluări

- Major Ammonia Leak From HP Ammonia Feed Pump: P.Hari Narayana Reddy, R. Raghavan and Ramashray SinghDocument10 paginiMajor Ammonia Leak From HP Ammonia Feed Pump: P.Hari Narayana Reddy, R. Raghavan and Ramashray Singhvaratharajan g rÎncă nu există evaluări

- Ammonia Training 1Document32 paginiAmmonia Training 1rohit100% (1)

- Shift Conversion OperationDocument26 paginiShift Conversion OperationMuhammad JunaidÎncă nu există evaluări

- Lessons Learned With Ammonia Synthesis CatalystsDocument12 paginiLessons Learned With Ammonia Synthesis CatalystssugumarÎncă nu există evaluări

- Plant Layout PDFDocument19 paginiPlant Layout PDFazzatul amiraÎncă nu există evaluări

- 01 A Malhotra - KBR PurifierTM Technology and Project Execution Options For Ammonia PlantsDocument15 pagini01 A Malhotra - KBR PurifierTM Technology and Project Execution Options For Ammonia PlantsDerek MorseÎncă nu există evaluări

- Casale Technologies For New Grass-Roots PlantsDocument10 paginiCasale Technologies For New Grass-Roots PlantsNguyen Thanh SangÎncă nu există evaluări

- Final ReportDocument46 paginiFinal ReportVarun Gupta100% (1)

- LTS Katalco (83-3)Document16 paginiLTS Katalco (83-3)ricko4001Încă nu există evaluări

- Steam Reforming - Approach To EquilibriumDocument39 paginiSteam Reforming - Approach To EquilibriumAlexReituÎncă nu există evaluări

- Advanced Gas-Heated Reformer: P. W. FarneilDocument9 paginiAdvanced Gas-Heated Reformer: P. W. FarneilAlfonso BlancoÎncă nu există evaluări

- Comparative Evaluation of Cryogenic Air SeparationDocument21 paginiComparative Evaluation of Cryogenic Air SeparationmuratÎncă nu există evaluări

- Benfield ProcessDocument2 paginiBenfield ProcessJitendra KumarÎncă nu există evaluări

- Proven Atr Technology For Modern Large Scale Methanol Plants Nitrogen Syngas Conference Feb 2014.ashx 0 PDFDocument12 paginiProven Atr Technology For Modern Large Scale Methanol Plants Nitrogen Syngas Conference Feb 2014.ashx 0 PDFAngeloÎncă nu există evaluări

- By Product in Ammonia Plant PDFDocument12 paginiBy Product in Ammonia Plant PDFMd. Imran HossainÎncă nu există evaluări

- NH3 Process DescriptionDocument8 paginiNH3 Process DescriptionMusa KaleemÎncă nu există evaluări

- Ammonia PlantDocument28 paginiAmmonia PlantHumayun Rashid Khan100% (1)

- Tkis AmmoniaDocument28 paginiTkis AmmoniaAhmed Nagy100% (1)

- 4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev ClaesDocument8 pagini4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev Claesvaratharajan g rÎncă nu există evaluări

- Ammonia and UreaDocument33 paginiAmmonia and UreaPRAJWAL RASTOGIÎncă nu există evaluări

- Haber Process For The Production of Ammonia 1Document4 paginiHaber Process For The Production of Ammonia 1Nisha SundarÎncă nu există evaluări

- 014 PDFDocument12 pagini014 PDFGrootÎncă nu există evaluări

- Olmi Urea Stripper & Carbamate Condenser LeafletDocument6 paginiOlmi Urea Stripper & Carbamate Condenser LeafletHamzaNoumanÎncă nu există evaluări

- Ammonia and Urea ProductionDocument10 paginiAmmonia and Urea Productionwaheed_bhattiÎncă nu există evaluări

- Topsøe Hydrogen Technology - Energy Efficient and Flexible SolutionsDocument8 paginiTopsøe Hydrogen Technology - Energy Efficient and Flexible Solutionsdavid alonzo100% (1)

- Ammonia - TOC (2019 Program) - 0Document10 paginiAmmonia - TOC (2019 Program) - 0oom_tgwÎncă nu există evaluări

- Lurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMDocument14 paginiLurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMFer MugrabiÎncă nu există evaluări

- ATR Haldor TopsoeDocument12 paginiATR Haldor Topsoepraveenk_13100% (1)

- Air Liquide Presentation (Siddhartha Mukherjee) Rev 0Document48 paginiAir Liquide Presentation (Siddhartha Mukherjee) Rev 0sara25dec689288100% (1)

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationDe la EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosÎncă nu există evaluări

- Ammonia Synthesis and Molecular SieveDocument25 paginiAmmonia Synthesis and Molecular Sieveaehque04Încă nu există evaluări

- High-Pressure Steam Reforming of EthanolDocument23 paginiHigh-Pressure Steam Reforming of EthanolMuhammad NaeemÎncă nu există evaluări

- Hydrogen GenerationDocument48 paginiHydrogen GenerationAshish100% (2)

- Fujitsu Lifebook A530 Notebook: DatasheetDocument6 paginiFujitsu Lifebook A530 Notebook: DatasheetnirwalamitÎncă nu există evaluări

- OrcDocument1 paginăOrcdolphinÎncă nu există evaluări

- MG Engine HistoryDocument86 paginiMG Engine HistoryDamian RoweÎncă nu există evaluări

- Qlite Presentation FTCDocument14 paginiQlite Presentation FTCArman Ul NasarÎncă nu există evaluări

- D601005184 Man 001Document17 paginiD601005184 Man 001Riski Kurniawan100% (1)

- 004 - Hadoop Daemons (HDFS Only)Document3 pagini004 - Hadoop Daemons (HDFS Only)Srinivas ReddyÎncă nu există evaluări

- Oxford Reading Tree: What Dogs LikeDocument12 paginiOxford Reading Tree: What Dogs LikeKanja100% (1)

- Tbm859cf PDFDocument18 paginiTbm859cf PDFCarlos ParapeÎncă nu există evaluări

- Active Directory Interview QuestionsDocument3 paginiActive Directory Interview QuestionsSameer PatelÎncă nu există evaluări

- Lauda E200Document63 paginiLauda E200Sepehr SaÎncă nu există evaluări

- Learning Selenium Testing Tools - Third Edition - Sample ChapterDocument44 paginiLearning Selenium Testing Tools - Third Edition - Sample ChapterPackt PublishingÎncă nu există evaluări

- 2017 Toy CatalogueDocument19 pagini2017 Toy CatalogueErc Nunez VÎncă nu există evaluări

- Machines and Equipment For The Production of Autoclaved Aerated ConcreteDocument9 paginiMachines and Equipment For The Production of Autoclaved Aerated ConcretebalajicaptainÎncă nu există evaluări

- Business Process Reengineering: M. Parthiban Dept of Mech EngineeringDocument60 paginiBusiness Process Reengineering: M. Parthiban Dept of Mech Engineeringgiri123aeroÎncă nu există evaluări

- Telephone Dir.Document1 paginăTelephone Dir.Sandeep PasumarthiÎncă nu există evaluări

- Master Posix Threading Inside Outside.Document1.756 paginiMaster Posix Threading Inside Outside.gili mudavanhuÎncă nu există evaluări

- Color Difference Measuring InstrumentsDocument5 paginiColor Difference Measuring InstrumentsJanine Ellyze EvangelistaÎncă nu există evaluări

- Pull Out HandlesDocument4 paginiPull Out HandlesSCRIBD DOCSÎncă nu există evaluări

- MOM Format 1Document7 paginiMOM Format 1Mriganabh ChoudhuryÎncă nu există evaluări

- Saniya: Mark Warner, Rahat AneesDocument5 paginiSaniya: Mark Warner, Rahat Aneesshrey guptaÎncă nu există evaluări

- Intensifying Screen 1Document39 paginiIntensifying Screen 1Faris Afif100% (1)

- MTPT ItsDocument1 paginăMTPT Itsone borneoÎncă nu există evaluări

- HGST Partitioning and Formatting GuideDocument21 paginiHGST Partitioning and Formatting GuidejaylorbenÎncă nu există evaluări

- UTM Security With FortinetDocument76 paginiUTM Security With FortinetNelson Valente GomesÎncă nu există evaluări

- 2016CompositeList Web 105Document1 pagină2016CompositeList Web 105AnuranjanÎncă nu există evaluări

- Smart Gloves Based Gesture VocalizerDocument3 paginiSmart Gloves Based Gesture VocalizerKarthik DmÎncă nu există evaluări

- Abb Relays Catalouge PDFDocument180 paginiAbb Relays Catalouge PDFABDUL GHAFOORÎncă nu există evaluări

- Bicmos TechnologyDocument37 paginiBicmos TechnologyPriya SinghÎncă nu există evaluări

- Preca Catalog - Read ViewDocument9 paginiPreca Catalog - Read ViewAnyaWestmorelandÎncă nu există evaluări

- CES Business PresentationDocument50 paginiCES Business PresentationGary David CrowhurstÎncă nu există evaluări