Documente Academic

Documente Profesional

Documente Cultură

Gas Lift Valve Domo

Încărcat de

Mikhaelrams RamsDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Gas Lift Valve Domo

Încărcat de

Mikhaelrams RamsDrepturi de autor:

Formate disponibile

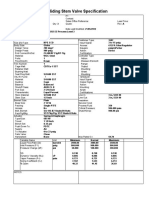

Figure 6

Dome Charge Pressure Corrections

A pressure-operated gas lift valve is charged to its specified dome pressure under controlled surface temperature conditions. Its use in a gas lift installation, however, is based on the charge pressure at its setting depth. The surface pressure therefore has to be corrected for changes in temperature and the gas compressibility factor. Brown (Vol. 2a, 1980), Winkler and Smith (1962), Takcs (2005) and others have published charts that can be used to determine the nitrogen dome charge pressure at a given downhole temperature. Winkler and Eads (1989) present the following formulas, which incorporate the effects of the deviation factor for nitrogen:

For Pd < 1238 psi, where Pd = dome charge pressure at 60 F, psia: Pd = Pd + (-0.00226 + 0.001934 Pd + 3.054 x 10-7 (Pd)2) x (Tvalve - 60) For Pd > 1238 psi: Pd = Pd + (-0.267 + 0.002298 Pd + 1.84 x 10-7 (Pd)2) x (Tvalve - 60)

Example: A gas lift valve has a dome charge pressure of 500 psia at a surface temperature of 60 F. What is this pressure at the valve setting depth of 6000 ft, where the temperature is equal to 144 F? Solution: Pd = 500 psia; Pd < 1238 psi Pd = Pd + (-0.00226 + 0.001934 Pd + 3.054 x 10-7 (Pd)2) x (Tvalve - 60) Pd = 500+ (-0.00226 + 0.001934 (500) + 3.054 x 10-7 (500)2) x (144 - 60) Pd = 587 psi

Gas Lift Valve Selection

The type of gas lift valve used in a given installation will depend on whether the well will be placed on continuous or intermittent lift. Some types of valves are suitable for either continuous or intermittent injection; these may be worth considering if the lift method has not been determined or if well performance is marginal.

CONTINUOUS GAS LIFT

The ideal continuous lift installation would be one in which gas is injected in a steady stream, resulting in more-or-less constant pressures and production rates according to the original design. In reality, production rates and pressures fluctuate from the design parameters, often on a day-to-day basis. The operating valve thus needs to be sensitive to production pressure when it is in the open position. As production pressure decreases, (i.e., tubing pressure for a tubing installation) the valve should begin to throttle closed to decrease gas throughput; as it increases, the valve should open to increase gas throughput. This proportional response maintains the established flowing wellhead pressure and keeps a constant pressure inside the tubing. Therefore, the best type of operating valve to use for continuous gas flow would be a throttling valve or one with identical gas throughput characteristics.

INTERMITTENT GAS LIFT

Operating valves used for intermittent lift must be designed for immediate or snap opening and closing. Immediate opening ensures that the gas is injected as a compressed slug and not as a gradual stream that bubbles up through the liquid, while quick valve closure prevents excess gas from being injected. Because the operating valve must be able to handle a relatively large volume of gas in a short time, it has to be able to open to a large port (normally between 3/8 and 3/4 inch), and remain fully open until closing. At the same time, the valve should have a small enough spread so that the volume of gas injected can be tightly controlled. In a single-point injection system, these requirements can be met by using a pilot valve. In a multipoint system, a number of valves are installed at various depths in the tubing string. At each depth, the valve should allow sufficient gas to enter the tubing so that the fluid slug can be moved upward to the next higher valve. As the fluid slug passes by each valve, the pressure under the slug opens that valve, allowing more gas to be injected and supplementing the gas that has entered through the deeper valves. The valves normally remain open until the slug is produced to the surface.

GAS LIFT VALVE MECHANICS

The opening and closing characteristics of gas lift valves are important considerations in system design and operation. It is important, therefore, to know how and when a valve opens and closes, and to understand the significance of its spread, or difference between opening and closing pressures.

Pressures To Operate a Valve

Consider an unbalanced IPO single-element valve in the closed position, represented schematically in (Figure 1).

S-ar putea să vă placă și

- Plunger Lift SolutionDocument24 paginiPlunger Lift SolutionojrfgmrfÎncă nu există evaluări

- Gas Lift Valve InjDocument3 paginiGas Lift Valve InjMikhaelrams RamsÎncă nu există evaluări

- Gas Lift ValvDocument2 paginiGas Lift ValvMikhaelrams Rams0% (1)

- A - Plunger Lift System - Uagrm PDFDocument38 paginiA - Plunger Lift System - Uagrm PDFBrenda Ortiz SolizÎncă nu există evaluări

- RMS Blancking PlugDocument3 paginiRMS Blancking PlugAzat100% (1)

- Bridge Plug WLTC Retrievable Bridge Plug InfoDocument1 paginăBridge Plug WLTC Retrievable Bridge Plug InfoJohnÎncă nu există evaluări

- 14to38162 Valves PDFDocument4 pagini14to38162 Valves PDFazze bouzÎncă nu există evaluări

- ESP: Electrical Submersible Pump OverviewDocument17 paginiESP: Electrical Submersible Pump OverviewMurad AliyevÎncă nu există evaluări

- Lock Mandrel Types and FeaturesDocument28 paginiLock Mandrel Types and Featuresabbas1368Încă nu există evaluări

- 7 European Electric Submersible Pump Round Table Aberdeen, ScotlandDocument8 pagini7 European Electric Submersible Pump Round Table Aberdeen, Scotlandshy_boyÎncă nu există evaluări

- Gas-Liquid Flow Through Electric Submersible PumpsDocument8 paginiGas-Liquid Flow Through Electric Submersible PumpspicapicÎncă nu există evaluări

- H03280 04 Horizontal Systems PDFDocument20 paginiH03280 04 Horizontal Systems PDFKeshav PujeriÎncă nu există evaluări

- Artificial Lift For Guest LectureDocument117 paginiArtificial Lift For Guest LectureZenga Harsya Prakarsa100% (1)

- ESP SystemsDocument22 paginiESP SystemsNabila GhaisaniÎncă nu există evaluări

- Wireline Completion Tools PDFDocument124 paginiWireline Completion Tools PDFSea CostÎncă nu există evaluări

- Tubing StringDocument32 paginiTubing StringKAORU AmaneÎncă nu există evaluări

- ESP Reliability Theory and Failure AnalysisDocument1 paginăESP Reliability Theory and Failure Analysisazareiforoush100% (1)

- Introductión The Plunger LiftDocument10 paginiIntroductión The Plunger LiftLuis Enrrique ArellanoÎncă nu există evaluări

- KPC BOP Section ChecklistDocument7 paginiKPC BOP Section Checklistislam atifÎncă nu există evaluări

- Gas Well De-Watering Techniques Using ESPsDocument31 paginiGas Well De-Watering Techniques Using ESPsTiffany BarlowÎncă nu există evaluări

- Well Head LayoutDocument18 paginiWell Head LayoutDeepak RanaÎncă nu există evaluări

- Reservoir SimulationDocument3 paginiReservoir SimulationEuler MendozaÎncă nu există evaluări

- Plunger LiftDocument17 paginiPlunger LiftShelo Rosas100% (5)

- Drilling EngineeringDocument77 paginiDrilling EngineeringLok Bahadur RanaÎncă nu există evaluări

- Saltel Expandable Steel Patch PsDocument1 paginăSaltel Expandable Steel Patch PsrezaÎncă nu există evaluări

- Plunger LiftDocument5 paginiPlunger LiftrocacantuÎncă nu există evaluări

- Sec 3 Well ServicingDocument38 paginiSec 3 Well ServicingWilliam EvansÎncă nu există evaluări

- To Uploadc OCW Well ControlDocument59 paginiTo Uploadc OCW Well ControlMuhammad FauzanÎncă nu există evaluări

- Pump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test MeasurementsDocument13 paginiPump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test Measurementsenriqueg_53Încă nu există evaluări

- Electrical Submersible Pumping (ESP) System Fundamentals: Dr. M. GhareebDocument25 paginiElectrical Submersible Pumping (ESP) System Fundamentals: Dr. M. Ghareebramzi aidliÎncă nu există evaluări

- Propellant-Assisted Perforating  - An Alternative ...Document15 paginiPropellant-Assisted Perforating  - An Alternative ...Konul AlizadehÎncă nu există evaluări

- 003 - Presentation From Nabors Drilling PDFDocument16 pagini003 - Presentation From Nabors Drilling PDFVi Et100% (1)

- 26 Mill-EZ Composite Bridge PlugDocument2 pagini26 Mill-EZ Composite Bridge PlugzbhdzpÎncă nu există evaluări

- MEB and Wellbore PerformanceDocument174 paginiMEB and Wellbore PerformanceAjay Suri100% (1)

- SLAP 29 Perforating For ShalesDocument20 paginiSLAP 29 Perforating For ShalesjcÎncă nu există evaluări

- COIL TUBING DEPLOYED ESP INSTALLATION IN MALAYSIAN OFFSHOREDocument6 paginiCOIL TUBING DEPLOYED ESP INSTALLATION IN MALAYSIAN OFFSHOREJhon Doe100% (1)

- Nov Asep Elmar Ict WL Tools Poster v3Document95 paginiNov Asep Elmar Ict WL Tools Poster v3Victor Martinez100% (1)

- Methods To Improve The Efficiency of Rod-Drawn Subsurface PumpsDocument16 paginiMethods To Improve The Efficiency of Rod-Drawn Subsurface PumpsRichard More LeonÎncă nu există evaluări

- Reelwell Drilling Method Pushes Limits for MPD, UBD & ERDDocument8 paginiReelwell Drilling Method Pushes Limits for MPD, UBD & ERDAnonymous H9n5g3aaCEÎncă nu există evaluări

- Effect of Gas Injection Rate On Oil Production Rate: Details of Operating MechanismDocument13 paginiEffect of Gas Injection Rate On Oil Production Rate: Details of Operating MechanismAsekhame Yadua100% (1)

- SCA2016-098 - Paper - D Whitby - NOV - Offshore Wireline Coring PDFDocument6 paginiSCA2016-098 - Paper - D Whitby - NOV - Offshore Wireline Coring PDFdave_whitbyÎncă nu există evaluări

- Mitigation of Production ProblemsDocument16 paginiMitigation of Production ProblemsShubham GuptaÎncă nu există evaluări

- Premier Packer PO 0911Document2 paginiPremier Packer PO 0911parag padoleÎncă nu există evaluări

- Packer HPHT Downhole Completion Equipment Bsee May 2015 Hilts PDFDocument16 paginiPacker HPHT Downhole Completion Equipment Bsee May 2015 Hilts PDFfredyÎncă nu există evaluări

- DRAFT - Requirements For Pressure TestingDocument3 paginiDRAFT - Requirements For Pressure TestingAdhie WaelacxhÎncă nu există evaluări

- Thiago Mikail - Apresentação IDocument50 paginiThiago Mikail - Apresentação IThiago Mikail De OliveiraÎncă nu există evaluări

- Waterflood in Basement Reservoirs - White TigerDocument14 paginiWaterflood in Basement Reservoirs - White TigerIsmail Mohammed100% (1)

- High Pressure PumpsDocument27 paginiHigh Pressure PumpsYuri SandersonÎncă nu există evaluări

- SPE-176195-MS Coiled Tubing Gas Lift Design and Troubleshooting - Case HistoryDocument6 paginiSPE-176195-MS Coiled Tubing Gas Lift Design and Troubleshooting - Case HistoryManuel ChÎncă nu există evaluări

- CT Fatigue ModificDocument24 paginiCT Fatigue Modificfrank vÎncă nu există evaluări

- Cut Pipe Costs with PowerCutterDocument6 paginiCut Pipe Costs with PowerCutterMaJo MoralesÎncă nu există evaluări

- Retrievable Packer Model - PCS-5Document3 paginiRetrievable Packer Model - PCS-5राजकुमार यादवÎncă nu există evaluări

- Drill EssDocument95 paginiDrill EssandrewÎncă nu există evaluări

- Capillary Injection System Restores Production in Offshore Gas WellsDocument6 paginiCapillary Injection System Restores Production in Offshore Gas WellsLuisAlbertoVazquezÎncă nu există evaluări

- The Pressure's On Innovations in Gas Lift, Maharon Bin JadidDocument10 paginiThe Pressure's On Innovations in Gas Lift, Maharon Bin JadidjoreliÎncă nu există evaluări

- Measurement While Drilling: Signal Analysis, Optimization and DesignDe la EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignÎncă nu există evaluări

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsDe la EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsÎncă nu există evaluări

- Gas Lift OperDocument3 paginiGas Lift OperMikhaelrams RamsÎncă nu există evaluări

- Pressure RegulatorDocument4 paginiPressure Regulatordevidutta_pandaÎncă nu există evaluări

- Tank BlankettingDocument6 paginiTank BlankettingBaskar KannaiahÎncă nu există evaluări

- Resin Coated SandDocument1 paginăResin Coated SandMikhaelrams RamsÎncă nu există evaluări

- Water FracDocument1 paginăWater FracMikhaelrams RamsÎncă nu există evaluări

- Proppand ConductivityDocument1 paginăProppand ConductivityMikhaelrams RamsÎncă nu există evaluări

- Gas Lift StarDocument4 paginiGas Lift StarMikhaelrams RamsÎncă nu există evaluări

- What If The Fracs Are NOT Longitudinal?Document1 paginăWhat If The Fracs Are NOT Longitudinal?Mikhaelrams RamsÎncă nu există evaluări

- Gas Lift StarDocument4 paginiGas Lift StarMikhaelrams RamsÎncă nu există evaluări

- Resin Coated SandDocument1 paginăResin Coated SandMikhaelrams RamsÎncă nu există evaluări

- Water FracDocument1 paginăWater FracMikhaelrams RamsÎncă nu există evaluări

- What If The Fracs Are NOT Longitudinal?Document1 paginăWhat If The Fracs Are NOT Longitudinal?Mikhaelrams RamsÎncă nu există evaluări

- Ceramic ProppantsDocument2 paginiCeramic ProppantsMikhaelrams RamsÎncă nu există evaluări

- Mohr Circle ADocument3 paginiMohr Circle AMikhaelrams RamsÎncă nu există evaluări

- Gas Lift PrincDocument2 paginiGas Lift PrincMikhaelrams RamsÎncă nu există evaluări

- Gas Lift Val InjDocument2 paginiGas Lift Val InjMikhaelrams RamsÎncă nu există evaluări

- Gas Lift OperDocument3 paginiGas Lift OperMikhaelrams RamsÎncă nu există evaluări

- Gas Lift SurfaceDocument4 paginiGas Lift SurfaceMikhaelrams RamsÎncă nu există evaluări

- Gas Lift InterDocument7 paginiGas Lift InterMikhaelrams RamsÎncă nu există evaluări

- Gas Lift PrincDocument2 paginiGas Lift PrincMikhaelrams RamsÎncă nu există evaluări

- Gas Lift PrincDocument2 paginiGas Lift PrincMikhaelrams RamsÎncă nu există evaluări

- Gas Lift DesingDocument5 paginiGas Lift DesingMikhaelrams RamsÎncă nu există evaluări

- Annular flow concerns and gas lift valvesDocument7 paginiAnnular flow concerns and gas lift valvesMikhaelrams RamsÎncă nu există evaluări

- Gas Lift DualDocument2 paginiGas Lift DualMikhaelrams RamsÎncă nu există evaluări

- Gas Lift Valve ContDocument5 paginiGas Lift Valve ContMikhaelrams RamsÎncă nu există evaluări

- Annular flow concerns and gas lift valvesDocument7 paginiAnnular flow concerns and gas lift valvesMikhaelrams RamsÎncă nu există evaluări

- Gas Lift DownDocument6 paginiGas Lift DownMikhaelrams RamsÎncă nu există evaluări

- Gas Lift Valve MechDocument4 paginiGas Lift Valve MechMikhaelrams RamsÎncă nu există evaluări

- Gas Lift ChamberDocument3 paginiGas Lift ChamberMikhaelrams Rams100% (1)

- Gas Lift DownDocument6 paginiGas Lift DownMikhaelrams RamsÎncă nu există evaluări

- Lecture 1 Gas Dynamics PDFDocument16 paginiLecture 1 Gas Dynamics PDFKarim MagdyÎncă nu există evaluări

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A PumpDocument11 paginiCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pumpthanh_79Încă nu există evaluări

- Steam Distillation ExplainedDocument2 paginiSteam Distillation ExplainedLouie Shaolin LungaoÎncă nu există evaluări

- Section 7Document22 paginiSection 7HAFIZ IMRAN AKHTERÎncă nu există evaluări

- Compressible Flow 12batchDocument74 paginiCompressible Flow 12batchSirajul IslamÎncă nu există evaluări

- Chemistry 6th Edition Mcmurry Test BankDocument46 paginiChemistry 6th Edition Mcmurry Test Bankrubydac7a9h05100% (26)

- States of Matter Final (2023-2025) - FilledDocument51 paginiStates of Matter Final (2023-2025) - Filledthedarkside7867Încă nu există evaluări

- Tutorial 3 (17109)Document21 paginiTutorial 3 (17109)Tan Hong WeiÎncă nu există evaluări

- Gay Lussac PDFDocument4 paginiGay Lussac PDFDefrianto PratamaÎncă nu există evaluări

- Energy Balance CalculationsDocument43 paginiEnergy Balance CalculationsSasmilah KandsamyÎncă nu există evaluări

- Science 8-Q3 M-EDocument2 paginiScience 8-Q3 M-Enelson dante jr.Încă nu există evaluări

- Vacuum Technology Review of Basic CalculationsDocument19 paginiVacuum Technology Review of Basic CalculationsyoggalamarÎncă nu există evaluări

- Example of BVP ProblemsDocument3 paginiExample of BVP ProblemsAbhishek KumarÎncă nu există evaluări

- Lecture Notes - Gases 2Document7 paginiLecture Notes - Gases 2goksu dundarÎncă nu există evaluări

- Calibration of Flow Meters Lab Report PDFDocument10 paginiCalibration of Flow Meters Lab Report PDFsaasÎncă nu există evaluări

- Process Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsDocument1 paginăProcess Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsamitkrayÎncă nu există evaluări

- Data Sheet Control Valve FisherDocument9 paginiData Sheet Control Valve FisherFIRMANSYAHÎncă nu există evaluări

- Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairDocument22 paginiVapour Absorption Refrigeration Systems Based On Ammonia-Water PairblauwwaterÎncă nu există evaluări

- Speciality Gases Like Nitrogen, Oxygen, Argon & HydrogenDocument15 paginiSpeciality Gases Like Nitrogen, Oxygen, Argon & HydrogenkumarneerajÎncă nu există evaluări

- Isothermal ChangeDocument16 paginiIsothermal ChangeMirahmad FadzlyÎncă nu există evaluări

- Gas Flow Mach Number and Normal Shock PropertiesDocument2 paginiGas Flow Mach Number and Normal Shock PropertiesBalaji HimakarÎncă nu există evaluări

- Boyle's Law: Navigation SearchDocument4 paginiBoyle's Law: Navigation SearchAdhoniyha Prospero Plinius-SuNealÎncă nu există evaluări

- Practice For Midterm 1 For SeparationDocument10 paginiPractice For Midterm 1 For SeparationManu KumarÎncă nu există evaluări

- Solution#2Document5 paginiSolution#2Mohammad W. JeeÎncă nu există evaluări

- Calculate oil and gas reserves using material balance equationsDocument3 paginiCalculate oil and gas reserves using material balance equationsDon Kedondon100% (1)

- DsdsDocument12 paginiDsdsCarlos....Încă nu există evaluări

- HMB From HYSYSDocument9 paginiHMB From HYSYSmuhammad lukmanÎncă nu există evaluări

- ICDA Line 24 Multiphase Flow Modeling Report Draft 1.0Document27 paginiICDA Line 24 Multiphase Flow Modeling Report Draft 1.0Pedro MarquezÎncă nu există evaluări

- Thermodynamics Question and AnswerDocument10 paginiThermodynamics Question and AnswerKumaran PalaniÎncă nu există evaluări

- SCIENCE UNIT TEST 1Document7 paginiSCIENCE UNIT TEST 1Alexius BaghiÎncă nu există evaluări