Documente Academic

Documente Profesional

Documente Cultură

Duratile Roofing System Installation Guide

Încărcat de

jrsiaseDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Duratile Roofing System Installation Guide

Încărcat de

jrsiaseDrepturi de autor:

Formate disponibile

INSTALLATION

GUIDE

DURATILE ROOFING SYSTEM

2

The Duratile Roofing System

Duratile Incorporated is pleased to introduce an innovative roofing system which is

wholly owned and manufactured on our beautiful island of Barbados. Our new facility in

Lears Quarry, Lears, St. Michael features state-of-the-art equipment and processing

technologies to provide you with the highest quality product.

Duratile Slate Roofing replicates the classic look of natural slate and adds prestige

and character to any architectural style of building. The low gloss variegated color and

natural slate colors enhance the design of your home. The unique hinged ridge cap

system allows the flexibility to accommodate roof angles from 5 - 90. This range of

movement allows a single component to adapt to a variety of roof pitches. With the

Duratile Roofing System, you will get the beauty you want plus the performance you

demand.

Duratile Slate Roofing is manufactured from a durable plastic composite material

extending your roofs life cycle substantially. Thanks to our extensive Research and

Development efforts, which have resulted in a proprietary resin compound, the product

exhibits superior structural integrity and impact resistance. The color through process

eliminates the need for painting or protective sealant throughout the life of the product.

Duratile Slate Roofing, while providing the look and texture of slate, is lighter in weight

than traditional slate or clay tile systems and therefore requires no additional structural

reinforcement when replacing conventional roofing nor does it require you to undo any

structural requirements for the new applications.

The Duratile Roofing System provides economical and ecologically sound roofing

solutions for today and the future of our island.

3

TABLE OF CONTENTS

General Construction Guidelines

General Application Details ......................................................................................................... 4

Slopes (Roof Pitch) ........................................................................................................................ 5

Decking........................................................................................................................................... 5

Self Adhering Membrane ............................................................................................................. 5

Underlayment ................................................................................................................................ 6

Torch Down Membrane ............................................................................................................... 6

Sheet Metal Flashing..................................................................................................................... 6

Vent Stacks .................................................................................................................................... 7

Roof Vents...................................................................................................................................... 7

Adhesives & Sealants .................................................................................................................... 7

Fasteners ........................................................................................................................................ 8

Compatibility ................................................................................................................................. 8

The Duratile Roofing System

General Installation Details

Starter Course ............................................................................................................................. 12

Flashing Requirements ............................................................................................................... 14

Valleys .......................................................................................................................................... 14

Hip Details ................................................................................................................................... 15

Ridge Details ................................................................................................................................ 16

Ridge / Hip Intersections ............................................................................................................ 18

Changes In Roof Pitch ................................................................................................................ 19

Projections And Penetrations .................................................................................................... 20

Chimneys ..................................................................................................................................... 21

Dormers ....................................................................................................................................... 22

Skylights ....................................................................................................................................... 24

Roof Vents.................................................................................................................................... 25

Vent Stacks .................................................................................................................................. 25

Continuous Ridge Vents ............................................................................................................. 26

4

GENERAL CONSTRUCTION GUIDELINES

The design of the roof is probably the most important consideration relating to the

performance of any roofing system. Typically, the steeper the roof pitch, the better the

performance of the roof design in adverse conditions. On the island of Barbados this is

extremely important in that we often endure severe storms with high winds and the

associated wind driven rain.

For your house to remain dry and un-damaged during these occasions of adverse

weather, Duratile has designed the slate shingle with weather resistant features such as

drain channels to prevent water migration into your home. To insure that the most

weather tight roof may be installed on your home, Duratile has developed this

installation manual which recommends the most current thinking in weatherproofing

your structure.

While many of the recommendations supplied in this manual are not necessarily

required by code, it is suggested that these recommendations be adhered to provide the

best long term performance for your roof installation.

At minimum, all installers of the Duratile Roofing System shall be fully familiar with and

equipped to install the product in a fully qualified manner and acceptable to the architect

specifying the roofing system and the general contractor responsible for the finished

product.

GENERAL APPLICATION DETAILS

Regardless of the style of roof the Duratile Roofing System is being installed on, the

following basic application details must be observed:

Roofing tiles must be doubled at all eaves.

Butts of the first course of tiles should project 3/4" beyond the fascia at all

rakes and eaves.

Spacing between adjacent roofing tiles should be a minimum of 1/8" and a

maximum of 1/4".

Install a minimum of two (2) fasteners per tile. Use fastener guide openings

wherever possible for the required exposure in the succeeding course.

It is recommended that in situations where a fastener opening is not readily

5

available (such as cut tiles fitting valleys, hips, ridges etc.), a 3/16" diameter hole

be drilled for fastening to minimize stress in the tile and to allow movement

caused by expansion and contraction.

Joints in any one course should be separated 6" from joints in the adjacent

courses.

SLOPES (Roof Pitch)

The Duratile Roofing System may be applied on any roof with a slope of 15 or greater.

The standard roofing tile may also be applied to exterior walls utilizing acceptable

construction practices as outlined in this manual.

DECKING

The Duratile Roofing System should be applied over solid decking 3/4" thick or greater.

Deck sheathing may consist of composite board panels, such as oriented strand board,

plywood or wood planking. In re-roofing applications the existing roof must be

completely removed down to the deck. The deck must be solidly fastened to the

building structure in accordance with applicable building codes and provide a smooth

base for application of the roofing tiles.

SELF ADHERING MEMBRANE

It is recommended, but not required, that a self-adhering waterproofing membrane be

applied at all eaves, hips, ridges and roof projections.

The self-adhering membrane should be comprised of modified asphalt with a consistent

layer of adhesive applied to one side, with a release paper applied to the underside.

The membrane shall be comprised of a substrate material and rubberized asphalt with a

1/4" bead of asphalt running continuously down each side of the roll.

Self-adhering membrane should be applied at the eaves extending 36" up the slope to a

line not less than 12" beyond the face of the exterior wall. The membrane shall overlap

the apron flashing at the eaves to prevent water damage under the flashing.

Self-adhering membrane should be applied at ridges and hips extending a minimum of

18" either side of the centerline of the ridge or hip.

6

Self-adhering membrane should be applied to all roof projections and penetrations in a

manner which will prevent water damage to the roof, for example around dormers,

skylights, vents, chimneys etc...

UNDERLAYMENT

Underlayment is recommended to be 30# plain roofing felt, type II, organic or in

accordance with the local code of jurisdiction and installed to the manufacturers

specification.

Install one ply of underlayment over the entire surface of the roof with the exception of

cut-out areas for vents etc..

Lay underlayment horizontal to the roof slope with a minimum headlap of 2" and a

sidelap of 4" or in compliance with manufacturers specifications. Fasten or staple

underlayment sufficiently to hold in place until roofing tiles are installed.

TORCH DOWN MEMBRANE

The islands reside in a very harsh environment which is hot and subjected to a great

deal of wind driven rain. The recommendation for underlayment contained in this

manual are at best a minimum requirement for the climate.

Duratile Inc. strongly recommends that the homeowner considers applying torch down

membrane over the entire roof prior to installing the roofing shingles.

This approach will provide the most weather tight installation as well as maximize the

functioning life of the roof.

SHEET METAL FLASHING

All sheet metal flashing shall be a minimum of 26 ga stainless steel, 16 oz. copper or

0.032" aluminum.

Install sheet metal flashing along eaves, rake edges, valleys, ridges, hips and all roof

projections and penetrations.

Sheet metal flashing work shall be manufactured in accordance with the best standard

7

practices of the industry; with joints locked, cleated, caulked as required, and exposed

edges hemmed. Allowance shall be made in all work for expansion and contraction

without compromising the waterproofing integrity of the structure.

Mitered corners shall be straight and profiles level as required to suit the specific site

conditions, with flat surfaces free of distortion and face nailing.

All free edges of metal flashing shall be reinforced by a fold of at least " wide, set out

slightly and presenting a straight line and neat finish.

Form flashing in the longest possible lengths to minimize water migration and allow for

appropriate expansion and contraction.

All flashing should be fabricated in a shop where possible, with proper sheet metal

tools. Lock seams should be provided for all corners and intersections where possible.

VENT STACKS

It is recommended that soil vent pipes be installed with a pre-manufactured self-

flashing base and sealed to the vent pipe projection with an elastomeric seal or boot.

All vent flashings shall be installed in accordance with the manufacturers

recommendations.

ROOF VENTS

Roof or ridge vents shall be pre- manufactured from aluminum, galvanized steel, copper

or plastic, sized to comply with the appropriate building code.

Ridge vents shall have waterproof ends, caps and connectors as required to complete

the installation in a manner recommended by the manufacturer.

ADHESIVES & SEALANTS

The contractor should ensure that all construction adhesives and sealants used in the

installation of the roof comply with appropriate codes and are compatible with the

roofing system.

8

A list of approved sealants and adhesives may be obtained from Duratile Inc..

FASTENERS

It is recommended that each Duratile Roofing Tile be attached with two non- corrosive

screws of sufficient length to fully engage the roof substrate. These fasteners may be

applied either manually or with pneumatic nailing equipment.

The recommended length for these screws follows:

3/4" starter course

1" first course

1 1/4" main course

1 3/4" caps and hips

Where fastening may be marginal such as around chimneys, valleys, hips, ridges etc.,

use a recommended construction adhesive in addition to screws to ensure that the tiles

are properly secured to the roof.

Approved fasteners are to be manufactured from electro-galvanized steel, ASTM 641,

Class 1; Type 304 or 316 passivated stainless steel, copper or aluminum.

COMPATIBILITY

The roofing contractor must ensure that all materials used in conjunction with the

installation of the roof are compatible with the Duratile roofing system and each other.

Failure to use compatible materials with a life span equal to the roofing shingles will not

only shorten the life of the roof but may void the warranty offered by Duratile Inc.

All installations must comply with the current Barbados building code and any

appropriate updates to this code.

9

THE DURATILE ROOFING SYSTEM

The Duratile roofing system consists of a standard roofing tile and a unique hinged ridge

cap.

The standard roofing tile has nominal dimensions of 12" X 16". The slate look tile

features a rain gutter on the upper face to minimize water migration under each

succeeding course. Nailing points are through molded for convenience and layout

reference marks are incorporated into the face to assist in installation

(Figure 1).

The rear side of the roofing tile is cored to minimize the weight. Cut locations for both

the starter course and the half shingles are adjacent to molded rib in place structures

(Figure 2).

10

The diagram below (Figure 3) illustrates the typical tile layout required for a weather-

tight roofing installation.

The hinged ridge cap consists of two parts, left and right halves (Figure 4).

As with the standard roofing tile, the ridge cap incorporates rain gutters and through

molded nailing points.

The rear side of the roofing tile is cored to minimize the weight. Reference marks are

molded into the rear surface to assist in cutting major reference angles used in

construction of a building (Figure 2).

11

The tapered hinge pin allows the ridge cap to rotate up to 90 to provide installation

adjustment to fit a variety of roof styles (Figure 5).

The diagram below (Figure 6) illustrates the typical tile layout required for a weather-

tight roofing installation.

GENERAL INSTALLATION DETAILS

For the most attractive visual appearance, the contractor should mix tiles from different

bundles to take advantage of minor variations between batches and ensure random

shading on the finished roof surface.

12

After the roof surface has been prepared inclusive of flashing, self- adhering membrane

and underlayment, the installation of the tiles may begin.

STARTER COURSE

The starter course consists of the upper portion of the tile (see figures 1 & 3). The

contractor should save the lower portions of the tile for use at hips, ridges and valleys.

Install the starter course by cutting one tile in half and then alternating with a full width

tile extending beyond the eaves and rakes by 3/4" ( Figure 7 ). Each starter tile should

be fastened with two (2) 3/4" screws in a parallel line with the eaves.

It is recommended that a 3/16" diameter hole be drilled for each screw to prevent

fastening stress build-up in the tile and to allow for expansion and contraction should

the provided fastening points not be suitable for the particular installation.

It is further recommended that the starter course of tiles be additionally fastened to the

roof with a compatible construction adhesive to ensure weather tightness. With the

starter course installed, the first of tiles may be installed, starting with a full tile,

extending 3/4" beyond the eaves and rakes in the prescribed manner using two (2) 1

screws per tile.

13

It is recommended that a compatible construction adhesive be applied between the

starter course and the first course of tiles to ensure weather tightness.

Install the second course of tiles by cutting a tile in half vertically and install at the

appropriate exposure. Alternate this with a full tile for the succeeding course over the

joints in the underlaying tile. The second and all remaining courses are fastened with

two (2) 1 1/4" screws each." (Figure 8).

Install the roof tiles with 6" of exposure on most roof slopes. An exposure of greater

than 6" but not exceeding 6 " may be used for roofs with a slope greater than 45.

The exposure markings on the tile allow the exposure to be defined by the tile below.

Do not install on roofs with a slope of less than 15 without first consulting with a

qualified engineer.

Provide 1/8" - 1/4" gap between tiles in the same course to compensate for any

movement in the roof surface or expansion of the roofing tiles.

14

FLASHING REQUIREMENTS

Most roof leaks occur where water is channeled off the roof or where the roof abuts a

vertical wall or chimney or where projections such as soil pipes pierce the roof structure.

At these points metal valleys saddle and flashings are used in conjunction with the

roofing tiles to keep the structure dry.

Structural members that protrude through the roof should be flashed at all intersecting

angles to prevent leakage. All base flashing should extend under the roofing tiles and

up vertical surfaces and should be covered by a second layer of flashing (counter

flashing).

Flashings should be stainless steel, copper or aluminum (as defined in the General

Construction Guideline section of this manual). The architect or contractor should

ensure that the selected flashing materials have the same longevity as the roofing tile.

VALLEYS

It is recommended but not required, that one ply of self-adhering membrane be installed

in all valleys. The membrane should be extended 30" up the slope from the centerline

of the valley.

15

Install the sheet metal valley flashing over the self-adhering membrane where applied.

The sheet metal flashing should extend not less than 12" up the slope from the valley

centerline. Cut and fit the tiles to provide a slight taper in the exposure in the exposure

of the flashing toward the head (top) of the valley (Figure 9).

Overlap the sheet metal flashing sections a minimum of 4". All joints should be crimped

or sealed with a compatible construction adhesive to ensure weather tightness.

HIP DETAILS

It is recommended but not required, that one ply of self-adhering membrane be installed

on all hip ridges prior to installing underlayment.

Intersecting roof sections at hips must be capped to ensure a weather tight roof joint.

The Duratile hinged ridge cap is designed to accomplish this task. The 6" exposure

incorporated into this unit matches the recommended roofing tile exposure creating a

visually unified finished roof.

The roof tiles of each course are trimmed to the appropriate angle creating a finished

hip centerline. The tiles creating this intersecting joint should maintain a gap of 1/8"-

1/4" between tiles to compensate for expansion and contraction.

Each course of intersecting tiles should be flashed at the joint to maintain weather

tightness. The flashing should be bedded in a compatible construction adhesive prior to

installing the cap (Figure 10).

16

Installation of the hinged cap will complete the hip construction. The hinge pin on the

right hand cap should have a bead of sealant spread along the centerline prior to

installation.

Spread a bead of construction adhesive the full length of the roof course

(Figure 11), approximately 4" on either side of the hip centerline and screw the hinged

cap on the course with two (2) screws on each side. The screws for the cap installation

must be longer than the screws used on the roof tiles (1 3/4"long).

To complete the hip installation, spread a bead of color matched sealant the entire

length of the hip on the open side of the hinge.

RIDGE DETAILS

It is recommended but not required, that one ply of self-adhering membrane be installed

on all ridges over the underlayment and extending down slope a minimum of 16" prior to

installing the flashing.

Sheet metal flashing should be applied over the ridge prior to installing the ridge cap.

The flashing should be bent to conform to the ridge angle and extend down either side

17

from the centerline a minimum of 3"

It is recommended that a bead of compatible construction adhesive be applied parallel

to the ridge and approximately 2 1/2" either side of the centerline of the ridge. For

maximum weather tightness it is desirable to spread a bead of compatible construction

adhesive under the final course of tiles at the ridge prior to fastening the tile with two (2)

screws.

Installation of the ridge may now be completed by applying the hinged ridge cap.

Beginning at one end of the roof, install the first hinged cap with the tapered tail facing

the far end of the roof. The hinge pin on the right hand cap should have a bead of

sealant spread along the centerline prior to installation.

Spread a bead of construction adhesive the full length of the roof course (Figure 11),

approximately 4" on either side of the hip centerline and fasten the hinged cap on the

course with two (2) screws on each side. The screws for the cap installation must be

longer than the screws used on the roof tiles (1 3/4" long).

Repeat this process for each successive ridge cap until the full ridge is completed. The

final cap should be trimmed to mate with the far roof rake taking care to ensure that only

the slate textured portion of the cap is exposed.

18

To complete the ridge installation, spread a bead of color matched sealant the entire

length of the ridge on the open side of the hinge.

RIDGE / HIP INTERSECTIONS

Roof styles which feature intersections of hips at the ridge of the roof require additional

care to ensure weather tightness. In these instances, the installer should start the ridge

installation at the intersection point rather than at the open end of the ridge.

There are two (2) basic methods of creating a visually attractive and weather tight

juncture (Figure 13).

Both approaches will provide an acceptable closure for the intersection, though, the

Mitred approach requires more care to ensure a weather tight closure.

The lap joint is the easiest to construct and provides the most reliable weather seal.

For either type of intersection, follow the recommended procedures outlined in the hip

and ridge installation sections.

19

CHANGES IN ROOF PITCH

There are many architectural styles which require changes in the roof pitch or require an

intersection with a side wall. Each of these conditions poses a unique set of

requirements to ensure weather tightness of the structure.

(Figures 14 - 17) illustrate recommended approaches to addressing these requirements.

All these conditions require proper flashing and appropriate underlayment to circumvent

water migration.

Whether these recommendations are followed is optional on part of the contractor.

However, the contractor must follow accepted industry practices and ensure the building

remains structurally sound and weather tight.

20

PROJECTIONS AND PENETRATIONS

Many architectural styles incorporate projections from the roof line such as dormers,

and almost all roof lines incorporate some form of penetration through the roof surface.

It is recommended but not required, that one ply of self-adhering membrane be installed

in conjunction with the required flashing for these applications. In projections such as

chimneys and dormers, it is recommended that the membrane should be extended 4"-6"

up any vertical wall.

21

It is advisable to utilize a compatible construction adhesive as well as mechanical

fastening when installing the required flashing for these applications.

CHIMNEYS

Chimneys are constructed in different forms and locations depending on the

architectural style of the building and local building practices.

(Figures 18-20), illustrate the most common styles and placement of the roof. Each

type exhibits its own unique flashing requirements to ensure weather tightness.

All chimneys should be flashed on all four sides with the flashing extending up the

vertical face of the chimney 6" and out onto the roof a minimum of 4". All base flashing

should have a headlap of 4" minimum and it is recommended that a construction

adhesive be used at all lap joints to minimize water penetration.

Counter flashing should be installed over the base flashing and the roofing tiles on the

down slope side of the chimney.

It is recommended that chimney saddles (Figure 20) be installed on chimneys where the

upper side of the roof slope exceeds 30"

A minimum space 1/4" must be allowed between the vertical flashing face and the

roofing tile courses to allow for expansion and contraction.

It is recommended that a compatible construction adhesive be used in conjunction with

nails on each tile immediately abutting the chimney.

Chimneys also tend to leak internally. It is the responsibility of the contractor to ensure

that the internal structure and flashings of the chimney weather tight and in good repair.

22

DORMERS

Many architectural styles utilize dormers to add interior space and to provide visual

interest to the roof line.

It is recommended but not required, that one ply of self-adhering membrane be installed

in conjunction with the required flashing for these applications. In projections which

include vertical walls, it is recommended that the membrane should be extended 4"-6"

up any vertical wall.

23

Standard dormers (Figure 21) require flashing techniques common to both valleys and

wall intersections. Refer to these sections for approved construction details. The only

unique flashing element is the counter flashing required on the downslope side of the

dormer.

Recessed dormers (Figure 22) provide a more challenging set of flashing requirements.

In addition to the valley and sidewall intersections, the contractor must provide a

weather tight floor and sidewalls for the recessed area of the dormer.

Typically the floors are formed from galvanized sheet steel, copper or aluminum. The

side walls must extend up the building structure a minimum of 6". All corners must be

welded, soldered or crimped and caulked in accordance with appropriate building

codes. The floor surface should have a downward slope of 1" per 12" of run.

24

The bottom edge of the floor pan should extend downslope a minimum of 4" with the

lower edge hemmed "

Additional counter flashing should extend out on the extended roof surface a minimum

of 6" and downward to cover the vertical wall of the floor pan by 4".

NOTE: Current techniques utilizing rubberized continuous membranes may be used in

place of a sheet metal floor when locally available and comply with appropriate building

codes.

SKYLIGHTS

Skylights (Figure 23) are utilized in many buildings to bring additional natural light into

the interior of the building. Opening models also offer the additional benefit of providing

ventilation.

When installing skylights, the builder or contractor should select a pre- manufactured

unit of reputable quality and ensure that the unit is installed to the manufacturers

specifications.

Trim roof tiles neatly around the base of the flange allowing a minimum of 1/4"

clearance for movement and secure to the roof with two (2) screws per tile.

It is recommended that a compatible construction adhesive be used in conjunction with

the screws to ensure weather tightness.

25

ROOF VENTS

Very often roof vents (Figure 24), are required to improve air flow throughout the

building. A major function of roof vents is to remove heat build up in the roof peak and

to remove condensation build-up in the upper portions of the building.

There are many styles of metal and plastic pre-manufactured roof vents available.

When installing roof vents, the builder or contractor should select a pre- manufactured

unit of reputable quality and ensure that the unit is installed to the manufacturers

specifications.

Trim roof tiles neatly around the base of the flange allowing a minimum of 1/4"

clearance for movement and secure to the roof with two (2) screws per tile.

It is recommended that a compatible construction adhesive be used in conjunction with

the nails to ensure weather tightness.

VENT STACKS

Vent stack and pipe flashings should consist of a self-flashing base with a friction fit

elastomeric boot which seals the pipe and locks securely on the flange. When installing

the flange, the contractor should ensure that the flange extends 6" onto the roof surface

26

and is secured in accordance with appropriate building codes.

Trim roof tiles neatly around the base of the flange allowing a minimum of 1/4"

clearance for movement and secure to the roof with two (2) screws per tile.

It is recommended that a compatible construction adhesive be used in conjunction with

the nails to ensure weather tightness.

CONTINUOUS RIDGE VENTS

Many buildings are constructed with pre-manufactured continuous ridge venting for

improved air flow in the structure.

There are basically two (2) styles of vents commonly in use today. The shingle over

style (Figure 26), allows the hinged ridge cap to be installed directly over the venting

system. This type of vent minimizes the visual presence of the venting system as the

roof appears to be of one material.

The second style of continuous vent is the filter vent type. This vent system is usually

manufactured from either metal or rigid plastic and is constructed with its own flashing

as part of the vent system. The unit attaches directly over the roof ridge and takes the

place of the conventional ridge cap.

27

28

Either type of venting system may be selected. The contractor should be familiar with

the selected venting system and ensure that the installation is carried out in accordance

with the manufacturers specifications and in compliance with the appropriate building

codes.

Duratile Inc. is confident that if the guidelines contained in this manual are followed,

and that the installation is performed in a professional manner, your new Duratile

Roofing System will provide many years of trouble free use.

Not only will your roof be trouble free; the appearance of natural slate will increase the

curbside appearance of your home and improve its value in the ensuing years.

You are not only purchasing a high quality roof for your home, but investing in the future

well-being of your island.

S-ar putea să vă placă și

- Structural Specification and ComputationsDocument4 paginiStructural Specification and ComputationsJazneil BelloÎncă nu există evaluări

- Revised IRR To National Building Code InjunctionDocument70 paginiRevised IRR To National Building Code InjunctionLloyd R. Ponce100% (1)

- Sample Slab Design DetailsDocument1 paginăSample Slab Design DetailsJoseph Cloyd LamberteÎncă nu există evaluări

- Brochure Architectural Collection A e Series Window Door 9064702Document68 paginiBrochure Architectural Collection A e Series Window Door 9064702Alejandra100% (1)

- Fire Code of The Philippines 2008Document475 paginiFire Code of The Philippines 2008RISERPHIL89% (28)

- Soil and Waste PipeDocument28 paginiSoil and Waste PipeRegine Kaye TagurdaÎncă nu există evaluări

- Engineering Design Manual 1Document70 paginiEngineering Design Manual 1Muh. Yousuf KhanÎncă nu există evaluări

- Rule 20 NBCPDocument20 paginiRule 20 NBCPDonna MelgarÎncă nu există evaluări

- Hip Roof Framing and BuildingDocument7 paginiHip Roof Framing and BuildingShepherd Nhanga100% (1)

- Project: 4 Storey Commercial and Residential Bldg. Subject: SpecificationDocument5 paginiProject: 4 Storey Commercial and Residential Bldg. Subject: SpecificationKUROÎncă nu există evaluări

- Technical Specification of 2 Storey ResidentialDocument7 paginiTechnical Specification of 2 Storey Residentializzy umandalÎncă nu există evaluări

- Simplified Reinforced Concrete Design 1Document87 paginiSimplified Reinforced Concrete Design 1Josua Biadno MenisÎncă nu există evaluări

- Asep NSCP Vol 3 - Housing DraftDocument8 paginiAsep NSCP Vol 3 - Housing DraftKaterina PetrovaÎncă nu există evaluări

- Inspection and Test Plan (Towers & Fasteners) : DescriptionDocument84 paginiInspection and Test Plan (Towers & Fasteners) : DescriptionPinku MaitiÎncă nu există evaluări

- Compressive Strength For Cast-In-Place Concrete: Table 1.7Document25 paginiCompressive Strength For Cast-In-Place Concrete: Table 1.7Ayban Dela CruzÎncă nu există evaluări

- Introduction To Industrial Wastewater Treatment SystemsDocument50 paginiIntroduction To Industrial Wastewater Treatment SystemsKaladorÎncă nu există evaluări

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing ConcreteDocument41 paginiACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concretebonnico75% (4)

- P'R 1 Dp"Jt-I : Republic of The PhilippinesDocument5 paginiP'R 1 Dp"Jt-I : Republic of The PhilippinesjrsiaseÎncă nu există evaluări

- NSCP 2015: NSCP: Free Download, Borrow, and Streaming ..Document3 paginiNSCP 2015: NSCP: Free Download, Borrow, and Streaming ..godofredo dumaliÎncă nu există evaluări

- Design Project 2013Document154 paginiDesign Project 2013Fahad HussainÎncă nu există evaluări

- Suspended Manual-English-Volume 3-Part 3 - Construction ManualDocument106 paginiSuspended Manual-English-Volume 3-Part 3 - Construction ManualkoklenderÎncă nu există evaluări

- Quality AssuaranceDocument150 paginiQuality Assuarancelamia97100% (1)

- Electrical BOQ FinalDocument45 paginiElectrical BOQ FinalmahasubbuÎncă nu există evaluări

- Demolition Specifications 1Document1 paginăDemolition Specifications 1JonÎncă nu există evaluări

- Australia Triboard Construction Manual (Aug02)Document112 paginiAustralia Triboard Construction Manual (Aug02)keithjonathan100% (1)

- Methods of ConstructionDocument25 paginiMethods of ConstructionIra MejiaÎncă nu există evaluări

- 2012 National Green Building Standard CommentaryDe la Everand2012 National Green Building Standard CommentaryÎncă nu există evaluări

- ACT Lab ManualDocument55 paginiACT Lab ManualDusk Slayer100% (1)

- BGA Rework - Hand Soldering - IPC CertificationDocument10 paginiBGA Rework - Hand Soldering - IPC CertificationKaty RadcliffÎncă nu există evaluări

- CBLM Rmo Core 5Document26 paginiCBLM Rmo Core 5Valcy Madz100% (1)

- Methods of Installation For Steel StructureDocument6 paginiMethods of Installation For Steel Structurenanamallow100% (1)

- Electrical Code of The PhilippinesDocument18 paginiElectrical Code of The PhilippinesZen Marl GaorÎncă nu există evaluări

- Philippine Green Building CodeDocument32 paginiPhilippine Green Building CodeTen ApolinarioÎncă nu există evaluări

- Column EstimateDocument8 paginiColumn Estimatedarkkaizer23Încă nu există evaluări

- Design of Parking SystemDocument59 paginiDesign of Parking SystemvnitceÎncă nu există evaluări

- 3 - Architectural SpecificationDocument44 pagini3 - Architectural SpecificationKing RickÎncă nu există evaluări

- C-5 One Way Two Way SlabDocument34 paginiC-5 One Way Two Way SlabBoopathi Yoganathan100% (2)

- Roof Framing SpecificationDocument10 paginiRoof Framing SpecificationLittleRedÎncă nu există evaluări

- Double Containment EDocument43 paginiDouble Containment EDavid FonsecaÎncă nu există evaluări

- Soportes de TuberíasDocument8 paginiSoportes de Tuberíasaecf_13Încă nu există evaluări

- Lighting TypesDocument38 paginiLighting TypesMelissa GomezÎncă nu există evaluări

- OW Building SpecificationsDocument20 paginiOW Building SpecificationsVholts Villa Vitug0% (1)

- Types of Cranes ComparisonDocument7 paginiTypes of Cranes ComparisonneoÎncă nu există evaluări

- PosiStrut Floor and Roof Installation InstructionsDocument28 paginiPosiStrut Floor and Roof Installation InstructionsTaimoo NaseemÎncă nu există evaluări

- IBR Thickness CalculationDocument18 paginiIBR Thickness Calculationreach_arindomÎncă nu există evaluări

- Mod 1 Precast and Cast in PlaceDocument28 paginiMod 1 Precast and Cast in PlaceNiel SalgadoÎncă nu există evaluări

- E7604-1!05!09 Practical Contamination Management enDocument45 paginiE7604-1!05!09 Practical Contamination Management enAlie Bhin Abhu DhabiÎncă nu există evaluări

- Rebar Cutting ListDocument20 paginiRebar Cutting Listleo dumapiÎncă nu există evaluări

- TS - Rough Carpentry (Interior Fit - Out) PDFDocument4 paginiTS - Rough Carpentry (Interior Fit - Out) PDFJo BompatÎncă nu există evaluări

- Batas Pambansa 344Document73 paginiBatas Pambansa 344Dayanski B-mÎncă nu există evaluări

- General and Technical Specification Section 1.0-GeneralDocument3 paginiGeneral and Technical Specification Section 1.0-GeneralTarhata KalimÎncă nu există evaluări

- Joint Certification - Quezon City DBO - Civil EngineerDocument1 paginăJoint Certification - Quezon City DBO - Civil EngineerJerome AsaÎncă nu există evaluări

- Usg Boral Gypsum Boards and Compounds: JointingDocument2 paginiUsg Boral Gypsum Boards and Compounds: JointingumamaheshÎncă nu există evaluări

- Spiral RampDocument15 paginiSpiral RampgouharÎncă nu există evaluări

- BP 344Document23 paginiBP 344vicentemariscalÎncă nu există evaluări

- Upang Cea 2bsar Arc142 P1Document66 paginiUpang Cea 2bsar Arc142 P1Park JiminÎncă nu există evaluări

- Roof Plan Roof Framing Plan: C A D B C A D BDocument1 paginăRoof Plan Roof Framing Plan: C A D B C A D BmjfprgcÎncă nu există evaluări

- Rececoat Base: Product Data SheetDocument2 paginiRececoat Base: Product Data SheetAmira Ramlee100% (1)

- Steel HandbbokDocument420 paginiSteel HandbbokMJ100% (1)

- ROOFINGDocument28 paginiROOFINGSachin Kumar PatelÎncă nu există evaluări

- Benefits of Using Plaswall - ProductsDocument2 paginiBenefits of Using Plaswall - ProductsJulius Alcantara100% (1)

- Chapter 9: Domestic Cold Water SupplyDocument23 paginiChapter 9: Domestic Cold Water SupplyRhey LuceroÎncă nu există evaluări

- Ramps in Car Parks: Connecting Ramps Parking RampsDocument8 paginiRamps in Car Parks: Connecting Ramps Parking Rampsjastine8mandapÎncă nu există evaluări

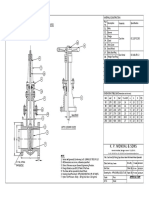

- Bureau of Design: Det. Plan of Stf-1Document1 paginăBureau of Design: Det. Plan of Stf-1VWSSI Technical TeamÎncă nu există evaluări

- Construction Specifications in The PhilippinesDocument4 paginiConstruction Specifications in The Philippinessunny sunflowerÎncă nu există evaluări

- Do's and Don'Ts in Planning SubdivisionDocument5 paginiDo's and Don'Ts in Planning SubdivisionJie FranciscoÎncă nu există evaluări

- Building Laws PDFDocument5 paginiBuilding Laws PDFNikki Angela Lirio BercillaÎncă nu există evaluări

- Material and Finishes SpecificationsDocument8 paginiMaterial and Finishes SpecificationsAldrin Ron MamarilÎncă nu există evaluări

- Hardiflex Ceiling PDFDocument16 paginiHardiflex Ceiling PDFJelaiÎncă nu există evaluări

- Quick Panel BrochureDocument11 paginiQuick Panel BrochuretantanÎncă nu există evaluări

- Program Outcomes (Pos) Addressed by The Activity: Activity No. 3: Building Envelope Systems and Assemblies 1.1Document13 paginiProgram Outcomes (Pos) Addressed by The Activity: Activity No. 3: Building Envelope Systems and Assemblies 1.1Jazcel GalsimÎncă nu există evaluări

- 4-Massing & Orientation For CoolingDocument3 pagini4-Massing & Orientation For CoolingaomareltayebÎncă nu există evaluări

- BrochureDocument2 paginiBrochurePotpot Solis Dacpano67% (3)

- Membrane StructuresDocument7 paginiMembrane StructuresHyacynth Pedrosa MenesesÎncă nu există evaluări

- GBDDocument17 paginiGBDCristian CameroÎncă nu există evaluări

- RuukkiDocument9 paginiRuukkiLogan JhonyÎncă nu există evaluări

- Flat Sheets and FacadesDocument41 paginiFlat Sheets and FacadesSarisha HarrychundÎncă nu există evaluări

- RulesonEarthquake - AccelerographDocument17 paginiRulesonEarthquake - AccelerographmjfprgcÎncă nu există evaluări

- Revised Guidelines For Coverage Screening and Standardized ReqtsDocument36 paginiRevised Guidelines For Coverage Screening and Standardized ReqtsReymond Igaya100% (1)

- Post Earthquake ChecklistDocument2 paginiPost Earthquake ChecklistjrsiaseÎncă nu există evaluări

- Do 081 S2015Document6 paginiDo 081 S2015jrsiaseÎncă nu există evaluări

- Do 083 S2015Document9 paginiDo 083 S2015jrsiaseÎncă nu există evaluări

- Do 027 S2007Document5 paginiDo 027 S2007jrsiaseÎncă nu există evaluări

- Power Source CharacteristicsDocument22 paginiPower Source CharacteristicsKyÎncă nu există evaluări

- Samsung MO1650xx Service ManualDocument29 paginiSamsung MO1650xx Service ManualBrent SmithÎncă nu există evaluări

- Your Total Utility Solution: CatalogDocument40 paginiYour Total Utility Solution: CatalogMichael Parohinog GregasÎncă nu există evaluări

- Daikin VRV IV Co BrochureDocument52 paginiDaikin VRV IV Co Brochuredokundot100% (1)

- ConclusionDocument2 paginiConclusionRohit Kumar75% (4)

- Sturbridge Case StudyDocument2 paginiSturbridge Case Studyárokszállási norbertÎncă nu există evaluări

- Types of PackersDocument7 paginiTypes of PackersAhmed AmirÎncă nu există evaluări

- ENA - 12 - 24 TS For Ducts - Buried Electric CablesDocument17 paginiENA - 12 - 24 TS For Ducts - Buried Electric CablessdvijayÎncă nu există evaluări

- Iso 527-2-2012 PDF - PDF - International Organization For Standardization - Composite MaterialDocument42 paginiIso 527-2-2012 PDF - PDF - International Organization For Standardization - Composite Materialanapaula.raizerÎncă nu există evaluări

- HaTelit Presentation 2Document18 paginiHaTelit Presentation 2Bagas YandiÎncă nu există evaluări

- SHIZUKI Capacitors and ReactorsDocument6 paginiSHIZUKI Capacitors and ReactorsUrsula JohnsonÎncă nu există evaluări

- Weather Pack Conectors & Pines 3377757Document9 paginiWeather Pack Conectors & Pines 3377757Rocky Escudero GonzalesÎncă nu există evaluări

- VIROGREEN-Safest and Best E-Waste Recycling Companies in UAE!Document2 paginiVIROGREEN-Safest and Best E-Waste Recycling Companies in UAE!ewastedubaiÎncă nu există evaluări

- 3D1 For 13 PlanerDocument32 pagini3D1 For 13 PlanerBrian ThompsonÎncă nu există evaluări

- Rising Type Sluice Valve With Hand Wheel Operated: Upto 150Mm SizeDocument1 paginăRising Type Sluice Valve With Hand Wheel Operated: Upto 150Mm SizeTanmoy DuttaÎncă nu există evaluări

- Parts Plastic Mold Design and Preparation ProcessDocument19 paginiParts Plastic Mold Design and Preparation ProcessKodhansÎncă nu există evaluări