Documente Academic

Documente Profesional

Documente Cultură

Expectativa de Vida 7329

Încărcat de

Paul RasmussenDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Expectativa de Vida 7329

Încărcat de

Paul RasmussenDrepturi de autor:

Formate disponibile

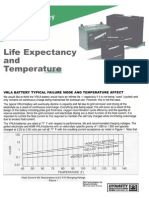

VRLA BATTERY TYPICAL FAILURE MODE AND TEMPERATURE AFFECT

We would like to think the VRLA battery would have an infinite life -especially if it is not being "used" (cycled) and

only remains on continuous charge being maintained for eventual use. However, this is not the case.

The typical VRLA battery will eventually decline in capacity and fail due to grid corrosion and drying of the

electrolyte as a result of continuous overcharge. Everything else being equal, this will occur as a result of the

design of the battery including plate grid thickness, oxygen recombination cycle efficiency and the quantity of

reserve electrolyte. Since the grid corrosion and electrolyte drying are a direct function of the float current, it is

important to control the float current to that required to maintain the cell fully charged while minimizing overcharge

due to excess float current.

The VRLA batteries are rated at 77' F with respect to performance, life and recommended charging voltages. The

gelled electrolyte and AGM VRLA batteries with an electrolyte specific gravity of 1 .280 to 1.300 are typically

charged at 2.25 to 2.30 volts per cell @ 77' F with the resulting current acceptance as noted in Figure 1. Note that

C&D Technologies, Inc

Dynasty Division

900 East Keefe Avenue

~

as the temperature of the battery is increased, the current acceptance at the constant voltage increases -almost

doubling for each 15 F increase. The life of the battery is determined by the total cumulative ampere-hours of over-

charge. This increased float current at elevated temperature accelerates the accumulation of ampere-hours of over-

charge. It has a significant impact on the grid corrosion rate and the gassing rate, and consequently the life of the

battery. The affect can be somewhat reduced through the use of a temperature compensated charger, which

reduces the charging voltage at elevated temperatures, but it cannot be entirely eliminated.

Elevated operating temperature is one of the most frequent causes of not attaining the design life of a VRLA battery.

Figure 2 illustrates the impact of elevated temperature operation on the life of the typical VRLA battery. Note that a

constant float charging voltage, for each 15 F increase in the battery operating temperature, the battery will experi-

ence a 50% loss in life (e.g., a battery designed for a 10 year life will provide only 5 years to 80% rated capacity).

CALCULATING EXPECTED LIFE AT ELEVATED TEMPERATURE

To determine the expected life of a VRLA battery operating at a constant elevated temperature, the calculation is

Actual life expected (LA> = derating factor at operating temperature (DT> x design life (LD>

100

90

80

70

w

u.

:J

o

w

f-

cr:

~

60

50

40

30

20

~

1-1-

10

0

70 80 90 120 130 140 100 110

TEMPERATURE (F)

Lead Acid Battery % Life (DT) VS. Temperature

Figure 2

~

For example, a battery with a 10 year design life (LO) operating at 85 F would have an actual life (LA) of 6.9 years

(6.9 years = 69% x 10 years).

When the battery is operated at a constant non-temperature compensated voltage and in an uncontrolled environ-

ment, for example when the ambient temperature varies with the seasons, the expected life can be calculated con-

sidering the cumulative affect of each of the average operating temperatures and the time for which it exists during

the year.

The actual life (LA) to be obtained would be calculated as follows:

LA (years) =

LO (months)

DT1 DT2 DT3 DT4

The following is an example of the calculation of the actual life (LA) of a battery operated under elevated tempera.

ture conditions that had a design life (LO) of 10 years at 77 F.

F Temperature

77

80

85

95

Months

1

2

4

5

% Life @ Temp

100

89

69

43

Operating Conditions

LA=

120 months

1 month + 2 months + 4 months + 5 months

1.00 0.89 0.69 0.43

LA =

120 months

1 month + 2.25 months + 5.8 months + 11.63 months

LA = 5.8 years

As can be seen) the affect of elevated temperature upon the life of the battery is dramatic and the desirability of a

temperature compensated charger and/or cooler environment is evident.

3

"

RECOMMENDATIONS FOR ELEVATED TEMPERATURE OPERATION

When operation of VRLA batteries is anticipated in an elevated temperature environment the following recommen-

dation should be followed to minimize the affects:

1. Use temperature compensated charging techniques.

2. Protect batteries from direct heat sources.

3. Install batteries with 1/2" or greater spacing to allow for free air circulation.

4. Incorporate effective active or passive ventilation of the enclosure.

5. Increase the frequency of periodic maintenance and capacity testing activities.

,-

S-ar putea să vă placă și

- Advanced Temperature Measurement and Control, Second EditionDe la EverandAdvanced Temperature Measurement and Control, Second EditionÎncă nu există evaluări

- Caravan and Motorhome Electrics: the complete guideDe la EverandCaravan and Motorhome Electrics: the complete guideEvaluare: 4.5 din 5 stele4.5/5 (2)

- Lead-X Tech Manual PDFDocument20 paginiLead-X Tech Manual PDFgenial72Încă nu există evaluări

- Charging Information For Lead Acid Batteries - Battery UniversityDocument92 paginiCharging Information For Lead Acid Batteries - Battery UniversityarthurÎncă nu există evaluări

- Ac Ripple Effects On Lead Acid BatteriesDocument8 paginiAc Ripple Effects On Lead Acid BatteriesRichard Flynn0% (1)

- Heat Run Test For TransformerDocument8 paginiHeat Run Test For TransformerHosni Mohamed KassimÎncă nu există evaluări

- Battery Life ExpentancyDocument4 paginiBattery Life ExpentancySAMEERÎncă nu există evaluări

- Battery Specs by SHDDocument7 paginiBattery Specs by SHDKEDARNATH SASTRY SUSARLAÎncă nu există evaluări

- Ieee C57.92-1981Document65 paginiIeee C57.92-1981yebri100% (1)

- Battery ChargingDocument9 paginiBattery Chargingtaiwong167Încă nu există evaluări

- Self-Equalization of Cell Voltages To Prolong The Life of VRLA Batteries in Standby ApplicationsDocument6 paginiSelf-Equalization of Cell Voltages To Prolong The Life of VRLA Batteries in Standby ApplicationsgilangpasekaÎncă nu există evaluări

- Harging EAD CID: Learn How To Optimize Charging Conditions To Extend Service LifeDocument4 paginiHarging EAD CID: Learn How To Optimize Charging Conditions To Extend Service LifebigsloÎncă nu există evaluări

- BU-808 - Prolong Lithium-Based BatteriesDocument3 paginiBU-808 - Prolong Lithium-Based BatteriesHugh Ell - auÎncă nu există evaluări

- Life Cycle Management of Power Transformers Using Transformer Protection RelayDocument7 paginiLife Cycle Management of Power Transformers Using Transformer Protection RelaycuamiÎncă nu există evaluări

- Gaston Batt Data SheetDocument23 paginiGaston Batt Data SheetAntony Sifuna WanjalaÎncă nu există evaluări

- VRLA BatteryDocument2 paginiVRLA BatteryPrashantKumarÎncă nu există evaluări

- Battery DataDocument8 paginiBattery DataChetan PrajapatÎncă nu există evaluări

- Transformer Ratings and Transformer LifeDocument6 paginiTransformer Ratings and Transformer LifeidfiÎncă nu există evaluări

- Battery LifeDocument32 paginiBattery LifeCharles RobiansyahÎncă nu există evaluări

- Capacitor LifeDocument11 paginiCapacitor LifeKrzyszto FPÎncă nu există evaluări

- Different Types of Battery Used For Auxiliary Power Supply in Substations and Power PlantsDocument7 paginiDifferent Types of Battery Used For Auxiliary Power Supply in Substations and Power PlantsEngr. Abdullah100% (1)

- Tutorial BatteryChargersDocument3 paginiTutorial BatteryChargersManuelÎncă nu există evaluări

- Battery LifeDocument24 paginiBattery LifemkÎncă nu există evaluări

- Effects of Environmental Factors in Transformer's Insulation Life PDFDocument10 paginiEffects of Environmental Factors in Transformer's Insulation Life PDFBoris EugeneÎncă nu există evaluări

- Battery Life (And Death)Document521 paginiBattery Life (And Death)Vijay Anand50% (2)

- VICTRON Datasheet - GEL and AGM Batteries - Rev 07 - enDocument4 paginiVICTRON Datasheet - GEL and AGM Batteries - Rev 07 - enfelipegonzalezmarquezÎncă nu există evaluări

- Long-Duration Duty Cycle Requirements: Is The Lead Acid Battery Still A Viable Back-Up Energy Source?Document13 paginiLong-Duration Duty Cycle Requirements: Is The Lead Acid Battery Still A Viable Back-Up Energy Source?Bores ModearÎncă nu există evaluări

- Power Transformers: Overview Factors On Assessing Insulation LifeDocument8 paginiPower Transformers: Overview Factors On Assessing Insulation LifeДенис ЛяпуновÎncă nu există evaluări

- Structure and OperationDocument14 paginiStructure and OperationAllan LariosaÎncă nu există evaluări

- Use-Maintenance-Guide For BateryDocument24 paginiUse-Maintenance-Guide For BateryOscar GonzalezÎncă nu există evaluări

- VRLA Battery White Paper Final 1Document4 paginiVRLA Battery White Paper Final 1p41005679Încă nu există evaluări

- Gelcelcharger Diagram PDFDocument6 paginiGelcelcharger Diagram PDFRemus PopescuÎncă nu există evaluări

- Battery Handbook Jul2010 FINALDocument16 paginiBattery Handbook Jul2010 FINALBalu MÎncă nu există evaluări

- A Guide To Lead Acid BatteriesDocument10 paginiA Guide To Lead Acid Batteriesgnpr_1010Încă nu există evaluări

- Rnp,+journal+manager,+1 +ANGGY+ERI+SDocument7 paginiRnp,+journal+manager,+1 +ANGGY+ERI+Syanuartw7Încă nu există evaluări

- 2017D.EGavrila 2014ICKEMDocument7 pagini2017D.EGavrila 2014ICKEMceko_genovski8285Încă nu există evaluări

- Battery Charging 14-22Document9 paginiBattery Charging 14-22Anonymous U7bJ4KAÎncă nu există evaluări

- TM According To 60354 - GBDocument8 paginiTM According To 60354 - GBbpchimeraÎncă nu există evaluări

- Battery Types Used For Auxiliary Power Supply in Substations and Power PlantsDocument8 paginiBattery Types Used For Auxiliary Power Supply in Substations and Power PlantsTigrilloÎncă nu există evaluări

- G Ravi - Analysis of Transformer Temperature Rise and Loss of Life in The Presence of Harmonic Load CurrentsDocument6 paginiG Ravi - Analysis of Transformer Temperature Rise and Loss of Life in The Presence of Harmonic Load CurrentskarnatisharathÎncă nu există evaluări

- 2 - Battery Installation and Operation Guide January. 2016 Rev. BDocument35 pagini2 - Battery Installation and Operation Guide January. 2016 Rev. BLWAMBWA LandryÎncă nu există evaluări

- Prediction of Power Transformers Lifetime UsingDocument6 paginiPrediction of Power Transformers Lifetime Usingsujit tiwariÎncă nu există evaluări

- The Truth About Batteries-White PaperDocument13 paginiThe Truth About Batteries-White PaperRahul ShelkeÎncă nu există evaluări

- Different Types of Battery Used For Auxiliary Power Supply in Substations and Power PlantsDocument8 paginiDifferent Types of Battery Used For Auxiliary Power Supply in Substations and Power PlantsRoberto AlissonÎncă nu există evaluări

- Load Capability Estimation of Dry Type Transformers Used in PV Systems by Employing Field MeasurementsDocument18 paginiLoad Capability Estimation of Dry Type Transformers Used in PV Systems by Employing Field MeasurementsKukuh MRÎncă nu există evaluări

- BT 2423072310Document4 paginiBT 2423072310IJMERÎncă nu există evaluări

- VRLA Guidelines-OGN-OPS-ELEC-015Document10 paginiVRLA Guidelines-OGN-OPS-ELEC-015Nageswar MakalaÎncă nu există evaluări

- Getting Familiar With VRLA BatteriesDocument5 paginiGetting Familiar With VRLA BatteriesSushil SharmaÎncă nu există evaluări

- Energy Storage SystemDocument10 paginiEnergy Storage Systemcif johnnyÎncă nu există evaluări

- Tripping BatteriesDocument5 paginiTripping BatteriesAashwinAndeÎncă nu există evaluări

- Marine Electrics Made Simple or How to Keep the Batteries ChargedDe la EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedÎncă nu există evaluări

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDe la EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesÎncă nu există evaluări

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaDe la EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaÎncă nu există evaluări

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe la EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsÎncă nu există evaluări

- Rechargeable Batteries Applications HandbookDe la EverandRechargeable Batteries Applications HandbookEvaluare: 2 din 5 stele2/5 (1)

- Charging Vrla BatteriesDocument20 paginiCharging Vrla BatteriesPaul RasmussenÎncă nu există evaluări

- Compressor ReliabilityDocument2 paginiCompressor ReliabilityPaul RasmussenÎncă nu există evaluări

- Fundamentos Analisis WeibullDocument1.383 paginiFundamentos Analisis WeibullPaul Rasmussen100% (1)

- Mil STD 750eDocument685 paginiMil STD 750ePaul Rasmussen100% (1)

- Eficiencia MGE Galaxy PW - 100 A+kvaDocument44 paginiEficiencia MGE Galaxy PW - 100 A+kvaPaul RasmussenÎncă nu există evaluări

- BATERIAS Ratcliff Paper 2016Document15 paginiBATERIAS Ratcliff Paper 2016Paul RasmussenÎncă nu există evaluări

- Corriente de Corto Circuito KorinekPaperFINAL2003Document7 paginiCorriente de Corto Circuito KorinekPaperFINAL2003Paul RasmussenÎncă nu există evaluări

- Manual de Instalación 7525Document19 paginiManual de Instalación 7525Paul RasmussenÎncă nu există evaluări

- Battry UPSDocument31 paginiBattry UPSrushi_007Încă nu există evaluări

- Tabla de Contenido de Electrolito Dynasty - HazmatDocument9 paginiTabla de Contenido de Electrolito Dynasty - HazmatPaul RasmussenÎncă nu există evaluări

- Gases y Ventilación 6739Document3 paginiGases y Ventilación 6739Paul RasmussenÎncă nu există evaluări

- Cabinet N TegrityDocument5 paginiCabinet N TegrityPaul RasmussenÎncă nu există evaluări

- Freeport-Mcmoran Copper & Gold Inc.: Form 10-KDocument191 paginiFreeport-Mcmoran Copper & Gold Inc.: Form 10-KPaul RasmussenÎncă nu există evaluări

- Embalamiento Termico (Thermal Runaway)Document14 paginiEmbalamiento Termico (Thermal Runaway)Paul RasmussenÎncă nu există evaluări

- Corriente de Corto Circuito KorinekPaperFINAL2003Document7 paginiCorriente de Corto Circuito KorinekPaperFINAL2003Paul RasmussenÎncă nu există evaluări

- RGM 300 User Manual ING REV. 8.1 15.09.2011Document44 paginiRGM 300 User Manual ING REV. 8.1 15.09.2011Paul RasmussenÎncă nu există evaluări

- 302239381Document4 pagini302239381Paul RasmussenÎncă nu există evaluări

- Corriente de Corto Circuito KorinekPaperFINAL2003Document7 paginiCorriente de Corto Circuito KorinekPaperFINAL2003Paul RasmussenÎncă nu există evaluări

- Información Tecnica Batería UPS12-540MRDocument6 paginiInformación Tecnica Batería UPS12-540MRPaul RasmussenÎncă nu există evaluări

- ConstructionDocument388 paginiConstructionPaul Rasmussen100% (1)

- Expectativa de Vida 7329Document4 paginiExpectativa de Vida 7329Paul RasmussenÎncă nu există evaluări

- Gases y Ventilación 6739Document3 paginiGases y Ventilación 6739Paul RasmussenÎncă nu există evaluări

- 41 7525 0712Document18 pagini41 7525 0712Paul RasmussenÎncă nu există evaluări

- NPX MiscellaneousDocument4 paginiNPX MiscellaneousPaul RasmussenÎncă nu există evaluări

- Gases y Ventilación 6739Document3 paginiGases y Ventilación 6739Paul RasmussenÎncă nu există evaluări

- Valve Regulated Lead Acid Battery For Ups Standby Power Applications 12V 35 AH at 20 HR RATE, 12V 148 WATTS/CELL at 15 Min RateDocument2 paginiValve Regulated Lead Acid Battery For Ups Standby Power Applications 12V 35 AH at 20 HR RATE, 12V 148 WATTS/CELL at 15 Min RatePaul RasmussenÎncă nu există evaluări

- Cabinet N TegrityDocument5 paginiCabinet N TegrityPaul RasmussenÎncă nu există evaluări

- HVAC 1ph TEAO UnitHeater PDFDocument1 paginăHVAC 1ph TEAO UnitHeater PDFPaul RasmussenÎncă nu există evaluări

- Liebert-Alber Battery MonitoringDocument47 paginiLiebert-Alber Battery MonitoringPaul RasmussenÎncă nu există evaluări