Documente Academic

Documente Profesional

Documente Cultură

MDSW Karnataka10

Încărcat de

miningnova1Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MDSW Karnataka10

Încărcat de

miningnova1Drepturi de autor:

Formate disponibile

M/s Mysore Minerals Limited

(A Govt. of Karnataka Undertaking)

# 39, M.G. Road, Bangalore – 560 001.

Rapid Environmental Impact Assessment

and

Environment Management Plan

(Winter Season Dec. 2006 –Feb. 2007)

FOR

“Chikkashellikeri Limestone Mines”

M. L. NO. - 2494

(Extent:- 64.35 ha.)

(Increase of Production from 0.12 to 0.250 million

tonnes per annum)

at

Chikkashellikeri Village, Bagalkot Taluk, Bagalkote

KARNATAKA

Prepared By

NETEL (INDIA) LIMITED

S. V. Road, Manpada, Thane – 400 607

Tel: 2589 0110/111 (D) 2589 2191 Fax: 022-2589 0976

E-mail: ems@netel-india.com

Website: www.netel-india.com

Rapid – EIA Study Contents

TABLE OF CONTENT

TABLE OF CONTENT.................................................................................................ii

LIST OF TABLES........................................................................................................vi

LIST OF FIGURES .....................................................................................................vii

EXECUTIVE SUMMARY ...........................................................................................1

CHAPTER 1 ..................................................................................................................1

1.1 PREAMBLE ...................................................................................................1

1.2 NEED FOR PROJECT ...................................................................................1

1.3 NEED FOR REIA/EMP .................................................................................1

1.4 METHODOLOGY OF THE STUDY ............................................................2

1.5 STRUCTURE OF EIA REPORT ...................................................................3

CHAPTER 2 ..................................................................................................................5

PROJECT DESCRIPTION............................................................................................5

2.1 INTRODUCTION ..........................................................................................5

2.2 PROJECT LOCATION ..................................................................................5

2.3 ACCESSIBILITY ...........................................................................................5

2.4 APPROVALS ACCORDED ..........................................................................8

2.5 PROJECT COST ............................................................................................8

2.6 PHYSIOGRAPHY..........................................................................................8

2.7 GEOLOGY AND RSERVES .........................................................................8

2.7.1 Black Cotton Soil .................................................................................9

2.7.2 Shale ......................................................................................................9

2.7.3 Dolomitic limestone..............................................................................9

2.7.4 High Calcium Limestone (Grey Limestone)......................................9

2.7.5 Reserves ................................................................................................9

2.7.6 Mineralogy..........................................................................................11

2.8 MINING........................................................................................................11

2.9 MINE DEVELOPMENT AND PRODUCTION .........................................12

2.9.1 Stacking of Mineral rejects and Disposal of Waste .......................12

2.10 BLASTING...................................................................................................13

2.10.1 Burden, Spacing, Depth and Sub Grade Drilling ..........................13

2.10.2 Explosives...........................................................................................13

2.10.3 Secondary Blasting............................................................................13

2.10.4 Explosive Requirement and Storage ...............................................13

2.10.5 Extent of Mechanism ........................................................................14

2.11 MINERAL BENIFICATION .......................................................................14

2.11.1 Mineral Processing.............................................................................14

2.12 ENVIRONMENTAL RESOURCE REQUIREMENT ................................15

2.12.1 Water...................................................................................................15

2.12.2 Workforce...........................................................................................16

2.10.3 Power Requirement ...........................................................................17

2.10.4 First Aid Station.................................................................................17

CHAPTER - 3 ..............................................................................................................18

BASELINE ENVIRONMENTAL STATUS ..............................................................18

3.1 INTRODUCTION ........................................................................................18

3.2 STUDY AREA .............................................................................................18

3.3 METEOROLOGY ........................................................................................19

3.4 AIR ENVIRONMENT .................................................................................25

3.4.1 Methodology adopted and Selection of sampling locations ...........26

M/s Netel (India) Ltd. ii

Rapid – EIA Study Contents

3.4.2 Details of sampling locations.............................................................28

3.4.3 Sampling and Analytical Techniques...............................................29

3.4.4 Results of AAQM ...............................................................................30

3.5 NOISE ENVIRONMENT ............................................................................33

3.5.1 Selection of Locations for Monitoring..............................................34

3.5.2 Results .................................................................................................34

3.6 WATER ENVIRONMENT ..........................................................................35

3.6.1 Methodology .......................................................................................35

3.6.2 Ground Water Sampling Locations .................................................36

3.6.3 Results of Ground Water Samples ...................................................38

3.6.4 Surface Water.....................................................................................38

3.6.5 Surface Water Sampling Locations..................................................38

3.6.6 Results of Surface Water Samples....................................................39

3.7 LAND ENVIRONMENT .............................................................................39

3.7.1 Mine Drainage....................................................................................41

3.8 LAND USE...................................................................................................43

3.8.1 Core Zone ...........................................................................................43

3.8.2 Buffer Zone.........................................................................................43

3.9 BIOLOGICAL ENVIRONMENT................................................................45

3.9.1 Objectives for Ecological Studies .....................................................45

3.9.2 Ecology of mining site and dumping site .........................................46

3.9.3 Flora ....................................................................................................46

3.9.4 Fauna...................................................................................................47

3.10 DEMOGRAPHY AND SOCIO - ECONOMICS.........................................47

3.10.1 Methodology Adopted for the Study ................................................47

3.10.2 Demographic ......................................................................................48

3.10.3 Socio economic profile .......................................................................48

CHAPTER 4 ................................................................................................................51

IMPACT PREDICTION..............................................................................................51

4.1 INTRODUCTION ........................................................................................51

4.2 IDENTIFICATION OF IMPACTS ..............................................................51

4.2.1 Mining Operations .............................................................................51

4.2.2 Limestone Crushing...........................................................................52

4.2.3 Associated Infrastructure..................................................................52

4.3 CLIMATE.....................................................................................................53

4.4 AMBIENT AIR QUALITY..........................................................................53

4.4.1 Occupational Health Hazards Due to Dust Pollution....................55

4.5 NOISE ENVIRONMENT ............................................................................56

4.5.1 Occupational Health Hazards of Noise Pollution ...........................58

4.6 GROUND VIBRATIONS ............................................................................59

4.7 WATER ENVIRONMENT ..........................................................................60

4.7.1 Impacts on Surface Water.................................................................60

4.7.2 Impacts of Mining on Ground Water ..............................................61

4.8 LAND USE...................................................................................................62

4.8.1 Soil .......................................................................................................63

4.9 SOLID WASTE DISPOSAL........................................................................63

4.10 ECOLOGICAL IMPACTS...........................................................................64

4.11 SOCIO-ECONOMIC IMPACTS..................................................................64

CHAPTER 5 ................................................................................................................65

IMPACT EVALUATION ...........................................................................................65

M/s Netel (India) Ltd. iii

Rapid – EIA Study Contents

5.1 APPROACH .................................................................................................65

5.2 IMPACT ON AIR ENVIRONMENT ..........................................................65

5.2.1 Quantitative Estimation of Impacts on Air Environment..............65

5.2.2 Sources of Dust Emission ..................................................................66

5.2.3 Emission Details .................................................................................66

5.2.4 Summary of Predicted Ground Level Concentrations (GLC’S) of

SPM .....................................................................................................69

5.2.5 Impact due to Transportation...........................................................70

5.3 ENVIRONMETAL IMPACT MATRIX......................................................71

5.4 PROJECT SPECIFIC EVALUATION ........................................................73

5.4.1 PIV For Environmental Components ..............................................73

5.4.2 Relative Parameter Importance Index (RPII) ................................75

5.4.3 Environmental Impact Index (EII) ..................................................76

5.4.4 Weighted Environmental Impact Index (WEII).............................84

5.5 POTENTIAL IMPACT IDENTIFICATION WITHOUT MITIGATIVE

MEASURES .................................................................................................84

5.6 SUMMARY OF IMPACTS .........................................................................84

5.7 POTENTIAL IMPACT IDENTIFICATION WITH MITIGATIVE

MEASURES .................................................................................................85

5.8 RESIDUAL IMPACT IDENTIFICATION..................................................85

CHAPTER 6 ................................................................................................................86

ENVIRONMENTAL MANAGEMENT PLAN..........................................................86

6.1 INTRODUCTION ........................................................................................86

6.2 AMBIENT AIR QUALITY MANAGEMENT............................................86

6.2.1 Controlling Dust Level ......................................................................86

6.2.2 Controlling CO Levels.......................................................................87

6.2.3 Controlling NOX Levels.....................................................................87

6.2.4 Green Belt ...........................................................................................88

6.2.5 Occupational Health & Safety Measures to Control Dust

Inhalation............................................................................................88

6.3 NOISE POLLUTION CONTROL ...............................................................88

6.3.1 Occupational Health and Safety Measures to Control Exposure to

Noise ....................................................................................................89

6.4 CONTROL OF GROUND VIBRATIONS & FLY ROCKS BOULDER ...89

6.5 WATER QUALITY MANAGEMENT........................................................90

6.5.1 Water Resources ................................................................................90

6.5.2 Water Management ...........................................................................90

6.6 LAND MANAGEMENT..............................................................................91

6.6.1 Land Reclamation..............................................................................91

6.6.2 Top Soil Management........................................................................94

6.7 AFFORESTATION PLAN...........................................................................95

6.7.1 Afforestation Already Carried Out..................................................96

6.7.2 Afforestation Proposed......................................................................96

6.7.3 Stage Wise Cumulative Plantation ...................................................96

6.8 SOLID WASTE MANAGEMENT ..............................................................97

6.9 OCCUPATIONAL HEALTH & HYGIENE................................................98

6.10 PROPOSED SOCIAL DEVELOPMENT ACTIVITIES ...........................102

6.11 ENVIRONMENTAL CONTROL & MONITORING PROGRAMME ....102

6.11.1 Environmental Management Cell (EMC) .....................................102

6.11.2 Monitoring Schedule and Parameters ...........................................103

M/s Netel (India) Ltd. iv

Rapid – EIA Study Contents

6.11.3 Budget Provision for EMP ..............................................................104

CHAPTER 7 ..............................................................................................................106

DISASTERS MANAGEMENT PLAN.....................................................................106

7.1 DEFINITION..............................................................................................106

7.2 SCOPE ........................................................................................................106

7.3 IDENTIFICATION AND ASSESSMENT OF HAZARDS ......................106

7.4 CONTROL MEASURES FOR HAZARDS/DISASTERS ........................107

7.5 ONSITE EMERGENCY PLAN .................................................................107

ANNEXURES ...........................................................................................................110

M/s Netel (India) Ltd. v

Rapid – EIA Study List of Tables

LIST OF TABLES

Table 1.1: Survey of Environmental Attributes.............................................................3

Table 2.1: Site Details....................................................................................................5

Table 2.2: Geological Reserves .....................................................................................9

Table 2.3: Salient features of the Mine........................................................................11

Table 2.4: Development and Production Proposals.....................................................12

Table 2.5: Requirement of Mining Machineries..........................................................14

Table 2.6: Water Requirement for the Mining Operations ..........................................15

Table 2.7: Manpower Requirement .............................................................................16

Table 3.1: Meteorological Data monitored at the Project Site....................................21

Table 3.2: Details of Ambient Air Quality Monitoring Stations .................................28

Table 3.3: Details of AAQM Parameters and Frequency of Sampling .......................28

Table 3.4: Methods used for Ambient Air Quality Monitoring...................................30

Table 3.5: Summary of the Ambient Air Quality Monitoring .....................................31

Table 3.6: National Ambient Air Quality Standards (NAAQS) ..................................33

Table 3.7: Details of Noise Monitoring Locations ......................................................34

Table 3.8: Noise Monitoring Results in the Study area ...............................................34

Table 3.9: Ambient Noise Quality Standards ..............................................................35

Table 3.10: Details of Ground Water Sampling Locations..........................................38

Table 3.11: Details of Surface Water Sampling Locations..........................................39

Table 3.12: Details of Soil Sampling Locations ..........................................................41

Table 3.13: Land Use Pattern of Mining Lease Area ..................................................43

Table 3.14: Landuse Pattern of Buffer Zone ...............................................................43

Table 3.15: Distribution of Literates............................................................................49

Table 4.1: Effects of Air Pollutants on Plants and Animals ........................................55

Table 4.2: Summary of Impact Assessment: Air Quality ............................................56

Table 4.3: Noise Exposure Levels and Its Effects .......................................................59

Table 4.4: Summary of Impact Assessment: Water Resources ...................................62

Table 4.5: Summary of Impact Assessment: Soil and Land-use .................................63

Table 5.1: Emissions Details........................................................................................67

Table 5.2: Overall Scenario .........................................................................................69

Table 5.3: Estimation of Tippers for Transport ...........................................................71

Table 5.4: Determination of EII for Category "A" Parameters....................................73

Table 5.5: Determination of EII for Category "B" Parameters....................................73

Table 5.6: Determination of PIV .................................................................................75

Table 5.7: Potential Impact Identification Matrix( Without Environmental

Management Plan) .......................................................................................................77

Table 5.8 : Potential Impact Identification Matrix (With Environment management

Plan i.e. with Mitigative Measures) .............................................................................81

Table 5.9: Impact Matrix Without Mitigative Measures .............................................84

Table 5.10:Impact Matrix with Mitigative Measures ..................................................85

Table 6.1: Stagewise Reclamation/Afforestation plan.................................................93

Table 6.2: Conceptual landuse plan (Post mining) ......................................................94

Table 6.3: Afforestation Already Carried Out .............................................................96

Table 6.4: Afforestation Proposed ...............................................................................96

Table 6.5:Stage Wise Cumulative Plantation ..............................................................97

Table 6.6: Suggested Monitoring Program................................................................104

Table 6.7: Budget for Environmental Protective Measures in Rs. Lakhs..................105

M/s Netel (India) Ltd. vi

Rapid – EIA Study List of Figures

LIST OF FIGURES

Figure 2.1: Location Map............................................................................................6

Figure 2.2: Mine Layout Plan/Surface Plan ..............................................................7

Figure 2.3: Geological Map of Mining Area............................................................10

Figure 2.4: Schematic Diagram of the Tentative Flow Sheet of Crusher .............15

Figure 3.1: Study Area within 10 km Radius from Project Site............................19

Figure 3.2 : Windrose for the Month of December 2006........................................22

Figure 3.3 : Windrose for the Month of January 2007...........................................23

Figure 3.4 : Windrose for the Month of February 2007.........................................24

Figure 3.5 : Windrose for the Month of December 2006 to February 2007 .........25

Figure 3.6: Locations of Ambient Air & Noise Quality Monitoring Stations ......27

Figure 3.7: Locations of Water Quality Monitoring Stations................................37

Figure 3.8: Locations of Soil Monitoring Stations ..................................................40

Figure 3.9: Drainage Plan of Study Area.................................................................42

Figure 3.10: Land Use Plan of Core Zone ...............................................................44

Figure 3.11: Occupational Pattern of the Study Area ............................................49

Figure 4.1: Predicted Noise Levels ...........................................................................58

Figure 5.1: Predicted Ground Levels Concentrations............................................70

Figure 6.1: Conceptual Post Mining Land Use Plan ..............................................95

Figure 6.2: Environment Management Plan ...........................................................99

Figure 6.3: Waste Management Plan for end of mining ......................................100

Figure 6.4: Sections of Waste Management Plan..................................................101

Figure A: Conceptual Mining Plan ........................................................................151

M/s Netel (India) Ltd. vii

Rapid – EIA Study Executive Summary

EXECUTIVE SUMMARY

INTRODUCTION

M/s Mysore Minerals Limited is a Government of Karnataka undertaking established

in the year 1966 with main objective of systematic mining and planned development

of mineral resources in the State. The main activities of the company are Exploration,

Development of Mineral Resources, Exploitation and Marketing of Minerals and

granites.

The existing production capacity at Chikkashellikeri Limestone Mine is only 0.12

million tonnes per annum. In view of great demand for Limestone ore and

commitment made for long term agreement, management has decided to increase the

production from 0.120 million tonnes per annum to 0.250 million tonnes per annum at

Chikkashellikeri limestone mine. The following approvals have been obtained from

concerned government departments

• Mining Lease granted : 26-04-1999

• Mining Plan approved by IBM : 10/04/2007

In order to evaluate the potential impacts that would arise due to increase of

production from 0.120 million tonnes per annum to 0.250 million tonnes per annum at

Chikkashellikeri Limestone Mines of MML, studies were carried out by M/s. Netel

India Ltd. during December 2006 to February 2007 covering air, water, Noise, land,

etc., as per the EIA guidelines laid by MoEF and various authorities. The findings of

study carried out during winter season are presented in this report.

LOCATION

Site Details

District & State Bagalkote District, Karnataka State

Taluka Bagalkote

Village Chikkashellikeri

Mine Lease Area 64.35 Ha

Type of the Area Patta Land

Survey of India Toposheet No 47/P/12

Latitude 16°8’00”N to 16°09’11”N

Longitude 75°31’11”E to 75°35’55”E

PROJECT DISCRIPTION

Geology

The mine area falls in Survey of India Topo Sheet No. 47/P/12. The lease area forms a

part of Kaladgi basin sedimentary formation of “Precambrain Era”. The following

geological stratigraphic sequence is identified for this region.

M/s Netel (India) Ltd. 1

Rapid – EIA Study Executive Summary

Geological Age Formation Lithology

Recent Precambrain ---- Black cotton soil

Precambrain Kaladgi Group Limestone Shale

Unconformity ----

Archean Granitic Gneises ----

The following geological formations/ exposures are observed in the lease area.

1. Thinly bedded, Soil /Black Cotton Soil

2. Shale

3. Dolomitic Limestone

4. Gray Limestone

Black Cotton Soil

The area is mainly covered by back soil of varying thickness (1 m to 2 m). The

contact between dolomite and high calcium limestone is well exposed. The general

strike of the formation is N 750 W to 750E and dipping 450 to 500 south observed in

the lease area.

Shale

The Shale is exposed in the Northern and Eastern end of the lease area. It exhibits

marine and gray to purple colour, compact less laminated and slaty. These shale bands

are exposed over a distance of 150 m to 120 m. with an average width of 80 m.

Dolomitic limestone

Prominent exposures of dolomitic limestone are observed to the Eastern side of the

lease area under laying the thin layer of black cotton soil it is traversed by a number

of silica veins these are striking almost parallel to the limestone deposit and dipping

450 to 600 South at different places. Dolomites are fine to medium grained and white

to gray in color it is comparatively hard.

High Calcium Limestone (Grey Limestone)

The Limestone bands are well exposed in the eastern and western part of the lease

area. These are intercalated with thin ribbon of shale and dolomite. Thin Veins of

Calcite are noticed at one or two locations in the exposed bands. The High Calcium

limestone presents a weathered surface as a smooth appearance with small potholes

which is very characteristic.

Reserves

Based on the exploration carried out, exposed ore body and other available

information, the geological reserves estimated by standard cross sectional method the

details are given in following table

M/s Netel (India) Ltd. 2

Rapid – EIA Study Executive Summary

Geological Reserves

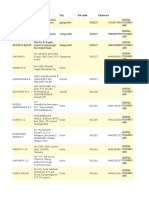

Sr. No. Reserves Type Insitu Reserves Mineable

Reserve in Tonnes

1 Proved 2,57,48,650 2,18,86,360

2 Probable 1,29,78,600 1,10,31,810

3 Total 3,87,27,250 3,29,18,170

Topography and drainage

In general the area is having flat topography. The general ground level varies from

521 to 548 meter above MSL. One seasonal nullah which flows in rainy season cuts

the lease area in two halves from South East corner to North West corner. This nullah

flows in North West direction. Based on observations made in the area, the water

table in the area is around 60-75 m below the ground level

Details of Production

The details of development & production proposed for 3 years i.e. 2006-09 is given

below

Development and Production Proposals

Years

Sr. No. 2006-07 2007-08 2008-09

Particulars

Development

1 4,341 5,346 5,598

(tonnes)

Production

2 1,94,970 2,40,075 2,51,715

(tonnes)

Equipment Details

The list of machinery to be deployed during the mining operation in the subject area is

as follows

Requirement of Mining Machineries

Sr.

Equipment Capacity Numbers of Equipments

No.

Existing Proposed Total

1 Dumpers 10 tonnes 2 4 6

2 Holman compressor 120 CFM 3 - 3

Drilling Machine

3 100 mm - 2 2

WDH

Jack hammer (Ford

4 33 mm 2 3 5

Tractor Atloscapco)

5 JCB 1 1 2

6 Water Pumps 1 1

Tractor trailer with

7 3 tonnes 5 5

hydraulic Tipping

2 (Common

8 Explosive van for group of - 2

mines)

9 Wheel Loader 1.30 CMTR 3 - 3

M/s Netel (India) Ltd. 3

Rapid – EIA Study Executive Summary

PRESENT ENVIRONMENT SCENARIO

For the description of the baseline environmental setting, the mining project area

together with the mine lease area have been considered as the core zone, and the area

falling within 10 km from the core zone has been considered as the buffer zone. Core

and buffer zones, taken together, form the study area. Baseline data generation was

performed for a period of 3 months, from December 2006 to February 2007 (winter).

Climate

The study area is part of tropical climate with hot summer, moderately cool winter

and moderate monsoon during June to August. The rains are scanty and average

rainfall of the area is around 560 mm. Hourly micrometeorological data was recorded

at Bagalkote town 25 km from project site for period of 3 months comprising one

Winter season from December 2006 to February 2007.The micrometeorological data

is given in below.

Summary of Micro-Metrological Data

Particulars Maximum Minimum Average

Temperature (°C) 35.2 10.2 21.9

Relative humidity 81 15 45

Wind speed (km/hr) 4.28 3.38 3.85

Predominant wind

From East (Calm Wind :- 10.75%)

direction

Ambient air quality

Total six Ambient Air Quality Monitoring Stations (1 in core zone and 5 in buffer

zone) were identified and monitored as per the norms. The summary of pollutants

results is as follows.

Results of Ambient Air Quality

Observed values range 24 hourly Standard laid down by CPCB 24

average (μg/m3) hourly average (μg/m3)

Pollutants

For

Core zone Buffer zone For Industrial

Residential

SPM 128.2-225.3 80.6-184.2 200 500

RPM 48.1-95.6 16.6-68.6 100 150

SO2 4.5-12.4 4-11.4 80 120

NOX 9.9-21 9-21.7 80 120

Noise Environment

Noise levels were monitored at six locations. One station representing core zone

activities and the remaining five stations representing buffer zone villages. The main

sources of noise will be due to movement of heavy earthmoving machinery, blasting,

M/s Netel (India) Ltd. 4

Rapid – EIA Study Executive Summary

crushing of Limestone, movement of trucks engaged for transportation of Limestone

as well as ore zone waste. The results are shown in the following table.

Summary of the Noise Level

Station Noise level dB (A)

Zone Location Activity

Code Day Night

Source mining

Core Mining area N1 64.6 44.0

activity

Hire shellikeri N2 54.2 44.1

On Hire

Chikkashellikere – N3 54.0 43.6 General, public

Buffer Kaladgi Road and limestone

Chikkashellikeri N4 52.8 43.2 transport

Nir Buddihal N5 54.8 43.7

Yandigeri N6 54.5 43.9

Water environment

Ghataprabha is the main river in study area. Water resources available in the area are

only rain water. The mining area forms a part of the drainage system of the

Ghataprabha river is situated towards Northern side of the mine. One major nullah

which flows during heavy rains cuts the lease area into two halves from South East

corner to the North Western corner of the lease area and flows in the North Western

direction. The ground water is the main source of potable water in the study area.

Quality of water

Water samples from 5 ground water sources and two surface water sources were

characterized. The quality of ground water in the study area varies widely. However,

characteristics of ground water samples from locations are in conformity with the

permissible limits for drinking water.

The analytical report of the water samples are found to be within the tolerance limits

for water specified as per IS: 10500 standards. Hence the water quality in the

surrounding area is good.

Landuse pattern and soil quality

The land is almost plain and cultivated. The major portion of the lease area is brought

under cultivation. The details of existing and proposed land use pattern of mining

lease area is given below.

M/s Netel (India) Ltd. 5

Rapid – EIA Study Executive Summary

Land use pattern in Core Zone

Total

Sr. Present

Particulars Proposed for area in

No. Occupation

ha.

End

2006- 5th 10th 15th of

09 year year Year Mine

Life

1 Mining 10.25 1.60 2.00 2.00 2.00 12.15 30.00

2 Road 1.80 0.30 0.20 0.20 - 0.50 3.00

3 Dump Yard 1.90 0.40 0.40 0.40 0.40 4.00 7.50

4 Stock Yards 0.45 0.60 0.40 0.40 0.40 1.75 4.00

5 Afforestation 0.65 2.00 0.60 0.60 0.60 4.4 8.85

6 Structures/Colony 0.50 - 1.00 - - 0.5 2.00

7 Crushers 2.5 - 0.50 - - - 3.00

8 Area unutilised 48.80 - - - - - 6.00

9 Total 64.35 7.4 5.1 3.6 3.4 23.3 64.35

Land use pattern in Buffer Zone

Sr. No. Land Use Area in ha. %

1 Forest land 2406.46 7.66

2 Irrigated land 5233.90 16.66

3 Un-irrigated land 16999.20 54.11

4 Cultivable waste land 1212.66 3.86

5 Not available for cultivation 2629.52 8.37

6 Infrastructures (road, residence) 2934.26 6.34

7 Total 31416.00 100

The soil pH was observed in the range of 7.3-7.8. The soils are rich in nutrients like

potash, phosphorous, nitrogen and organic matter. The soil appeared light brown to

Black in colour and all soil samples have slit loam structures.

Ecology

Density of trees is very less on mining lease area. Major activities within 5kms radius

of the buffer zone are mining and dry agriculture activities only during rainy season.

However, under the green belt development and plantation programme,

approximately 8 hectares of ML has been brought under plantation. No wild life of

any sort is found within the lease hold area. The fauna found in the area are of

common variety and no endangered or threatened species are reported in the study

area.

Socio-economic condition

The mine is already under operation. There is no habitation within the project area.

Hence, no rehabilitation will be required. In the study area, there are all inhabited

revenue villages. Out of the 25 vilages, 16 fall within Bagalkot Tehsil and 9 under

M/s Netel (India) Ltd. 6

Rapid – EIA Study Executive Summary

Badami Tehsil. The total population in these 25 villages is 49,998.The distribution of

population is as under

Population SC ST

Male Female Total Male Female Male Female

24,999 24,999 49,998 2,864 3,003 2,549 2,546

44.58% of total population is literate. Out of these 63.83% are male literate and only

36.17% are female literate. The composition of SC and ST in the study area is 11.7%

and 10.2% respectively. 22% of the total populations are total main other workers,

23% of total main cultivators, 23% of total main agriculture laboures, 3% of

household industries workers and Marginal workers are 29%.

ENVIRONMENTAL IMPACT ASSESSMENT

Air quality

The mining operation being open-cast, the dust generation due to excavation of land,

movement of machinery on unpaved surfaces, blasting & handling of rejects, sub-

grade ore & products is common. The impacts on air are mainly due to generation of

dust during loading, unloading and transportation of Limestone and some emissions

from the transporting trucks. The air pollutants are SPM/SO2/NOx emissions from the

activity. The overall scenario after increase in production is given below.

Overall Scenario

Worst

Predicted Total

Station Direction background Standards

max. GLC Concentration

concentration

μg/m3 μg/m3 μg/m3 μg/m3

Core Zone

17.204 W 168.2 185.404 500

(100 m)

Buffer Zone

9.779 W 160.95 170.729 200

(500 m)

Buffer Zone

6.898 W 153.7 160.598 200

(1000 m)

Water resources

No change in drainage pattern will take place due to mining. Ghataprabha river is

situated towards Northern side of the mine. One major nullah which flows during

rainy season only. Since it is open cast mining the quarry pit will receive

accumulation of rain water as direct precipitation. The water table in the area rest at

60 m below the ground level. Therefore the water table will not be cut and no loss of

ground water. Therefore, no adverse impact on ground water regime is expected.

Water quality

There is no discharge of effluent from the mine. Sewage generated from labour

colony and office will be very less and this will be treated in septic tank. Treated

sewage will be discharged in soak pit. Ground water level at the site and its

surrounding area is 60 m below the ground level. The likely chances of the

M/s Netel (India) Ltd. 7

Rapid – EIA Study Executive Summary

contaminants reaching the ground water are very rare. Hence, no deterioration of

ground water or surface water is anticipated.

Land degradation

It is envisaged that about 30 ha area will be disturbed by mining activity during entire

life.

Flora and Fauna

The core zone is agricultural land. The land acquired will need due compensation to

owners as mitigation measure. The impact on flora and vegetation will be mitigated

through a detailed afforestation plan. The fauna found in the area are of common

variety and no endangered or threatened species are reported in the study area.

Noise level, traffic

The application of drilling, blasting, haulage/transportation, crushing is expected to

raise noise level in ML area. The observed noise level will be well within the

prescribed limits for surrounding population due to control measures proposed in

management plan.

The 0.250 million tonnes per annum limestone production per year will contribute to

the traffic density by adding about (84 loaded and 84 empty). 168 trucks, which is a

marginal increase and will warrant control measures as spelt out in management plan.

Socio-economic conditions

The project will provide more direct and indirect job opportunities and better

economic standard to the project affected people and others, through improved

infrastructural, community facilities, etc.

ENVIRONMENTAL MANAGEMENT PLAN.

In order to mitigate the environmental impact due to mining and its allied activities, a

comprehensive environmental management plan (EMP) has been formulated. The

management has already initiated the following steps to contain pollution and the

same shall be continued vigorously in future also. All likely parameters that will be

affected by mining have been addressed and these are briefly mentioned in the

following paragraphs.

Land degradation control measures

The mining and associated operations will disturb about 30 ha. of area which is about

46.62% of the lease hold area at the end of life of mine. It is proposed to convert most

of the land as water ponds and remaining land for plantation out of the void left after

the completion of excavation, since it is not possible to back-fill the area. This top soil

will be utilized for agriculture purposes, by adjacent pattaland owners and remaining

soil will be stacked in stock yard. Waste generation during course of mine will 2.36

million tonnes. Overburden will be stacked in dump yard located away from the

workings. Waste dump will be protected by way of construction of retention wall all

along the toe of the dump to prevent wash offs during rainy seasons.

M/s Netel (India) Ltd. 8

Rapid – EIA Study Executive Summary

Air pollution control measures

• Dust extraction systems to be used in drill machines; and

• Use of sharp drill bits for drilling holes and drills with water flushing

systems (wet drilling) to reduce dust generation.

• Dense plantation of specific more efficient dust collector species

• OB waste dumps, if any, shall be sprayed with water, as they are the major

source of air borne particulate matter/dust.

• Trucks will be covered with tarpaulin and over filling of tippers will be

strictly avoided

• Maintenance of haulage road on regular basis

• Regular water spraying on haulage roads during transportation of

Limestone and waste by water sprinklers;

• Water sprinkling system to be provided to check any fugitive emissions

from the crushing operation.

• Installation of a dust collector at crusher

Control measures for water pollution

• To prevent surface water contamination by oil/grease, leak proof

containers shall be used for storage and transportation of oil/grease.

• During dewatering operations, the water pumped out will be used for

fulfilling the needs of mine and plant related activities

• During excavation and drilling activities effort must be taken to avoid face

collapse at these cracks and fissures.

• Construction of retaining wall to avoid sliding of loose material from

dumps

Noise Control Measures

• Innovative approaches of using improvised plant and machinery designs,

with in-built mechanism to reduce sound emissions like improved

silencers, mufflers and closed noise generating parts;

• Confining the equipment with heavy noise emissions in soundproof cabins,

so that noise is not transmitted to other areas;

• Regular and proper maintenance of noise generating machinery;

• Blasting operations to be carried out only during daytime so as to avoid

high noise intensity in night time;

M/s Netel (India) Ltd. 9

Rapid – EIA Study Executive Summary

• Thick green belt should be provided at the mine periphery, within the mine

lease area along the roads and all around the working areas, to screen the

noise

Ground Vibration

• Use of milli-second detonators,

• Good blasting design,

• Lesser quantity of charge per delay,

• Less frequency of blasting.

Measures to improve socio economic condition

People affected by the project will be paid due to compensation. Land a effected

person of the area will be provided with direct or indirect employment.

Communication, education facilities, health facilities and recreational facilities will be

improved due to mining activity.

Environmental matrix

The modified Leopold matrix was applied to evaluate the impact before adopting

control measures and after adopting control measures. It is observed that the total

score which was originally –453.3 (without mitigative measures) has improved to

–138.406(with mitigative measures). The negative score of 453.3 at pre-mitigative

stage indicates significant adverse and reversible impacts that can be managed by

adopting appropriate pollution control measures (-138.406).

ENVIRONMENTAL CONTROL AND MONITORING ORGANIZATION

An appropriate team has been proposed to take care of pollution monitoring aspects

and implementation of control measures. A schedule has been spelt out for periodical

monitoring. The capital investment on environmental improvement works is

envisaged as Rs. 41.55 Lakhs and recurring expenditure is Rs. 8.31 Lakhs per year.

DISASTER MANAGEMENT PLAN

• Entry of unauthorised persons shall be prohibited;

• Fire fighting and first aid provisions in the mines office complex and

mining Area;

• Provision of all the safety appliances such as safety boots, helmets,

goggles etc. would be made available to the employees and regular check

to ensure the use;

• Training and refresher courses for all the employees working in the

hazardous premises;

• Working of mine as per approved plan, related amendments and other

regulatory provisions;

M/s Netel (India) Ltd. 10

Rapid – EIA Study Executive Summary

• Handling of explosives, charging and blasting shall be carried out by

competent persons only;

• Provision of magazine at safe place with fencing and necessary security

arrangement;

• Awareness of safety and disaster through competitions, posters and other

similar drives;

CONCLUSION

Based on the EIA study it is observed that there will be a marginal increase in the dust

pollution, which will be controlled by sprinkling of water and transportation of ore in

closed trucks.

There will be insignificant impact on ambient environment and ecology due to the

mining activities. On the other hand mining operation will lead to direct and indirect

employment generation in the area.

Hence, it can be summarized that the development of Chikkashellikeri limestone

Mines of M/s Mysore Minerals Limited at Chikkashellikeri village, will have a

positive impact on the socio-economic of the area and lead to sustainable

development of the region.

M/s Netel (India) Ltd. 11

Rapid – EIA Study Introduction

CHAPTER 1

1.1 PREAMBLE

M/s Mysore Minerals Limited is a Government of Karnataka undertaking

established in the year 1966 with main objective of systematic mining and

planned development of mineral resources in the State. The main activities of

the company are Exploration, Development of Mineral Resources, Extraction

and Marketing of Minerals and granite.

Government of Karnataka has been granted mining lease over an area of 64.35

ha. Under ML No 1593 at Chikkashellikeri Village, Bagalkote Taluk,

Bagalkote District, Karnataka State for a period of 20 years with effect from

26-04-1999 which expired on 25.04.2019. The copy of notification is enclosed

as Annexure I

The Chikkashellikeri limestone mining lease is not attract forest clearance as

the entire area is patta land. The existing production is only 0.120 million

tonnes per annum with open cast mining method. In views of great demand for

limestone minerals, commitments are made for long term supply to local

industries and decided to increase the production from 0.120 million tonnes

per annum to 0.250 million tonnes per annum. The mining plan required under

rule 10(2) of MCDR 1988 has been got approved by IBM GOI vide letter No.

MSH/MAN - 86 (KNT)/GOA/2003-04 Vol. I dated 10/04/2007 for a period of

5 years and its copy is enclosed as Annexure II

1.2 NEED FOR PROJECT

The site is situated in the backward area of the state. This project would

increase the capita income, life style, local employment, socio-economic

aspects, revenue generations to the government as well as company and

industrial development in the state.

1.3 NEED FOR REIA/EMP

In order to increase the production from 0.120 million tonnes per annum to

0.250 million tonnes per annum the size of mining activities needs to be

modernized, required additional infrastructure etc. As per EIA notification

dated 14 Sept. 2006, increase in the production or modernization required

environmental clearance under EPA 1986. Therefore this proposal Category A

1(a), (> 50 ha of mining lease area) of the Environmental Impact Assessment

Notification dated 14 Sept. 2006

The purpose of this Environmental Impact Assessment (EIA) study is to

provide information on the surroundings and the extent of environmental

M/s Netel (India) Ltd. 1

Rapid – EIA Study Introduction

impacts likely to arise on account of the increase in mining activity, and also

to define an Environmental Management Plan (EMP) to minimise and mitigate

the likely adverse environmental impacts.

1.4 OBJECTIVES OF THE EIA STUDY

The objective of the EIA study is:

• Environmental monitoring so as to establish the baseline environmental

status of the study area.

• Collection of available secondary data from concerned department.

• Identify various existing pollution loads due to industrial and domestic

activities.

• Prediction of impacts on environmental attributes.

• Evaluate the predicted impacts on the various environmental attributes in

the study area by using scientifically developed and widely accepted

Environmental Impact Assessment (EIA) Methodologies.

• Preparation an Environmental Management Plan (EMP) outlining the

measures for improving the environmental quality.

1.4 METHODOLOGY OF THE STUDY

Keeping in view the nature of activities, area of mines and various

environmental guidelines, an area covering a radial aerial distance of 10 km

from the centre of the mining area was selected as study area for the purpose

of EIA study. To establish baseline status of air, water, noise, land, biological

and socio-economic environment in the study area, extensive field studies

were undertaken. The various steps involved in the study for a particular

project are divided into three following phases.

• Identification of significant environmental parameters and assessing

the status within the study area

• Prediction of Impacts envisaged due to proposed scheme on various

environmental parameters

• Evaluation of impacts after superimposing the predicted scenario over

the baseline scenario to preparation of Environmental Management

Plan

The approach to data collection is outlined in Table 1.1

Impact of various project activities on the baseline environmental quality was

predicted to identify areas of concern.

Measures for mitigation of adverse impacts were identified and Environmental

Management Plan incorporating these measures was developed.

M/s Netel (India) Ltd. 2

Rapid – EIA Study Introduction

Table 1.1: Survey of Environmental Attributes

Sr. Attribute Parameters No. of Locations, Frequency of Monitoring,

No. etc.

1 Ambient air SPM, RPM, SO2, NOx Locations: 6 nos.

quality and CO SPM, RPM, SO2 and NOx - One 24 hourly

sample CO - Three 8 hourly samples, Twice a

week

2 Meteorology Wind speed and direction, Primary data: at Bagalkote town.

temperature relative Secondary data collection from IMD.

humidity and rainfall.

3 Water quality Physical, Chemical and Primary data – Sampling at 2 locations for

Bacteriological surface and at 5 locations for ground water

parameters. quality.

4 Ecology Existing terrestrial and Based on the data collected from secondary

aquatic flora and fauna. sources.

6 Noise levels Noise levels in dB(A) Continuous 24-hourly monitoring at 6

locations during the study period

7 Land use Land use for different Based on data published in Primary Census

categories. abstract 2001 and satellite imagery

8 Socio-economic Socio-economic Based on data collected from secondary

aspects characteristics of local sources.

population

9 Geology Geology of the area Based on data collected from secondary

sources.

10 Hydrology Drainage pattern, nature Based on data collected from secondary

of streams, aquifer sources.

characteristics recharge

and discharge areas.

1.5 STRUCTURE OF EIA REPORT

The Environmental Impact Assessment (EIA) report contains baseline data,

assessment of likely impacts, preparation of environmental management plan

& the disaster management plan. The report is organised in following six

chapters:

Chapter 1 Introduction

This chapter describes objectives and methodology for EIA.

Chapter2 Project Description

This chapter gives a brief description of the location,

approachability, and details of mining activities, equipments

and machinery.

Chapter 3 Baseline Environmental Status of Project Area

This chapter presents details of the baseline environmental

status of all environmental attributes i.e. micro climate

condition, air quality, noise, traffic, water quality, soil quality,

flora, fauna and socio-economic status etc.

M/s Netel (India) Ltd. 3

Rapid – EIA Study Introduction

Chapter 4 Impact Identification

This chapter discusses the potential impacts of the proposed

mining and allied activities, which could cause significant

environmental concerns, are identified and discussed. This

discussion will form the basis for environmental management

activities.

Chapter 5 Impacts Evaluation

This chapter discusses environmental impacts due to the

proposed limestone mining activities have been quantified

under two scenarios (1) without environmental management

plan , and (2) with the environmental management plan using

modified Leopold Impact Matrix to establish cause-effect

relationship.

Chapter 6 Environment Management Plan

This chapter deals with the Environmental Management Plan

(EMP) for the proposed expansion of mining activities,

indicates measures proposed to minimize the likely impacts on

the environment. It also describes the proposed environmental

monitoring programme.

Chapter 7 Disasters Management Plan

This chapter deals with the Disasters Management Plan (DMP)

for the proposed expansion of mining activities, indicates

measures proposed to minimize the manmade and natural

disasters.

M/s Netel (India) Ltd. 4

Rapid – EIA Study Project Description

CHAPTER 2

PROJECT DESCRIPTION

2.1 INTRODUCTION

This chapter presents the salient features of the project viz. location, process

and details of operation, infrastructure and environmental resource

requirement.

2.2 PROJECT LOCATION

“Chikkashellikere Limestone Mine” of M/s Mysore Minerals Limited over an

area of 64.35 ha under M.L. No. 2494 is located at Chikkashellikeri Village in

Bagalkote Taluka, Bagalkote District, Karnataka.

Table 2.1: Site Details

District & State Bagalkote District, Karnataka

Taluka Bagalkote

Village Chikkashellikeri village

Mine Lease Area 64.35 ha

Type of the Area Patta Land

Survey of India Toposheet No 47 P/12

Latitude 16°8’00”N to 16°09’11”N

Longitude 75°31’11”E to 75°35’55”E

2.3 ACCESSIBILITY

Chikkashellikeri Limestone Mines is situated at 25 km south west of Bagalkot

town in Bagalkot Taluk of Bagalkot District in Karnataka State.

The mining lease area is accessible by Kerkalmatti - Kaladgi road. The

nearest railway station is at Bagalkot, about 25 km away from the mine area.

The nearest airport is at Belgaum, about 120 km away from mining lease area.

The nearest state highway is about 5 km away from site. The general ground

level varies from 521 to 548 meter above MSL.

The location map indicating the project site and Layout Plan/Surface Plan of

mine area are depicted in Figure 2.1 and 2.2 respectively

The photographs of mines and its surroundings is given in Annexure III

M/s Netel (India) Ltd. 5

Rapid – EIA Study Project Description

Figure 2.1: Location Map

Karnataka Map

District Map

PROJECT SITE

M/s Netel (India) Ltd. 6

Rapid – EIA Study Project Description

Figure 2.2: Mine Layout Plan/Surface Plan

540.630

539

PIT NO. 3

542.128

533.078

542

B. M. 0

PIT NO. 2

MRY

533.640 545

OFFICE

541.128 STORE

AGL

MSY

BORE HOLE

MSY

0

PDY

.45

BORE HOLE

543

TSPY

AGL

528.888

TO V

ILLA

GE

PIT NO. 1

548

526.298

545

533.000 542

539 537.338

.288

HOUSE TO VILLAGE

AGL AGL

535.920

SE

AS

539 ON

AL

NU

LL

AH

542

LEGEND

CONTOUR PLAN 545

AGL

CONCEPTIUAL PIT PLAN

ROADS 548

DUMPS

M. L. BOUNDARY

NULLAH

AGL AGRICULTURE LANDS

RETENTION WALL

Client Name: M/S. MYSORE MINERALS LIMITED.

ELECTRICITY LINE Name of Mine: Chikkashellikeri Limestone Mines

Sheet Title: Surface Plan

PROPOSED DUMPS

Plate No: Scale:

AFFORESTATION Consultant Name: NETEL (INDIA) LTD.

Scale: S. V. Road., Manpada

0 20 40 60 80 100m

Thane (W) - 400 607

M/s Netel (India) Ltd. 7

Rapid – EIA Study Project Description

2.4 APPROVALS ACCORDED

Chikkashellikeri Limestone mines does not fall in designated forestland

therefore, forest clearance is not a part of the approval.

The other approvals accorded to Mysore Minerals Ltd. include the following:

• Grant of Mining Lease vide letter no. DMG/MLS/14AML 98/RML –

1593/813 dated 21-04-2004 with effect from 26.04.1999

• Approval of mining scheme by Indian Bureau of Mines, Goa vide

Letter No.MSH/MAN-86(KNT)/GOA/2003-2004 Vol. I dated

10/04/2007

2.5 PROJECT COST

The total cost of the project which includes development cost, Production cost,

Crushing Plant and equipments and all other infrastructure facilities of the

present and proposed expansion works out to be Rs. 70 lakh and 150 lakh

respectively.

2.6 PHYSIOGRAPHY

The mining lease area lies between longitude 750-31’-11” to 750-35’-55” and

160-08’-00” to 160-09’-11 covered under survey of India toposheet no.

47/P/12. The area is generally devoid of vegetation. The land is almost plain

and cultivated. The general contour height observed in the lease area ranges

from 521 to 548 m above MSL. One seasonal nullah which flows in rainy

season cuts the lease area in two halves from South East corner to North West

corner. This nullah flows in North West direction. The average rainfall in the

area is around 400 to 500 mm annually. The maximum temperature attained in

the area is around 380 to 400 during summer.

2.7 GEOLOGY AND RSERVES

The mine area falls in Survey of India Topo Sheet No. 47/P/12. The lease area

forms a part of Kaladgi basin sedimentary formation of “Precambrain Era”.

The following geological stratigraphic sequence is identified for this region.

Geological Age Formation Lithology

Recent Precambrain ---- Black cotton soil

Precambrain Kaladgi Group Limestone Shale

Unconformity ----

Archean Granitic Gneises ----

The following geological formations/ exposures are observed in the lease area.

1 Thinly bedded, Soil /Black Cotton Soil

2 Shale

M/s Netel (India) Ltd. 8

Rapid – EIA Study Project Description

3 Dolomitic Limestone

4 Gray Limestone

2.7.1 Black Cotton Soil

The area is mainly covered by back soil of varying thickness (1 m to 2 m). The

contact between dolomite and high calcium limestone is well exposed. The

general strike of the formation is N 750 W to 750E and dipping 450 to 500 south

observed in the lease area.

2.7.2 Shale

The Shale are exposed in the Northern and Eastern end of the lease area. It

exhibits marine and gray to purple colour, compact less laminated and slaty.

These shale bands are exposed over a distance of 150 m to 120 m. with an

average width of 80 m.

2.7.3 Dolomitic limestone

Prominent exposures of dolomitic limestone are observed to the Eastern side

of the lease area under laying the thin layer of black cotton soil it is traversed

by a number of silica veins these are striking almost parallel to the limestone

deposit and dipping 450 to 600 South at different places. Dolomites are fine to

medium grained and white to gray in color it is comparatively hard.

2.7.4 High Calcium Limestone (Grey Limestone)

The Limestone bands are well exposed in the eastern and western part of the

lease area. These are intercalated with thin ribbon of shale and dolomite. Thin

Veins of Calcite are noticed at one or two locations in the exposed bands. The

High Calcium limestone presents a weathered surface as a smooth appearance

with small potholes which is very characteristic.

2.7.5 Reserves

Based on the exploration carried out, exposed ore body and other available

information, the geological reserves estimated by standard cross sectional

method the details are given in Table 2.2

Table 2.2: Geological Reserves

Sr. No. Reserves Type Insitu Reserves Mineable

Reserve in Tones

1 Proved 2,57,48,650 2,18,86,360

2 Probable 1,29,78,600 1,10,31,810

3 Total 3,87,27,250 3,29,18,170

The geological map of mining site is given in Figure 2.3

M/s Netel (India) Ltd. 9

Rapid – EIA Study Project Description

Figure 2.3: Geological Map of Mining Area

540.630

539

PIT NO. 3

533.078 542.128

542

B. M.

0

PIT NO. 2

533.640 545

D. H. 1 OFFICE

541.128 STORE

AGL

BORE HOLE

0

.45

BORE HOLE

543

AGL

528.888

TO V

ILLA

GE

D. H. 2

PIT NO. 1

548

D. H. 6

526.298

545

533.000 542

539 537.338

.288

HOUSE TO VILLAGE

AGL AGL

535.920

SE

AS

539 ON

AL

NU

LL

AH

542

545

AGL

LEGEND 548

CONTOUR PLAN

CONCEPTIUAL PIT PLAN

ROADS

HIGH CALCIUM LIMESTONE

DOLOMITE LIMETONE

M. L. BOUNDARY

Client Name: M/S. MYSORE MINERALS LIMITED.

SHALE Name of Mine: Chikkashellikeri Limestone Mines

Sheet Title: Geological Plan

NULLAH Plate No: Scale:

AGL Consultant Name: NETEL (INDIA) LTD.

AGRICULTURE LANDS Scale:

S. V. Road., Manpada

0 20 40 60 80 100m

Thane (W) - 400 607

M/s Netel (India) Ltd. 10

Rapid – EIA Study Project Description

2.7.6 Mineralogy

The principal carbonate rocks used by industries are limestone and dolomite.

Limestone and dolomite are sedimentary or metamorphic rocks composed

mostly of the mineral calcite (CaCO3), which has the same chemical

composition as calcite but with a different crystal structure, is economically

important only in modern deposits, such as oyster shells and oolites. Aragonite

is metastable and alters to calcite in time. Some other carbonate minerals,

notably siderite (FeCO3), ankerite (Ca2MgFe(CO3)4), and magnesite (MgCO3),

are commonly found associated with limestones and dolomite.

The average chemical specification of Limestone produced in this mining area

is as follows

Sr. No. Radicals Percentage

1 CaO +40 to +48%

2 MgO 3 to 6%

3 SiO2 3.5 to 6 %

4 R2O3 0.45 to 3 %

2.8 MINING

The lease area is an operative mine with manual open cast mining method for

the production of 0.120 million tonnes per annum. Now it is proposed to carry

out mining work by semi mechanized open cast mining method with capacity

of 0.250 million tonnes per annum production. The work will start from

highest level of 448 m RL at East side and extended towards West & NW side.

The salient features of the proposed mining lease area at Chikkashellikeri are

as given in the Table 2.3

Table 2.3: Salient features of the Mine

Sr. No. Particulars Existing Details Proposed Details

Open cast mining with

1 Method of Mining Manually open cast mining

mechanization

2 Mining leased area 64.35 ha. 64.35 ha.

3 Geological reserves 38.72 million tonnes 38.72 million tonnes

Mineable

4 reserves(based on 32.92 million tonnes 32.92 million tonnes

proved reserves only)

5 Pit slope angle 60◦ to the horizontal 60◦ to the horizontal

Annual Limestone

6 0.12 million tonnes per annum 0.250 million tonnes per annum

Production

7 Life of the Mine 323 Years 155 Years

8 Bench height 3m 5m

9 Bench Width 5m 10 m

Average Quality of

10 CaO +40 to +48% CaO +40 to +48%

Limestone

MgO 3 to 6% MgO 3 to 6%

M/s Netel (India) Ltd. 11

Rapid – EIA Study Project Description

SiO2 3.5 to 6 % SiO2 3.5 to 6 %

Al 2O3 0.45 to 3 % Al 2O3 0.45 to 3 %

11 Land lease period - 20 years (Valid up to 2019)

12 Water Requirement 27 m3/day 67 m3/day

13 Working hours One shifts 8 hour One shifts 8 hour

14 No. of employees 49 92

2.9 MINE DEVELOPMENT AND PRODUCTION

A tentative ultimate pit has been conceptualized based on the geological

investigation done so far within the lease area. Once detailed investigations in

the probable and possible reserves areas are completed the ultimate pit limit

within the lease area will need to be modified. The mining lease is valid up to

2019. The mining scheme has been approved up to 2008 - 2009. Due to

increase in demand of Limestone ore the remaining period of 3 years i.e. from

2006-2007 to 2008 -2009 the proposal has been revised. The benches will be

formed at 5 m height and 10 m width with the slope angle of 60° to the

horizontal. The details of development and production proposed for remaining

3 years i.e. 2006-07 to 2008 – 09 is given below.

Table 2.4: Development and Production Proposals

Sr. Years

2006-07 2007-08 2008-09

No. Particulars

Development (tonnes) 4,341 5,346 5,598

2 Production (tonnes) 1,94,970 2,40,075 2,51,715

2.9.1 Stacking of Mineral rejects and Disposal of Waste

During the course of mining apart from the mineral other waste like

overburden and ore zone waste will be generated. The overburden chiefly

consists of shale bands, dolomitic limestone and ore zone waste. The

generation of waste will be 2.36 million tonnes during life of mine. The

overburden will be transported to the dump yard located away from the

workings. This site is considered to be barren as per the field investigation

carried out in the area. The area selected for dump yard is around 7.50 ha is

sufficient to accommodate the waste generated during the course of life of

mine. The height of the dumps will be maintained average 20 m. from the

ground surface taking necessary measures to maintain the dump slope at an

angle of 28° natural slope from the horizontal for proper stability, keeping a

road width of 5 m with 1 to 16 gradient. This waste dump will be protected by

way of construction of retention wall all along the toe of the dump to prevent

wash offs during rainy seasons.

M/s Netel (India) Ltd. 12

Rapid – EIA Study Project Description

2.10 BLASTING

2.10.1 Burden, Spacing, Depth and Sub Grade Drilling

The mining method chosen is conventional drilling and blasting followed by

loading. Based on the nature of the Limestone deposit, the blast hole

parameters proposed are as follows:

Details Existing Proposed

Bench height 3m 5m

Burden 0.75 0.75

Spacing 1.20 m 1.20 m

Depth of hole 3.30 m 5.50 m

Sub grade/secondary drilling 0.30 m 0.30 m

Angle of hole 10°- 15° to vertical 10°- 15° to vertical

Primer charge for hole 2/3 of the hole depth 2/3 of the hole depth

Maximum no. of holes blasted at a

8 holes in a day 17 holes in a day

time

2.10.2 Explosives

The types of explosives used are as under

• Nitro-glycerine based (NG) gelatinous explosives. Major usage of this

class will be as boosters;

• Ammonium Nitrate fuel Oil (ANFO) mixture. ANFO will be the chief

column charge during the dry season ; and

• Slurry explosives (AN based), viz., Powergel, Acquadyne, Superdyne,

etc during monsoon season mainly.

• Ordinary detonators/Electrical Detonators

• Safety Fuse

2.10.3 Secondary Blasting

Secondary blasting is not required as the purpose will be fulfilled during

primary blasting itself.

2.10.4 Explosive Requirement and Storage

Average daily requirement of explosive requirement is envisaged as 125

kg/day as per given break-up:

Sr. No. Particulars Explosive Requirements in kg/day

1 Present 42

2 Proposed 83

3 Total 125

M/s Netel (India) Ltd. 13

Rapid – EIA Study Project Description

Blasting accessories required are:

Sr. No. Particulars Present Proposed Total

1 Safety Fuse(m/day) 26.4 49.5 75.9

2 Denoters (No./day) 8 9 17

Presently the required explosive are brought from the B type Magazine of

Neralakere Dolomite mines Situated 25 kms from the lease area which is safe

and secured storage of explosives, having a capacity of 100 kg of gelatin 2500

m of safety fuse and 500 numbers of denoters.

2.10.5 Extent of Mechanism

The mine is already producing 0.12 million tonnes per annum of ore. For

increasing the production from 0.12 million tonnes per annum to 0.25 million

tonnes per annum, additional machinery has to be deployed. The machineries

proposed to produce 0.25 million tonnes per annum of limestone and 0.00555

tonnes per annum of ore zone waste per annum is given in Table 2.5

Table 2.5: Requirement of Mining Machineries

Sr.

Equipment Capacity Numbers of Equipments

No.

Existing Proposed Total

1 Dumpers 10 tonnes 2 4 6

2 Holman compressor 120 CFM 3 - 3

Drilling Machine

3 100 mm - 2 2

WDH

Jack hammer (Ford

4 33 mm 2 3 5

Tractor Atloscapco)

5 JCB 1 1 2

6 Water Pumps 1 1

Tractor trailer with

7 3 tonnes 5 5

hydraulic Tipping

2

(Common

8 Explosive van - 2

for group

of mines)

9 Wheel Loader 1.30 CMTR 3 - 3

2.11 MINERAL BENIFICATION

No mineral benification carried out in the mine. Only the ore removed from

the mine will be transported to the respective stock yards / destination. There

are two crushers installed in the area for crushing of minerals as per buyers

specification. The capacity of the crushers are 60 tonnes per shift.

2.11.1 Mineral Processing

It is proposed to set up a crushing unit of 100 tonnes per hour capacity within

lease area on the northern side. Raw material of upto 200 mm will be stacked

in the raw material yard near the crushers and the same will be feed through

hopper to the crusher. The crushers will crush the material to different sizes

and pass on to the screening plant where double deck screen with different

M/s Netel (India) Ltd. 14

Rapid – EIA Study Project Description

size meshes of 0 to 10 mm, 10 to 40 mm and 40 to 80 mm through conveyor

belts which are moveable. The materials collected will be loaded to the tippers

and transported to the stack yard for stacking. A schematic diagram of the

tentative flow sheet of crusher is given below as Figure 2.4:

Figure 2.4: Schematic Diagram of the Tentative Flow Sheet of Crusher

200 mm Raw Limestone

Hopper

Feeder

Two Stage

Roller

Double Deck

Screen

Belt Conveyor

2.12 ENVIRONMENTAL RESOURCE REQUIREMENT

2.12.1 Water

Total water requirement has been estimated as 67 m3/day. Water will be drawn

from bore wells. Details of water requirement are presented in Table 2.6.

Table 2.6: Water Requirement for the Mining Operations

Sr. Purpose Quantity, m3/day Source

No. Present Proposed Total

Bore

1. Dust suppression, sprinkling 11 25 36

well/Tanker

2. Domestic purpose 9 3 12 Bore well

3. Afforestation 7 12 19 Bore well

Total 27 40 67

M/s Netel (India) Ltd. 15

Rapid – EIA Study Project Description

Water Balance Chart

Source of Water:

Bore Well/Tanker

Source 67 m3/day

Consumption

Dust Suppression Domestic Green Belt Development

36 m3/day 12 m3/day 19 m3/day

Management

Septic Tank & Soak Pit

Final Discharge Zero Effluent to Environment

2.12.2 Workforce

The workforce required for mining activity comprises of engineers,

administrative, skilled and semi skilled type. At present 49 staff is working in

mining and total of 92 staff would be engaged for the mining activity. Work is

carried out in 8 hr shift with Thursday as non-working day. The details of

manpower requirement is given in Table 2.7

Table 2.7: Manpower Requirement

Sr. No. Manpower Present Proposed Total

1 Mine Manager 1 -- 1

2 Assistant Manager 1 -- 1

4 Cleark 3 -- 3

5 Mineforman 3 1 4

6 Mechanics 1 1 2

7 Supervisor 2 1 3

8 Mine Mate 2 1 3

9 Drivers/Operators 13 15 28

11 Peon 2 -- 2

12 Blaster 2 1 3

13 Workers 19 23 42

Total 49 43 92

M/s Netel (India) Ltd. 16

Rapid – EIA Study Project Description

2.10.3 Power Requirement

The required quantity of power will be taken from Karnataka state electricity

board.

2.10.4 First Aid Station

A first aid station will be provided with all necessary medical kit. All

engineers and supervisors will be trained in first-aid treatment to take care of

any emergency. An Ambulance is also proposed for this purpose.

M/s Netel (India) Ltd. 17

Rapid – EIA Study Baseline Environmental Status

CHAPTER - 3

BASELINE ENVIRONMENTAL STATUS

3.1 INTRODUCTION

Baseline data generation forms a part of the Environmental Impact

Assessment study, which helps to evaluate the predicted impacts on the

various environmental attributes in the study area by using scientifically

developed and widely accepted environmental impact assessment

methodologies. This also helps in preparing an Environmental Management

Plan (EMP) outlining the measures for improving the environmental quality

and scope of future expansions for environmentally sustainable development.

Baseline environmental study also helps to identify the critical environmental

attributes, which are required to be monitored after the implementation of

project. Baseline data on environment is important to understand region’s

existing physical, biological, cultural and social environmental characteristics.

This chapter illustrates the descriptions of the existing environmental status of

the study area with reference to the prominent environmental attributes. The

existing environmental setting is considered to be adjudge the baseline

conditions which are described with respect to climate, hydro-geological

aspects, atmospheric conditions, water quality, soil quality, vegetation pattern,

ecology, socio-economic profile, land use, etc.