Documente Academic

Documente Profesional

Documente Cultură

Drum Level Control - Three-Element Feedwater Control

Încărcat de

பிரசன்னகுமார் ஆனந்தன்Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Drum Level Control - Three-Element Feedwater Control

Încărcat de

பிரசன்னகுமார் ஆனந்தன்Drepturi de autor:

Formate disponibile

United States Patent [191

Feet

[54] FEEDWATER CONTROL FOR DRUM TYPE

STEAM GENERATORS

l l l l l l l Il l| | l l lIl l l l l l l l l l l l l l l l l l l l l l l l

US005148775A

[111 Patent Number:

[45]

_

5,148,775

Sep. 22, 1992

Date of Patent:

_

4,619,224 10/1986 Takita et al. .................. .. 122/451 R

Primary Exammer--Edward G. Favors

[75] hlvemori [73] Assignee:

William J- Peel, Cambndge Canada The Babcock & Wilcox Company, New Orleans, La. [21] Appl No: 823503 [22] Filed: Jan. 22, 1992

5

Attorney, Agent. or Firm-Vytas R. Matas; Robert J. Edwards [57] ABSTRACT An improved feedwater control for drum type steam generators is provided in order to gain improved drum

level control for drum type steam generators which are subjected to great 10ad changes at high rates of change.

.............................................. ..

[581 ri'eidoisiii"IIIIIIII'iii?iii'ii"is1s448.1

[56] References Cited

U.S. PATENT DOCUMENTS

3,417,737 12/1968 Shinskey et a1. ............... .. 122/4481

,1 37/11

Thecomwlsystemaccountsforchangesinthemass

inventory within the circulation lop by monitoring and

adjusting to changes in steam flow and drum pressure.

Thus, during load changes, the drum level will remain

constant.

4 Claims, 3 Drawing Sheets

4,242,989

1/1981 Chamberlain ................. .. 122/451 R

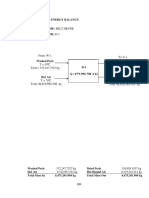

DRUM LEVEL

STEAM FLOW

DRUM PRESSURE

FEEDWATER FLOW

no 2

I

20

l4

.

@30

IS

W

1 4o

'8

J

23 W

22

42

/\./

'

't

Z(K)

/

7'5

34

755 7

"/25 X

~ 29

27

.

2s

'

l

44

r f(t)

36 WHK.

M37

/\/

K d, ,v 32

45

M72

V

38 W K.

l

ft

M 33

~39

- M

DRUM LEVEL ( out+ d /dt (M) + d/dl (6M) +ERR R )

FEEDWATER CONTROL VALVE

US. Patent

Sep. 22, 1992

Sheet 1 of 3

5,148,775

FIG. I

DRUM LEVEL STEAM FLOW FEEDWATER FLOW

@vuo

.,II2

I20

I2I

I40

|4l

0H4

I23

I22

I24

M- I42

Ml43

44

> A ~l|6

I08

1|

1

#HK) M28

m) ~I48

#430

I60 AIKU ';

I05 I

I65 I50

I70

I80 I

FEEDWATER

CONTROL VALVE 200

U.S._ Patent

Sep. 22, 1992

Sheet 2 of 3

5,148,775

FIG. 2

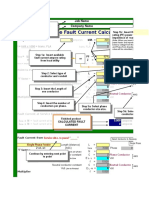

CHANGE IN MASS INVENTORY WITH STEAM FLOW.

. 2

E6. M= A- B(MQUT)

M ' WHERE M=MASS IN CIRC. 1.00!D

(Emma/o)

MOUT= STEAM FLOWRATE

A,B = CONSTANTS

MOUT

.....___>

"0

(M 0m) |oo%

FIG. 3

CHANGE IN MASS INVENTORY WITH DRUM PRESSURE

WT (M@|oo%)

E.G. 5M=C(PD)+D

WHERE s M= MASS CHANGE P0 = DRUM PRESSURE

c,0= CONSTANTS

US. Patent

Sep. 22, 1992

Sheet 3 of 3

5,148,775

FIG. 4

DRUM LEVEL STEAM FLOW DRUM PRESSURE FEEDWATER FLOW

Y 4,,

#18

I2

25

22

24 /

" A M70

/

;

34

'

2e

43 /"

76

M35 x 2.8

~ 29

44,,m)

72

37

32

33

45

'

38/IZ(K)

N39

46 / A| K U

48 w Min.(Mc>ut+ d/m (M)+ d/dt( 6M)+ ggggRLEvEL

FEEDWATER CONTROL VALVE

5,148,775

FEEDWATER CONTROL FOR DRUM TYPE STEAM GENERATORS

FIELD AND BACKGROUND OF THE INVENTION The present invention relates in general to an im proved feedwater control system for drum type steam

control 170, based on the PI value 165, will automati cally control a feedwater control valve 180 which ad justs the amount of feedwater 200 sent to the drum type steam generator. 5 Although a three element feedwater control system can provide satisfactory feedwater control when the boiler is operated at steady loads through the use of the

drum level set point 105 speci?ed in FIG. 1, it is incapa

generators, and in particular to a new and useful method 10 ble of handling great load changes at high rates of and apparatus for providing improved drum level con change because there is not a way for the system to trol to units which are subjected to great load changes account for the change in mass inventory within the

at high rates of change.

The current feedwater control systems for drum type -

circulation loop. The circulation loop existing as the water and water/steam circulation system comprises

the steam drum water space, the downcomers, the

steam generators include the popular three-element

feedwater control system which is a cascade-feedfor

ward control loop which maintains water ?ow input equal to feedwater demand. The system employs feed

back of the difference between the desired level as indi cated by the set point and the actual level to compensate

measurement errors etc.

supplies, the furnace water walls, the boiler bank and mud drum, risers and the water/steam annulus in the

steam drum.

The current state of the art in feedwater control sys

tems can only react to a change in mass inventory once for any system errors such as transmitter drift, flow 20

the drum level diverges from the set point. Thus, during

a load change, the drum level cannot be maintained.

A typical prior art feedwater control system is illus

trated in FIG. 1.

steam generators by incorporating changes in mass transmitter 110, a steam flow transmitter 120, and a inventory within the circulation loop enabling the sys feedwater ?ow transmitter 140. tem to control great load changes at high rates of The drum level transmitter 110 sends a drum level signal 112 to a difference unit 116 wherein the differ 30 change. In order to control great load changes, the control ence between the drum level signal 112 and a drum system maintains a constant drum level before and after level set point 105, originating from an analog control the load change such that the difference between the 170 is formed. The difference resulting from the com steam ?ow from the drum and the feedwater ?ow to the parison of the drum level signal 112 and the drum level 35 drum accounts for the change in the mass inventory set point 105 is the drum level error 108. A drum level indicator 114 displays the value of the within the circulation loop by a load and pressure drum level signal 112 sent by the drum level transmitter change. The circulation loop includes, for example, the 110. water and water/steam circulation system comprising > The transmitter 120 sends a differential pressure sig the steam drum water space, the downcomers, the nal 121 to a square root unit 122 for taking the square 40 supplies, the furnace water walls, the boiler bank and root of the signal 121 to determine the steam ?ow value mud drum, risers, and the water/steam annulus in the

123. '

SUMMARY OF THE INVENTION The present invention comprises a method and appa of feedwater 200 to a drum type steam generator 25 ratus for an improved feedwater control for drum type through three separate controls, namely a drum level

A feedwater control valve 180 controls the sending

A steam ?ow indicator 124 displays the steam ?ow The changes in mass inventory within the circulation value 123 after execution of the square root function by loop are incorporated into the feedwater control system the square root unit 122. 45 by the present invention based on the relationships The steam ?ow value 123 is then sent to a summation listed later in this disclosure. unit 128 which is a proportion controller which per An object of the present invention is, thus, to provide forms a summing function of the drum level error 108 a feedwater control system that adjusts for differences and the steam ?ow value 123 in order to determine a

steam drum.

in mass inventory before drum level changes are experi enced because a mechanism is provided to incorporate The differential pressure transmitter 140 sends a pres changes in mass. sure signal 141 to a feedwater ?ow square root unit 142 A further object of the invention is to provide a feed which performs a square root function on the signal 141. water control system that automatically adjusts to vary A feedwater ?ow indicator 144 displays the feedwater ?ow signal 143. 55 ing rates of change for load and pressure. A further object of the invention is to provide a feed The feedwater ?ow value 143 is sent to a signal lag water control system that operates automatically with unit 148 which delays the sending of the feedwater flow out relying upon ?xed feedwater demands for a timed value 143 for a period of time determined by the func period before releasing back to normal control. tion f(t) resulting in the signal lag value 150. A further object of the invention is to provide a feed A PI controller 160 serves as a proportional action~ water control system that accounts for differences in plus integral controller for the deviation between the boiler characteristics found in various boiler designs, output of the summer unit 128 and the output of the

summation value 130.

50

signal lag unit 148 (where A is the deviation, K is pro

namely mass inventory versus load or pressure because

portion and f is the integral) and determines the output

hand/auto station 170 which serves as the automatic

the invention relies upon the differential of the equation value 165 of the PI controller. 65 specific for each individual boiler type. A further object of the invention is to provide a feed Once determined, the Pl value 165 is then sent to the

water control system that accounts for all factors which affect drum level outside of factors attributable to drum

control station with bias for the system. The station

5,148,775

where

mm=Feedwater flow rate to the drum

shrink and swell from sever drum water sub-cooling or

lack thereof. A further object of the invention is to provide a feed water control system that accounts for both step changes and ramp changes in load or pressure. The various features of novelty which characterize the invention are pointed out with particularity in the

claims annexed to and forming a part of this disclosure.

Substituting for equations (1) and (2) gives:

7 Using the substitution:

For a better understanding of the invention, its operat

ing advantages and speci?c objects attained by its uses,

reference is made to the accompanying drawings and descriptive matter in which the preferred embodiments

of the invention are illustrated.

d/dt = (d/dn'iam) (dn'iom/dl) and d/dt = (d/dPd) (dPd/dt) gives

(5)

BRIEF DESCRIPTION OF THE DRAWINGS

Since the functional relationship per equations (1) and

(2) are known for any type of boiler, the differentials d/dmou,(f(n'1,,,,,)) and d/dPd(f(Pd)) can be determined and will be depend on the degree of the polymonial represented by equations (1) and (2). _

In the drawings:

FIG. 1 is a schematic drawing of the prior art for a three element control with remote set point for a drum type steam generator;

FIG. 2 is a graph plotting the change in mass inven 20 Thus, a relationship is developed, equation (5), which tory with steam ?ow according to the present inven determines the difference in feedwater flow and steam tiOn; ?ow required to maintain a constant drum level, for any FIG. 3 is a graph plotting the change in mass inven rate of change of load (d/dt(1i1,,,,,)) and pressure tory with drum pressure according to the present inven (d/dt(Pd)). 25 tion; and Referring now to the invention embodied in FIG. 4, FIG. 4 is a block diagram of the present invention. an improved feedwater control for drum type steam generators having a four element control comprises a DESCRIPTION OF THE PREFERRED drum level transmitter 10, a differential pressure trans EMBODIMENTS

The variation in the total mass within a circulation loop for a constant drum level can be determined for

changes in steam ?ow and changes in pressure. FIGS. 2 point 72 generated by a hand/auto-station 50. and 3 are graphical representations of necessary unit The drum level transmitter 10 sends the drum level circulation characteristics for boilers in general. signal 12 to a difference unit 70 which determines devia The total mass inventory in the circulation loop ver 35 tions between the drum level signal 12 and the drum sus the unit load is calculated on the basis of the normal level set point 72 set by the station 50. The resulting operating mode, i.e., constant pressure or sliding pres deviation measured by the difference unit 70 is the drum sure operation. FIG. 2 is a graphical illustration of the level error 76. change in mass inventory with steam ?ow utilizing the

mitter 20 for steam ?ow, a drum pressure transmitter 30 and a differential pressure transmitter 40 for feedwater ?ows. The invention also employs a drum level set

formula M =A--B(ri1,,,,)2

where M=mass in circulation loop; mom=steam flow rate from drum; and

The differential pressure transmitter 20 sends a flow signal 14 to a square root unit 22 which performs a square root function in order to determine the steam ?ow value 23. The steam ?ow value 23 is sent to three

proportional controller 24 which performs a propor C,D=constants. tionally function to the steam ?ow value 23 resulting in As a result, the following relationships would be known: 55 a proportional value 25.

The steam flow value 23 is sent to a ?rst summer or The mass inventory versus drum pressure is calcu 45 summation unit 34 which determines the proportional lated based on pressure variations from the normal. action of the steam ?ow value 23 in conjunction with FIG. 3 is a graphical illustration of the change in mass the drum level error 76 taken from the difference unit inventory with drum pressure utilizing the formula 70. The sum of the proportional action of the steam flow 6M=C(Pd)+D value 23 and the drum level error 76 is the ?rst summer where value 35. 5M=mass change increment due to pressure; Additionally, the steam ?ow value 23 is sent to a Pd=drum pressure; and

A,B=constants.

separate units.

M=mhwo

6M=f(Pd)

<1)

(2)

Also, the steam flow value 23 is sent to a steam ?ow derivative action rate unit 26 which determines the derivative action rate value 27 by performing a deriva tive action rate function on the steam flow value 23.

The rate of change of inventory would be given by:

d/dt (M) & d/dt (5M)

Both the proportional value 25 and the derivative action rate value 27 are taken by the multiplier 28 which performs a multiplication function to determine the

mass rate 29 of steam ?ow within the system identi?ed as d/dt(M), where M=f(ri10,,,). The difference in the rate of ?ow in and out of the The mass rate of 29 of the steam ?ow is sent to a drum should equal the rate of change of mass in the 65 second summer 36 along with the ?rst summer value 35 circulation loop-i.e.,: in order to determine the sum of proportional action of

the mass rate 29 and the ?rst summer value 35. The

5,148,775

resulting calculation after the summing function is per

formed, is a second summer value 37. The drum pressure transmitter 30 transmits a drum pressure signal 16 to a drum pressure derivative action rate unit 32 which determines the mass flow increment

feedwater ?ow measuring means for measuring ac tual feedwater ?ow to the steam generator;

summation means connected to the steam mass flow rate means and to the differential means for deter

mining a proportional action sum of the drum level

error value, the mass flow rate of steam and the rate of mass increment due to changes in steam

33 and is identi?ed by the formula d/dt(8M), where

8M=f(Pd). _ ,

The mass increment 33 is sent to a third summer 38

?ow and changes in drum pressure; and

calculation means connected to the summation means

where a summation function is performed on the mass increment 33 in conjunction with the second summer

value 37. The resulting summation of proportional ac

tion determined by the third summer 38 is a third sum

mer value 39.

and to the feedwater measuring means for calculat ing adjustments to the feedwater supply based on a proportional action sum of the drum level error,

the mass flow rate of steam and the rate of mass

The differential pressure transmitter 40 transmits a signal 18 to a feedwater ?ow square root unit 42 which 15 performs a square function on the pressure signal 18 resulting in a feedwater ?ow value 43.

increment due to changes in steam flow and drum pressure and feedwater ?ow, in order to maintain a

constant drum level; -

The feedwater value is then sent to a signal lag unit 44

which determines the signal lag value 45 by using the

value 43 as a function of the time identi?ed as f(t).

20

The signal lag value 45 and the third summer value 39 are sent to the PI (proportional integral) 46 identi?ed as

said calculation means being connected to the analog control means for supplying the adjustments to the analog control means for maintaining constant drum level while adjusting feedwater flow control to accommodate changes in load for the steam generator. 2. An apparatus according to claim 1, wherein the

where

A"Kl f,

A=deviation between the signal 39 and signal 45; K=proportional action

calculation means comprises square root means con nected to the steam mass ?ow rate means for taking a 25 square root of the steam mass ?ow rate, the square root

being supplied to the summation means, a proportional

76).

action controller and a differential action controller connected to the square root means for receiving the The PI 46 performs a proportional plus-integral ac tion upon the deviation signal in order to determine the 30 square root value, multiplication means connected to the proportional and differential action means for multi PI value 48. The PI value 48 is de?ned by the formula plying a proportional value by a differential value for mi" (mm + d/dt(M) + d/dt(5M) + drum level error the square root to form a mass rate value, second sum

I =integral action.

d/dt(M)+d/dt (8M)=rate of change of the total and to the ?rst mentioned summation means for forming mass inventory in the circulation loop while the drum 35 a second summation value which is supplied to the level error 76==deviation of drum level signal 12 from calculation means. drum level set point 72. 3. An apparatus according to claim 2, including dif The PI value 48 is taken by the hand/auto station 50 ferential drum pressure action means connected to the which provides automatic control with bias for the drum pressure mass increment means for taking a mass

system and is used to control the feedwater control

mation means connected to the multiplication means

increment due to change in drum pressure, and third

summation means connected to the second summation means and to the drum pressure proportional action rate

valve 60 which has the ?nal controlling function for the system and regulates the feedwater 200 for the system.

' While speci?c embodiments of the invention have

been shown and described in detail to illustrate the

application of the principles of the invention, it will be

understood that the invention may be embodied other

45

means, forming part of the calculation means for apply ing the adjustments to the analog control means. 4. A method of improving feedwater control for drum type steam generators which undergo load

wise without departing from such principles.

What is claimed is: 1. An apparatus for improving feedwater control to a drum type steam generator which undergoes load 50

changes, comprising:

setting a drum level set point and controlling feedwa

ter flow in a steam generator to maintain a selected

changes, comprising:

drum level; determining the difference between the drum level

set point and an actual drum level to form a drum

analog'control means for setting a drum level set

point;

drum level measuring means for measuring an actual drum level for the steam generator; 55 differential means connected to the analog control means and to the drum level measuring means for

determining a drum level error value as a differ

level error value;

determining a mass rate for the steam generator based

on changes in steam flow;

determining a mass rate increment for the system

based on changes in drum pressure; calculating a proportional action sum of the drum

level error, the mass rate of steam ?ow, the mass

ence between the drum level set point and the

actual drum level;

steam mass flow rate means for determining a steam mass ?ow rate for steam from the steam generator; mass increment means for determining a rate of mass

rate for the change in steam ?ow and the mass rate

increment for change in drum pressure; calculating adjustments in the system to account for

the mass rate of steam ?ow, the mass rate for the

65

increment for the steam based on changes in steam

flow;

mass increment means for determining a rate of mass

change in steam flow, the mass rate increment for changes in drum pressure and feedwater ?ow in the system; and maintaining a constant drum level based on the calcu

increment for the steam generator based on

lated adjustments.

4 8 t t #

changes in drum pressure;

S-ar putea să vă placă și

- Wedding ChecklistDocument15 paginiWedding Checklistபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- Question 1 (15 Marks)Document5 paginiQuestion 1 (15 Marks)Farouk BassaÎncă nu există evaluări

- Dokumen - Tips Pipe Insulation THK Calculation 55846188ba816Document9 paginiDokumen - Tips Pipe Insulation THK Calculation 55846188ba816Diksha surekaÎncă nu există evaluări

- Partial Discharge Testing and AC Characterization of HV Connectors and TerminationsDocument5 paginiPartial Discharge Testing and AC Characterization of HV Connectors and Terminationsابو شهدÎncă nu există evaluări

- Industrial BoilerDocument30 paginiIndustrial Boilerஇராம் பாபுÎncă nu există evaluări

- Cooling Tower Evaporation, Heat and Mass Balance CalculationDocument1 paginăCooling Tower Evaporation, Heat and Mass Balance CalculationSachin TechguideÎncă nu există evaluări

- Arc Calculation DCDocument16 paginiArc Calculation DCmike mikeÎncă nu există evaluări

- Ii2Geexiaiict6: Device Group Ignition Prote-Ction Class Temperature Class Explosion Group Category IdentifierDocument7 paginiIi2Geexiaiict6: Device Group Ignition Prote-Ction Class Temperature Class Explosion Group Category IdentifierClaudio GonzalezÎncă nu există evaluări

- Furnace Explosion in CFBC BoilersDocument6 paginiFurnace Explosion in CFBC BoilersHardik Kumar MendparaÎncă nu există evaluări

- 1.3.2 Air Cooler: T Tin ToutDocument3 pagini1.3.2 Air Cooler: T Tin ToutRita YuliandaÎncă nu există evaluări

- Mov's DetailsDocument13 paginiMov's DetailsArjun ThakurÎncă nu există evaluări

- BOX-V2 User Manual - R5Document40 paginiBOX-V2 User Manual - R5mahmoudzaki100% (1)

- Chapter 5 Energy Balance April 10 2017.v2Document31 paginiChapter 5 Energy Balance April 10 2017.v2kennethmsorianoÎncă nu există evaluări

- Life Time Deterioration of Turbine ComponentsDocument10 paginiLife Time Deterioration of Turbine Componentsபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- UPS SizingDocument2 paginiUPS SizingRoumya Darshan RayÎncă nu există evaluări

- Three Element Boiler Drum Level ControlDocument63 paginiThree Element Boiler Drum Level ControlYuthish Prabakar100% (1)

- Grid Stability SVC STATCOM - APTranscoDocument30 paginiGrid Stability SVC STATCOM - APTranscosriramojÎncă nu există evaluări

- Eff. of HarmonicsDocument7 paginiEff. of HarmonicsSwapnil SawantÎncă nu există evaluări

- Condenser Calculation, Using Thermo Utilities v2Document2 paginiCondenser Calculation, Using Thermo Utilities v2Ram MohanÎncă nu există evaluări

- Control of Flow Rates at Startup: GAT2004-GKP-2010.009 September, 2010Document2 paginiControl of Flow Rates at Startup: GAT2004-GKP-2010.009 September, 2010Enyerberht Castañeda BritoÎncă nu există evaluări

- Boiler ControlsDocument27 paginiBoiler ControlsMY NAME IS NEERAJ..:):)Încă nu există evaluări

- Evaporation Falling Film Forced Circulation Vapor Recompression Gea 170546Document20 paginiEvaporation Falling Film Forced Circulation Vapor Recompression Gea 170546Johan van der MenerÎncă nu există evaluări

- Condensate Line SizingDocument4 paginiCondensate Line SizingMubin Ashraf SheikhÎncă nu există evaluări

- DP LT CalibrationDocument6 paginiDP LT CalibrationkvsangeethÎncă nu există evaluări

- Kaydon Dry Gas SealDocument12 paginiKaydon Dry Gas Sealxsi666Încă nu există evaluări

- Vortex TubeDocument25 paginiVortex TubePrasad Patil100% (1)

- HY10 1630US 5 2012-Diaphragm AccumulatorsDocument6 paginiHY10 1630US 5 2012-Diaphragm AccumulatorsAlejandro GilÎncă nu există evaluări

- Redapt Hazardous Area GuideDocument11 paginiRedapt Hazardous Area GuidekarthipetroÎncă nu există evaluări

- Basket FilterDocument8 paginiBasket Filterarachman297988Încă nu există evaluări

- Dga 900 A4Document2 paginiDga 900 A4LaurentiuÎncă nu există evaluări

- SLD For 3ph Batt - Charger With DCDBDocument1 paginăSLD For 3ph Batt - Charger With DCDB1382aceÎncă nu există evaluări

- Technical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Document12 paginiTechnical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Bijaya Kumar MohantyÎncă nu există evaluări

- GTP of 132 KV CT & PTDocument5 paginiGTP of 132 KV CT & PTgohilnarendraÎncă nu există evaluări

- Facts at Your Fingertips: Variable Frequency DrivesDocument1 paginăFacts at Your Fingertips: Variable Frequency Drivesagrocel_bhv5591Încă nu există evaluări

- Fault Current Calculation V7 1Document6 paginiFault Current Calculation V7 1Pedro ComodoroÎncă nu există evaluări

- Stahl11 eDocument144 paginiStahl11 eCarlos Veron100% (1)

- Micro ScannerDocument2 paginiMicro ScannerArun KumarÎncă nu există evaluări

- Self Excitation of Induction MotorsDocument5 paginiSelf Excitation of Induction MotorsDiego Nicolás López-RamírezÎncă nu există evaluări

- Power PlantDocument28 paginiPower PlantSanjay SharmaÎncă nu există evaluări

- Seminar Topic On: Circuit Breaker-IDocument25 paginiSeminar Topic On: Circuit Breaker-IParameshwar TummetiÎncă nu există evaluări

- ABB ADVAC Circuit Breaker BrochureDocument20 paginiABB ADVAC Circuit Breaker BrochurepitarrilloÎncă nu există evaluări

- 10mva GTP - 01.04.2019Document5 pagini10mva GTP - 01.04.2019Shahriar AhmedÎncă nu există evaluări

- Expansion Indicator Boiler #1Document6 paginiExpansion Indicator Boiler #1Muhammad AbyÎncă nu există evaluări

- Automatic Slip RegulatorDocument4 paginiAutomatic Slip RegulatorRajesh ThulluriÎncă nu există evaluări

- TeSys - Selection - Guide - IE3-IE4 Type 2 Coordination ChartsDocument26 paginiTeSys - Selection - Guide - IE3-IE4 Type 2 Coordination Chartskatgokul69100% (1)

- 0626-REF CT CALCS New Not ReviewedDocument2 pagini0626-REF CT CALCS New Not ReviewedtceterexÎncă nu există evaluări

- Skin Effect Heat Management SystemDocument19 paginiSkin Effect Heat Management SystemPIpelinesTebodinÎncă nu există evaluări

- Siemens: Motor Type: 1PQ8 356-XXXX-X N-Compact SeriesDocument3 paginiSiemens: Motor Type: 1PQ8 356-XXXX-X N-Compact SeriesDhirender KapoorÎncă nu există evaluări

- Fuse Selection ProcessDocument8 paginiFuse Selection ProcessUsman Asghar SandhuÎncă nu există evaluări

- Detronics UV-IR Flame Detector Model X5200Document2 paginiDetronics UV-IR Flame Detector Model X5200selvajanarÎncă nu există evaluări

- Bhel Mini Pro Report On Turbo Generators 1Document53 paginiBhel Mini Pro Report On Turbo Generators 1Akirakumar100% (1)

- CFCB Bed Ash CoolerDocument11 paginiCFCB Bed Ash CoolerUdhayakumar VenkataramanÎncă nu există evaluări

- TR SetsDocument2 paginiTR SetsShambhu Poddar100% (1)

- Manual Contactor Lc1dfk Lc1dgk Lc1dpk Lc1dwk (Conde.)Document4 paginiManual Contactor Lc1dfk Lc1dgk Lc1dpk Lc1dwk (Conde.)joseÎncă nu există evaluări

- Desuperheater Sizing CalculationDocument1 paginăDesuperheater Sizing CalculationErnestoÎncă nu există evaluări

- The Transfer Function Method For Detection of Winding Displacements On Power TransformersDocument14 paginiThe Transfer Function Method For Detection of Winding Displacements On Power TransformersShravan BhattÎncă nu există evaluări

- Properties of Gases, Liquids, and Solutions: Principles and MethodsDe la EverandProperties of Gases, Liquids, and Solutions: Principles and MethodsÎncă nu există evaluări

- Hydraulic Control SystemDocument16 paginiHydraulic Control SystemHeerok Kumar100% (1)

- Experiment 8 - FreeDocument15 paginiExperiment 8 - Freeluis_uni_fimÎncă nu există evaluări

- Once Through Boiler Recirculation PumpDocument6 paginiOnce Through Boiler Recirculation Pumpபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- 20080012322-Vortex Flow ControlDocument10 pagini20080012322-Vortex Flow Controlozland9Încă nu există evaluări

- Drum LVL Control by PkgangwarDocument13 paginiDrum LVL Control by Pkgangwarank_mehraÎncă nu există evaluări

- Us4177950 PDFDocument7 paginiUs4177950 PDFThang Cao DaiÎncă nu există evaluări

- BoilerDocument21 paginiBoilerJITHIN PÎncă nu există evaluări

- Taller Final de EjerciciosDocument7 paginiTaller Final de EjerciciosEduar QuirozÎncă nu există evaluări

- RRB NTPC Important NoticeDocument1 paginăRRB NTPC Important Noticeபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- IEEE Standards Applicable For Electrical EngineersDocument5.341 paginiIEEE Standards Applicable For Electrical Engineersபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- Equal Area Criterion Power System DynamicsDocument28 paginiEqual Area Criterion Power System Dynamicsபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- HART Protocol in Head Mounted TTDocument5 paginiHART Protocol in Head Mounted TTபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- Hart Din Rail Temperature TransmitterDocument3 paginiHart Din Rail Temperature Transmitterபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- GATE 2016 List of Defective ApplicationsDocument285 paginiGATE 2016 List of Defective Applicationsபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- Electric Machinery 6ed Fitzgerald - Kingsley - Uman - C2Document15 paginiElectric Machinery 6ed Fitzgerald - Kingsley - Uman - C2பிரசன்னகுமார் ஆனந்தன்100% (1)

- Technical Specification PE 100-TB - PE 100-TE - PE 100-TW: Mobile High Pressure Compressor Für Breathing AirDocument5 paginiTechnical Specification PE 100-TB - PE 100-TE - PE 100-TW: Mobile High Pressure Compressor Für Breathing AirChieuÎncă nu există evaluări

- Product Information VDROO20-10: Project Name Item NODocument7 paginiProduct Information VDROO20-10: Project Name Item NODado FahssaÎncă nu există evaluări

- Industrial Steam Tray ST5 PDFDocument4 paginiIndustrial Steam Tray ST5 PDFKim Swee LimÎncă nu există evaluări

- Spec. No. E) CRX75C: Orion Machinery Co., LTDDocument5 paginiSpec. No. E) CRX75C: Orion Machinery Co., LTDHa CongÎncă nu există evaluări

- Correction in Tutorial 4Document12 paginiCorrection in Tutorial 4Spam AccÎncă nu există evaluări

- Hydrostatic Measurements FinalDocument8 paginiHydrostatic Measurements FinalalexÎncă nu există evaluări

- Dehydration of Natural Gas by Solid DesiccantDocument20 paginiDehydration of Natural Gas by Solid DesiccantMadhankumar LakshmipathyÎncă nu există evaluări

- John Thompson Electropac Boiler BrochureDocument2 paginiJohn Thompson Electropac Boiler BrochureARIYO ANINDITOÎncă nu există evaluări

- BREAKDOWNDocument74 paginiBREAKDOWNAlexis MUHIRWAÎncă nu există evaluări

- Design Details of A Turbine Model Used For Energy Conversion in Low Flow Rate Water StreamsDocument5 paginiDesign Details of A Turbine Model Used For Energy Conversion in Low Flow Rate Water Streamsrabei romulusÎncă nu există evaluări

- Vapour Compression Refrigeration PDFDocument5 paginiVapour Compression Refrigeration PDFjose100% (1)

- Energy Conservation in Reciprocating CompressorDocument5 paginiEnergy Conservation in Reciprocating CompressorRuturaj UmaranikarÎncă nu există evaluări

- Two Screw Pumps: Reprint From Petromin October Issue 1994Document4 paginiTwo Screw Pumps: Reprint From Petromin October Issue 1994Luis ReyesÎncă nu există evaluări

- Appendix 8.5 Equipment DatasheetsDocument20 paginiAppendix 8.5 Equipment DatasheetsIboniks Beponpiks DabondatskiÎncă nu există evaluări

- What Is FlarebackDocument3 paginiWhat Is FlarebackVince Saavedra100% (1)

- Pressure Distribution Around A Symmetrical AerofoilDocument18 paginiPressure Distribution Around A Symmetrical Aerofoilabrahamaudu100% (2)

- Me 6302 HW 3Document2 paginiMe 6302 HW 3dsblendo0% (1)

- LP Gas Container Fact SheetDocument3 paginiLP Gas Container Fact SheetCONSULTORIA Y PM COALSAÎncă nu există evaluări

- Questions Refrigeration and Air ConditioningDocument4 paginiQuestions Refrigeration and Air ConditioningGp MishraÎncă nu există evaluări

- Partida 1 y 2. LI-10411A LI-10413A Indicador Jerguson Magnicator Magnetic Liquid Level Products BrochureDocument20 paginiPartida 1 y 2. LI-10411A LI-10413A Indicador Jerguson Magnicator Magnetic Liquid Level Products BrochureAndree' WsÎncă nu există evaluări

- QB 114335Document6 paginiQB 114335Vijay AnandÎncă nu există evaluări

- 2019-12-20 Reboiler - Spec. SheetDocument1 pagină2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaÎncă nu există evaluări

- Atmosphere of EarthDocument17 paginiAtmosphere of EarthAlfonso Carlos Gutierrez MartinezÎncă nu există evaluări

- Module 1 - Introduction To Fluid MechanicsDocument94 paginiModule 1 - Introduction To Fluid MechanicsFarhan Shajahan100% (1)

- 3.2. Contraction: Design Methodology For A Quick and Low-Cost Wind Tunnel 9Document2 pagini3.2. Contraction: Design Methodology For A Quick and Low-Cost Wind Tunnel 9Dang Tien PhucÎncă nu există evaluări

- Study of A Single Pass Shell and Tube Heat ExchangerDocument21 paginiStudy of A Single Pass Shell and Tube Heat Exchangermahbub1332Încă nu există evaluări

- ASTM D1657-12 Densidad o Densidad Relativa de Hidrocarburos LigerosDocument6 paginiASTM D1657-12 Densidad o Densidad Relativa de Hidrocarburos LigerosDiana Alejandra Castañón IniestraÎncă nu există evaluări