Documente Academic

Documente Profesional

Documente Cultură

1582 GB

Încărcat de

Mohamed ShehataDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1582 GB

Încărcat de

Mohamed ShehataDrepturi de autor:

Formate disponibile

Polysius rotary kiln. Centre piece of the pyroprocessing system.

A company of ThyssenKrupp Technologies

Polysius

tk

Rotary kilns from Polysius: economical reliable resource-saving.

In 1899, Polysius put Europes first rotary kiln into operation. In those days, rotary kilns were a maximum of 2 m in diameter and 20 m in length, managing daily outputs of 30 to 50 tonnes of cement clinker per day. Nowadays, production capacities of 10,000 tonnes per day are nothing unusual. Today, the demands of the industry with regard to quality, maximum capacity and minimum costs have become the decisive factors for competitive strength. And that is why. . . x robust and reliable design, x low resource consumption, x high operating reliability and x low specific operating costs and capital expense are the most important elements in the success of Polysius kiln technology.

Since the introduction of the rotary kiln, Polysius has constructed more than 1,500 production lines worldwide. Polysius kiln lines are used in the cement and refractories industry, in the chemical industry, in the iron and steel producing industry and in the mineral processing industry. Due to optimisation of the overall pyroprocessing concept, modern rotary kilns have significantly smaller dimensions and thus require less capital investment than their predecessors, despite their higher output rates. The actually required kiln dimensions essentially depend on the raw materials and fuels to be used, the plant configuration, the quality of the cement clinker and on the desired production capacity. Taking these factors into account, the optimum kiln shell dimensions are accurately determined with the aid of laboratory test processes, computer simulations and design calculations. Thanks to the use of modern precalcination processes, rotary kilns nowadays seldom need a length to diameter ratio above 15:1. Up to this L / D ratio, Polysius offers both the classical 3support kiln and the modern POLRO two support kiln. For the first time, rotary kiln dimensioning can therefore concentrate on suiting the characteristics of the material and the burning process, without having to take the actual kiln system into account.

POLRO two support kiln for a cement clinker output of 4,900 tpd in Australia.

5,000 tpd cement clinker kiln on 3 roller stations.

Splined kiln tyre fixture.

POLRO Knowhow to the last detail.

The POLRO is a directly driven rotary kiln with a statically determined support configuration using just two roller stations. The kiln shell is supported in splined tyres on tilting rollers that align themselves to provide optimum contact conditions. It is directly driven via the inlet-end roller station, a system which supersedes the conventional girth gear and pinion drive. Pneumatic inlet and outlet seals and an aircooled inlet trough round off the POLRO. Thanks to the statically determined kiln support configuration, POLRO owners benefit from high operating reliability, minimal maintenance and inspection requirements and very low operating costs. Self-aligning supporting rollers For effective transmission of the torque, perfect contact conditions are required between

Electrohydraulic drive system with 4 drive units.

Splined kiln tyre fixture.

Assembly of a POLRO.

Air-cooled kiln inlet trough.

In order to prevent contact surface wear during operation of the POLRO, the axes of rotation of supporting rollers and kiln tyres are always parallel. This is ensured by a positioner, which adjusts the rollers relative to the tyre during the kiln operation. The positioner also serves as an axial roller thrust system, with the same effect as the familiar axial kiln thrust system. The kiln is held in position by a single thrust roller. Splined kiln tyre Direct driving of the supporting rollers requires splined tyres for transmitting the torque to the kiln shell. The splined tyres internal toothing forms a positive connection with the kiln shell all around its circumference. The entire weight of the kiln is supported tangentially on the internal toothing of the tyre and the tangential transmission of the load keeps the kiln shell round under all operating conditions. As constriction of the kiln shell is impossible, the service life of the refractory lining is greatly increased. Direct drive system The drive system of the POLRO rotary kiln is simple

and robust. Also, the maintenance requirement is low, due to elimination of the otherwise necessary maintenance of a girth gear and pinion mechanism. Depending on requirements, both or only one of the supporting rollers of the inletend kiln tyre station are driven. The drive system can be electromechanical or electrohydraulic. Measurements taken to establish the maximum usable friction for transmitting the driving torque demonstrated that the employed friction drive is able to transmit 8 to 9 times the actual operating torque of the kiln. As this figure greatly exceeds the maximum torque of the motor, slipping of the drive roller is impossible in any conceivable operating condition. Inlet and outlet seals The pneumatic inlet and outlet seals adapt themselves to the different rotational, radial and axial movements and thus prevent infiltration of false air into the kiln system. Because Polysius rotary kiln seals are highly efficient, robust and wear resistant they save energy and are extremely durable.

the driven rollers and the kiln tyre. The supporting rollers therefore have to compensate for the negative results of a thermally distorted kiln shell or foundation settlement without affecting the stability of the kiln support system. In order to effectively satisfy these two contrary demands (optimum alignment of the contact surfaces of roller and tyre and safe, stiff support of the kiln shell), the roller bedplates also have a selfaligning mounting on two axial pivoting bearings. These axial pivoting bearings absorb the supporting and spreading forces of the kiln shell and, due to their universal joints, can follow any wobbling of the tyre. This ensures that the contact pattern is uniform under all load conditions while reliably preventing edge contact of the tyre and rollers.

Electromechanical drive system with 2 drive units.

Pneumatic rotary kiln outlet seal.

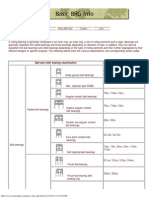

3-support kiln.

If the length to diameter ratio is above 15, it is advisable to support the rotary kiln on three roller stations. Polysius provides numerous innovative detail solutions that ensure economical pyroprocessing. Some of our proven components are used for both the 2-support and the 3-support kiln. These are the variable-speed electromechanical drive system with planetary gear unit, the splined kiln tyre, the inlet and outlet seals, the air-cooled inlet trough, and the hydraulic axial thrust system. However, the drive system with self-aligning pinion and the floating tyre (as a more favourably priced alternative to the splined tyre) are specific features of the 3-support kiln. Drive system with selfaligning pinion The electromechanical drive system with frequency-controlled speed is a very reliable solution for the 3-support kiln. Planetary gear units directly flangemounted on the pinion shaft have been increasingly employed in recent years. The use of a self-aligning pinion ensures that an optimum contact pattern is achieved over the entire width of the tooth gearing. The self-aligning pinion compensates any thermal distortion of the kiln shell and associated wobbling of the girth gear. In comparison to the rigid drive mechanism, the dimensions of girth gear and pinion are about 20 % smaller, due to the improved tooth

Rotary kiln supported on 3 roller stations.

Self-aligning drive pinion: the design permits a tilting of 10 mm.

Kiln system with 3-support kiln in Argentina.

Modern control room with POLCID NT process automation system.

Dual rotary kiln drive with planetary gear unit.

Automation solution for optimum process control In order to meet the constantly increasing demands imposed on process control systems while also promoting the economical and competitive operation of kiln plants, Polysius offers process knowhow in the form of the POLEXPERT-KCE automation system. This is the logical completion of our range of process technological systems. By linking current process data and expert knowledge, POLEXPERT systems enable automatic expert system process controlling in every operating situation. With this automatic operation, the installed machines are consistently run at an optimum utilisation rate. As a result, emission rates are low, wear is minimised, energy consumption is reduced and the personnel are relieved of routine tasks. Combination of the POLEXPERT with the POLCID NT master process control system provides a highly effective automation solution for monitoring, controlling and optimising the kiln plant.

POLSCAN measuring system Foundation subsidence, uneven wear and faulty alignment of the supporting rollers e.g. after repair work cause kiln axis deviations. To permit quick and precise diagnosis and correction of rotary kiln axis misalignment, Polysius offers the POLSCAN service. Using an optoelectronic measuring system, the kiln components are precisely surveyed and readjusted without interrupting operation. The analysis and documentation of the measured data is performed directly on the spot.

Bearing stations The compact and stable bearings of any roller station are interchangeable. They are designed as plain bearings with oil scooping system and their seating on the bedplate is self-centring, so that an optimum contact pattern in the bearing is always maintained. Floating kiln tyre As an alternative to the splined tyre, Polysius offers the floating tyre, which is only secured on the kiln shell in the axial direction. This means that it can turn in the circumferential direction relative to the kiln shell. The fastening system of the floating tyre consists of bridge plates which engage positively with the kiln shell. Retaining elements secure the fastening system in the circumferential and axial directions.

Floating-tyre fixture.

POLSCAN measurement of a rotary kiln.

bearing pattern and the full frictional connection. This back gear unit is also a favourably priced refurbishment measure for existing kilns.

S-ar putea să vă placă și

- Dial Indicator Alignment Procedure PDFDocument4 paginiDial Indicator Alignment Procedure PDFMohamed ShehataÎncă nu există evaluări

- FNL Flanged Bearing HousingDocument11 paginiFNL Flanged Bearing HousingMohamed ShehataÎncă nu există evaluări

- Shaft AlignmentDocument8 paginiShaft AlignmentTarek MohamedÎncă nu există evaluări

- Example by Microsoft Project PDFDocument1 paginăExample by Microsoft Project PDFMohamed ShehataÎncă nu există evaluări

- Dial Indicator Alignment ProcedureDocument4 paginiDial Indicator Alignment ProcedureMohamed ShehataÎncă nu există evaluări

- Basic BRG InfoDocument5 paginiBasic BRG InfoMohamed ShehataÎncă nu există evaluări

- Dynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250Document0 paginiDynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250SreenivasÎncă nu există evaluări

- CarbDocument84 paginiCarbJurun_BidanshiÎncă nu există evaluări

- Example by Microsoft Project PDFDocument1 paginăExample by Microsoft Project PDFMohamed ShehataÎncă nu există evaluări

- 5aese Yang ImproDocument6 pagini5aese Yang ImproMohamed ShehataÎncă nu există evaluări

- YbearingsDocument227 paginiYbearingsmasmuinÎncă nu există evaluări

- Bearing Basics ExplainedDocument6 paginiBearing Basics ExplainedMohamed ShehataÎncă nu există evaluări

- Europe Largest KilnDocument11 paginiEurope Largest KilnMohamed ShehataÎncă nu există evaluări

- Gears and PinionsDocument5 paginiGears and Pinionsmahreza189Încă nu există evaluări

- CP Profile - English 0106Document16 paginiCP Profile - English 0106Mohamed ShehataÎncă nu există evaluări

- Plant 2000tpdDocument9 paginiPlant 2000tpdMohamed ShehataÎncă nu există evaluări

- Pages 9-66 From Complete Idler Roller CatalogDocument59 paginiPages 9-66 From Complete Idler Roller CatalogjashmithÎncă nu există evaluări

- WisdomDocument6 paginiWisdomMohamed ShehataÎncă nu există evaluări

- CP Pci TechnikDocument8 paginiCP Pci TechnikMohamed ShehataÎncă nu există evaluări

- CP Dry Mortar & MixDocument12 paginiCP Dry Mortar & MixMohamed ShehataÎncă nu există evaluări

- 100,000t ExpansionDocument8 pagini100,000t ExpansionMohamed ShehataÎncă nu există evaluări

- Water Cooling For Cement Mill PDFDocument2 paginiWater Cooling For Cement Mill PDFjagrutÎncă nu există evaluări

- Heat correction of kiln cranks is cost effectiveDocument4 paginiHeat correction of kiln cranks is cost effectiveMohamed Shehata100% (2)

- Laboratory ServicesDocument6 paginiLaboratory ServicesMohamed ShehataÎncă nu există evaluări

- Unax InternalsDocument4 paginiUnax InternalsMohamed ShehataÎncă nu există evaluări

- After Sales ServiceDocument10 paginiAfter Sales ServiceSamehibrahemÎncă nu există evaluări

- Mech Kiln InspectionDocument2 paginiMech Kiln InspectionMohamed ShehataÎncă nu există evaluări

- Mech Kiln InspectionDocument2 paginiMech Kiln InspectionMohamed ShehataÎncă nu există evaluări

- Laboratory ServicesDocument6 paginiLaboratory ServicesMohamed ShehataÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hydrostatics Pressure Variation and TransmissionDocument32 paginiHydrostatics Pressure Variation and TransmissiondaphcosiÎncă nu există evaluări

- Grove Rt890e - PM - 223843Document977 paginiGrove Rt890e - PM - 223843mariojoaofreireÎncă nu există evaluări

- Leaflet Scania Bus Euro5 K410CB 6x2Document4 paginiLeaflet Scania Bus Euro5 K410CB 6x2Abu Faiz100% (3)

- Operating ManualDocument110 paginiOperating ManualAbdelrahman SharafÎncă nu există evaluări

- CAT775GDocument32 paginiCAT775GAndy Chan100% (1)

- 2021 WTS 12 Vertical ProjectileDocument36 pagini2021 WTS 12 Vertical Projectilehopemandi25Încă nu există evaluări

- Brahma Specs ScrewCompressorsDocument12 paginiBrahma Specs ScrewCompressorsDavid AbbadoÎncă nu există evaluări

- Cost Saving Acoustic CleanersDocument2 paginiCost Saving Acoustic CleanersShivnandan SahuÎncă nu există evaluări

- Useful formula for flat plate solar collector efficiencyDocument3 paginiUseful formula for flat plate solar collector efficiency김동욱Încă nu există evaluări

- Casing Design in Sour Gas Well Mitigating SSCDocument5 paginiCasing Design in Sour Gas Well Mitigating SSCArthur LachiniÎncă nu există evaluări

- 49 Mag Fichetech GRATES XCC V6Document2 pagini49 Mag Fichetech GRATES XCC V6mohammedÎncă nu există evaluări

- FRP (Fiber Reinforced Plastic) : Physical PropertiesDocument1 paginăFRP (Fiber Reinforced Plastic) : Physical PropertiesSaurabh saxenaÎncă nu există evaluări

- OIQ Mechanical Reference TextbooksDocument4 paginiOIQ Mechanical Reference TextbooksAnonymous scnl9rHÎncă nu există evaluări

- Muhammad Nur Adib Jumain, Muhammad Aizat Hanif Sanif, Davson Howel Lim, Hairul Mubarak HassimDocument9 paginiMuhammad Nur Adib Jumain, Muhammad Aizat Hanif Sanif, Davson Howel Lim, Hairul Mubarak HassimIceÎncă nu există evaluări

- Komatsu Wa600 3 Wa600 3d TBG Spec Wheel Loader Service Repair ManualDocument20 paginiKomatsu Wa600 3 Wa600 3d TBG Spec Wheel Loader Service Repair Manualedna100% (33)

- PDT 3 PDFDocument66 paginiPDT 3 PDFChristopher GilbertÎncă nu există evaluări

- In Service Exhaust Emission Standards For Road Vehicles Seventeenth EditionDocument204 paginiIn Service Exhaust Emission Standards For Road Vehicles Seventeenth EditionSvetoslavÎncă nu există evaluări

- Chapter 3. Refrigeration CycleDocument18 paginiChapter 3. Refrigeration CycleCəvahir AğazadəÎncă nu există evaluări

- Grecon Spark DetectorDocument16 paginiGrecon Spark DetectorHakim GaprakÎncă nu există evaluări

- Research: John W. HutchinsonDocument25 paginiResearch: John W. HutchinsonskcÎncă nu există evaluări

- C175 16-20 Troubleshooting KENR5398!04!01-ALLDocument260 paginiC175 16-20 Troubleshooting KENR5398!04!01-ALLChristian MontesÎncă nu există evaluări

- Pressure Calculation Sheet For Locking Load: 20% of 13.8 TonsDocument3 paginiPressure Calculation Sheet For Locking Load: 20% of 13.8 TonsKrushna RamaÎncă nu există evaluări

- Woodward EasYgen Configuration Manual - CO LOGICDocument201 paginiWoodward EasYgen Configuration Manual - CO LOGICbacuoc.nguyen356Încă nu există evaluări

- Functions and Selection of GeosyntheticsDocument27 paginiFunctions and Selection of GeosyntheticsChainun TaidamrongÎncă nu există evaluări

- Chapter Wise Test Physics 9th English #KLSDocument9 paginiChapter Wise Test Physics 9th English #KLSShahbaz AnwarÎncă nu există evaluări

- DLG2524 Service ManualDocument43 paginiDLG2524 Service ManuallixiuserÎncă nu există evaluări

- Fish Feed Manufacturing Plant: Presented byDocument15 paginiFish Feed Manufacturing Plant: Presented bymizanÎncă nu există evaluări

- Captiva SE - OrGDocument366 paginiCaptiva SE - OrGDaniel CofrecavieresÎncă nu există evaluări

- An Analysis of Functional Modelling Approaches Across Disicplines-AnnotatedDocument11 paginiAn Analysis of Functional Modelling Approaches Across Disicplines-AnnotatedKarthik KarunanidhiÎncă nu există evaluări

- VibMatters Current IssueDocument17 paginiVibMatters Current IssueganeshdhageÎncă nu există evaluări