Documente Academic

Documente Profesional

Documente Cultură

Hoehsyianglungaa 060075 D 10 THT

Încărcat de

dcf67myTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hoehsyianglungaa 060075 D 10 THT

Încărcat de

dcf67myDrepturi de autor:

Formate disponibile

PSZ 19:16 (Pind.

1/07)

ya

DECLARATION OF THESIS / UNDERGRADUATE PROJECT PAPER AND COPYRIGHT

Authors full name :

Date of birth :

Title : SUSTAINABILTY: RAINWATER HARVESTING SYSTEM

IN CAMPUS

Academic Session:

I declare that this thesis is classified as:

I acknowledged that Universiti Teknologi Malaysia reserves the right as follows:

1. The thesis is the property of Universiti Teknologi Malaysia.

2. The Library of Universiti Teknologi Malaysia has the right to make copies for the

purpose of research only.

3. The Library has the right to make copies of the thesis for academic exchange.

Certified by:

SIGNATURE SIGNATURE OF SUPERVISOR

(NEW IC NO. /PASSPORT NO.) NAME OF SUPERVISOR

Date : 16 APRIL 2010 Date : 16 APRIL 2010

NOTES : * If the thesis is CONFIDENTIAL or RESTRICTED, please attach with the letter from

the organisation with period and reasons for confidentiality or restriction.

UNIVERSITI TEKNOLOGI MALAYSIA

CONFIDENTIAL (Contains confidential information under the Official Secret

Act 1972)*

RESTRICTED (Contains restricted information as specified by the

organisation where research was done)*

OPEN ACCESS I agree that my thesis to be published as online open access

(full text)

HOE HSYIANG LUNG

2009/2010

860805-52-6035 ASSOC. PROF. DR JOHAN SOHAILI

5 AUGUST 1986

I hereby declare that I have read this thesis and in my opinion this thesis is

sufficient in terms of scope and quality for the award for the degree of Bachelor of

Civil Engineering.

Tandatangan : ______________________

Nama Pensyarah : Assoc. Prof. Dr. Johan Bin Sohaili

Tarikh : 16 April 2010

\

SUSTAINABILITY: RAINWATER HARVESTING SYSTEM

IN CAMPUS

HOE HSYIANG LUNG

A report submitted in partial fulfillment of the

Requirement for the award of the degree of

Bachelor of Civil Engineering

Faculty of Civil Engineering

Universiti Teknologi Malaysia

APRIL 2010

ii

I declare that this thesis entitled Sustainability: Rainwater Harvesting System in

Campus is the result of my own research excpt as cited in the references. The thesis

has not been accepted for any degree and is not concurrently submitted in

candidature of any other degree.

Signature : ______________________

Author : HOE HSYIANG LUNG

Date : 16 APRIL 2010

iii

To my beloved parents whom I loved

iv

ACKNOWLEDGEMENT

In preparing this thesis, I was in contact with many people as well as

references. They have contributed towards my understanding and thoughts. In

particular, I wish to express my sincere appreciation to my thesis supervisor,

Associate Professor Dr. Johan Bin Sohaili, for the encouragement and guidance in

this thesis as well as friendship.

My thanks also go to the librarians in Faculti Kejuruteraan Awam (FKA) for

their help. I am indebted with my fellow undergraduate students for their support and

assistance. Unfortunately, it is not possible to list all of them in this limited space.

Last but not least, to my family members who have been supportive I wish to

extend my deepest thanks.

v

ABSTRACT

Harvesting rainwater will contribute towards a sustainable living. It will

eliminate the wastage and reduce the dependency of potable water. The demand of

potable water increases in accordance to the population. Rainwater harvesting is

capable to combat water crisis and serves as an alternative water resources during

water shortage. The purposes of this study are to evaluate the potential of rainwater

in potable water saving, propose a rainwater harvesting system for the usage of

flushing of toilets and estimate the total cost for the construction of the rainwater

harvesting system. By practicing rainwater harvesting, the total dependence on usage

of potable water can be minimise to only cater for activities involving direct human

contact. Result indicated that the quality of rainwater samples meet the WHO

standards for drinking water parameters. The rainwater harvesting system is design

using the flow of gravity and the total cost for construction estimated to be RM 1715.

Payback period for the rainwater harvesting system are 15.5 years. There is a

probability that rainwater in UTM campus being harvested.

vi

ABSTRAK

Pengumpulan air hujan akan mewujudkan kehidupan lestari. Air hujan

terkumpul akan mengelakkan pembaziran dan mengurangkan pergantungan terhadap

air dirawat. Permintaan terhadap air dirawat sentiasa bertambar berekoran dengan

populasi. Pengumpulan air hujan mampu menagatasi masalah air bekalan dan

digunakan sebagai punca air alternatif apabila berlakunya kekurangan air. Tujuan

kajian ini adalah untuk mengkaji air hujan dalam penjimatan air dirawat,

mencadangkan satu system pengumpulan air hujan untuk kegunaan tandas dan

membuat anggaran terhadap cost pembinaan system. Dengan penggunaan air hujan,

pergantungan terhadap air dirawat dapat dikurangkan kepada tujuan kegunaan

manusia. Keputusan menunjukkan bahawa kualiti sampel air hujan menepati

parameter yang ditetapkan oleh WHO. Sistem penuaian air hujan direka supaya

menggunakan graviti dan cos pembinaan dianggar sebanyak RM 1715. Permulangan

balik sistem ini adalah 15.5 tahun. Kemungkinan penuaian air hujan di campus UTM

dapat dijalankan.

vii

TABLE OF CONTENTS

CHAPTER TITLE PAGE

DECLARATION ii

DEDICATION iii

ACKNOWLEDGEMENT iv

ABSTRACT v

ABSTRAK vi

TABLE OF CONTENTS vii

LIST OF TABLES xi

LIST OF FIGURES xii

1 INTRODUCTION

1.1 Research Background 1

1.2 Problem Statement 2

1.3 Study objectives 4

1.4 Scope of study 4

1.5 Significance of Study 5

2 LITERATURE REVIEW

2.1 Water 6

2.2 Water Cycle 7

2.3 Rainfall Pattern in South East Asia 8

viii

2.4 Sustainability of Rainwater 9

2.4.1 Rainwater Harvesting in Malaysia 10

2.4.2 Historical Development for Rainwater

Harvesting Policy 11

2.5 Economic Impact 12

2.6 Rainwater Harvesting System Components 13

2.6.1 Collection Area 13

2.6.2 Conveyance System 15

2.6.3 Storage Tank 16

2.7 Rainwater Storage Tank Design 18

3 RESEARCH METHODOLOGY

3.0 Introduction 20

3.1 Testing of Parameters 20

3.1.1 pH 21

3.1.2 Dissolved Oxygen 21

3.1.3 Biological Oxygen Demand 21

3.1.4 Chemical Oxygen Demand 22

3.1.5 Total Suspended Solids 23

3.1.6 Escherichia coli 23

3.2 Design of Rainwater Harvesting System 24

3.2.1 Storage Tank 24

3.2.2 Height of storage tank 24

3.2.3 Piping System 24

3.3 Cost 25

3.3.1 Water Savings 25

3.3.2 Rainwater Harvesting System

Construction Cost 25

3.4 Volume of Rainwater Collected 25

ix

4 RESULT ANALYSIS

4.0 Introduction 27

4.1 Water Quality 27

4.2 Designing Rainwater Harvesting System 29

4.2.1 Flow Rates, Q 30

4.2.2 Hazen-Williams Coefficient, C

w

31

4.2.3 Effective Pipe Length, L

eff

31

4.2.4 Head Loss, h

L

32

4.2.5 Flow Velocity, 32

4.2.6 Residual Pressure Head 33

4.2.7 Designing Water Storage Tank Capacity 34

4.2.8 Designing Cistern Tank 35

4.3 Cost 37

4.3.1 Collection Area 37

4.3.2 Conveyance System 38

4.3.3 Storage Tank 39

4.3.4 Concrete Platform 39

4.3.5 Summary 41

4.3.6 Cost Saving 42

5 CONCLUSION AND RECOMMENDATION

5.1 Conclusions 45

5.2 Recommendations 46

REFERENCES 48

APPENDICES 51

x

LIST OF TABLES

TABLE NO. TITLE PAGE

2.1 Estimated Global Water Distribution 7

2.2 Pattern of Rainfall on Prominent Locations in

Peninsular Malaysia 9

2.3 Sizing of Rainwater Pipe for Roof Drainage 15

2.4 Advantages and Disadvantages of a Cistern Type 17

2.5 Minimum Storage Capacity 18

2.6 Storage Requirement Per Fittings 18

2.7 Storage Requirement Per Person 19

4.1 The test results for collected rainwater 28

4.2 Comparison of test results with WHO drinking guideline,

INWQS class IV and Standard A effluent 28

4.3 Design Flow Rates for Fittings 30

4.4 Hazen-Williams coefficients 31

4.5 Equivalent Pipe Lengths 31

4.6 The computation of flow rate 34

4.7 Calculation of cost for installation of gutter 38

4.8 Estimation of cost for the piping system 39

4.9 Total volume of concrete in m

3

40

4.10 Daywork Labour Rates 40

4.11 Workers pay 41

4.12 The overall cost for the installation of

rainwater harvesting 41

4.13 The price per m

3

of water in RM 42

xi

LIST OF FIGURES

FIGURE NO. TITLE PAGE

2.1 The Water Cycle 8

2.2 A Diagram of Rainwater Harvesting Storage Tank 17

4.1 The Proposed Rainwater Harvesting System 29

4.2 Schematic Drawing for Piping System 30

4.3 The Design of Rainwater Storage Tank 35

4.4 Automation system for switching between

rainwater and potable water 36

4.5 The Dimension of Rooftop 38

CHAPTER 1

INTRODUCTION

1.1 Research Background

Water is essential for life in this world. All living organisms require water to

sustain life. Human consists of 57% of body water (Guyton, 1991). It is subdivided

into two categories which is the intercellular and intracellular fluid (John and Bruce,

2002). Biological processes which are on going inside the human bodies majorly

depend on water to help facilitate the processes. Such processes are digestion and

absorption of food, serve as a medium for transportation of nutrients and oxygen in

the blood stream, as an internal cooling system to sustain body temperature and so

forth. Water which form streams, lakes, rivers and oceans serves as a natural habitat

to accommodate millions and billions of sea creatures. Apart from that, the other

common usage of water for human activities includes drinking, cooking, washing,

agriculture and aquaculture, power generation, transportation, recreational and

aesthetic purposes.

As the demand for clean water increases due to the increase in population

growth, numerous methods have been introduced to combat the chronic problem of

obtaining clean water due to the ever increasing pollution of water bodies. One of

such methods introduced is Rainwater Harvesting (RWH). RWH is not considered as

a new technology because it has provided a water source for communities around the

world dating back to circa 1500 B.C (Hunt and Laura, 2006). This ancient

2

technology continues to serve populations today, mainly in poor, rural or dry regions

of the world and island communities (Hicks, 2008).

Basically, RWH is a technology used for collecting and storing rainwater

from rooftops, land surfaces, road surfaces or rock catchments using simple

techniques such as pots, tanks and cistern as well as more complex techniques such

as underground check dams (Prinz, 1995; Zhu et al., 2004). It consists of three basic

components: a collection area (roof), a conveyance system and a cistern or storage

tank (Texas Water Development Board, 2005).

Harvested rainwater is a renewable source of non potable water. Non potable

uses may include toilet flushing, building or car washing, air conditioner coolant, fire

suppression, industrial processes and landscape irrigation (LaBranche et al., 2007)

Water harvesting systems provide flexible solutions that can effectively meet the

needs of new and existing, as well as of small and large sites, using a water

harvesting system is an ongoing proves that can be developed over time. The greater

attraction of a rainwater harvesting system is low cost, accessibility and easy

maintenance at the household level (Fayez, 2009).

1.2 Problem Statement

The water pollution in Malaysia is originated from point sources and non-

point sources. Point sources that have been identified include sewage treatment

plants, manufacturing and agro-based industries and animal farms. Non-point

sources are mainly diffused ones such as agricultural activities and surface runoffs.

According to Malaysia Environmental Quality Report 2004, the Department of

Environment has recorded 17,991 water pollution point sources in 2004 comprising

mainly sewage treatment plants (54%), manufacturing industries (38%), animal

farms (5%) and agro-based industries (3%). In 2006, a total of 1,064 water quality

monitoring stations located within 146 river basins were monitored. Out of these

1,064 monitoring stations, 619 (58%) were found to be clean, 359 (34%) slightly

polluted and 86 (8%) polluted. Stations located upstream were generally clean, while

3

those downstream were either slightly polluted or polluted. In terms of river basin

water quality, 80 river basins (55%) were clean, 59 (40%) slightly polluted and 7

(5%) were polluted (Malaysia Environmental Quality Report, 2005).

Changing weather patterns can cause disruption to the water supply. Such

phenomenon was El Nino. El Nino, driven by an abnormal warming of the eastern

Pacific Ocean, can create havoc in weather patterns across the Asia-Pacific region,

unleashing droughts in some places and heavy storms in others. It typically lasts

from 9 to 12 months. In 1998, the El Nino related drought caused severe water stress

in the states of Kedah, Penang and Selangor. The state of Selangor was forced to

impose severe water rationing in Kuala Lumpur and Petaling Jaya for many months.

This shows that Malaysia is still not ready to face unexpected events to curb the

problems that surfaces.

Population growth is inevitable. In Malaysia, population has increased from

8.1 million in 1960 to 27 million in 2008. As the population increases, the demand

for clean water increases as well. And to cater the demand, dams and water treatment

plant has to be constructed to meet the needs of the people. As the supply and

demand are in a cat and mouse race, with the limited water resources, eventually the

demand will exceed the supply and this situation will create problems to the country.

The peoples attitude also plays an important part towards creating a

sustainable living. Campaigns had been ongoing to educate and remind the public

that water is precious thus it is not to be wasted. Not only will it save the water bill

but also reduce the water stress on water demand as well as possess sufficient

reserves for emergencies uses such as droughts and dry spells.

Since clean water is important, it is seen as a waste for it to be used for

flushing of toilets and for watering plants. Furthermore, rainwater can be used as a

substitute by collecting and utilise it rather than let it go to waste. Apart from that, by

collecting rainwater from roof, flash floods can be avoided or minimise as few

percentage of rainfall is retained and thus reduce the volume of surface run-off.

Besides, by using rainwater as an alternative, clean water can be saved and be used

for other purposes and simultaneously decrease the demand of clean water which

4

resulted in lower cost of water bill and cost of operation in the water plants. The use

of untreated rainwater for non-potable uses that would otherwise be supplied by

potable water ultimately conserves municipally supplied potable water (Persyn et al.,

2004).

1.3 Study Objectives

The objectives of this study are:

(i) To estimate the amount of rainwater that can be collected in Universiti

Teknologi Malaysia (UTM) campus by obtaining the total catchment area available

in campus.

(ii) Obtain the quality of the rainwater collected for decision making based on

these 6 parameters; ph, Dissolved Oxygen (DO), Biological Oxygen Demand

(BOD), Chemical Oxygen Demand (COD), Total Suspended Solid (TSS) and

Escherichia coli (E.Coli).

(iii) Evaluate the potential for potable water savings by using rainwater and

the payback period for the system.

(iv) Propose a rainwater harvesting system.

1.4 Scope of Study

To accomplish the objectives specified above, it was necessary to obtain

rainfall data and population in UTM campus. Then, the total roof area in the campus

was calculated based on the aerial map of the campus. The potential rainwater

harvesting volume is estimated based on the total roof area, the average annual

rainfall and the runoff coefficient. After that, the potential saving percentage is

calculated by dividing the potential volume of harvested rainfall by the annual

5

domestic demand. Rainwater collected is tested to obtain these 6 parameters namely

pH, DO, BOD, COD, TSS and E.Coli. Next is to propose an appropriate rainwater

harvesting system based on the data and information collected.

1.5 Significance of Study

This project will help to initiate a starting point to create a green campus

concept into reality. Besides that, it will also give an idea to other researchers in this

field to better the design to give a more effective result and the same time maximize

the usage of harvested rain water. Furthermore, other campus can adapt this system

and start to realize the concept of green campus to create environmental friendly

surroundings as a stepping stone to educate and the same time save the environment

and minimize the energy wastage.

CHAPTER 2

LITERATURE REVIEW

2.1 Water

Water is the most abundant substance on Earth. About 75% of the surface is

covered with salt-water oceans, the remainder consisting of continents and islands.

Based on the research done by (Gleick, 1996), it is estimated that the amount of

water volume on Earth is 1,386,000,000 km

3

. Based on Table 2.1, approximately

1,338,000,000km

3

that is around 97% of the total volume is saline water which is the

oceans, seas and bays. The remainder 3% of Earth water is fresh water which

consists of ice caps and glaciers, groundwater and surface water. Although the Earth

holds that much amount of water, only the freshwater is drinkable after treatment

where as the saline water have to undergo desalination processes to get rid of the

salts before treated for drinking purposes.

With the little amount of availability of freshwater versus the ever growing

population of the Earth now at 6 billion people and counting, we will soon deplete

the natural reservoirs of this precious water for our own needs. To make things

worse, pollution by human activity in the name of development has further decrease

the availability of fresh water. Without fresh water, other methods such as treating

water apart from fresh water will be proposed. More costly technologies will be

invented to perform such task and poor countries will suffer from clean water

shortage. This problem can be seen in Jordan where the scarcity of water resources

seemed to be dictated by climatic conditions such as aridity and abundance of high

solar radiation and by population pressure (Salemah and Bannayan, 1993). Before

7

we reach a point of no return, we must have proper planning for water usage to

ensure that water will always be available for us in the distant future.

Table 2.1 Estimated Global Water Distribution (Gleick, 1996)

Water source Water volume,

in cubic miles

Water volume, in

cubic kilometers

Percent of

freshwater

Percent of

total water

Oceans, Seas & Bays 321,000,000 1,338,000,000 -- 96.5

Ice caps, Glaciers, &

Permanent Snow

5,773,000 24,064,000 68.7 1.74

Groundwater 5,614,000 23,400,000 -- 1.7

Fresh 2,526,000 10,530,000 30.1 0.76

Saline 3,088,000 12,870,000 -- 0.94

Soil Moisture 3,959 16,500 0.05 0.001

Ground Ice &

Permafrost

71,970 300,000 0.86 0.022

Lakes 42,320 176,400 -- 0.013

Fresh 21,830 91,000 0.26 0.007

Saline 20,490 85,400 -- 0.006

Atmosphere 3,095 12,900 0.04 0.001

Swamp Water 2,752 11,470 0.03 0.0008

Rivers 509 2,120 0.006 0.0002

Biological Water 269 1,120 0.003 0.0001

Total 332,500,000 1,386,000,000 - 100

2.2 Water Cycle

Water is considered a renewable source as it cannot be destroyed nor created.

There is no beginning or end to water. This is because water will continually exist in

a cycle called the Water Cycle and illustrated in Figure 2.1.

The sun plays a vital role to ensure the continuity of the cycle. From the heat

of the sun, water evaporates from the surface of any surface water namely oceans as

the surface of the water is almost still. These vapours then rise into the atmosphere

and condense into clouds as the temperature is much cooler. Evapotranspiration

which is the process of transpiration from plants and evaporation from soil occurring

simultaneously also involved in the process of cloud formation through the process

of evaporation and condensation. The accumulation of water particles, also known as

cloud, from the condensation of water vapour, until a certain point where the water

particles cannot hold together longer, will fall towards Earth as rain or precipitation.

Other form of precipitation can be snow or hail. Water that flows on the ground is

known as surface runoff which will eventually enter rivers and oceans to continue

8

the cycle. A portion of surface runoff will seep into the ground through the process

of infiltration where it will accumulate as groundwater. In time, the water will seep

back into surface water bodies and the water cycle will continue.

Figure 2.1: The Water Cycle (United States Geological Survey, Colorado

District)

2.3 Rainfall Pattern in South East Asia

Countries in South East Asia are blessed with abundant rainfall spread more

or less evenly throughout the annual cycle, with peaks during the monsoon periods.

It is noted that annual rainfall in these countries ranges between 1500mm to

2500mm, with certain highlands experiencing rainfall in excess of 4000mm. seasonal

variations inevitable occur, with high monsoonal rainfall in the last quarter of the

annual cycle and season low rainfall in a few regions, mostly in the first quarter of

the year. Overall monthly average rainfall ranges from 176mm to 260mm. Table 2.2

shows the pattern of rainfall on prominent locations in South East Asia. In the state

of Johor, the range of rainfall throughout the year is 156mm to 264mm with a wetter

side at the last quarter of the year. Although the average of rainfall does not depict

9

the actual situation, it provides sufficient data on how much water can be saved for

the use of rainwater to substitute the potable water in activities that requires non-

potable water usage.

Table 2.2: Pattern of Rainfall on Prominent Locations in Peninsular Malaysia

(Jitender, 2008)

Location Q1 Q2 Q3 Q4 Cum Annual

Perlis 64 173 228 191 1970

Kedah 70 192 227 212 2103

Terengganu 140 120 153 479 2676

Kelantan 159 192 240 422 3038

P. Pinang 92 176 219 237 2172

Pahang 178 166 155 313 2434

Johor 188 168 156 264 2327

Selangor 145 172 153 237 2121

N. Sembilan 153 162 137 241 2077

Perak 128 161 144 211 1933

Melaka 102 145 175 139 1684

2.4 Sustainability of Rainwater

For a sustainable urban future, society must move towards the goal of

efficient and appropriate water use. Rainwater harvesting has a significant role to

play in this task. Water availability has been a matter of concern all over the world. It

has been reported that rainwater harvesting can promote significant water saving in

residences in different countries. In Germany, a study performed by Herrmann and

Schimida, (1999) showed that the potential of potable water saving in a house might

vary from 30% - 60%, depending on the demand and roof area. In Australia,

Coombes et al. (1999) analysed 27 houses in Newcastle and concluded that

rainwater usage would promote potable water saving of 60%. In Brazil, a study

performed by Ghisi et al. (2006) showed the potential water saving by using water

harvesting in 62 cities ranges from 34%to 92%, with an average potential for potable

saving of 69%.

Rainwater harvesting is a technology used for collecting and storing

rainwater from rooftops, land surfaces, road surfaces or rock catchments using

simple techniques such as pots, tanks and cistern as well as more complex techniques

10

such as underground check dams (Prinz, 1995; Zhu et. al, 2004). It consists of three

basic components: a collection area (roof), a conveyance system and a cistern or

storage tank (Texas Water Development Board, 2005). The collection of rainwater

from roofs, its storage and subsequent use is a simple method of reducing the

demand on both the public water supplies and waste treatment facilities. In the

Uniter Kingdom, 30% of potable water supplied to the domestic sector is used for

water closet (WC) flushing and the transportation of foul waste (Welsh Office,

1992). Without extensive treatment the rainwater is suitable for a range of uses such

as WC flushing, garden irrigation and clothes washing. The capacity of the rainwater

store is important both economically and operationally (Fewkes, 1999).

Harvested rainwater is a renewable source of clean water that is ideal for

domestic and landscape uses. Water harvesting systems provide flexible solutions

that can effectively meet the needs of new and existing, as well as of small and large

sites, using a water harvesting system is an ongoing proves that can be developed

over time. The greater attraction of a rainwater harvesting system is low cost,

accessibility and easy maintenance at the household level.

2.4.1 Rainwater Harvesting in Malaysia

Malaysias capital city, Kuala Lumpur and its industrial state neighbor,

Selangor, are working hard to find alternative water supply to cope with the rising

demand in water, to this end, they are planning to build the first underground pipe in

the country to get water supply from Sungai Bernam in the State of Perak starting

2009. The estimated cost for the project is RM9 billion and will be able to supply

one billion liters of water daily to Kuala Lumpur and Selangor. Be that as it may, the

need for inter-state supply of water of water rationing may not have arisen should all

Malaysians learn from the 1998 draught incident where water was rationed and many

had to do without it.

11

Straight after the incident, the Ministry of Housing and Local Government

has introduced a guideline on rainwater harvesting in 1999 but it generally passed by

without notice. Up till now very few government buildings have used rainwater

harvesting. On March 27, 2006, the prime minister announced that rainwater

harvesting would be made mandatory to large buildings. It remains to be seen

whether this motion would be implemented without resistance or reservations.

2.4.2 Historical Development for Rainwater Harvesting Policy

The 1999 Guidelines for Installing a Rainwater Collection and Utilization

System can be seen as the initial phase of rainwater harvesting policy in Malaysia.

Introduced after the 1998 drought, it aims at reducing the dependence on treated

water and provides a convenient buffer in times of emergency or a shortfall in the

water supply. It also proposes the construction of mini dams or rainwater tanks in

urban areas instead of continuing to build giant dams upstream. This may not only

conserve the treated water but can act as urban flood control. Nevertheless the

guideline is intended as an ideal manual for reference for those who want to install

a rainwater collection and utilization system. It generally does not deal with cost and

implementation issues. As rainwater harvesting is new to many Malaysian, as well as

the fact that most of the system was not available locally, the implementation of the

new policy was not really successful.

After five years of the introduction of the Guidelines, the Ministry prepared

another cabinet paper to the National Water Resources Council to encourage

government buildings to install a rainwater collection and utilization system. The

Council has later announced that water utilization is to e encouraged but not

mandatory in all federal and state government buildings, there is a need for rainwater

utilization campaign and to provide a solution for prevention of mosquito breeding.

To date, only two federal government buildings have been equipped with the

rainwater harvesting system, namely the Department of Irrigation and Drainage and

the Ministry of Energy, Water and Communication. With a few exceptions as in

12

Johore and Penang, many local governments have not implemented rainwater

harvesting in their locality. Few types of council like in Sandakan and Shah Alam

has introduced it in new housing developments. Despite this effort, it is unfortunate

to learn that in the Kota Damansaras new housing project; nearly 40% of the

rainwater harvesting system installed has been dismantled to give way for

renovation.

2.5 Economic Impact

Rainwater harvesting plays major roles in reducing potable water demands

and averting water wastages. Several R&D efforts of rainwater utilization for

domestic, office and mosque complex, industry and agriculture use have been

conducted by NAHRIM in collaboration with other government bodies and

universities.

One of the projects is installation of two 2500 litre capacity high density

polyethylene (HDPE) tanks that were later replaces with a 3,300 litre brick storage

tank design that incorporated aesthetic and utility aspects to trap rainwater falling

onto a 60m

2

roof top area. This system was able to save on one third of the

household water use of 40650 litres (Ahmad Jamaluddin and Adhityan, 2000). The

rainwater utilization system for a double storey terrace house located at Taman

Melawati for non-potable household use and also reducing peak storm runoff. The

system was able to trap 61.4 to 65.5% of the rainwater flow. The initial cost was RM

2700 for the two HDPE tank constructions and RM4300 for the rainwater cum

detention storage system. The maintenance cost for both was RM53/year. The annual

total cost of the earlier system is RM188/year and the latter was RM268/year. The

HDPE tank is projected to collect 109m

3

of water resulting in a unit ccost of

RM1.72/m

3

. While the brick tank could collect 102m

3

of water incurring a unit cost

of RM2.62/m

3

.

Second is the installation of an underground 60 m

3

storage tank to collect

rainwater to be pumped to toilets and standpipes at a mosque in Ampang. The

13

installed cost of the system was RM95000 with the life expectancy of 25 years. With

the annual cost of RM4100 and an annual rainwater utilization of 3249 m

3

/annum,

the unit cost of water is RM1.26m

3

. in both cases, the per unit costs are both still

high. The government has to urgently provide subsidies to encourage the public to

install new rainwater harvesters (Mohd Shahwahid et al., 2007)

2.6 Rainwater Harvesting System Components

Rainwater is harvested sing an installation of pipes and tanks in such a way

that allows automatically or manually diverting the first flush of rain that is

contaminated with debris and dirt on the catchment area followed by collection in a

storage tank for further use. The basic rainwater harvesting system consists of 3

major parts which is the collection area, the conveyance system and the storage

tanks. The materials use for these components will influence the efficiencies as well

as the quality of the rainwater collected.

2.6.1 Collection Area

Catchment area is the surface area from which rainwater can be collected as

clean water. The most popular shape of rooftops in homes in Asia is a sloping roof in

inverted V shape in varied designs and architectural features (Jitender, 2008). The

roof is fitted with gutters to divert rainwater into drains, to prevent erosion of ground

surface directly below the edge of the roof as well as diverting the flow into storm

water drains.

To harvest rainwater, a suitable catchment area namely the roof must be

installed with suitable material. The material used for the roof must not jeopardize

the water quality of the rainwater as well as provide a good surface to optimize the

harvest rainwater. Besides that, the materials must be ready available and

economically wise to reduce the starting cost for the installation of the rainwater

harvesting system.

14

The effective roof area and the material used in constructing the roof

influence the efficiency of collection and the water quality. Smoother, cleaner and

more impervious roofing materials are preferred. They contribute to better water

quality and greater quantity (Fayez, 2009)

Not all roofing materials are suitable to act as a surface to collect rainwater.

One of the roofing materials that should be avoided is asphalt roof. Asphalt is

commonly used as the roofing material. Nevertheless, asphalt does not give a good

surface to harvest rainwater. Besides that, it can create debris from crumbling asphalt

shingles and also leach petroleum into the rainwater. Next, wooden shingles are not

suitable as well because it is porous and harbor mold and fungus that will end up in

your rainwater harvesting system. There are those treated wooden shingles as well to

avoid the growth of fungus are not fit to harvest as it will be contaminate the

rainwater with chemicals.

Roofing materials that are considered acceptable for rainwater harvesting is

slate or tile. It provides a good surface to harvest rain when kept clean and it does not

deteriorate. Fiberglass can be considered as it provides great surface to harvest rain

as well as is light weight to east the installation of roof. Apart from that, membrane

roofing material, although not commonly used in residential application, is

considered ideal because its chemical makeup is not friendly to bacteria and could be

painted on an existing rooftop.

Nonetheless, take note that all rooftops are not clean no matter what material

they are made from. The reason is that bird dropping and other debris such as leaves

and branches as well as dirt will fall and contaminate the rainwater and wash into the

rainwater harvesting systems. So it is wise to clean the rooftop on a regular basis,

install filter and install a first flush system to remove contaminant that passes

through the filter to obtain clean rainwater.

15

2.6.2 Conveyance System

A conveyance system usually consists of gutters and pipes that deliver

rainwater falling on the rooftop to cisterns or tanks. Gutter or pipes must be properly

sized, sloped and installed in order to maximize the quantity of harvested water.

These transport channels collect and divert water into down spouts that drain away

the water into storm water drains. At suitable intervals alongside the gutters,

sufficient sized vertical or slanting down spouts are installed to drain away the water

into water storage tank.

The most common materials of gutters are galvanized steel, fiberglass, plastic

and stainless steel. The gutters and down pipes are usually installed in the wall of the

building and sometimes the down pipes are fitted inside the wall during construction.

The size of the gutters depends upon the area of the roof and the rainfall

amount. The size of the gutters used ranges between 20-50 cm diameters (Alpaslan

et al., 1992). Drainpipes and roof surfaces should be constructed of chemically inert

materials such as wood, plastic, aluminum, or fiberglass, in order to avoid adverse

effects in water quality (Fayez, 2009). Table 2.3 shows the relationship between

average rate of rainfall and diameter of pipe.

Table 2.3: Sizing of Rainwater Pipe for Roof Drainage

Diameter of

Pipe (mm)

Average rate of rainfall in mm/h

50 75 100 125 150 200

50 13.4 8.9 6.6 5.3 4.4 3.3

65 24.1 16.0 12.0 9.6 8.0 6.0

75 40.8 27.0 20.4 16.3 13.6 10.2

100 85.4 57.0 42.7 34.2 28.5 21.3

125 - - 80.5 64.3 53.5 40.0

150 - - - - 83.6 62.7

Debris both coarse and fine may cause blockage and contaminate the water

quality. To avoid blockage, leaf screens, made of inch wire mesh in a metal frame

is installed above the gutters to prevent debris from entering the system. The angle

bends in the system should not exceed 45 degrees. Another filtering system is placed

before the head of the cistern to filter out smaller debris from the roof.

16

To ensure clean water enters the storage tank, a first flush tank is installed

prior the entrance of the storage to trap the first flush of the rainwater that is used to

clean the roof due to debris and dust that may have deposited on it. A small container

with adequate size is installed to receive at least 30 litres of first flush dirty water for

every 100 m

2

of catchment area. It is fitted with an overflow pipe that starts to

deliver clean water after the container is filled with the predetermined quantity of

first flush water. The dirty water collected may be used for watering of plants

(Jithender, 2008).

2.6.3 Storage Tank

The water ultimately is stored in a storage tank or cistern. The size of the

cistern depends on the amount of rainwater to be collected. The tank must provide

for adequate capacity to receive required amount of rainwater to maximize

availability of water during dry period. Typically, a 500-2000 litre capacity tank is

commonly used, since the replenish frequency by rainfall in the South East Asian

region is high (Jithender, 2008).

Cistern can be built in almost any geometrical shape desired. All cisterns

should be watertight, durable and have a clean smooth interior. The cover needs to

be tight fitting to prevent evaporation and mosquitoes. A cistern with a lid allows for

easy access to attach a faucet and to occasionally clean inside. It is best to place the

cistern out of direct sunlight to prevent algae and bacteria growth, which can clog the

system. The use of two or more smaller cisterns enables service on one unit at a time

without disrupting the entire system.

There are unlimited number of options for the construction of these tanks

with respect to the shape (cylindrical, rectangular and square), the size and the

material of construction (brickwork, stonework, cement bricks, plain cement

concrete and reinforced cement concrete (Fayez, 2009), fiberglass, polyethylene,

plastic and galvanized). Table 2.4 shows the normally used cistern types and its

advantages and disadvantages of the particular cistern.

17

The placement of the cistern is elevated approximately 3 to 4 feet on a sturdy,

load bearing foundation or structure to create enough pressure to use gravity for

running the rainwater. Foundations can be made of bricks, concrete or a wooden

frame. Figure 2.2 shows a sample diagram of rainwater harvesting storage tank.

Table 2.4: Advantages and Disadvantages of a Cistern Type

Cistern type Advantages Disadvantages

Fiberglass tanks Prevents algae growth and

evaporation, rust resistant, durable

Higher initial costs, degradable,

requires exterior coating

Polyethylene tanks Various sizes, shapes, alterable,

inexpensive, movable

Can deteriorate over time if not

treated for UV radiation

Plastic garbage can Available, inexpensive Use only new cans

Barrels Attractive, alterable, great for

small systems

Hard to find, small

55 gallon steel drums Available, durable, great for small

systems, moveable

Prone to corrosion, rust and/or

toxins

Galvanised tanks Inexpensive, attractive, moveable,

alterable

Can rust, higher long term costs

Plaster cisterns Low profile, inexpensive, can

alter colour

Large footprint, unalterable,

immovable

Concrete tanks, stone

or concrete block

Durable, permanent Potential to crack, difficult to

maintain

Figure 2.2: A Diagram of Rainwater Harvesting Storage Tank (Southface

Energy Institute)

18

2.7 Rainwater Storage Tank Design

The design criteria are based on one day minimum storage of domestic tank.

It is divided into 3 methods which are:

(i) Minimum Storage Per Capacity

(ii) Storage Requirement Per Fittings

(iii) Storage Requirement Per Person

These 3 methods are categories based on demand in the kitchen and

bathroom in a day or a person per day. Table 2.5 shows the minimum storage

capacity for different type of building. Table 2.6 shows the storage requirement per

fitting for different type of domestic activities that requires the usage of water and

table 2.7 shows the storage requirement per person in different type of buildings. The

data is obtained from MWAs Design Guidelines for Water Supply Systems. This

manual serves as useful reference material to water engineers and sub-professionals

both in the public and private sectors when designing water supply systems.

Table 2.5: Minimum Storage Capacity (MWA, 2000)

Type of Building Minimum Nominal Storage Capacity

Dwelling House (rural) 450 litres/day

Dwelling house and flats (urban) 680 litres/day

Multi-storey flats with high level

bulk storage cistern

140 litres/day

Low cost housing (approved by

Government)

450 litres/day

Others One days supply or decided by the State Director

Table 2.6: Storage Requirement Per Fittings (MWA, 2000)

Type of Activities Storage Requirement

Shower 450-900 litres/day

Sliper Bath 900 litres/day

Water Closet 180 litres/day

Lavatory Basin 90 litres/day

Sink 90 litres/day

Urinal 180 litres/day

Bed Pan Washer 180 litres/day

Wash-up Sink 225 litres/day

19

Table 2.7: Storage Requirement Per Person (MWA, 2000)

Type of Building Storage Requirement

Hotels 270 litres/person/day

Hostels 180 litres/person/day

Day Schools 30 litres/person/day

Boarding Schools 180 litres/person/day

Offices without canteens 70 litres/person/day

Offices with canteens 90 litres/person/day

Restaurants 14 litres/person/day

Mosque 14 litres/person/day

Barrack (Army/Police) 270 litres/person/day

Out of the 3 methods, the 2

nd

method is used for reference. By referring to

table 2.5, minimum storage capacity shows the storage capacity for a building. It will

be suitable for houses that have permanent residents such as families. With the

constant number of occupants thus minimum storage capacity will be more accurate

for estimation. By referring to table 2.7, storage requirement per person indicate the

usage of water for a person in specific place. It will be suitable for buildings that

have permanent occupants as well. Due to the fact that the number of occupants is

inconsistent, storage requirement per fitting is used.

CHAPTER 3

RESEARCH METHODOLOGY

3.0 Introduction

Rainwater is to be collected in the campus to be tested for these 6 parameters;

pH, DO, BOD, COD, TSS and E.Coli. The location and the time of sampling are

crucial to obtain the most accurate results that reflect the actual state of rivers.

Therefore, the rainwater is collected at the end of the gutter before the rainwater is

discharged into the drain. The collection of the sample has to be done on a rainy day

and a container is used for the collection of the sample. The sample should be

collected with care to ensure originality of the sample and free from other

contaminants. Sample is then brought to the lab to proceed with the testing. The

accuracy of the results depends on how the samples are taken. Therefore, attentions

must be given to the execution of the collection and sampling techniques.

3.1 Testing of Parameters

The parameter of this study includes pH, Dissolved Oxygen (DO), Biological

Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Suspended

Solids (TSS) and E.Coli. pH is measured using a pH meter where as DO, BOD, and

COD are measured using the HACH machine DR 5000 series. E.Coli is tested using

Colilert.

21

3.1.1 pH

Calibration should be performed with at least two standard buffer solutions

that span the range of pH values to be measured. For general purposes buffers at pH

4 and pH 10 are acceptable. The pH meter has one control (calibrate) to set the meter

reading equal to the value of the first standard buffer and a second control (slope)

which is used to adjust the meter reading to the value of the second buffer. A third

control allows the temperature to be set. Standard buffer sachets, which can be

obtained from a variety of suppliers, usually state how the buffer value changes with

temperature.

3.1.2 Dissolved Oxygen

The High Range Dissolved Oxygen AccuVac Ampul contains reagent

vacuum-sealed in a 14-mL ampule. When the AccuVac Ampul is opened in a sample

containing dissolved oxygen, it forms a yellow color which turns purple. The purple

color development is proportional to the concentration of dissolved oxygen. Test

results are measured at 535 nm.

3.1.3 Biological Oxygen Demand

The Biological Oxygen Demand (BOD) test is carried out according to

Standard Method APHA 5210-B. The method consists of filling the samples into an

air tight 350mL BOD bottle and put into incubating at 20C for 5 days. Dissolved

Oxygen (DO) is measured initially and after incubation using Microprocessor

Logging DO Meter Model HI964400.

Samples for BOD testing may degrade significantly during collection, storage

and analysis resulting in low BOD values. Therefore, it is crucial to minimize

degradation of quality of the water samples as soon as possible by cooling them to a

22

near-freezing temperature during storage period. Chilled sample water should be

warmed to 203C before analysis is carried out. Formula to calculate BOD is as

follows:

P = Vs / (Vs + Vdw) (3.1)

BOD5 = (DOi DO5) / P (3.2)

Where :

V

s

= Volume of sample

V

dw

= Volume of dilution water

BOD

5

= Biological oxygen demand, mg/L

DO

i

= initial DO of the diluted sample about 15minutes after preparation, mg/L

DO

5

= final DO of the diluted sample after 5 days of incubation, mg/L

P = dilution factor

3.1.4 Chemical Oxygen Demand (COD)

The procedure for Chemical Oxygen Demand (COD) test is according to

Standard Method APHA 5220-C. The mg/L COD results are defined as the mg of O

2

consumed per liter of sample under conditions of this procedure. In this procedure,

the sample is heated for two hours with a strong oxidizing agent, potassium

dichromate. Oxidizable organic compounds react, reducing the dichromate ion

(Cr

2

O

7

2

) to green chromic ion (Cr

3+

). When the 0.740.0 or the 3150 mg/L

colorimetric method is used, the amount of Cr

6+

remaining is determined. When the

201500 mg/L or 20015,000 mg/L colorimetric method is used, the amount of Cr

3+

produced is determined. The COD reagent also contains silver and mercury ions.

Silver is a catalyst, and mercury is used to complex chloride interferences. Test

results for the 0.7 to 40.0 mg/L range are measured at 350 nm. Test results for the 3

to 150 mg/L range are measured at 420 nm. Test results for the 20 to 1500 and the

2000 to 15,000 mg/L COD range are measured at 620 nm.

23

3.1.5 Total Suspended Solids

The procedure to determine Suspended Solid (SS) is according to the

Standard Methods APHA 2540-D. Glass microfiber filter disc is used to filter the

water sample. The weight of a clean filter paper is recorded before the sample water

is poured into it. The filter paper is then dried in the oven for about an hour, cooled

and weight. The calculation of the TSS is:

SS, mg/L = [(A-B) x 1000] / C (3.3)

Where :

A = weight of filter + residue (mg)

B = weight of filter (mg)

C = volume of sample filtered (mL)

3.1.6 Escherichiacoli

A 100mL of sample is being mixed with a reagent i.e. Colilert in a mixing

bottle and then pour into a cell house and finally incubate it for 24hours under

temperature of 35C. Colilert simultaneously detects total coliforms and Escherichia

coli (E.Coli) in water. It is based on IDEXXs patented Defined Substrate

Technology (DST). When total coliforms metabolise Colilerts nutrient indicator,

ONPG, the sample turns yellow. When E.Coli metabolise the nutrients, the sample

fluoresces. Colilert can simultaneously detect these bacteria at 1 cfu/100mL within

24 hours even with as many as 2 million heterotrophin bacteria per mL present. After

24 hours incubation, any changes of colour to yellowish, then this sample is being

observed under UV light. When florescent is being observed, this indicates that

E.coli is present within the sample. The calculation of E.coli is being done according

to the IDEXX Quanti-Tray/2000 chart.

24

3.2 Design of Rainwater Harvesting System

The criteria needed to be taken into consideration for the design of RWH is

the storage tank to store sufficient rainwater, the piping system to determine the flow

rate in each pipe, type of pipe used and determine the diameter of each pipe and the

height of which the tank is needed to be elevated to produce enough pressure without

the use of pump.

3.2.1 Storage Tank

The storage tank volume is estimated based on the demand of water using

Storage Requirement Per Fitting method in Table 2.6. For this design, 10 days of

storage rainwater is used to estimate the volume. From the volume required the size

of the tank can be determine.

3.2.2 Height of Storage Tank

The height of storage tank is determined using the internal plumbing design.

This is a trial and error method where the height is choose until all the pressure head

at each end of pipe passed the approved pressure by the local authority.

3.2.3 Piping System

For this system a dead end pipe network system is used. The computation of

flow rates within the pipe is to be determine based on data obtained from MWAs

manual and then the computation of residual pressure head at the end of each pipe to

ensure the pressure is sufficient as suggested by the local water authority.

25

3.3 Cost

To build rainwater harvesting system does not come without the price.

Estimation of water usage and its cost and the cost of construction of rainwater

harvesting system versus the estimated water saving cost have to be done in order to

show that this system is useful economically and environmentally.

3.3.1 Water Savings

One of the objectives of this study is to identify the amount of clean water

that can be saved and to calculate the saving of expenditure in water consumption

which is replaced by rainwater. The water tariff is based on the data provided by

Syarikat Air Johor (SAJ).

3.3.2 Rainwater Harvesting System Construction Cost

The cost of construction of a rainwater harvesting system is estimated based

on the type of material used, the amount of the material and the workers pay. The

material used is taken from Schedules of Rates (JKR, 2005).

3.4 Volume of Rainwater Collected

The volume of rainwater that could be harvested in campus is calculated

considering the annual rainfall data, the total roof area and a run-off coefficient of

0.8. The coefficient indicates a loss of 20% of the rainwater that is discarded for roof

cleaning and evaporation (Gould, 1993). Thus, the volume of rainwater that could be

harvested is determined by using Equation 3.4.

26

V = C x A x R/1000 (3.4)

Where:

V = annual volume of rainwater that could be harvested

C = run-off coefficient (non-dimensional)

A = total roof area (m2)

R = average annual rainfall (mm/year)

1000 = conversion factor from mm to m

CHAPTER 4

RESULTS AND DISCUSSIONS

4.0 Introduction

The rainwater sample is taken from site located at M41. The sample is taken

directly from the downpipe and the sample is taken in between the raining event. 3

samples are taken separately at 3 different raining events dated 6 February, 23

February and 8 March all in the year of 2010. After the collection which is all done

in the late afternoon around 5 pm, the sample is then carefully sealed and kept in the

lab and testing is done at the next day. To ensure the quality is not disturbed, the

sample should be tested not more than 24 hours. The purpose is to determine the

condition of the rooftop and the gutter if it is dirty and needed to be either cleaned

or replace with a new ones. By doing so, it will help with the decision making in

construction of the system whether to install new roof tiles and gutter system.

4.1 Water Quality

There are 6 parameters namely pH, DO, BOD, COD, TSS and E.Coli are

tested to determine the quality of rainwater using the instruments available in the

environment lab in University Technology Malaysia. Table 4.1 shows the result

obtained after lab testing.

28

Table 4.1: The test results for collected rainwater

Parameter Sample(6 Feb) Sample(23 Feb) Sample(8 March)

pH 7.31 7.07 7.25

DO 7.83 ppm 7.92 ppm 7.85 ppm

BOD 1.13 mg/L 1.24 mg/L 1.47 mg/L

COD 5 mg/L 4 mg/L 28 mg/L

TSS 5 mg/L 4 mg/L 3 mg/L

E.Coli 0 cfu/100mL 0 cfu/100mL 0 cfu/100mL

Based on the test result compare to the WHO guideline for drinking water as

stated in Table 4.2, pH, TSS and E.Coli is acceptable for drinking purpose. pH for

the sample collected are in between 7.07 to 7.31 which is in the range of WHO

guideline of 6.5-8.5. Although there is no value for DO, BOD, COD and TSS for

WHO guideline, test results are compared with INWQS and Standard A.

Table 4.2: Comparison of test results with WHO drinking guideline, INWQS

class IV and Standard A effluent

Parameter Sample WHO INWQS (Class IV) Standard A

pH 7.07-7.31 6.5-8.5 5-9 6-9

DO 7.83-7.92 - <3 -

BOD 1.13-1.47 - 12 50

COD 4-28 - 100 100

TSS 3-5 - 300 100

E.Coli 0 Absent in 100ml - -

All the parameters mentioned are below the maximum value allowed. These

indicate that the water quality of the rainwater is still considered clean and the level

of pollution for both organic and inorganic is at minimum due to the low value when

compare relatively to the two standards. Lastly, there is no sign of E.Coli or total

coliforms presence in the sample when tested for E.Coli test. This result fit the

requirement for WHO guideline which requires E.Coli to be absent in 100 mL of

sample.

Nevertheless, the purpose of collecting rainwater is for toilet flushing and

irrigation purposes only and no consumption and human contact is allowed for

precaution. Therefore, it is safe to say that the rainwater is considered clean and no

further treatment is necessary. Only physical treatment such as filtering is used to

ensure that the debris does not go into the storage tank which could lead to blockage.

29

4.2 Designing Rainwater Harvesting System

By using the internal plumbing design, the height of the storage tank can be

determine as well as the type of pipe used, the flow rate in each pipe and the

diameter of the pipe so that the residual pressure head at the end meets the criteria.

Figure 4.1 shows the proposed rainwater harvesting system.

The system provides rainwater to two water cistern exist in the building and

the tank is situated on top of a concrete platform which is to be raised to the required

height according to the calculation. By raising the storage tank, it will enable gravity

to supply rainwater to the cistern tank. The reason is to create a sustainable

environment thus the usage of electricity and other energy is minimise. Besides that

the cost is also taken into consideration to achieve a less energy consumption and

relatively cheap system to construct. Gravity is used because it is naturally

occurrence and it is sufficient to provide the energy to transfer the rainwater from the

storage tank to the cistern tanks without the assistance of electrical equipments such

as pumps which is costly and high energy consumption

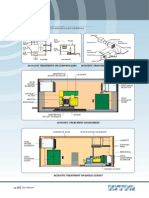

Figure 4.1: The Proposed rainwater harvesting system

30

4.2.1 Flow Rates, Q

The flow rates in each pipe is determined based on the demand at each fitting

fitted at the end of the pipe system. Figure 4.2 shows the schematic drawing for

piping system with numbering for calculation purposes. Table 4.3 can be used to

determine the flow rate, Q for each fitting in use.

Figure 4.2: Schematic drawing for piping system

Table 4.3: Design Flow Rates for Fittings (MWA, 2000)

Fittings Rate of Flow (litre/second)

WC flushing cistern 0.1

WC flush valve* 1.5

Wash basin tap 0.15

Bidet 0.15

Bath tap, 25mm 0.6

Shower head 0.2

Sink tap, 12mm** 0.2

Sink tap, 20mm 0.3

Sink tap, 25mm 0.6

Urinal flushing cistern 0.004 per bowl

* Discharge per flush shall not exceed 9 litre per WC and 4.5 litres per stall for bowl urinal

** Clothes and dishwashing machines in individual dwelling can normally be satisfied by a 12 mm

sink tap but manufacturers instruction should be checked.

Example of calculation

Referring to table 4.6, pipe 1-2 provides water to 2 WC

Flow rate, Q = 2 x 0.1litre/s

= 0.2 l/s or 0.0002m

3

/s

31

4.2.2 Hazen-Williams Coefficient, C

w

Table 4.4 provides the Hazen-Williams coefficient that is used for designing

the internal plumbing systems. The coefficient is used for the calculation of head loss

in pipe. The value chosen is 155 for uPVC pipe.

Table 4.4: Hazen-Williams coefficients

Type of Pipe Hazen-Williams C

w

Asbestos cement all ages 140

Cast iron new 130

(good condition) 10 years old 100

20 years old 90

Cast iron coated good condition old ages 135

Welded steel uncoated new 125

old 100

Galvanised iron new 130

Polyethene /ABS all ages 155

uPVC all ages 155

4.2.3 Effective Pipe Length, L

eff

The effective pipe length is the actual pipe length plus the equivalent pipe

length. The equivalent pipe length is the pipe length taking into consideration the

minor losses in pipe such as stop valve, elbow etc. The effective pipe length is used

in the design to consider the friction loss as well as the minor losses available in the

pipe run. The equivalent pipe length for minor losses can be obtained from table 4.5.

Table 4.5: Equivalent Pipe Lengths (MWA, 2000)

Nominal Diameter Elbow (m) Tee (m) Stop valve (m) Check Valve (m)

12 0.5 0.6 4 2.5

20 0.8 1 7 4.3

25 1 1.5 10 5.6

32 1.4 2 13 6

40 1.7 2.5 16 7.9

50 2.3 3.5 22 11.5

65 3 4.5 - -

73 3.4 5.8 34 -

100 4.5 8 - -

32

Example of calculation

By referring to figure 4.2, let pipe 1-2 diameter, d = 65mm

Actual pipe length, L = 2 m

Pipe 1-2 contains 2 elbows, L

equivalent

= 2 x 3

= 6 m

Therefore, effective length for Pipe 1-2, L

eff

= Actual length + L

equivalent

(4.1)

= 2 m + 6 m

= 8 m

4.2.4 Head Loss, h

L

The head loss will consider both friction loss and minor losses such as elbow,

tee, stop valve etc. The Hazen-Williams formula is sufficient to be used to

determine the head loss using this formula: =

.

.

. .

Example of calculation

By referring to figure 4.2, pipe 1-2, =

. ( )( . )

.

( )

.

( . )

.

(4.2)

= 6.56 x 10

4.2.5 Flow Velocity,

The flow velocity (m/s) in each pipe is determined by using equation

= =

p

The flow velocity in each pipe must not exceed 2.5 m/s (MWA, 2000).

Example of calculation

By referring to figure 4.2, For pipe 1-2, n =

( . )

p( . )

(4.3)

= 0.06 m/s

33

4.2.6 Residual Pressure Head

The residual pressure head at the downstream end of each pipe is determined

using Bernoullis equation.

Example

For pipe 1-2, + = + +

( )

(4.4)

0 + 2 = + 0 + 6.56 x 10

= 1.999 m

The value is the residual pressure head at the downstream end of pipe 1-2 that is

equal to the pressure head at node 2. This pressure head will become the pressure

head at the upstream end of pipe 2-3. The pressure head at each fitting must not be

less than 0.8m.

The height of the outlet and the diameter of the pipe can be adjusted to fit the

criteria but the cost of operation is needed to be taken into consideration as well. By

having a high elevated outlet will definitely yield enough pressure to the end pipe but

the cost of elevating the storage tank to that level will increase the cost of material

used to elevate the storage tank and the stability of the structure has to be considered

too. Besides that, the diameter of the pipe can be adjusted to suit the needs of the

residual end pipe. Increasing the pipe will give rise to the residual pressure head but

it also increases the cost as bigger pipe are more costly than smaller pipe. This is the

process of designing internal plumbing systems for the conveyance of harvested

rainwater to water closets.

Table 4.6 shows the computation of flow rates and 4.7 shows the overall

computations of the required parameters to determine sufficient pressure head to the

end pipe. From the calculations, few trials and errors are done on the height of the

outlet of the storage tank and the diameter of the pipe to ensure that the residual

pressure head meets the criteria.

34

Finally, the height of which the outlet of the tank should be elevated is 2m

above datum where the datum is which the lowest elevation of the pipe system and

the size of diameter are as shown in Appendix A.

Table 4.6: Computation of Flow Rates

Pipe WC Q (m

3

/s)

1-2 2 0.0002

2-3 1 0.0002

3-4 1 0.0001

4-5 1 0.0001

5-6 1 0.0001

4.2.7 Designing Water Storage Tank Capacity

The capacity of the water storage tank is important as it determine the

amount of rainwater that can be stored. The size of storage of rainwater is important

because the rainwater can be stored and used even when there is no rain but to have a

very big tank will indicate a large quantity of rainwater can be stored but with higher

cost of construction and taking up space. So the size of the tank as well as the cost

and space need to be taken into consideration to obtain an acceptable storage tank.

The average daily use of water for flushing is 30 litres (Shaaban and Appan,

2003). There are two water closets present in the building thus the total usage per

day is 60 litres or 0.06 m

3

. The number of days of storage is assumed to be 10 days.

This means that a full tank can supply enough water for flushing for 10 days without

rain. So the capacity of storage tank is 600 litres.

To store up 600 litres of rainwater, a taper tank model R6.8TD (2) is used

(refer to Appendix B). This model has the capacity of 680 litres. Its top diameter

measures 1395mm, bottom diameter is 1035mm and the height of 965mm as shown

in Figure 4.3.

35

Figure 4.3: The design of the rainwater storage tank for 600 litres

4.2.8 Designing Cistern Tank

In order to maximise the usage of rainwater, rainwater is prioritised to fill the

cistern tank. By doing so, it will substitute the usage of potable water for flushing.

Therefore, the pipe for rainwater from the storage tank has to be connected to the

existing cistern tank. Whenever the toilet is flushed, rainwater will replaced the

flushed water thus this is the reason of rainwater harvesting system for toilet

flushing.

However, the storage tank is designed to store 10 days of water supply. In

case of long days of no rain which exceed 10 days, it will cause the storage tank to

be empty thus no supply of rainwater to the cistern tank. To ensure hygiene is kept,

water has to be continuously flow into the cistern tank. And for that reason, potable

water will assume the role of replenish the cistern tank.

The switching of roles between rainwater and potable water has to automatic

so that water will always be available for flushing. So, an extra cistern tank is

connected to the existing cistern tank as shown in Figure 4.4.

36

Figure 4.4: Automation system for switching between rainwater and potable

water

The extra cistern tank has to be sufficient to accommodate the size of the

flotation device that controls the valve. Rainwater pipe from the storage tank will be

connected to the existing cistern tank with the flotation device connected to the valve

that controls the flow of rainwater. On the other hand, the potable water pipe will be

connected to the extra cistern tank and also controlled by a valve that is connected to

a flotation device. For the potable water pipe, the flotation device will be adjusted so

that when the water level drops beyond the minimum level, the valve will be opened

and potable water will starts to fill up the cistern tank.

The assumption to this automation system is that the rainwater will replenish

the lost water due to flushing before it reaches the minimum level thus only

rainwater will fills the cistern tank. When the storage tank is empty, potable water

will assume its role until the next rainy day. The reason for this is to make sure that

the system is sustainable whereby no additional usage of energy is required to

perform this task such as the usage of electric to operate a machine that controls the

switching. However, further study and field tests need to be done to obtain the best

size for both cistern tanks, the minimum volume of water needed for flushing to

obtain the minimum level and to evaluate the efficiency of this automation system so

that necessary modification will be done if required.

37

4.3 Cost

Rainwater harvesting system consists of 3 major components, namely the

collection area which is the roof, conveyance system which is the piping and the

storage tank. All of this has to be taken into consideration into calculating the cost of

installing the system. The cost of materials mostly referred to Schedules of rates

2005 by Public Works Department of Malaysia. Besides that, the worker pays as

well as other materials that are needed to construct this system are considered.

4.3.1 Collection Area

According to the test result conducted on the quality of rainwater collected, it

can be said that the water is in good quality and it is also save to say that the roof is

clean and safe to use as the collection area for the rainwater. Therefore, no further

changes are done to the roof and will be used as it is now.

Nevertheless, to direct all the rainwater collected to the storage tank, a gutter

system has to be installed around the perimeter of the roof to allow the rainwater

flows directly into the storage tank.

At the entrance of the downpipe leading towards the storage tank, a coarse

strainer is installed to block big objects and debris such as leaves from entering the

storage tank which can pollute the quality of the rainwater and cause blockage in the

system. Next before the rainwater enters the storage tank, another fine strainer is

installed to capture the smaller objects and debris.

The dimension of the roof of the building is shown in Figure 4.4. The

perimeter of the roof is 92.73m. Only the middle section of the building is high

enough to transfer rainwater into the storage tank. Therefore, the estimated length

needed for the gutter system is the addition of 10.2 with14.18 and 10.82 and 10.86

yields 46m.

38

Dimension in metre

Figure 4.5: The dimension of the rooftop

According to the catalogue in Appendix C, 6m of F300 Gutter cost RM93.

Therefore, 8 of 6m are needed to construct the required gutter system for the

collection of water. Besides that, for the overall construction of the gutter, 4 Mitre

Joint In is needed for the connection at the bend section, one Spouthead Fin for the

downpipe, joiner at every 1m span that only include the span of 24 metre and Debris

Trap before rainwater enters the downpipe. The overall cost for the installation of

gutter is shown in Table 4.8.

Table 4.7: Calculation of cost for installation of gutter

Description Quantity Rates (RM) Total (RM)

Gutter F300 6 93 558

Mitre Joint In 4 20 80

Spouthead Fin (4 ) 1 15 15

Joiner 25 5 125

Debris Trap (4 ) 1 15 15

Total 793

4.3.2 Conveyance System

The type of pipe use for this system is Unplasticised Polyvinyl Chloride

(uPVC). The pipe will be installed from the storage tank to the cistern and first flush

in order to convey the rainwater to the intended destination. The quantity is rounded

39

up to ensure that sufficient pipe is available for the system. The costing is as shown

in Table 4.8.

Table 4.8: Estimation of cost for the piping system

Description Quantity Rate (RM) per quantity Total (RM)

65mm class D 2 18.10 36.20

32mm class D 2.4 7.10 17.04

25mm class E 3.5 7.90 27.65

Elbow 65mm 2 16.20 32.40

Elbow 25mm 2 2.20 4.40

Tee 25mm 2 4.90 9.80

Elbow 32mm 3 3.10 9.30

Tee 32mm 3 6.70 20.10

Stop valve 32mm 2 8.00 16.00

Total 172.89

4.3.3 Storage Tank

The storage tank that will be used is a taper tank model R6.8TD (2)

(Appendix B). This model is manufactured by Weida Water Sdn. Bhd. with the

brand name Polystor. The material used is polyethylene tank with a 10 years

warranty. The price of this product is RM160.

4.3.4 Concrete Platform

The water tank has to be elevated as high as 2m above datum to achieve the

sufficient pressure at the end of the pipe. A concrete platform is casted to give the

structure strength to carry the burden exerted by the storage tank. Size of column use

is 300 x 300 mm where as the slab for the storage tank is 1.1m x 1.1m x 0.2m.

Besides that, the structure must be laid on a firm ground. Since the structure

will be build on soil, a concrete foundation will be casted to avoid settlement and

give a stable foundation to the structure. The size of the foundation will be 1.1m x

1.1 m x 0.5m.

40

The concrete Grade 30 will be mixed in the ratio of 1:3:6. Cement cost

RM202/tonne and 1m

3

of cement is 1.44 tonne. Sand cost RM7/tonne and 1m

3

of

sand is 1.53 tonne. Aggregate cost RM20/tonne and 1m

3

of aggregate is 1.68 tonne.

Calculation

1m

3

cement @ 1.44 tonne @ RM202/tonne = RM 290.88

3m

3

sand @ 1.52 tonne @ RM7/tonne = RM 31.92

6m

3

aggregate @ 1.60 tonne @ RM20/tonne= RM 192.00

= RM 514.80

Shrinkage 40% = RM 205.92

10m

3

= RM 720.72

The required volume is 1.027 m

3

as shown in Table 4.9. So the cost for concrete

materials for the foundation is

.

1.027 = RM 74.

Table 4.9: Total volume of concrete in m

3

Components Dimension (m) Total Volume (m

3

)

Slab 1.1 x 1.1 x 0.2 0.242

4 Columns 0.3 x 0.3 x 2 0.18

Footing 1.1 x 1.1 x 0.5 0.605

Total 1.027

To construct this system, workers are needed to accomplish this task. Table

4.10 shows the daywork labour rates per day. The number of workers is estimated to

be 5 people. There will be 2 general labours, Concrete leveller, Carpenter and

Plumber. Table 4.11 shows the number of days each worker works and their pays.

Minimum of 3 days is estimated for the completion of construction of this rainwater

harvesting system.

Table 4.10: Daywork Labour Rates (JKR, 2005)

Description Unit Rate (RM)

General Labour Day 45.00

Concrete Leveller/Screeder Day 65.00

Carpenter and Joiner Day 65.00

Plumber Day 70.00

41

Table 4.11: Workers pay (JKR, 2005)

Workers Days Rate (RM) Pay (RM)

2 General Labours 2 45.00 180.00

Concrete Leveller/Screeder 1 65.00 65.00

Carpenter and Joiner 2 65.00 130.00

Plumber 2 70.00 140.00

Total 515.00

As the material is made available, the concrete leveller will start with mixing

the concrete to its ratio and lay at the designated position. Before concreting, the

ground is to be compacted to give an even surface for concreting the foundation.

Carpenter can work on building the platform for the storage tank and plumber on the

piping. The next day, the platform can be raise to its intended height once the

concrete has harden and fasten the column to the concrete to give extra support to the

structure. The plumber will finish the piping system once platform structure has been

erected. The general workers will be helping in placing the storage tank to its placed,

fixing the gutters and clear up the working area.

4.3.5 Summary

Table 4.12 shows the overall cost needed for the installation of rainwater

harvesting system on M41. The total cost of construction is RM 1714.89. These

include the gutter, piping, storage tank, concrete and workers pays. This value does

not depict the actual cost as it is only estimation but can be use as reference.

Table 4.12: The overall estimation cost for the installation of rainwater

harvesting

Components Amount (RM)

Gutter 793.00

Piping 172.89

Storage Tank 160.00

Concrete materials 74.00

Workers pays 515.00

Total 1714.89

42

4.3.6 Cost Saving

One of the advantages of installing rainwater harvesting system is the cost

saving from using clean water by substituting with free rainwater. Every state has

its own water tariffs. In Johor, the cost for every cubic of water used is shown in

table 4.13. Price is taken from Syarikat Air Johor (SAJ).

Table 4.13: The price per m

3

of water in RM

Usage category Rate (m

3

) Price per m

3

(RM) Minimum payment (RM)

Domestic 0 - 15

16-30

31-45

46-100

>100

0.38

1.31

1.82

2.20

2.23

4.00

Industrial 0-20

21-40

>40

2.22

2.96

2.96

18.48

Government and hospital Average rate 2.13 9.24

Shipping Average rate 5.20 -

Estate Average rate 1.14 -

Apartment Average rate 1.18 4.00