Documente Academic

Documente Profesional

Documente Cultură

In A Spur Gear Drive For A Stone Crusher

Încărcat de

selva_raj215414Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

In A Spur Gear Drive For A Stone Crusher

Încărcat de

selva_raj215414Drepturi de autor:

Formate disponibile

In a spur gear drive for a stone crusher, the gears are made of C40 steel.

The pinion

is transmitting 30kW at 1200 r.p.m. The gear ratio is 3. ear is to !ork " hours per

da#, si$ da#s a !eek and for 3 #ears. %esign the drive.

P = 30 kW, N

1

= 1200 rpm, i = 3

Since the pinion and gear are made of same material, therefore we have to do the design

of pinion alone.

&aterial selection Pinion and gear are made of ! "0 Steel,

#ss$me s$rface hardness % 3&0

'ear life = ( ) &2 ) * ) 3 = +"(( ho$rs

,ife in n$m-ers of c.cles, N = *0 ) +"(( )1200 = &3./ ) 10

+

c.cles

!alc$lation of initial design tor0$e 12

t

3

4esign tor0$e 12

t

3 = 2

t

. 5. 5

d

= 1.3 ) 23(.+3 = 310.3" Nm

Calculation of '

e(

, )*

+

,, )*

c

,-

6

e0

= 2.1& ) 10

&

N7mm

2

n = 2 5

8

= 1.& , N= &3./) 10

+

c.cles9 5

-l

=0.+, 8

$

= *30 N7mm

2

2

1

7 & . **2 120 3& . 0 mm N

u

+

1

" . 1

3 1

nK

K

bl

b

= 111.23 N7mm

2

!:= 2*.& ;:! = && 5

cl

= 0.&(&

[ ] Kcl HRC

R

C

c

= (&2.*" N7mm

2

Center distance #ss$me < =0.3

[ ]

[ ]

3

2

+" . 0

= 1 >

,

_

,

_

+

i

t

M

eq

E

c

i a

= 1&& mm

?

1

= 1+, ?

2

= i.?1 = 3 ) 1+ = &1

2 1

2

z z

a

m

+

= ".&* mm standard m = & mm

.evised Center distance a = 1+0 mm

Calculation of +, d

1

, v and /

p

-

- = <.a = 0.3 ) 1+0 = &1 mm

d

1

= m.?

1

= & ) 1+ = (& mm

Picth line velocit. >v= =

2 1

1 1

z z

N d

+

= &.3" m7s

<

p

= -7d

1

= 0.* 5 =1.03 5

d

= 1." .evised %esign tor(ue )&

t

, 0 344.24 1m

Check for 2ending-

abmy

t

M i

b

3 =1 1 > +

= (*.+( N7mm

2

@ 18

-

3

Check for !ear strength-

ib

i

t

M

eq

E

a

i

c

1

3 1

= 1 >

+" . 0

+ +

= +*&./ N7mm

2

@ 18c3

3 helical gear !ith 30

o

heli$ angle has to transmit 34 kW at 1400 rpm !ith a speed

reduction ratio of 2.4. If the pinion has 24 teeth, %esign the gear for 20

o

full depth

teeth and service is continuous. 3ssume 401i2Cr1&o2" material for +oth pinion

and !heel.

Selection of material properties

8

$

= 1&&0 N7mm

2

S$rface hardness && :! and core hardness%3&0A;N

!alc$lation of design stresses

n = 2.& 5

8

= 1.& N= 10000 ) *0 ) 1&00 =/0 ) 10

+

c.cles9 5

-l

=0.+

1

" . 1

3 1

nK

bl

K

b

= 1+3.1N7mm

2

2

7 & . **2 120 3& . 0

1

mm N

u

+

!:= 2*.& ;:! = && 5

cl

= 0.&(&

[ ]

cl

K HRC

R

C

c

=(&2.*N7mm

2

12

t

3 = 2(/.** N.m 6 = 2.1)10

&

i = 2.& < =0.&

[ ]

[ ]

3

2

+ . 0

= 1 >

,

_

,

_

+

i

t

M E

c

i a

= 112.03 mm

2 1

cos 2

z z

a

n

m

+

= 2."+ mm Standard mod$le = 2.& mm

:evise the !enter distance a = 122.&mm

!alc$late - = < a = *1.2& mm

:evise design tor0$e

5 =1.0* k

d

= 1.2

12t3 = 2(3." Nm

v

y

n

abm

t

M i

b

3 =1 1 > + . 0 +

= (1.(/ N7mm

2

@ 18

-

3

ib

i

t

M E

a

i

c

1

3 1

= 1 >

+ . 0

+ +

= +3+ N7mm

2

@ 18c3

%esign a hardened steel !orm and phosphor +ron5e !orm !heel to transmit 14 kW

from an electric motor running at 1440 rpm to a shaft running at "0 rpm. 3ssuming

the friction coefficient +et!een !orm and !orm !heel as 0.03, calculate the

transmission efficienc# of the !orm drive. 3lso check for heat dissipating capacit#.

Selection of material

Worm B Steel Wheel B Aron?e >Sand !ast=

8

$

@ 3/0 N7mm2 18

-

3 = &0 N7mm2 >:otation in one direction=

!alc$lation of !entre distance

Speed red$ction i = 1(9 No of starts C = 3 ? = i C = &"9 0 = 11

#ss$me 18

c

3 = 1&/ N7mm

2

at Ds = 3 m7s 9 kk

d

= 1

Wheel tor0$e 12t3 = 1+/0."/N.m

[ ]

10

3 1

3 =1 7 >

&"0

1 = 7 >

2

3

t

c

M

q z

q z a

1

]

1

= 2*0.&2 mm

!alc$lation of a)ial mod$le

m

)

= 2a7>0E?= = (.01mm Standard m

)

=10mm

:evise a and o-tain d

1

a = 0.& m

)

>0E?= = 32& mm

Pitch circle diameter of worm = d

1

=0 m

)

= 110 mm

Ds=D17cosF tanF= C70 = % lead angle F = 1&.2&

o

D1 = Pitch line velocit. of the worm

=

,

_

1000 *0

1 1

n d

= (.3 m7s

:evised 18

c

3 = 12+ N7mm

2

%etermination of induced stresses

10

3

1 = 7 >

7

&"0

1

1

]

1

1

1

]

1

t

M

a

q z

q z

c

= 120 N7mm

2

@ 18c3

[ ]

v x

t

b

qzy m

M

3

/ . 1

= 2.33 N7mm

2

@ 18

-

3

= tan>

tan

/& . 0

= 0.("/

6eat .emoval 3nal#sis

>1GH= ) Inp$t Power = 22*0 Nm

%esign a 12 speed gear +o$ for an all geared headstock of a lathe. &a$imum and

minimum speeds are 700 rpm and 24 rpm respectivel#. The drive is from an electric

motor giving 2.24 kW at 1440 rpm.

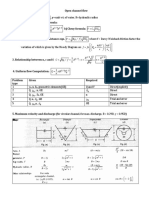

Progression ratio

1

1

min

ma)

,

_

N

n

n

= 1.33& Where N B No of Speeds in gear -o)

Jrom :"0 series Speed >Skip " speeds= B 2&,33.&, "&, *0, (0, 10*, 1"0, 1/0, 2&0, 33&, "&0 and

*00 rpm

Str$ct$ral form$la for 12 speeds

= 3>1= 2>3= 2>*=

3 machine tool gear +o$ po!ered +# 11 kW, 890 rpm motor is to give 14 spindle

speeds ranging from 20 to 400 rpm. %ra! the kinematic arrangement and the speed

chart.

Progression ratio

1

1

min

ma)

,

_

N

n

n

= 1.2&/ Where N B No of Speeds in gear -o)

Jrom :10 series Speed B 20,2&,31.&,"0,&0,*3,(0,100,12&,1*0,200,2&0,31& and "00 rpm

Str$ct$ral form$la for 1( speeds

= 3>1= 3>3= 2>/=

1" Speeds are re0$ired

Str$ct$ral form$la for 1" speeds

= 3>1= 3>3= 2>/G"=

5inematic #rrangement for 1" speed gear -o)

:a. diagram

S-ar putea să vă placă și

- 77-1 Spur GearDocument12 pagini77-1 Spur Gearrip11117675% (4)

- Ugural - Advanced Strength PDFDocument435 paginiUgural - Advanced Strength PDFA Chilik50% (2)

- k111 k311 CVT COROLLADocument151 paginik111 k311 CVT COROLLARoberto Fernandes De Carvalho100% (2)

- Mini Belt Grinder Project ReportDocument20 paginiMini Belt Grinder Project ReportVenky100% (2)

- Report On Helical Gear DesignDocument3 paginiReport On Helical Gear Designdanish100% (1)

- Mechanical Vibrations: Vibration Isolation DesignDocument11 paginiMechanical Vibrations: Vibration Isolation DesignNABIL HUSSAINÎncă nu există evaluări

- Metrology Solved ExamplesDocument17 paginiMetrology Solved Examplesjoin2ravikantÎncă nu există evaluări

- Design and Fabrication of an Oldham Coupling MechanismDocument20 paginiDesign and Fabrication of an Oldham Coupling MechanismSidharth MalohtraÎncă nu există evaluări

- Presentation On CrankshaftDocument20 paginiPresentation On CrankshaftSachin Kumar100% (7)

- ME Plasticity and Metal Forming Test - Stress Strain DiagramsDocument1 paginăME Plasticity and Metal Forming Test - Stress Strain Diagramsselva_raj215414Încă nu există evaluări

- Beam DesignDocument46 paginiBeam DesignAnik Sarker100% (1)

- Steam SilencerDocument3 paginiSteam SilencerAntonio Perez100% (1)

- At Very Low Cutting SpeedsDocument40 paginiAt Very Low Cutting SpeedsThulasi Ram100% (1)

- DTS - Unit - 2 PDFDocument14 paginiDTS - Unit - 2 PDFmani100% (1)

- Designof14speedgearbox 170425062133Document8 paginiDesignof14speedgearbox 170425062133Muket AgmasÎncă nu există evaluări

- Design of 9 Speed Gear BoxDocument23 paginiDesign of 9 Speed Gear BoxDeeraj Varma93% (15)

- Swadesh Singh Production EngineeringDocument4 paginiSwadesh Singh Production EngineeringSandeep Patil100% (1)

- Design Procedure For Spur and Helical Gear PDFDocument15 paginiDesign Procedure For Spur and Helical Gear PDFBinoy K B100% (2)

- Assignment Cum Tutorial Sheet - 7 (With Solution)Document2 paginiAssignment Cum Tutorial Sheet - 7 (With Solution)HARSHVARDHAN SINGH RATHOREÎncă nu există evaluări

- VTU Exam Question Paper With Solution of 18ME62 Design of Machine Elements-II Aug-2022-Manikandan HDocument43 paginiVTU Exam Question Paper With Solution of 18ME62 Design of Machine Elements-II Aug-2022-Manikandan HFusion gaming100% (1)

- 2 Stage GearboxDocument47 pagini2 Stage GearboxSanad Shajahan0% (1)

- Project Report On: "Construction of Road Pavements Using Geotextile Sheet"Document53 paginiProject Report On: "Construction of Road Pavements Using Geotextile Sheet"Sanjay NgarÎncă nu există evaluări

- Car Jack ProjectDocument8 paginiCar Jack ProjectmagnifcoÎncă nu există evaluări

- VTU Exam Question Paper With Solution of 18ME61 Finite Element Methods Aug-2022-Prashant S. HattiDocument53 paginiVTU Exam Question Paper With Solution of 18ME61 Finite Element Methods Aug-2022-Prashant S. HattiFusion gaming100% (1)

- Module 2 STRUCTURE OF CNC MACHINE TOOLDocument22 paginiModule 2 STRUCTURE OF CNC MACHINE TOOLsiddharth100% (2)

- C-Clamp design guide under 40 charactersDocument10 paginiC-Clamp design guide under 40 charactersmadhu100% (1)

- Unit 3 CNC Machine Tools: StructureDocument17 paginiUnit 3 CNC Machine Tools: StructureRohit GhulanavarÎncă nu există evaluări

- Dme - Mod 1Document36 paginiDme - Mod 1Linto Varghese100% (1)

- Determine Material Property (PSG Data Book Page No 1.9 & 1.5)Document28 paginiDetermine Material Property (PSG Data Book Page No 1.9 & 1.5)Sagarias Albus100% (1)

- ME8072 Renewable Sources of EnergyDocument10 paginiME8072 Renewable Sources of EnergyvikirhythmÎncă nu există evaluări

- Design of a 2-Stage Helical-Bevel GearboxDocument33 paginiDesign of a 2-Stage Helical-Bevel GearboxNikhil SatbhaiÎncă nu există evaluări

- Screw Jack Project 1 by EbrahimDocument73 paginiScrew Jack Project 1 by Ebrahimsofiya100% (2)

- Design of The Toggle JackDocument30 paginiDesign of The Toggle Jackkoanakist91% (11)

- Cotter Joint Design GuideDocument15 paginiCotter Joint Design GuidenkchandruÎncă nu există evaluări

- Machine Design-II Question BankDocument9 paginiMachine Design-II Question BankProf. Avinash MahaleÎncă nu există evaluări

- MCF VTU Question BankDocument6 paginiMCF VTU Question BankRAKSHITH MÎncă nu există evaluări

- Manufacturing and Working of Eccentric Gear Driven PressDocument92 paginiManufacturing and Working of Eccentric Gear Driven PressLucky pavanÎncă nu există evaluări

- MEB 532 - Modern Machining Processes GuideDocument2 paginiMEB 532 - Modern Machining Processes GuideHoe Bhaji100% (1)

- Design of Gear BoxDocument19 paginiDesign of Gear BoxSUMIT MALUSARE100% (1)

- PL Ballaney Theory of Machines PDF 121 PDFDocument3 paginiPL Ballaney Theory of Machines PDF 121 PDFLoriÎncă nu există evaluări

- 78 - 5 - Gear BoxDocument9 pagini78 - 5 - Gear Boxrip1111760% (1)

- Workshop Technology by Raghuvanshi Vol 2 PDFDocument4 paginiWorkshop Technology by Raghuvanshi Vol 2 PDFrudrakshengg.67% (3)

- Design and Analysis of Rocker ArmDocument23 paginiDesign and Analysis of Rocker ArmAvt Shubhash25% (4)

- Gear Box DesignDocument74 paginiGear Box DesignRanjib BiswasÎncă nu există evaluări

- CNC Turning Centre GuideDocument10 paginiCNC Turning Centre GuideArun100% (1)

- DOM ProblemsSolvedinClassDocument129 paginiDOM ProblemsSolvedinClassrukmini_ramkiÎncă nu există evaluări

- Dynamics of Machines Study MaterialDocument20 paginiDynamics of Machines Study Materialsara vanaÎncă nu există evaluări

- FABRICATION OF GRASS CUTTING MACHINE Report (C) (20-03-18)Document53 paginiFABRICATION OF GRASS CUTTING MACHINE Report (C) (20-03-18)sabareesh91mechÎncă nu există evaluări

- Machine Design Unit 1 Design PhilosophyDocument12 paginiMachine Design Unit 1 Design PhilosophyAnand Babu100% (3)

- Constructional Details of CNC MachinesDocument10 paginiConstructional Details of CNC Machinessri787750% (2)

- Gate Mechanical SM by NodiaDocument159 paginiGate Mechanical SM by NodiaAndrew Marsh100% (6)

- Interim Project Presentation On Coconut DehuskerDocument17 paginiInterim Project Presentation On Coconut DehuskerMithun Mohan0% (1)

- Question Bank - All UnitsDocument11 paginiQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- Mini Refrigerator ProjectDocument35 paginiMini Refrigerator ProjectRavi PannuÎncă nu există evaluări

- Punching Shear design and reinforcement calculationDocument4 paginiPunching Shear design and reinforcement calculationMohafisto SofistoÎncă nu există evaluări

- Design Calculations for Regulator Bridge Hoist SystemDocument20 paginiDesign Calculations for Regulator Bridge Hoist SystemTarunPatra100% (1)

- 1.0 Objective: A A B BDocument20 pagini1.0 Objective: A A B BMazliah Zainal AbidinÎncă nu există evaluări

- DamBTCT Ban ModifiedDocument22 paginiDamBTCT Ban ModifiedNguyễn Thành TâmÎncă nu există evaluări

- Mathcad - CONICOS - 2Document15 paginiMathcad - CONICOS - 2Entrerriano de CorzonÎncă nu există evaluări

- Vehicle Dynamics Project: University "Transilvania" of BraşovDocument11 paginiVehicle Dynamics Project: University "Transilvania" of BraşovAlexa StrumfÎncă nu există evaluări

- Tugas Elemen Mesin Pemindah DayaDocument28 paginiTugas Elemen Mesin Pemindah DayaYudha RamadhaniÎncă nu există evaluări

- Nine-Speed Gearbox Design for Motor Running at 720 RPMDocument14 paginiNine-Speed Gearbox Design for Motor Running at 720 RPMrip111176100% (2)

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 paginiWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraÎncă nu există evaluări

- Tema Proiect:: Roturn 400Document8 paginiTema Proiect:: Roturn 400Gabriela PetcuÎncă nu există evaluări

- Torsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionDocument26 paginiTorsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionHafiezul HassanÎncă nu există evaluări

- 15CD105Document2 pagini15CD105selva_raj215414Încă nu există evaluări

- 2015 - 15CD 002 - Advanced Mechanics of Materials PIIDocument1 pagină2015 - 15CD 002 - Advanced Mechanics of Materials PIIselva_raj215414Încă nu există evaluări

- Comparison Between Society Bank Vs HDFCbankDocument5 paginiComparison Between Society Bank Vs HDFCbankselva_raj215414Încă nu există evaluări

- Shri Subramania Bharathi .: Welcome The Gathering, I Would Like To Start With Quote ofDocument1 paginăShri Subramania Bharathi .: Welcome The Gathering, I Would Like To Start With Quote ofselva_raj215414Încă nu există evaluări

- BiimpctDocument2 paginiBiimpctselva_raj215414Încă nu există evaluări

- ZR PropertiesDocument2 paginiZR Propertiesselva_raj215414Încă nu există evaluări

- Degree of Crystallinity of Well-Known Polymers (I.e., Nylon 6,6, LDPE, and HDPE) UsingDocument12 paginiDegree of Crystallinity of Well-Known Polymers (I.e., Nylon 6,6, LDPE, and HDPE) Usingselva_raj215414Încă nu există evaluări

- Tensile Test DataDocument2 paginiTensile Test Dataselva_raj215414Încă nu există evaluări

- Coriolis Acceleration 1Document1 paginăCoriolis Acceleration 1selva_raj215414Încă nu există evaluări

- Incremental FormingDocument2 paginiIncremental Formingselva_raj215414Încă nu există evaluări

- Co Po Mapping (Example)Document2 paginiCo Po Mapping (Example)selva_raj215414Încă nu există evaluări

- II/III Sem (2012-2016) Result Analysis Nov/Dec 2013Document1 paginăII/III Sem (2012-2016) Result Analysis Nov/Dec 2013selva_raj215414Încă nu există evaluări

- Vision of DepartmentDocument1 paginăVision of Departmentselva_raj215414Încă nu există evaluări

- Journal of Materials Processing Technology Volume 203, Issues 1-3Document2 paginiJournal of Materials Processing Technology Volume 203, Issues 1-3selva_raj215414Încă nu există evaluări

- Titanium Metals 1Document2 paginiTitanium Metals 1selva_raj215414Încă nu există evaluări

- Chapter 4Document24 paginiChapter 4selva_raj215414Încă nu există evaluări

- Process Planning Guide for ManufacturingDocument12 paginiProcess Planning Guide for Manufacturingselva_raj215414Încă nu există evaluări

- Cad LaboratoryDocument1 paginăCad Laboratoryselva_raj215414Încă nu există evaluări

- Modal Analysis of a Cantilever Beam in ANSYSDocument41 paginiModal Analysis of a Cantilever Beam in ANSYSselva_raj215414Încă nu există evaluări

- Stress Concepts in Biosolid MechanicsDocument16 paginiStress Concepts in Biosolid Mechanicsselva_raj215414Încă nu există evaluări

- Work StudyDocument1 paginăWork Studyselva_raj215414Încă nu există evaluări

- Unit IV Product ArchitectureDocument9 paginiUnit IV Product Architectureselva_raj215414Încă nu există evaluări

- Solid Groung CuringDocument16 paginiSolid Groung Curingselva_raj215414100% (2)

- Five Points Reg Material SelectionDocument2 paginiFive Points Reg Material Selectionselva_raj215414Încă nu există evaluări

- Modeling and Assembly of Leaf Drill JigDocument8 paginiModeling and Assembly of Leaf Drill Jigselva_raj215414Încă nu există evaluări

- 8086 Software and Interrupts GuideDocument3 pagini8086 Software and Interrupts Guideselva_raj215414Încă nu există evaluări

- NCC - Binding The Nation Together - National Integration - NDocument4 paginiNCC - Binding The Nation Together - National Integration - Nselva_raj215414Încă nu există evaluări

- 8085 AND 8086 MICROPROCESSORS AND I/O INTERFACINGDocument7 pagini8085 AND 8086 MICROPROCESSORS AND I/O INTERFACINGjpradeek0% (1)

- Deaign of Vibrating ScreenDocument13 paginiDeaign of Vibrating Screenprashant mishraÎncă nu există evaluări

- Ecg503 Week 4 Lecture Note Chp2Document66 paginiEcg503 Week 4 Lecture Note Chp2Muhammad Zulhusni Che RazaliÎncă nu există evaluări

- Chapter 37Document47 paginiChapter 37NurrahmisrÎncă nu există evaluări

- Civil Engg. With Software LabDocument10 paginiCivil Engg. With Software LabRajkumarJhapteÎncă nu există evaluări

- Basics of Heat PowerDocument82 paginiBasics of Heat Powerharish151984Încă nu există evaluări

- Mechanics of Deformable Bodies ProblemsDocument9 paginiMechanics of Deformable Bodies ProblemsZie Agustin67% (3)

- Lecture 4 - Losses in PSDocument12 paginiLecture 4 - Losses in PSLexi BarcelonÎncă nu există evaluări

- Ansys Aqwa User Manual 2.4.1Document8 paginiAnsys Aqwa User Manual 2.4.1ODG_290473Încă nu există evaluări

- Sound Waves Problems PDFDocument16 paginiSound Waves Problems PDFsoumengoswami10Încă nu există evaluări

- Catálogo Phywe 2017Document246 paginiCatálogo Phywe 2017Antonio Herrera EscuderoÎncă nu există evaluări

- Ganzeboom Transmission Parts & Torque Converters: RWD 4 SpeedDocument2 paginiGanzeboom Transmission Parts & Torque Converters: RWD 4 SpeedMiguel Angel Perez RosasÎncă nu există evaluări

- 5.20 CE Quantum Concentration For Ideal GasDocument10 pagini5.20 CE Quantum Concentration For Ideal GasCindy GaticaÎncă nu există evaluări

- Measurment of ViscosityDocument21 paginiMeasurment of ViscosityGailan GardiÎncă nu există evaluări

- Charged Particle Motion in Time-Varying Electromagnetic FieldsDocument2 paginiCharged Particle Motion in Time-Varying Electromagnetic FieldsMridusmita BoruahÎncă nu există evaluări

- Week 8 ModifiedDocument3 paginiWeek 8 ModifiedNirmal KumarÎncă nu există evaluări

- Molecular Orbital Theory ExplainedDocument80 paginiMolecular Orbital Theory ExplainedMridul Bhaskar0% (1)

- Physical Modelling of The Behaviour of Helical AnchorsDocument19 paginiPhysical Modelling of The Behaviour of Helical AnchorsCristina De Hollanda Cavalcanti TsuhaÎncă nu există evaluări

- Example 2 - Bending TestDocument10 paginiExample 2 - Bending TestMuhd Fauzan IbrahimÎncă nu există evaluări

- Suva 507 Refrigerant: Thermodynamic Properties ofDocument18 paginiSuva 507 Refrigerant: Thermodynamic Properties ofSebastian Andres Catalan BrionesÎncă nu există evaluări

- JEE-MAIN - Part Test - 1 - PaperDocument12 paginiJEE-MAIN - Part Test - 1 - PaperApex Institute100% (1)

- Nimonic 115Document4 paginiNimonic 115sunsirÎncă nu există evaluări

- For Exchanger Tube Rupture PDFDocument3 paginiFor Exchanger Tube Rupture PDFNikhil DivateÎncă nu există evaluări

- SteamWhirl PhenomenaDocument6 paginiSteamWhirl PhenomenaAle MilicÎncă nu există evaluări

- Variation of Which Is Given by The Moody Diagram As:: V RS NDocument3 paginiVariation of Which Is Given by The Moody Diagram As:: V RS NSathyamoorthy VenkateshÎncă nu există evaluări

- Holonomic Implementation of Three Wheels Omnidirectional Mobile Robot Using DC MotorsDocument7 paginiHolonomic Implementation of Three Wheels Omnidirectional Mobile Robot Using DC MotorsVinay PatilÎncă nu există evaluări

- 10c-Electrostatics MC Practice Problems-ANSWERSDocument10 pagini10c-Electrostatics MC Practice Problems-ANSWERSJanel EdwardsÎncă nu există evaluări