Documente Academic

Documente Profesional

Documente Cultură

JMPT 2013 Secondary Deformation of Hot Stamping Specimens

Încărcat de

hezihilikDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JMPT 2013 Secondary Deformation of Hot Stamping Specimens

Încărcat de

hezihilikDrepturi de autor:

Formate disponibile

(This is a sample cover image for this issue. The actual cover is not yet available at this time.

This article appeared in a journal published by Elsevier. The attached copy is furnished to the author for internal non-commercial research and education use, including for instruction at the authors institution and sharing with colleagues. Other uses, including reproduction and distribution, or selling or licensing copies, or posting to personal, institutional or third party websites are prohibited. In most cases authors are permitted to post their version of the article (e.g. in Word or Tex form) to their personal website or institutional repository. Authors requiring further information regarding Elseviers archiving and manuscript policies are encouraged to visit: http://www.elsevier.com/copyright

Author's personal copy

Journal of Materials Processing Technology 213 (2013) 818825

Contents lists available at SciVerse ScienceDirect

Journal of Materials Processing Technology

journal homepage: www.elsevier.com/locate/jmatprotec

Effect of thermo-mechanical process on the microstructure and secondary-deformation behavior of 22MnB5 steels

Junying Min a , Jianping Lin a, , Yongan Min b

a b

School of Mechanical Engineering, Tongji University, Shanghai 201804, China School of Material Science and Engineering, Shanghai University, Shanghai 200072, China

a r t i c l e

i n f o

a b s t r a c t

22MnB5 steel specimens were deformed at 923 K and 693 K to three strain levels to study the effect of applied strain level on the microstructure and secondary-deformation behavior. As the steel was deformed at 923 K, deformation induced ferrite transformation (DIFT) occurred even when a small strain of 0.044 was applied, and the volume fraction of deformation induced ferrite (DIF) increases with increasing applied strain level. When deformed at 693 K, deformation induced bainite transformation (DIBT) was observed when the applied strain was larger than 0.109. The incubation period for DIFT is shorter than that for DIBT, but the DIBT proceeds much faster than DIFT. Sub-size tensile specimens were cut from the hot deformed 22MnB5 steel specimens, and digital image correlation technique was employed to investigate the secondary-deformation behavior of the sub-size tensile specimens at room temperature. It is found that the appearance of DIF or DIB (deformation induced bainite) decreases the yield strength and ultimate tensile strength (UTS) but increases the elongation and strengthductility product of the hot deformed 22MnB5 steel specimens compared with the as-quenched 22MnB5 steel specimen with full martensite. 2013 Elsevier B.V. All rights reserved.

Article history: Received 30 July 2012 Received in revised form 26 November 2012 Accepted 29 December 2012 Available online xxx Keywords: Secondary-deformation 22MnB5 Digital image correlation (DIC) Ferrite transformation Bainite transformation

1. Introduction The requirements on automotive light-weighting and increasing crashworthiness stimulate the application of hot stamping technology of 22MnB5 steel. According to Hein and Wilsius (2008), hot stamping technology has been developed to partial hot stamping, hot stamping of tailor-rolled blank, etc. to obtain hot stamped components with tailored mechanical properties, while the conventional hot stamping process is aimed to manufacture full-martensite components with ultimate tensile strength (UTS) as high as 1500 MPa as introduced by Karbasian and Tekkaya (2010). For a B-pillar, the design of tailored microstructure with gradient mechanical properties, namely, a tailored structure of harder upper B-pillar and softer lower B-pillar with larger elongation, is benecial to increase both the resistance of deformation invasion and energy absorption during side crash. The microstructure of hot stamped components is closely related to the thermo-mechanical process of the 22MnB5 steel. As stated by Bardelcik et al. (2010), a cooling rate of 25 K/s leads to a constituent of 95% martensite and 5% bainite in the 22MnB5 steel without hot deformation. At room temperature, the UTS of

Corresponding author. Tel.: +86 13901719457. E-mail address: jplin58@tongji.edu.cn (J. Lin). 0924-0136/$ see front matter 2013 Elsevier B.V. All rights reserved. http://dx.doi.org/10.1016/j.jmatprotec.2012.12.012

quenched 22MnB5 steel with full martensite shows little strain rate sensitivity when the strain rate increases from quasi-static state (0.003/s) to the high strain rate state (960/s). Nikravesh et al. (2012) investigated the effect of hot deformation on the martensite and bainite start temperature (Ms and Bs ), and it was concluded that the hot deformation decreases the Ms but increases the Bs from 853 K to 873 K. Abbasi et al. (2012) reported isothermal deformation lowered the Ms and Mf . Eman et al. (2009) described the necking process of press hardened boron steel by employing digital speckled correlation method. Recently, Shi et al. (2012) reported the phase transformation in non-isothermally deformed boron steel, and it is concluded that the non-isothermal deformation promotes the diffusional transformation, such as ferrite and bainite, and lowers the Ms . The microstructure of the hot formed boron steel determines its mechanical properties which is important to the crash performance of hot stamped components. Especially, components with a mixture of ferrite and martensite or bainite and martensite have been manufactured due to excellent combined performances of high strength and elongation. Therefore, it is of signicance to understand the secondary-deformation behavior of boron steel after hot deformation, so as to determine the appropriate hot stamping process to manufacture hot stamped components with better mechanical performances. In this paper, 22MnB5 steel specimens were austenized at 1173 K and pulled at 923 K or 693 K to three strain levels and then

Author's personal copy

J. Min et al. / Journal of Materials Processing Technology 213 (2013) 818825 Table 1 Chemical composition of 22MnB5 steel. Alloy elements Content (wt./%) C 0.221 Mn 1.211 P 0.019 S 0.003 Si 0.258 Al 0.036 Ti 0.039 B 0.0037 Cr 0.190 819

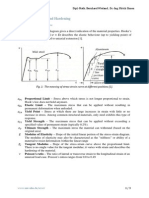

quenched to room temperature with a cooling rate of 30 K/s, and the microstructures of the specimens were examined. Sub-size tensile specimens were cut from the hot deformed specimens and pulled at room temperature with the aid of DIC technique to investigate the secondary-deformation behavior of 22MnB5 steels. 2. Experiments The experiments in this paper include uniaxial tensile tests of 22MnB5 steel specimens at elevated temperatures, metallographic observations and uniaxial tensile tests of hot deformed 22MnB5 steel specimens at room temperature with the aid of DIC technique. 2.1. Uniaxial tensile tests at elevated temperatures The chemical composition of the 22MnB5 steel is listed in Table 1. The dimensions of 22MnB5 steel specimens shown in Fig. 1 follow the standard GB/T 4338-2006, and round grids with a diameter of 2.5 mm (d0 ) and a center-to-center distance of 3 mm were laser etched on one surface of the specimens in order to measure the strains after hot deformation. The depth of the grids is 30 m to make sure the grids keep clear after hot deformation and heat treatment. All tensile tests were carried out on a thermo-mechanical simulation system Gleeble 3800. The specimens were heated to 1173 K at a rate of 15 K/s for full austenitization and the soaking time was 5 min. The specimens were quenched to the 923 K or 693 K at a cooling rate of 30 K/s. Then isothermal deformation was performed on the specimens with a crosshead speed of 5 mm/s. The crosshead displacements were set as 2 mm, 4 mm and 10 mm, giving dwelling time of 0.4 s, 0.8 s and 2 s at each temperature, respectively. Three specimens were repeated for each experimental condition, where one specimen was for metallographic microstructure observation and the other two were for secondary tensile tests at room temperature. Hence, there are 2 3 3 = 18 specimens in total. After deformation, the hot deformed specimens were quenched to room temperature at a cooling rate of 30 K/s immediately, and the round grids on the specimens become ellipses with a length of d1 in the major axis, namely, in the tensile direction. Then the major strain (1 ) can be calculated as ln(d1 /d0 ). Since this work focuses on the effect of hot deformation on the microstructure and secondary deformation behavior of 22MnB5 steels, it is worth to mention here whether ferrite or bainite transformation in 22MnB5 steel specimens with no hot deformation when the specimens statically dwell at 923 K or 693 K and the other heat treatment conditions are the same as those for hot deformed specimens. Fig. 2 shows the dilatations of three 22MnB5 steel specimens (10 mm 10 mm) with no hot deformation

during cooling, where the heating rate, soaking time and cooling rate are the same as described above. One specimen has no dwelling period at elevated temperature, namely, it was directly quenched to room temperature after soaking. The other two specimens statically dwelled at 923 K and 693 K for 2 s, respectively. The arrows in Fig. 2 indicate the Ms (669 K) in the three non-deformed specimens. The static dwelling at 923 K or 693 K for 2 s has little effect on the dilatation vs. temperature curve and the Ms , and obvious evidence indicating there is ferrite transformation or bainite transformation is not observed in Fig. 2. Fig. 3 shows the metallographic microstructures of the three non-deformed specimens. For the specimens with direct quenching and static dwelling at 693 K for 2 s, the microstructures (Fig. 3(a) and (c), respectively) are full martensite. Therefore, the incubation period for isothermal bainite transformation at 693 K is larger than 2 s, and consequently, the microstructure will be full martensite for the 22MnB5 steel specimens with static dwelling at 693 K for even shorter period (e.g. 0.4 s and 0.8 s). As regard to the specimen with static dwelling at 923 K for 2 s, the microstructure is composed of a very limited amount of ferrite (1% in volume fraction) and 99% (in volume fraction) martensite. Hence, the isothermal ferrite transformation needs an incubation period 2 s at 923 K, and the volume fraction of ferrite is much less than 1% in the 22MnB5 steel specimens with static dwelling at 923 K for a shorter period (e.g. 0.4 s and 0.8 s). The above results will be referred in Section 3 to clarify the effect of static dwelling time at 923 K or 493 K on the ferrite transformation or bainite transformation. 2.2. Metallographic experiments Metallography specimens with dimensions of 4 mm 5 mm were cut from the middle of the specimens by wire-electrode cutting and mounted. The 4 mm direction is the major strain direction. The mounted specimens were ground by abrasive paper and polished by woolen cloth with diamond paste. Then the Vickers hardness of each specimen was measured on a hardness tester HXD-1000TC. Each specimen was tested three times and the mean value was calculated. The metallographic microstructure observations of all specimens, which were chemically etched by 4% nitric acid, were performed on a scanning electron microscope.

Fig. 1. Illustration for the dimensions of specimens for hot tensile tests (unit in mm). The diameter and the center-to-center distance of the round grids laser etched on the specimens are 2.5 mm and 3 mm, respectively.

Fig. 2. Dilatation vs. temperature during cooling of three non-deformed 22MnB5 steel specimens. The arrows indicate the Ms of the three specimens.

Author's personal copy

820 J. Min et al. / Journal of Materials Processing Technology 213 (2013) 818825

Fig. 4. (a) Illustration for dimensions of sub-size tensile specimen (solid line, unit in mm) and (b) an image for a hot deformed specimen (upper) and a ground sub-size tensile specimen (lower).

Fig. 3. Metallographic microstructures of non-deformed 22MnB5 steel specimens with (a) direct quenching, (b) static dwelling at 923 K for 2 s and (c) static dwelling at 693 K for 2 s.

2.3. Secondary-tensile tests at room temperature with the aid of DIC technique Since there was a uniform temperature zone, which is consequently a uniform deformation zone, with a length of about 30 mm positioned on the middle of each hot deformed specimen, a sub-size tensile specimen was wire-electrode cut from each hot deformed specimen for secondary-tensile test at room temperature as illustrated in Fig. 4(a). For comparison, two sub-size tensile specimens were also cut from the as-quenched 22MnB5 steel sheet. The cooling rate of the as-quenched 22MnB5 steel sheet is 30 K/s to obtain full martensite microstructure. The length of parallel section on the sub-size tensile specimen is 18 mm to ensure the material between two shoulders are homogeneous and to

avoid heterogeneity in microstructure resulted from non-uniform thermo-mechanical process. Due to slight oxidization on surfaces of specimens during hot tensile tests, the sub-size tensile specimens were ground with 150# and 240# sand paper successively to remove the thin oxidized layers on two surfaces and two sides, as shown in Fig. 4(b). Care was taken during grinding to ensure the deviation in thickness is less than 0.5%. Then the thickness and width of the ground sub-size tensile specimens were measured for stress calculation. Prior to secondary-tensile testing, the surfaces of sub-size tensile specimens were cleaned with chloroform. One surface of each specimen (including two shoulder areas) was decorated with a thin layer of white spray paint. Black spray paint droplets were then applied but care was taken to ensure no single droplet exceeded the size of the chosen square pixel subset region during the DIC post-processing. The tensile tests were conducted on a ZWICK/ROELL Z050 universal testing machine with a crosshead speed of 1.08 mm/min giving a nominal strain rate of 103 /s. All sub-size specimens were pulled till fracture. Stereo digital image correlation detailed by Sutton et al. (2009) was employed to measure full-eld strains during tensile test of each sub-size tensile specimen. Digital images were recorded by two 5-mega-pixel cameras. The time step was set as 0.3 s corresponding to a frame rate of 3.33 frame/s. Each image was tagged with a load and crosshead displacement from the analog output of the ZWICK/ROELL machine. The strain elds are computed from digital grids superimposed on each image during post-processing of the images. The strain eld data should be converted to a uniaxial eld to compute true stress. In the present study, the uniaxial strain measurement was accomplished with two methods, which have been successfully applied in previous studies of metal deformation by Tong et al. (2005) and Zavattieri et al. (2009). The rst corresponds to the conventional method by use of an extensometer in tensile testing.

N M

1 =

1 MN

1 (i, j)

j=1 i=1

(1)

Here, M is grid point number along the tensile axis with a gauge length (to be determined in a following section) positioned above tensile specimen, and N is the grid point number transverse to the tensile axis. Therefore, Eq. (1) calculates the axial strain

Author's personal copy

J. Min et al. / Journal of Materials Processing Technology 213 (2013) 818825 Table 2 The major strains (1 ) measured on hot deformed 22MnB5 steel specimens. Deformation amount 923 K 693 K 2 mm 0.044 0.041 4 mm 0.081 0.109 10 mm 0.200 0.206 821

integrated along both the length and the width of the specimen. The 2nd method corresponds to a localized strain measurement: 1 =

3

1 N

1 (M, j)

j=1

(2)

Eq. (2) is the axial strain integrated across a line running across the width of the specimen at any location along the specimen length. From volume constancy of plastic deformation and force equilibrium along the tensile direction, the true stress can be computed by Eq. (3).

1

F exp 1 w0 t0

(3)

where F is the crosshead load, w0 and t0 are the initial width and thickness of the parallel section on the sub-size specimens. 3. Metallographic results As reported in the authors previous study (Min et al., 2012), a cooling rate of 30 K/s after full austenitization can inhibit ferrite and bainite transformations during cooling to room temperature, and full martensite (Fig. 3(a)) can be obtained in the 22MnB5 steel specimen. In addition, according to Barcellona and Palmeri (2009), stored energy will be introduced in the austenite due to hot deformation, which shortens the incubation period and promotes the nucleation in ferrite transformation and bainite transformation. Therefore, the austenite deformation at elevated temperature will induce ferrite transformation and bainite transformation and even promote these transformations during following cooling after deformation. The strain levels of hot deformed 22MnB5 specimens are shown in Table 2. The metallographic microstructures of the specimens deformed at 923 K and 693 K are shown in Figs. 5 and 6, respectively, and the corresponding Vickers hardness of the specimens is shown in Fig. 7. As detailed by Min et al. (2012) (923) K is higher than the bainite transformation start temperature (Bs ). It can be seen in Fig. 5 that ferrite transformation is induced by hot deformation even when a small strain of 0.044 is applied. Hence, the incubation period for deformation induced ferrite transformation (DIFT), which should be less than 0.4 s (calculated from the deformation level and crosshead speed), is much shorter compared with conventional isothermal ferrite transformation (2 s). Furthermore, the volume fraction of deformation induced ferrite (DIF), which includes the ferrite transformed during deformation and following cooling phase, increases with increasing the applied strain level. Consequently, the Vickers hardness decreases from 395HV5 to 302HV5 as shown in Fig. 7. Qi et al. (2005) has demonstrated that the DIF prefers to nucleate on the grain boundaries since there is always higher distortion energy at these locations. Therefore, the ne ferrite distributes by a network in the case of a small strain (0.044) applied at 923 K, which can be seen in Fig. 5(a) and the martensite still dominates the microstructure, and the volume fraction of DIF is 7.3%. As increasing deformation level at 923 K, the stored energy in austenite grains increases, and the effect of deformation inducing ferrite transformation is enhanced. When the ferrite nucleation sites on the grain boundaries of the deformed austenite are exhausted, large amount of deformation bands in original austenite grains and the fresh ferrite front can provide plenty of nucleation sites as stated by Qi et al. (2005). Hence, the nucleation

Fig. 5. Metallographic (SEM) images of the 22MnB5 steel specimens deformed at 923 K with strain levels of (a) 0.044, (b) 0.081 and (c) 0.200. F indicates deformation induced ferrite, and M indicates martensite.

sites of ferrite turn into austenite grain inside from grain boundaries of deformed austenite as the deformation level increases, which can be seen in Fig. 5(b) and (c). As a result, the volume fraction of DIF increases to 58% and the martensite becomes a minor phase when the applied strain level increases to 0.2. Here it is worth to clarify that the effect of dwelling time (2 s) at 923 K on the ferrite transformation of 22MnB5 steel specimens can be negligible, since the volume fraction of ferrite in the non-deformed specimen with static dwelling at 923 K is 1% as stated in the Section 2.1, which is a very small proportion compared with the ferrite amount in the 22MnB5 steel specimens deformed at 923 K. When the 22MnB5 steel was deformed at 693 K that is 24 K higher than the Ms , almost full martensite is observed in the specimen with an applied strain level of 0.041. Nevertheless, deformation induced bainite transformation (DIBT) can be found (8.7% in volume fraction) from the metallographic microstructures when the applied strain is 0.109. The deformation induced bainite (DIB) is acicular ferrite (AF) according to Zhang and Boyd (2010), which

Author's personal copy

822 J. Min et al. / Journal of Materials Processing Technology 213 (2013) 818825

Fig. 7. Vickers hardness of the hot deformed 22MnB5 steel specimens. The dashed line indicates the hardness of the as-quenched 22MnB5 steel.

barriers for the growth of martensite, the size of martensite lath is reduced and the lath renement is enhanced by increasing the stress in austenite. Therefore, the martensite lath in the specimens deformed at 693 K is much ner than that deformed at 923 K due to higher ow stress at a lower temperature. Certainly, the formation of ferrite or bainite in austenite grains and the recrystallization of austenite grains during deformation will also decrease the size of martensite lath. 4. Secondary-deformation behavior of hot deformed 22MnB5 steels 4.1. Flow curves The evolution of true strain eld on the as-quenched 22MnB5 steel specimen is shown in Fig. 8(a). Each panel in Fig. 8(a) indicates the strain eld at the instant shown below and it covers the parallel section of 18 mm on the sub-size tensile specimen as shown in Fig. 4(a). For comparison, each panel was set to be the same size to eliminate the elongation effect after deformation. Figs. 8(b), 9(a) and (b) show the strain distribution along the 18 mmsection at different instants of the as-quenched and hot deformed 22MnB5 steel specimens with a deformation level of 10 mm at 923 K and 693 K, respectively. As described above, the microstructures of the specimens corresponding to Figs. 8, 9(a) and (b) are full martensite, 58% ferrite with 42% martensite and 86% bainite with 14% martensite, respectively. As shown in Fig. 8(a), the necking band nucleated at t = 246 s for the as-quenched 22MnB5 specimen. Before t = 246 s, the deformation in the 18 mm-section was nearly uniform, after that, the deformation tended to be localized with a center at x = 7.2 mm. Then the strain at x = 7.2 mm increased faster than any other location until fracture. To obtain elongation of sub-size tensile specimens, the gage length should be determined rstly. Since the dimensions of subsize tensile specimens are non-standard, the length of parallel section is 18 mm, smaller than the gage length (25 mm or 50 mm) of the commonly used extensometers. Hence, the 25 mm- or 50 mmextensometers cannot be employed to measure the elongation of the sub-size tensile specimens in this paper. The necking band width (wnb ) is dened as: beyond the two edges of necking band, the strain at any location does not increase as deformation proceeds, and the distance between two edges is the width of necking band (wnb ), as shown in Fig. 8(b), where the wnb is 8.3 mm. Hence,

Fig. 6. Metallographic (SEM) images of the 22MnB5 steel specimens deformed at 693 K with strain levels of (a) 0.041, (b) 0.109 and (c) 0.206. B indicates deformation induced bainite, and M indicates martensite.

is different from the conventional bainite (CB) generated from continuous cooling transformation or isothermal transformation of non-deformed austenite, and the AF is formed as randomly distributed ferrite laths, which are much ner than the CB and can be seen in Fig. 6(b) and (c). When the applied strain increases to 0.206, the volume fraction of DIB induced by hot deformation increases signicantly to 86% but the hardness decreases to 339HV5. Consequently, after a short incubation period less than 0.8 s (a deformation level of 4 mm), the DIBT process proceeds much fast, and it is even faster than the DIFT process. Here it is also worth to clarify that the effect of dwelling time (2 s) at 693 K on bainite transformation can be ruled out since the incubation period that isothermal bainite transformation at 693 K needs is larger than 2 s as stated in the Section 2.1. Comparing the martensite transformed from non-deformed austenite (Fig. 3(a)) with the martensite in Fig. 5(a) and 6(a), the martensite lath is rened by introducing deformation in austenite. Since the dislocation cells in deformed austenite will act as

Author's personal copy

J. Min et al. / Journal of Materials Processing Technology 213 (2013) 818825 823

Fig. 8. (a) True strain eld evolution and (b) true strain distribution along the 18 mm section of the as-quenched 22MnB5 steel specimen.

the half necking band width (whnb ) is the distance from the center of a necking band to one of its edge. However, when the center of a necking band is close to a gripper end (x = 0 mm or x = 18 mm), one edge of the necking band may locate out of the 18 mm parallel section, namely, the 18 mm-section does not cover the full necking band, which is similar as the case that a specimen fractures outside of an extensometer in a conventional tensile test. Therefore, the gage length cannot be set as 18 mm which covers the whole parallel section. To avoid the situation described above and minimize the ratio of necking band width to the gage length, the gage length is set as 9 mm and one end of the gage section is the center of necking band, and another end locates between the center of necking band and the further gripper end, as illustrated in Figs. 8(b), 9(a) and (b). The ratio of half necking band width (whnb ) to gage length (9 mm) is between 0.45 and 0.5 according to Figs. 8(b), 9(a) and (b). Once the gage length is determined, the average true strain 1 (1 ) based on Eq. (1) can be calculated. Then the corresponding 1 engineering strain (e1 ) and engineering stress (S 1 ) are respectively computed by e1 = exp 1 1 S1 = F w0 t0

1 3 1 1

Fig. 9. True strain distribution along the 18 mm section of hot deformed 22MnB5 specimens with a deformation level of 10 mm at (a) 923 K and (b) 693 K.

on Fig. 10(a). The Ef and b are important indicators to evaluating the capability of energy absorption. The work hardening exponent (n-value) is tted from Fig. 10(b), in the strain range from 0.01 to the maximum strain on each curve. 4.2. Mechanical properties Fig. 11 shows the effect of volume fraction of DIF or DIB on the y and b of the hot deformed 22MnB5 steel specimens, and the dashed lines show the y and b of the as-quenched 22MnB5 steel specimens. It can be seen in Fig. 11 that both the y and b are signicantly dependent on the volume fraction of DIF or DIB. When 22MnB5 steel was deformed at 693 K to a small strain of 0.041, there is no soft phase like bainite transformed from austenite and the microstructure is nearly full martensite. As aforementioned, the introduction of dislocation into austenite due to hot deformation renes the martensite lath. Hence, its hardness and strength are higher than the as-quenched 22MnB5 steel as shown in Figs. 7 and 11. With increasing applied strain level at 693 K or 923 K, the volume fraction of DIB or DIF increases. The appearance of soft phase like DIF or DIB decreases the y and b signicantly. It is worth noting that the specimen composed of 42% martensite and 58% DIF shows comparable b with but signicantly lower y than the one composed of 14% martensite and 86% DIB. The former was deformed at 923 K to a strain of 0.2 and the latter was deformed at 693 K to the same strain level. Therefore, it can be concluded that the DIF in the hot formed 22MnB5 is softer than the DIB. Since the applied strain level shows similar effect on the hardness (H) as that

(4) (5)

The S 1 vs. e1 and 1 vs. 1 curves of hot formed and as quenched 22MnB5 steel specimens are shown in Fig. 10(a) and (b), respectively. Since the ratio of the whnb to the gage length is much higher than the tensile specimens with standard dimensions (Zavattieri et al., 2009), the post necking part (beyond the maximum engi1 1 neering stress) on S 1 vs. e1 curves is more obvious on the S 1 vs. e1 curves. The elongation to failure (Ef ), yield strength ( y ) and ultimate tensile strength ( b ) of the specimens are determined based

Author's personal copy

824 J. Min et al. / Journal of Materials Processing Technology 213 (2013) 818825

Fig. 12. Relationships between hardness (H) and yield strength ( tensile strength ( b ).

y)

and ultimate

Fig. 10. (a) Engineering stress (S 1 ) vs. engineering strain (e1 ) curve and (b) true stress ( 1 ) vs. true strain (1 ) curve of the hot formed and as-quenched 22MnB5 steel specimens.

3

on the y and b , the relationships y H and b H are plotted in Fig. 12, where the lled symbols indicate the y and b of the asquenched 22MnB5 steel specimens. For all hot deformed specimens with different combinations of microstructures, the b shows good linear correlation with the hardness. When the hardness is lower than 400HV5, the linear correlation between y H is not good, since the DIB shows lower hardness but high yield strength. Fig. 13 shows the effect of volume fraction of DIF or DIB on the elongation to failure (Ef ) and the work hardening exponent (n-value) of hot deformed 22MnB5 steel specimens. The dashed lines show the Ef and n-value of the as-quenched 22MnB5 steel specimens. The Ef and n-value of all hot deformed specimens are larger than those of the as-quenched specimens. In addition, the Ef and n-value increase with increasing the volume fraction of DIF or DIB in specimens. For the specimens containing DIF which are deformed at 923 K, they exhibit higher n-value and larger Ef , hence better secondary-formability, than the specimens containing the same amount of DIB which are deformed at 693 K. It is also indicated that the secondary-formability of DIF is better than that of DIB. The strengthductility product () reects the energy absorption directly and it is computed as = b Ef . The dependence of the on the volume fraction of DIF or DIB is shown in Fig. 14. With increasing the volume fraction of DIF, though the b decreases, the

Fig. 11. Effect of volume fraction of DIF or DIB on the yield strength ( y ) and ultimate tensile strength ( b ) of hot deformed 22MnB5 steel. The dashed lines indicate the y and b of as-quenched 22MnB5 steel.

Fig. 13. Effect of applied true strain on the elongation to failure (Ef ) and work hardening exponent (n-value) of hot deformed 22MnB5 steel specimens. The dashed lines indicate the Ef and n-value of the as-quenched 22MnB5 steel specimens.

Author's personal copy

J. Min et al. / Journal of Materials Processing Technology 213 (2013) 818825 825

Fig. 14. Dependent of strengthductility product () of hot deformed 22MnB5 steel specimens on the volume fraction of DIF or DIB. The dashed lines indicate the of the as-quenched 22MnB5 steel specimens.

increases to 15.4 GPa% since the Ef increases signicantly. However, the situation is not the same for specimens composed of DIB and martensite, which were deformed at 693 K. As mentioned before, when the applied true strain is 0.109, 8.7% DIB is generated, which decreases the b but increases the Ef compared with the specimens with full martensite. Consequently, the still increases to 14.9 GPa% from 13.5 GPa%. When the volume fraction of DIB increases to 86%, the increase of Ef cannot compensate the decrease of b , and then the decreases to 13.6 GPa%. To this point, the appearance of DIF decreases the b signicantly, and the b decreases with increasing the volume fraction of DIF, but the Ef and increases, which indicates better secondaryformability and energy absorptive capability. A mixture of 58% DIF and 42% martensite exhibits a b of 1000 MPa class and relative larger elongation and strengthductility product. The DIB in microstructure decreases the b and increases the Ef . The b is larger but the Ef is smaller than the specimens containing the same volume fraction of DIF. Hot deformed 22MnB5 steel specimen with a small volume fraction (8.7%) of DIB shows a b of 1382 MPa and a of 14.9 GPa%, hence, a better combination of b and . 5. Conclusions 22MnB5 steel specimens were deformed at 923 K and 693 K to three strain levels, and microstructures of the specimens were examined. Sub-size tensile specimens were cut from the hot deformed 22MnB5 steel specimens, and their secondarydeformation behaviors were studied by using of DIC technique. Following conclusions are yielded: (1) When the 22MnB5 steel is deformed at 923 K, the incubation period for ferrite transformation is shortened signicantly to less than 0.4 s, and ferrite transformation is induced even when a small strain of 0.044 is applied. The volume fraction of DIF increases with increasing the applied strain level. (2) As deformed at 693 K, DIB is observed when the applied strain level is 0.109 but not in the 22MnB5 steel specimen with a strain of 0.041. Therefore, the incubation period for DIBT is shortened to less than 0.8 s, but it is longer than that of DIFT. With increasing the applied strain to 0.206, the volume fraction of DIB increases to 86%, which is much larger than the volume fraction of DIF when the specimen is deformed at 923 K to the

comparable strain level. Consequently, the DIBT proceeds faster than the DIFT once it starts. (3) The appearance of DIF decreases the b of hot deformed 22MnB5 steel specimens signicantly, and a larger volume fraction of DIF leads to a lower b but larger Ef and . As a result, increasing the volume fraction of DIF indicates a better secondary-formability and energy absorptive capability. From this aspect, the mixture of martensite and DIF is acceptable to the lower B-pillar mentioned in the introduction, e.g. a mixture of 58% DIF and 42% martensite exhibits a b of 1000 MPa, a Ef of 15.5% and a of 15.4 GPa%. (4) For the hot deformed 22MnB5 steel specimens composed of martensite and DIB, the b decrease and Ef increases with increasing the volume fraction of DIB. However, the b is larger and the Ef is smaller than that in the specimens containing the same volume fraction of DIF. A smaller volume fraction of DIB leads to a better combination of b and , e.g. the specimen with 8.7% DIB shows a b of 1382 MPa and a of 14.9 GPa%. Full martensite or a mixture of martensite with a small amount of DIB is appropriate to the upper B-pillar as mentioned in the introduction. (5) The ultimate tensile strength of all hot deformed and asquenched 22MnB5 specimens shows a good linear correlation with the hardness. Due to the DIB exhibiting higher yield strength but low hardness, the yield strength correlates the hardness well only when the hardness is higher than 400HV5. Acknowledgment The authors would like to thank the nancial support from the project under grant no. 51075307 of the National Natural Science Foundation of China. References

Abbasi, M., Saeed-Akbari, A., Naderi, M., 2012. The effect of strain rate and deformation temperature on the characteristics of isothermally hot compressed boron-alloyed steel. Materials Science and Engineering A 538, 356363. Barcellona, A., Palmeri, D., 2009. Effect of plastic hot deformation on the hardness and continuous cooling transformations of 22MnB5 microalloyed boron steel. Metallurgical and Materials Transactions A 40, 11601174. Bardelcik, A., Salisbury, C.P., Winkler, S., Wells, M.A., Worswick, M.J., 2010. Effect of cooling rate on the high strain rate properties of boron steel. International Journal of Impact Engineering 37, 694702. Eman, J., Sundin, K.G., Oldenburg, M., 2009. Spatially resolved observations of strain elds at necking and fracture of anisotropic hardened steel sheet material. International Journal of Solids and Structures 46, 27502756. Hein, P., Wilsius, J., 2008. Status and innovation trends in hot stamping of USIBOR 1500P. Steel Research International 79, 8591. Karbasian, H., Tekkaya, A.E., 2010. A review on hot stamping. Journal of Materials Processing Technology 210, 21032118. Min, J.Y., Lin, J.P., Min, Y.A., Li, F.F., 2012. On the ferrite and bainite transformation in isothermally deformed 22MnB5 steels. Materials Science and Engineering A 550, 375387. Nikravesh, M., Naderi, M., Akbari, G.H., 2012. Inuence of hot plastic deformation and cooling rate on martensite and bainite start temperatures in 22MnB5 steel. Materials Science and Engineering A 540, 2429. Qi, J.J., Yang, W.Y., Sun, Z.Q., Zhang, X.Z., Dong, Z.F., 2005. Acta Metallurgica Sinica 41, 605610. Shi, Z., Liu, K., Wang, M., Shi, J., Dong, H., Pu, J., Chi, B., Zhang, Y., Jian, L., 2012. Effect of non-isothermal deformation of austenite on phase transformation and microstructure of 22SiMn2TiB steel. Materials Science and Engineering A 535, 290296. Sutton, M.A., Orteu, J.J., Schrier, H.W., 2009. Image Correlation for Shape, Motion and Deformation Measurements. Springer, New York, pp. 81117. Tong, W., Tao, H., Jiang, X., Zhang, N., Marya, M., Hector Jr., L.G., Gayden, X.Q., 2005. Deformation and fracture of miniature tensile bars with resistance-spot-weld microstructures. Metallurgical and Materials Transactions A 36, 26512669. Zavattieri, P.D., Savic, V., Hector Jr., L.G., Fekete, J.R., Tong, W., Xuan, Y., 2009. Spatio-temporal characteristics of the Portevin-Le Chtelier effect in austenitic steel with twinning induced plasticity. International Journal of Plasticity 25, 22982330. Zhang, R.Y., Boyd, J.D., 2010. Bainite transformation in deformed austenite. Metallurgical and Materials Transactions A 41, 14481459.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Chap 2Document20 paginiChap 2hezihilik40% (5)

- Renault Nissan AllianceDocument5 paginiRenault Nissan AllianceColin Farley100% (1)

- Aircraft Design Project-1Document50 paginiAircraft Design Project-1Ajith Kumar100% (2)

- False Failure in Flexural Fatigue Tests PDFDocument11 paginiFalse Failure in Flexural Fatigue Tests PDFhezihilikÎncă nu există evaluări

- Ternary PDFDocument10 paginiTernary PDFhezihilikÎncă nu există evaluări

- Mmsm1 Handout PlasticityDocument3 paginiMmsm1 Handout PlasticityKuldeep SinghÎncă nu există evaluări

- Internal Friction of Materials Anton PuskarDocument342 paginiInternal Friction of Materials Anton PuskarhezihilikÎncă nu există evaluări

- 4 Kramer Good Foundry PracticesDocument25 pagini4 Kramer Good Foundry PracticeshezihilikÎncă nu există evaluări

- 4 Kramer Good Foundry PracticesDocument25 pagini4 Kramer Good Foundry PracticeshezihilikÎncă nu există evaluări

- Thermo EquationsDocument3 paginiThermo EquationshezihilikÎncă nu există evaluări

- Tender Indonesia BusinessDocument23 paginiTender Indonesia BusinessSmkmigas PaliÎncă nu există evaluări

- Schneider Electric Energy Efficiency File018501Document12 paginiSchneider Electric Energy Efficiency File018501SargurusivaÎncă nu există evaluări

- TSB XK 2101505Document2 paginiTSB XK 2101505jdroalkvamÎncă nu există evaluări

- What Is PETDocument7 paginiWhat Is PETAza_AzlinAizri_2765Încă nu există evaluări

- Quest SQL Optimizer For Oracle 7.5.3Document47 paginiQuest SQL Optimizer For Oracle 7.5.3awda0Încă nu există evaluări

- SAP Business OneDocument8 paginiSAP Business OneCrave InfotechÎncă nu există evaluări

- 3WT AcbDocument12 pagini3WT AcbMutharasan VishnuÎncă nu există evaluări

- NSC-400-CE-3110-MOS-01-A-Method Statement For 69kV Transmission Line ConstructionDocument28 paginiNSC-400-CE-3110-MOS-01-A-Method Statement For 69kV Transmission Line ConstructionElisco Pher SalmasanÎncă nu există evaluări

- Bs 5950 Part4 1994 Design of Composite SlabsDocument39 paginiBs 5950 Part4 1994 Design of Composite SlabsEng Venance MasanjaÎncă nu există evaluări

- GDST 1241 ManualDocument24 paginiGDST 1241 ManualLida PerezÎncă nu există evaluări

- FORM - HSE - Daily Project HSE ReportDocument44 paginiFORM - HSE - Daily Project HSE ReportWerman SeptianÎncă nu există evaluări

- Challenger Ethical Case StudyDocument7 paginiChallenger Ethical Case StudySam GitongaÎncă nu există evaluări

- Car RentalDocument30 paginiCar RentalKarthik Arumugham100% (5)

- Hands On ExerciseDocument6 paginiHands On ExerciseTakeaslynn Khalia GardnerÎncă nu există evaluări

- Stadium With Tribune 2 EL RatedDocument41 paginiStadium With Tribune 2 EL RatedHailuGelanHubenaÎncă nu există evaluări

- UPU CatalogueStandardsCatalogueOfUpuStandardsEnDocument28 paginiUPU CatalogueStandardsCatalogueOfUpuStandardsEntrujillo66@yahooÎncă nu există evaluări

- P136 - FIME EMV Tool First To Automate Complex Terminal Integration Testing ProcessesDocument3 paginiP136 - FIME EMV Tool First To Automate Complex Terminal Integration Testing ProcessesAnonymous 9bkCCPWÎncă nu există evaluări

- Tecaran ® Abs: General InfoDocument6 paginiTecaran ® Abs: General InfoPaolo VisentinÎncă nu există evaluări

- Aviation InsuranceDocument30 paginiAviation Insurancelaxmi sambreÎncă nu există evaluări

- QMS DeclarationDocument3 paginiQMS DeclarationMuhammad Saqib AsifÎncă nu există evaluări

- 1517618394299Document26 pagini1517618394299Nagaraju Dummu100% (1)

- Material Handling PRD 430Document94 paginiMaterial Handling PRD 430Dr_M_Soliman75% (4)

- PowerCenter Level1 Unit03Document18 paginiPowerCenter Level1 Unit03Christian AcostaÎncă nu există evaluări

- Buddhist Chanting Book in DevanagariDocument31 paginiBuddhist Chanting Book in DevanagariSujanÎncă nu există evaluări

- Piping Engineering CourseDocument2 paginiPiping Engineering CourseprasannaÎncă nu există evaluări

- Digital India1Document19 paginiDigital India1RamanÎncă nu există evaluări

- Ssrs BookDocument117 paginiSsrs BookMajnu KhanÎncă nu există evaluări

- Insulation Resistance NotesDocument27 paginiInsulation Resistance NotessdvijayÎncă nu există evaluări