Documente Academic

Documente Profesional

Documente Cultură

Structural Calculation Platform

Încărcat de

Landon MitchellDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Structural Calculation Platform

Încărcat de

Landon MitchellDrepturi de autor:

Formate disponibile

Design Report

KD-VGM2500 MILL ASSEMBLY

Consulting Engineer

315 Patel Avenue, Off Grand Bhagvati, S.G Road, Ahmedabad-300 059. Tel: +91-9898650557, Email: dipak@siliconinfo.com

Project Name: VGM2500

INDEX

No

1

Contents

INTRODUCTION 1.1 Introduction 1.2 Scope of Analysis and Design 1.3 Overview of loading and Combinations 1.4 Overview of Structural Analysis and Design 1.5 Abbreviations GEO TECHNICAL SURVEY & DETAILS LAYOUTS AND 3D MODELS 3.1 Geometry data 3.2 Member Numbers 3.3 Node Numbers 3.4 Member Sizes DESCRIPTION OF STAAD ANALYSIS 4.1 Software Package 4.2 Units 4.3 Coordinate System 4.4 Geometry 4.5 Support Condition/boundary condition 4.6 Load Applications 4.7.1 Dead load 4.7.2 Live load 4.7.3 Seismic loads 4.7.4 Wind loads 4.7.5 Snow load 4.7.6 Temperature loads 4.7 Load combinations 4.8.1 Load combinations for design LIST OF DESIGN CODES & STANDARDS ANALYSIS RESULTS 6.1 Bending moment diagrams 6.2 Shear force diagrams 6.3 Axial force diagrams 6.4 Support reactions

Page No.

3

2 3

4 5

14

5 6

31 31

7 8

Design output

Conclusion

45 50

1.0 INTRODUCTION 1.1 Introduction

This document forms the Engineering Analysis and Design basis for Structural Works of proposed Assembly. The contents of these documents form the guideline for engineering and to provide information to the other disciplines concerned. This technical specification summarizes the concept and detailed engineering analysis / design report prepared on basis of codes to be followed.

1.2 Scope of Analysis and Design

The scope of this structural analysis and design is to check the assembly for better performance and provide enough protection against adverse natural loadings like Wind and Seismic activity. Structure is designed to safeguard the equipments.

1.3 Overview of loading and Combinations

The following loads were considered in the analysis and design of structure: Dead weight of the assembly. Live load applicable as per mentioned by client. Wind and seismic loads as per mentioned in codes.

1.4 Overview of structural Analysis and Design

Structural analysis and design is done using hi-end FE software called STAADPro. All elements are modelled as beam elements with six degree of freedom at each end. Synchronized structural model has been created as a rigid portal frame with hinge supports at bottom. All structural elements are modelled as per actual shapes and inbuilt library is used to create realistic model. Load has been applied as per relevant AISC Code and Static FE analysis and design is done as per code specifications. 1.5 Abbreviations

v = Seismic Base Shear m = Total mass of the building above the foundation Sd(T1) = Ordinate of the design spectrum at period T1 H= Height of the building

Vbo = Fundamental Basic Wind Velocity Vb = Basic Wind Velocity Ze = Reference Height Zo = Roughness Length Zmin = Minimum Height Zmax = Maximum Height qp(z) = Peak Velocity Pressure Co = Orography factor = Air Density Cr(z) = Roughness factor Kr = Terrain factor Vm(z) = Mean Wind Velocity We = Wind Pressure on External Surface Wi = Wind Pressure on Internal Surface Cpe = External pressure coefficients Cpi = Internal pressure coefficients Ce = Exposure Coefficient Ct = Thermal Coefficient

2.0 GEO-TECHNICAL EXPLORATORY SURVEY The GEO technical investigation Engineer is responsible for the acquisition of a geo-technical exploratory survey to obtain accurate information about the soil conditions at the site. The depth, thickness, extent, composition of each stratum, and the depth of ground water shall be determined. Provide a geotechnical report based on survey data, which includes boring logs, field and laboratory test results, interpretation of data, building foundation and earthwork recommendations.

3.0 LAYOUTS AND 3D ANALYSIS MODELS 3.1 Geometry Data

3.2

Member Numbers

Isometric:

Node Numbers

10

Member Sizes: Column Sizes are HSS: 8" x 8" x 1/2"

TUBE TUBE TUBE TUBE

TUBE TUBE TUBE TUBE

Beam Sizes are HSS: 8" x 8" x 1/2" at 5.04 ft level

5.04ft

11

All elevation Bracing Sizes are L5 " x 5" x 0.31"

Beam Sizes are HSS: 8" x 6" x 1/2" at 17.75 ft level

12

Beam Sizes are C12x30 at 15.59 ft height Access Platform

Beam Sizes are C10x15.3 at 15.59 ft height Access Platform

13

4.0 DESCRIPTION OF STAAD Pro ANALYSIS 4.1 Software package

For analysis and Design high end Finite Element based software called STAAD Pro is being used to analyze and design the structure. Structural framing members are modeled as a beam element with six degree of freedom at each end. Space frame has been generated as per approved General arrangement drawing and finalized column position. All loads have been simulated in the model to analyse the structure for stability. Unic feature of optimization available in software package has been used to optimize the structure. 4.2 Units

S.I. units were used in this analysis, see table below: Quantity Name Length Feet ft Mass Pound lb Load Kilo Pound kip Density --Force Pound lb Area Sqrare inches ---

Unit

Lb/ft3 in^2

4.3 Coordinate System The FE model was built in the Global Coordinate System whose origin is at the (0,0,0). The Y-axis points vertically upward. The X-axis points in the direction parallel to longer side of building. Z-axis points in the direction parallel to width of the building. 4.4 Geometry

14

4.5 Support Condition/boundary condition All supports have been considered as pinned with restrain of forces in all three directions (Fx, Fy, Fz). Moments are released in all three directions ( Mx, My, Mz) 4.6 Loading Data

Design Loads: Building Design Loads will be in accordance with the more stringent of either the following criteria or as set forth by governing local and national codes. Structural design is based on coordinated loads supplied from client of different equipments, self weight, seismic and wind. Wind and seismic loads are considered as the most critical one to design the structure.

15

4.6.1 Dead load: Load data Dead Load **Upper frame weight 6253/4=1563lb

16

**motor weight 24000/4=6000lb

17

**bearing assembly 1400/4=350lb

18

*full barrel weight 30000lb/(6.625*4)=1132lb/ft

19

**grinding assembly weight 8000lb*/4=2000lb

20

Live Load Main Plate form Live Load 60lb/sq.ft as per ASCE 7-05 Table no 4.1 page no 12

-0.10 kips/ft -0.10 kips/ft -0.10 kips/ft -0.10 -0.10 kips/ft kips/ft -0.10 kips/ft -0.10 kips/ft 2*-0.10 2*-0.10 kips/ft kips/ft -0.10 kips/ft -0.10 kips/ft -0.10 -0.10 kips/ft -0.10 kips/ft -0.10 kips/ft -0.10 kips/ft

21

MOTOR TORQUE 24,340 FT*LB OPERATING LOAD 1 & 3

22

MOTOR TORQUE: 24,340 FT*LB APPLIED TO BASE OF BARREL IN SANDED OUT CONDITION. OPERATING LOAD 2 & 4 IN ADDITION TO MOTOR TORQUE ABOVE

23

MOTOR TORQUE: 24,340 FT*LB APPLIED TO BASE OF BARREL IN SANDED OUT CONDITION. OPERATING LOAD 2 & 4 IN ADDITION TO MOTOR TORQUE ABOVE

24

Wind Load Calculation

25

1.

Figures Wind 1 in +X direction

2.

Wind 2 in -X direction

26

3.

Wind 1 in +Z direction

4.

Wind 2 in -Z direction

27

Seismic Load Calculation

28

1.

EQ in -X direction

29

4.7

Load Combinations

1) LOAD COMB 101 DL + LL 1+LL 2 2) LOAD COMB 102 DL + LL 1+LL 3 3) LOAD COMB 103 DL + 0.75 (LL 1 + LL 2) 4) LOAD COMB 104 DL + 0.75 (LL 1 + LL 3) 5) LOAD COMB 105 DL + WL+X(CPE + CPI) 6) LOAD COMB 106 DL + WL-X(CPE - CPI) 7) LOAD COMB 107 DL + WL+Z(CPE + CPI) 8) LOAD COMB 108 DL + WL-X(CPE - CPI) 9) LOAD COMB 109 DL +0.7 EQ +X 10) LOAD COMB 110 DL + 0.7 EQ -X 11) LOAD COMB 111 DL + 0.7 EQ +Z 12) LOAD COMB 112 DL + 0.7 EQ -Z 13) LOAD COMB 113 DL + 0.75 WL+X(CPE + CPI) + 0.75 LL 1 + 0.75 LL 2 14) LOAD COMB 114 DL + 0.75 WL-X(CPE - CPI) + 0.75 LL 1 + 0.75 LL 2 15) LOAD COMB 115 DL + 0.75 WL+Z(CPE + CPI) + 0.75 LL 1 + 0.75 LL 2 16) LOAD COMB 116 DL + 0.75 WL-X(CPE - CPI) + 0.75 LL 1 + 0.75 LL 2 17) LOAD COMB 117 DL + 0.75 WL+X(CPE + CPI) + 0.75 LL 1 + 0.75 LL 3 18) LOAD COMB 118 DL + 0.75 WL-X(CPE - CPI) + 0.75 LL 1 + 0.75 LL 3 19) LOAD COMB 119 DL + 0.75 WL+Z(CPE + CPI) + 0.75 LL 1 + 0.75 LL 3 20) LOAD COMB 120 DL + 0.75 WL-X(CPE - CPI) + 0.75 LL 1 + 0.75 LL 3 21) LOAD COMB 121 DL + 0.525 EQ +X + 0.75 LL 1 + 0.75 LL 2 22) LOAD COMB 122 DL + 0.525 EQ -X + 0.75 LL 1 + 0.75 LL 2 23) LOAD COMB 123 DL + 0.525 EQ +Z + 0.75 LL 1 + 0.75 LL 2 24) LOAD COMB 124 DL + 0.525 EQ -Z + 0.75 LL 1 + 0.75 LL 2 25) LOAD COMB 125 DL + 0.525 EQ +X + 0.75 LL 1 + 0.75 LL 3 26) LOAD COMB 126 DL + 0.525 EQ -X + 0.75 LL 1 + 0.75 LL 3 27) LOAD COMB 127 DL + 0.525 EQ +Z + 0.75 LL 1 + 0.75 LL 3 28) LOAD COMB 128 DL + 0.525 EQ -Z + 0.75 LL 1 + 0.75 LL 3 29) LOAD COMB 129 0.6 DL + WL+X (CPE + CPI) 30) LOAD COMB 130 0.6 DL + WL-X (CPE - CPI) 31) LOAD COMB 131 0.6 DL + WL+Z (CPE + CPI) 32) LOAD COMB 132 0.6 DL + WL-X(CPE - CPI) 33) LOAD COMB 133 0.6 DL +0.7 EQ +X 34) LOAD COMB 134 0.6 DL + 0.7 EQ -X 35) LOAD COMB 135 0.6 DL + 0.7 EQ +Z 36) LOAD COMB 136 0.6 DL + 0.7 EQ -Z

30

5.0

LIST OF DESIGN CODES AND STANDARDS IS Code No. ASCE/SEI 7-05 Description Minimum design loads for buildings and other structures IBC-2009 ASTM-A992 International building code Material code

6.0

Analysis Results

Bending moment diagrams

Bending Moment of whole assembly for DL + LL

31

Bending Moment of whole assembly for EQ X

32

Bending Moment of whole assembly for EQ Z

33

Bending Moment of whole assembly for WIND LOAD X Dir.

34

Bending Moment of whole assembly for WIND LOAD Z Dir.

35

Shear force Diagrams Shear Force of whole assembly for DL + LL

36

Shear Force of whole assembly for WIND LOAD in X dir.

37

Shear Force of whole assembly for WIND LOAD in Z dir.

38

Shear Force of whole assembly for EQ in X dir.

39

Shear Force of whole assembly for EQ in Z dir.

40

Displacement diagram LOAD COMB 117 DL + 0.75 WL+X(CPE + CPI) + 0.75 LL 1 + 0.75 LL 3

41

LOAD COMB 126 DL + 0.525 EQ -X + 0.75 LL 1 + 0.75 LL 3

42

LOAD COMB 129 0.6 DL + WL+X(CPE + CPI)

43

6.4 Support Reactions

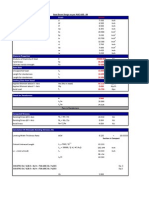

Support Reactions for Typical Frame

L/C Dead Live -1 Live -2 Live -3 EQ - X EQ - Z -28.438

Force-X kN 1.842 0.080 -4.090 0.006` -25.416 -0.006 -28.438 Force-X kN -1.842 -0.080 -4.090 0.006 -25.416 0.006 -28.568

Force-Y kN 88.063 9.223 0.031 -0.045 -118.653 -118.653 -120.033 Force-Y kN 88.063 9.223 -0.031 0.045 118.653 -118.653 120.068

Force-Z kN 1.835 0.075 4.081 0.006 -0.008 -25.416 -0.002 Force-Z kN 1.835 0.075 -4.081 -0.006 0.008 -25.416 0.001 L/C Dead Live -1 Live -2 Live -3 EQ - X EQ - Z Wind Force-X kN -1.842 -0.080 4.090 -0.006 -25.416 -0.006 -28.564 Force-Y kN 88.063 9.223 0.031 -0.045 118.653 118.653 120.036 Force-Z kN -1.835 -0.075 -4.081 -0.006 -0.008 -25.416 0.017

L/C Dead Live -1 Live -2 Live -3 EQ - X EQ - Z Wind

L/C Dead Live -1 Live -2 Live -3 EQ - X EQ - Z Wind

Force-X kN 1.842 0.080 4.090 -0.006 -25.416 0.006 -28.438

Force-Y kN 88.063 9.223 -0.031 0.045 -118.653 118.653 -120.033

Force-Z kN -1.835 -0.075 4.081 0.006 0.008 -25.416 0.028

44

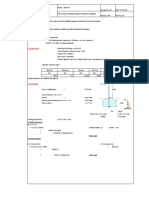

7.0 Design output

MEMBER RESULT/ CRITICAL COND/ RATIO/ LOADING/ FX MY MZ LOCATION ======================================================================= 1 ST TUB E PASS 15262.67 T 2 ST TUB E PASS 24214.42 C 3 ST TUB E PASS 21972.22 C 4 ST TUB E PASS 46535.79 C 5 ST TUB E PASS 28619.67 C 6 ST TUB E PASS 26198.70 C 7 ST TUB E PASS 46528.86 C 8 ST TUB E PASS 28607.63 C 9 ST TUB E PASS 25916.86 C 10 ST TUB E PASS 46532.62 C 11 ST TUB E PASS 29086.98 C 12 ST TUB E PASS 26151.52 C 101 ST TUB E PASS 0.00 T 102 ST TUB E PASS 0.00 T 103 ST TUB E PASS 0.00 T 104 ST TUB E PASS 0.00 T 301 ST C10X15 PASS 229.72 T 302 ST C10X15 PASS 76.83 T 303 ST C10X15 PASS 77.95 T 304 ST C10X15 PASS 229.96 T 305 ST C10X15 (CANADIAN SECTIONS) AISC- H2-1 0.374 -372217.22 14686.66 (CANADIAN SECTIONS) AISC- H1-3 0.098 -8132.31 29278.40 (CANADIAN SECTIONS) AISC- H1-3 0.095 17167.75 33462.89 (CANADIAN SECTIONS) AISC- H1-3 0.496 24972.15 -413630.75 (CANADIAN SECTIONS) AISC- H1-3 0.116 -21888.71 -22960.01 (CANADIAN SECTIONS) AISC- H1-3 0.112 17879.22 -41376.75 (CANADIAN SECTIONS) AISC- H1-3 0.496 -24727.92 -413572.09 (CANADIAN SECTIONS) AISC- H1-3 0.117 -22485.54 21495.36 (CANADIAN SECTIONS) AISC- H1-3 0.112 -17470.78 -42267.58 (CANADIAN SECTIONS) AISC- H1-3 0.496 -413155.56 24780.59 (CANADIAN SECTIONS) AISC- H1-3 0.117 -39332.47 5264.48 (CANADIAN SECTIONS) AISC- H1-3 0.111 -36893.27 22005.21 (CANADIAN SECTIONS) AISC- H1-3 0.344 0.00 392152.91 (CANADIAN SECTIONS) AISC- H1-3 0.344 0.00 391685.16 (CANADIAN SECTIONS) AISC- H1-3 0.344 0.00 392108.50 (CANADIAN SECTIONS) AISC- H1-3 0.344 0.00 391644.47 (AISC SECTIONS) AISC- H2-1 0.617 22262.13 1359.44 (AISC SECTIONS) AISC- H2-1 0.719 25984.66 1360.71 (AISC SECTIONS) AISC- H2-1 0.719 25970.35 1361.31 (AISC SECTIONS) AISC- H2-1 0.617 22265.35 1360.04 (AISC SECTIONS) TABLE

131 60.50 126 134.52 126 0.00 105 60.50 117 0.00 113 0.00 105 60.50 119 0.00 117 0.00 107 60.50 107 134.52 115 0.00 107 0.00 105 79.50 107 0.00 105 79.50 107 41.22 107 0.00 107 39.72 107 0.00

45

PASS 740.93 T 306 ST C10X15 PASS 473.35 T 307 ST C10X15 PASS 2150.31 C 308 ST C10X15 PASS 740.59 T 309 ST C10X15 PASS 3846.46 T 310 ST C10X15 PASS 2278.81 C 311 ST C10X15 PASS 2150.32 C 312 ST C10X15 PASS 3846.55 T 313 ST C10X15 PASS 216.44 C 314 ST C10X15 PASS 202.51 C 315 ST C10X15 PASS 331.00 C 316 ST C10X15 PASS 1288.97 T 317 ST C10X15 PASS 204.47 T 318 ST C10X15 PASS 170.07 T 319 ST C10X15 PASS 204.47 T 320 ST C12X30 PASS 805.87 T 321 ST C12X30 PASS 2474.06 C 322 ST C12X30 PASS 805.87 T 323 ST C10X15 PASS 223.08 T 324 ST C10X15 PASS 223.08 T 325 ST C12X30 PASS 4162.31 T 326 ST C12X30 PASS 2487.27 C 327 ST C12X30 PASS 4162.31 T

AISC- H2-1 0.213 7240.11 5380.94 (AISC SECTIONS) AISC- H2-1 0.461 -16588.45 -107.16 (AISC SECTIONS) AISC- H1-3 0.494 17030.28 1687.72 (AISC SECTIONS) AISC- H2-1 0.213 7241.44 5380.68 (AISC SECTIONS) AISC- H2-1 0.213 -6125.14 6475.38 (AISC SECTIONS) AISC- H1-3 0.439 14766.75 4265.05 (AISC SECTIONS) AISC- H1-3 0.465 15931.58 2164.87 (AISC SECTIONS) AISC- H2-1 0.213 -6114.65 6588.49 (AISC SECTIONS) AISC- H1-3 0.522 18672.55 2210.14 (AISC SECTIONS) AISC- H1-3 0.590 21142.56 2216.18 (AISC SECTIONS) AISC- H1-3 0.715 25655.85 2006.67 (AISC SECTIONS) AISC- H2-1 0.509 -18075.25 591.13 (AISC SECTIONS) AISC- H2-1 0.550 19911.34 662.54 (AISC SECTIONS) AISC- H2-1 0.569 20578.19 663.69 (AISC SECTIONS) AISC- H2-1 0.550 19911.31 661.68 (AISC SECTIONS) AISC- H2-1 0.188 11355.11 6962.86 (AISC SECTIONS) AISC- H1-3 0.385 23420.84 2910.52 (AISC SECTIONS) AISC- H2-1 0.188 11355.20 6963.88 (AISC SECTIONS) AISC- H2-1 0.128 -4588.28 -0.47 (AISC SECTIONS) AISC- H2-1 0.128 -4588.23 -0.47 (AISC SECTIONS) AISC- H2-1 0.197 -10836.37 7709.69 (AISC SECTIONS) AISC- H1-3 0.359 21208.39 9899.06 (AISC SECTIONS) AISC- H2-1 0.197 -10836.19 7711.08

107 41.22 131 39.78 106 0.00 107 0.00 108 41.22 106 0.00 106 39.72 108 0.00 106 41.22 106 0.00 106 39.72 108 0.00 105 41.22 105 0.00 105 0.00 105 41.22 108 39.75 105 0.00 105 0.00 105 41.22 106 41.22 108 0.00 106 0.00

46

328

ST

C10X15 PASS 228.79 C

329

ST

C10X15 PASS 491.88 C

330

ST

C10X15 PASS 1246.14 T

1013

ST

TUB E PASS 0.00 T

1014

ST

TUB E PASS 0.00 T

1015

ST

TUB E PASS 0.00 T

1016

ST

TUB E PASS 0.00 T

1071

ST

L50505 PASS 14071.89 T L50505 PASS 19322.01 T L50505 PASS 19292.62 T L50505 PASS 13996.24 T L50505 PASS 19323.15 T L50505 PASS 14071.90 T L50505 PASS 13996.25 T L50505 PASS 19295.29 T C10X15 PASS 170.07 T C12X30 PASS 286.89 T C10X15 PASS 1218.20 T C12X30 PASS 2659.86 C C10X15 PASS 304.80 T C10X15 PASS 304.84 T

1072

ST

1073

ST

1074

ST

1075

ST

1076

ST

1077

ST

1078

ST

1079

ST

1080

ST

1081

ST

1082

ST

1083

ST

1084

ST

(AISC SECTIONS) AISC- H1-3 0.488 17512.41 1085.25 (AISC SECTIONS) AISC- H1-3 0.564 20136.10 1575.31 (AISC SECTIONS) AISC- H2-1 0.458 -16261.86 -118.04 (CANADIAN SECTIONS) AISC- H1-3 0.002 0.00 1897.29 (CANADIAN SECTIONS) AISC- H1-3 0.002 0.00 1897.29 (CANADIAN SECTIONS) AISC- H1-3 0.002 0.00 1897.29 (CANADIAN SECTIONS) AISC- H1-3 0.002 0.00 1897.29 (AISC SECTIONS) TENSION 0.155 0.00 0.00 (AISC SECTIONS) TENSION 0.212 0.00 0.00 (AISC SECTIONS) TENSION 0.212 0.00 0.00 (AISC SECTIONS) TENSION 0.154 0.00 0.00 (AISC SECTIONS) TENSION 0.212 0.00 0.00 (AISC SECTIONS) TENSION 0.155 0.00 0.00 (AISC SECTIONS) TENSION 0.154 0.00 0.00 (AISC SECTIONS) TENSION 0.212 0.00 0.00 (AISC SECTIONS) AISC- H2-1 0.569 20578.18 662.83 (AISC SECTIONS) AISC- H2-1 0.358 -22488.07 1026.85 (AISC SECTIONS) AISC- H2-1 0.466 -16562.67 160.88 (AISC SECTIONS) AISC- H1-3 0.324 19621.49 1101.73 (AISC SECTIONS) AISC- H2-1 0.161 5849.51 27.51 (AISC SECTIONS) AISC- H2-1 0.161 5847.28 27.50

108 0.00 108 0.00 130 41.22 101 0.00 101 0.00 101 0.00 101 0.00 110 0.00 105 0.00 107 0.00 112 0.00 105 0.00 110 0.00 112 0.00 107 0.00 105 39.75 105 0.00 106 39.75 108 39.75 107 41.22 107 0.00

47

Utility stress ratio of Plateform

48

Utility stress ratio of Whole assembly

49

8.0 CONCLUSION

Analysis Methodology: Structure is being modelled with beam elements which is having six degree of freedom at each end. Member profiles are being taken as per provided by client. Orientation of members are also kept same as of provided drawing Geometrical dimensions are being kept exactly same as of provided. Gravity loads like equipment loading, selfweight of structure applied in vertical Y direction. Torsion load of the rotary equipment has been applied as per supplied data Lateral loads e.g wind and seismic loads are applied as per worst condition mentioned in International building Code 2006. Lateral loads are applied in +X, X, +Z and Z direction to check behaviour of structure in worst condition. Analysis of structure is done with Finite element method.

Design Methodology and outcome: Load combinations are applied as per International building Code2006 to check the structure against worst loads. Permissible stresses in members are taken for design as per given grade of steel. Allowable Stress Design (ASD) has been used to check the structure for worst load combinations. All structural members are designed for worst loads On basis of rigorous analysis done in STAAD pro structure is found SAFE to carry out Gravity, Dynamic and lateral loads.

50

S-ar putea să vă placă și

- Design Calculation Steel Structure Power PlantDocument58 paginiDesign Calculation Steel Structure Power Plantrajeshdebnath100% (2)

- Structural Design Calculation SampleDocument17 paginiStructural Design Calculation Sampleihpeter83% (6)

- Steel Structural Calculation ReportDocument79 paginiSteel Structural Calculation ReportSandeep Patil100% (4)

- Steel Beam Design As Per AISC ASDDocument2 paginiSteel Beam Design As Per AISC ASDKov Chanthy100% (1)

- DESIGN CALCULATION Report PDFDocument61 paginiDESIGN CALCULATION Report PDFShaikh Muhammad Ateeq100% (1)

- XXX-XXXX-XXX - Details of Completion Skid Structural Calculation ReportDocument33 paginiXXX-XXXX-XXX - Details of Completion Skid Structural Calculation Reportsridhar100% (1)

- Calculation For Service Platform & Pump Shelter StructureDocument36 paginiCalculation For Service Platform & Pump Shelter Structuretrian33100% (1)

- Baseplate Design AiscDocument20 paginiBaseplate Design AiscShamim Ahsan ZuberyÎncă nu există evaluări

- Structure Calculation ReportDocument37 paginiStructure Calculation ReportMasoodMiyanÎncă nu există evaluări

- Structural Steelwork ConnectionsDocument4 paginiStructural Steelwork Connectionstheunknown076Încă nu există evaluări

- Lifting CalculationDocument7 paginiLifting CalculationAsaru DeenÎncă nu există evaluări

- Design Basis For Roof TrussDocument22 paginiDesign Basis For Roof TrussUmer AziqÎncă nu există evaluări

- Gpp2 Pe 030 RPT 00002 - r1 B.S. Shelter Design Report CommentsDocument47 paginiGpp2 Pe 030 RPT 00002 - r1 B.S. Shelter Design Report Commentsisaacjoe77Încă nu există evaluări

- Equipment StructuresDocument86 paginiEquipment StructuresFauzankalibata100% (1)

- ASME SpreaderBar DWGDocument1 paginăASME SpreaderBar DWGInspetor SoldagemÎncă nu există evaluări

- STAAD Pro Advanced AnalysisDocument7 paginiSTAAD Pro Advanced AnalysisGuru Prasad67% (3)

- BollardDocument2 paginiBollardJoe Nadakkalan100% (1)

- Dj1 Dj2 Unb Unt Unl Ver 1.5Document2 paginiDj1 Dj2 Unb Unt Unl Ver 1.5ajayssarode100% (1)

- STeelCON Presentation - ConnectionsDocument42 paginiSTeelCON Presentation - Connectionsprabhu81Încă nu există evaluări

- SSF Skid Analysis & Design - Doc Rev ADocument19 paginiSSF Skid Analysis & Design - Doc Rev AsridharÎncă nu există evaluări

- Platform Design Calculation - Rev B - 21!03!18Document10 paginiPlatform Design Calculation - Rev B - 21!03!18viv99844Încă nu există evaluări

- C22-ZG31-J-8273 - 0 Steel Structure Design Calculation For Typical Sub Storage BuildingDocument379 paginiC22-ZG31-J-8273 - 0 Steel Structure Design Calculation For Typical Sub Storage BuildingsartajÎncă nu există evaluări

- Crane Gantry Girder (BS5950 - Part1 - 2000)Document6 paginiCrane Gantry Girder (BS5950 - Part1 - 2000)sayed100% (1)

- Structural Design of Warehouse Using Structural SteelDocument154 paginiStructural Design of Warehouse Using Structural Steelnirez14100% (3)

- Design of Isolated FootingDocument10 paginiDesign of Isolated Footingramdev panditÎncă nu există evaluări

- Beam Ledge DesignDocument2 paginiBeam Ledge Designauatipu100% (1)

- Helipad Structural AnalysisDocument1.250 paginiHelipad Structural AnalysisMark Roger Huberit IIÎncă nu există evaluări

- Structure Steel Design Calculation (Closed Drain Pump)Document359 paginiStructure Steel Design Calculation (Closed Drain Pump)vamcodong100% (1)

- Modified Structural Design PDFDocument373 paginiModified Structural Design PDFDINESHÎncă nu există evaluări

- Metal Building Software, Inc.: Element in AnalysisDocument11 paginiMetal Building Software, Inc.: Element in Analysisgenkatrov100% (1)

- Skid Under The Lifting ConditionDocument150 paginiSkid Under The Lifting ConditionAmarjit KulkarniÎncă nu există evaluări

- Beam Aisc LRFDDocument7 paginiBeam Aisc LRFDsocrates00701227100% (1)

- Beam Bending Strenght Aisc 9th EditionDocument17 paginiBeam Bending Strenght Aisc 9th EditionKory Estes100% (1)

- Calculation Sheet For Steel StructureDocument156 paginiCalculation Sheet For Steel StructureAndiWSutomoÎncă nu există evaluări

- Base Plate Design - 8m Span - Max Vertical LoadDocument7 paginiBase Plate Design - 8m Span - Max Vertical Loadnitin400Încă nu există evaluări

- Base Plate With Moment & Axial CompressionDocument2 paginiBase Plate With Moment & Axial CompressionAnonymous b3NKZUb100% (3)

- Design Basis For Steel Structures 20160921 FINALDocument9 paginiDesign Basis For Steel Structures 20160921 FINALshangz1511Încă nu există evaluări

- Software Verification: AISC-360-05 Example 001Document8 paginiSoftware Verification: AISC-360-05 Example 001Zakir KhanÎncă nu există evaluări

- Structural Analysis ReportDocument3 paginiStructural Analysis ReportLandz GanzonÎncă nu există evaluări

- Lifting Analysis Report - TemplateDocument31 paginiLifting Analysis Report - TemplateLukman Hakim100% (2)

- Calculation Sheet: Design PhilosophyDocument18 paginiCalculation Sheet: Design PhilosophyrammohanÎncă nu există evaluări

- Base Plate CalculationDocument10 paginiBase Plate Calculationsiva100% (2)

- Steel Beam DesignDocument8 paginiSteel Beam DesignKatracho2Încă nu există evaluări

- Design of Base PlateDocument166 paginiDesign of Base PlateAnonymous ciKyr0t86% (7)

- Joists Deck Uplift Webinar - 032524 Final - 1slideDocument78 paginiJoists Deck Uplift Webinar - 032524 Final - 1slideAPÎncă nu există evaluări

- Design of Lateral Load Resisting Frames Using Steel Joists and Joist GirdersDocument48 paginiDesign of Lateral Load Resisting Frames Using Steel Joists and Joist GirdersJoel MooreÎncă nu există evaluări

- ADAPT-MAT Foundation Design ExampleDocument23 paginiADAPT-MAT Foundation Design ExampleBryan Pinol0% (1)

- Cooling Tank Support StructureDocument44 paginiCooling Tank Support Structurevj8584100% (1)

- Design Calculations: For Steel StructureDocument46 paginiDesign Calculations: For Steel Structurethiện50% (2)

- Load Calculations PDFDocument19 paginiLoad Calculations PDFJeffrey Buquing ValdezÎncă nu există evaluări

- Horizontal Vessel Loading Calculation ProcedureDocument20 paginiHorizontal Vessel Loading Calculation ProcedurepandianÎncă nu există evaluări

- DR - Majid Albana CalculationDocument22 paginiDR - Majid Albana CalculationStruct EngineeringÎncă nu există evaluări

- Calculation Haw0296 ADocument69 paginiCalculation Haw0296 Aredflex9001889Încă nu există evaluări

- Foundation Design Philosophy For Equipment On SkidDocument5 paginiFoundation Design Philosophy For Equipment On SkidParimelazhagan RsÎncă nu există evaluări

- March-Webinar Wind-NASCC-2017 031417 FINALDocument120 paginiMarch-Webinar Wind-NASCC-2017 031417 FINALAntonÎncă nu există evaluări

- RC-Pier LRFD 3 Column Frame Pier ExampleDocument160 paginiRC-Pier LRFD 3 Column Frame Pier ExampleMTCLS100% (2)

- ParaDocument17 paginiParaنصر عبدالسلامÎncă nu există evaluări

- STRUCTURAL DESIGN ReportDocument25 paginiSTRUCTURAL DESIGN ReportRajendra AcharyaÎncă nu există evaluări

- Foundation Design Philosophy For Bullet VesselsDocument5 paginiFoundation Design Philosophy For Bullet Vesselsdicktracy11Încă nu există evaluări

- PIP STC01018 (Blast Resistant Building Design Criteria)Document55 paginiPIP STC01018 (Blast Resistant Building Design Criteria)Liu Leo100% (3)

- Gripple India New CatalogueDocument17 paginiGripple India New CatalogueFaizan UlhaqueÎncă nu există evaluări

- Final Report PDFDocument14 paginiFinal Report PDFArjun S SanakanÎncă nu există evaluări

- R GFRG Bace Swiftbuild Panel Specs 29,4,23Document7 paginiR GFRG Bace Swiftbuild Panel Specs 29,4,23Landon MitchellÎncă nu există evaluări

- Design of Culvert - Excel SheetDocument17 paginiDesign of Culvert - Excel Sheethafiz zain saeed67% (3)

- BACE India GFRG - Advantages NewDocument7 paginiBACE India GFRG - Advantages NewLandon MitchellÎncă nu există evaluări

- Consideration For Reinforced Soil Walls in Urban FlyoversDocument16 paginiConsideration For Reinforced Soil Walls in Urban FlyoversDilipÎncă nu există evaluări

- 01 8th Nift MathsDocument12 pagini01 8th Nift MathsLandon MitchellÎncă nu există evaluări

- Boyd C.Ringo. Robert B. Anderson. - Designing Floor Slabs On Grade PDFDocument289 paginiBoyd C.Ringo. Robert B. Anderson. - Designing Floor Slabs On Grade PDFCassey Mond100% (2)

- 5 Viii Ismo-Set-2 QPDocument7 pagini5 Viii Ismo-Set-2 QPLandon MitchellÎncă nu există evaluări

- 5 Viii Ismo-Set-2 QPDocument7 pagini5 Viii Ismo-Set-2 QPLandon MitchellÎncă nu există evaluări

- Tieback Wall Design and ConstructionDocument184 paginiTieback Wall Design and Constructionlaporpo123100% (1)

- Grouts GroutingDocument4 paginiGrouts GroutingBalaiya ParthibanÎncă nu există evaluări

- 6 Viii Ismo-Set-2 KeyDocument1 pagină6 Viii Ismo-Set-2 KeyLandon MitchellÎncă nu există evaluări

- MSW Legacy Waste - 19!3!2019Document34 paginiMSW Legacy Waste - 19!3!2019Landon MitchellÎncă nu există evaluări

- FHWA-NHI-10-024 Design & Construction of MSE Walls and Reinforced Soil Slopes - Volume IDocument332 paginiFHWA-NHI-10-024 Design & Construction of MSE Walls and Reinforced Soil Slopes - Volume IKathleen Noonan100% (3)

- Detailed Project Report For Biogas Power PlantDocument132 paginiDetailed Project Report For Biogas Power PlantLandon MitchellÎncă nu există evaluări

- 4.22nd April AP Class IV Maths Assignment 1Document2 pagini4.22nd April AP Class IV Maths Assignment 1Landon MitchellÎncă nu există evaluări

- Design and Construction of Bridge Embankment Using R.E. Wall PanelsDocument7 paginiDesign and Construction of Bridge Embankment Using R.E. Wall PanelsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Design ExamplesDocument7 paginiDesign ExamplesLandon MitchellÎncă nu există evaluări

- Detailed Project Report For Biogas Power PlantDocument132 paginiDetailed Project Report For Biogas Power PlantShubham Jain100% (2)

- Prefab Bamboo House Floor PlansDocument16 paginiPrefab Bamboo House Floor PlansLandon MitchellÎncă nu există evaluări

- Gravity Wall (RCC) R0 (27!11!2017) 5m For TestingDocument81 paginiGravity Wall (RCC) R0 (27!11!2017) 5m For TestingLandon MitchellÎncă nu există evaluări

- Oxidation PondDocument2 paginiOxidation PondLandon MitchellÎncă nu există evaluări

- AISSEE Sainik Schools Syllabus 2021 For Class 6 PDF - Exam Pattern - SainikSchoolGuide - inDocument5 paginiAISSEE Sainik Schools Syllabus 2021 For Class 6 PDF - Exam Pattern - SainikSchoolGuide - inLandon MitchellÎncă nu există evaluări

- Parametric Studies of Guyed Towers Under Wind and Seismic LoadsDocument14 paginiParametric Studies of Guyed Towers Under Wind and Seismic LoadsmohaÎncă nu există evaluări

- Blast CalculationDocument35 paginiBlast CalculationnhulugallaÎncă nu există evaluări

- Time History Input Integration Time Steop CalculationDocument2 paginiTime History Input Integration Time Steop CalculationLandon MitchellÎncă nu există evaluări

- Eqp FoundationDocument24 paginiEqp FoundationLandon MitchellÎncă nu există evaluări

- Design For Blower Foundation - SATORPDocument30 paginiDesign For Blower Foundation - SATORPsinambeladavid100% (3)

- 2.4 Assembly ManualDocument139 pagini2.4 Assembly Manualgustavo dlsÎncă nu există evaluări

- Noxim MANUALDocument5 paginiNoxim MANUALSAI NRUSIMHA DEEPAK BURRA SAI NRUSIMHA DEEPAK BURRAÎncă nu există evaluări

- Ays 082914 3331 PDFDocument18 paginiAys 082914 3331 PDFFabian R. GoldmanÎncă nu există evaluări

- Neuromuscular Diseases. ALSDocument7 paginiNeuromuscular Diseases. ALSjalan_zÎncă nu există evaluări

- 1 Introduction To Microsoft VirtualizationDocument36 pagini1 Introduction To Microsoft VirtualizationRavinder KantÎncă nu există evaluări

- Movimiento Circular, Momentun Lineal y EnergíaDocument92 paginiMovimiento Circular, Momentun Lineal y EnergíaJulio César Macías ZamoraÎncă nu există evaluări

- Digital Trail Camera: Instruction ManualDocument20 paginiDigital Trail Camera: Instruction Manualdavid churaÎncă nu există evaluări

- InTech-Batteries Charging Systems For Electric and Plug in Hybrid Electric VehiclesDocument20 paginiInTech-Batteries Charging Systems For Electric and Plug in Hybrid Electric VehiclesM VetriselviÎncă nu există evaluări

- Kiss Forex How To Trade Ichimoku PDFDocument72 paginiKiss Forex How To Trade Ichimoku PDFSastryassociates Chartered100% (3)

- Caption Sheet 4-Kailynn BDocument4 paginiCaption Sheet 4-Kailynn Bapi-549116310Încă nu există evaluări

- ManufactureDocument2 paginiManufactureRahima Akter RakhiÎncă nu există evaluări

- Calculate Cable Size and Voltage Drop Electrical Notes Articles PDFDocument10 paginiCalculate Cable Size and Voltage Drop Electrical Notes Articles PDFRavi SharmaÎncă nu există evaluări

- Gold Advanced Progress Test 5Document6 paginiGold Advanced Progress Test 5BernardÎncă nu există evaluări

- TR189 Kathuria PDFDocument168 paginiTR189 Kathuria PDFuqiÎncă nu există evaluări

- 10 - Enzymes - PPT - AutoRecoveredDocument65 pagini10 - Enzymes - PPT - AutoRecoveredFaith WilliamsÎncă nu există evaluări

- Stress Management PPT FinalDocument7 paginiStress Management PPT FinalAdarsh Meher100% (1)

- Ieee 802Document3 paginiIeee 802M Zubair AslamÎncă nu există evaluări

- 19 Work Energy TNDocument2 pagini19 Work Energy TNAna DorueloÎncă nu există evaluări

- Vintage Tavern - PrintInspectionDocument4 paginiVintage Tavern - PrintInspectionBryce AirgoodÎncă nu există evaluări

- Resource Access ControlDocument19 paginiResource Access Controlusamadar707Încă nu există evaluări

- Yamaha r6 Yec Kit ManualDocument2 paginiYamaha r6 Yec Kit ManualAlexander0% (1)

- Gcat Threathorizons Full Jan2023Document26 paginiGcat Threathorizons Full Jan2023josbjsÎncă nu există evaluări

- Monthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)Document20 paginiMonthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)winda septiaraÎncă nu există evaluări

- Stokerchapter25lipidmetabolism 160320032037Document29 paginiStokerchapter25lipidmetabolism 160320032037Dawlat SalamaÎncă nu există evaluări

- NURS1108 Lecture 10 - Nervous System ENHANCEDDocument40 paginiNURS1108 Lecture 10 - Nervous System ENHANCEDJacia’s SpaceshipÎncă nu există evaluări

- CopernikDocument2 paginiCopernikSinister JinÎncă nu există evaluări

- Offsetting Macro-Shrinkage in Ductile IronDocument13 paginiOffsetting Macro-Shrinkage in Ductile IronmetkarthikÎncă nu există evaluări

- Over Current & Earth Fault RelayDocument2 paginiOver Current & Earth Fault RelayDave Chaudhury67% (6)

- Dinacharya HandbookDocument5 paginiDinacharya Handbookvera sirakovaÎncă nu există evaluări

- TA1515VDocument4 paginiTA1515VLeo LeiÎncă nu există evaluări

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDe la EverandArizona, Utah & New Mexico: A Guide to the State & National ParksEvaluare: 4 din 5 stele4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDe la EverandNew York & New Jersey: A Guide to the State & National ParksÎncă nu există evaluări

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDe la EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptEvaluare: 5 din 5 stele5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDe la EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensÎncă nu există evaluări

- The Bahamas a Taste of the Islands ExcerptDe la EverandThe Bahamas a Taste of the Islands ExcerptEvaluare: 4 din 5 stele4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDe la EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoEvaluare: 5 din 5 stele5/5 (1)