Documente Academic

Documente Profesional

Documente Cultură

FUndamentals of PV Systems Tutorial

Încărcat de

jcrodriguez830 evaluări0% au considerat acest document util (0 voturi)

66 vizualizări10 paginiThis paper provides an overview of the photovoltaic power supply with battery as the energy storage device. Stand-alone systems typically include batteries for energy storage. Grid-connected systems do not include batteries, but instead depend on energy from the grid to support the electrical loads during hours of darkness and on cloudy days.

Descriere originală:

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis paper provides an overview of the photovoltaic power supply with battery as the energy storage device. Stand-alone systems typically include batteries for energy storage. Grid-connected systems do not include batteries, but instead depend on energy from the grid to support the electrical loads during hours of darkness and on cloudy days.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

66 vizualizări10 paginiFUndamentals of PV Systems Tutorial

Încărcat de

jcrodriguez83This paper provides an overview of the photovoltaic power supply with battery as the energy storage device. Stand-alone systems typically include batteries for energy storage. Grid-connected systems do not include batteries, but instead depend on energy from the grid to support the electrical loads during hours of darkness and on cloudy days.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 10

7 - 1

FUNDAMENTALS OF PV SYSTEMS: TUTORIAL

Robert L. Hammond Spencer Everingham

Principal Investigator Research Assistant

Arizona State Univ.

Tempe, AZ 85282

INTRODUCTION

Year-by-year, the application of photovoltaic (solar-electric) power supplies in telecommunications, telemetry, and

other battery charging applications is increasing. Photovoltaic (PV) systems use stationary batteries in a cycling

application unlike the more familiar (e.g., UPS) float-stationary applications.

This paper provides an overview of the photovoltaic power supply with battery as the energy storage device.

Topics covered are:

Typical PV applications with battery storage

Basic components of a PV system (e.g., solar cells, modules, charge controller, batteries, and inverters) and their

characteristics

PV system configurations and components

The solar resource

Definition of common PV terms

Battery performance in two typical PV applications

Useful web sites and other reference material

PV APPLICATIONS DEFINED

Photovoltaic applications can be divided into two broad areas:

1. Stand-alone systems (i.e., no connection to the utility grid) and

2. Grid-connected systems

Except for water pumping applications, nearly all stand-alone systems include batteries for energy storage. Grid-connected

systems typically do not include batteries for energy storage, but instead depend on energy from the grid to support the

electrical loads during hours of darkness and on cloudy days. The remainder of this paper will focus on stand-alone systems

that use batteries for energy storage.

Stand-Alone PV Applications With Battery Storage

The majority of stand-alone applications with battery storage will fall into one of the following areas:

Telemetry, e.g., data transmission and signaling

Telecommunications, e.g., mountain top repeaters, telephone and cable, highway call boxes

Lighting, e.g., billboards, railroad crossings, parking lots, walk lights

Cathodic Protection, the prevention of corrosion, e.g., in underground pipelines)

Residential/remote home or cabin

Village Power/Rural communities

7 - 2

THE POWER SOURCE: PHOTOVOLTAICS

Photovoltaic (PV) is the technical name for a technology in which radiant (photon) energy from the sun is converted to direct

current (dc) electrical energy. This is a direct conversion process that converts sunlight directly into electricity with no

moving part, no noise and no pollution. Solar cells, like diodes, transistors, and integrated circuits, are made of

semiconductor materials, typically silicon, doped with special additives such as phosphorous and boron. When sunlight

strikes the solar cell surface, a flow of electrons (electricity) is generated. Desired power, voltage and current can be

obtained by connecting individual solar cells in series and in parallel, in much the same fashion as batteries.

Bell Laboratories developed the first practical solar cell during the mid

1950s (about the same time that the first transistor was developed).

Solar Cells

Solar cells, (i.e., photovoltaic devices) are the fundamental building

block of PV modules.

Modules

Groups of interconnected solar cells are packaged into standard modules

(sometimes called panels or collectors) designed to

a) provide useful voltages and currents and

b) to protect the interconnected solar cells from the environment.

The number of cells in series determines the module voltage. Thirty-six

series cells are typically used to charge a 12-volt battery. Cell surface

area and the number of parallel cells determine the module current

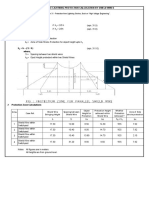

The current-voltage (IV) curve of a typical crystalline-silicon module (36-cells) is shown in Figure 3

1

. This curves defines

the characteristics of the module at a given sunlight intensity (irradiance), and cell temperature. As irradiance and cell

temperature change:

Isc and Pp are directly proportional to irradiance. Isc increases about 0.08% for each degree C increase in cell

temperature

Voc and Pp decrease about 0.5% for

each degree C increase in cell

temperature

The load (which is typically the battery)

determines the operating point on the IV

curve. As the battery is charged, the

operating point will move to the right in

Figure 3.

Characteristics for commercially available

modules, including IV curves and

selectable operating conditions (e.g.,

irradiance, cell temperature, etc.) are

defined in a free software program,

IVTracer, developed by David King at

Sandia National Laboratories

2

.

Figure 1. Basic solar cell

Figure 2. PV Module

M55 IV CURVE

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

02468

1

0

1

2

1

4

1

6

1

8

2

0

Voltage, Volts

C

u

r

r

e

n

t

,

A

m

p

s

0

5

10

15

20

25

30

35

40

45

50

P

o

w

e

r

,

W

a

t

t

s

I-V

Pp

Vp

Ip

Pp

Tc = 59.6

Irradiance = 1029 W/m2

43.9 Watts

Isc

Voc

Figure 3. Module IV Curve

7 - 3

Arrays

Modules are connected in series and/or parallel to form a larger unit called an array. The number of modules and the series-

parallel connections will determine the voltage, current and power characteristics of the array.

PV SYSTEM CONFIGURATIONS AND COMPONENTS

Most PV systems with battery storage can be defined by Figure 4. The most basic system will consist of:

1. PV Module(s); the power source

2. Charge Controller to prevent

overcharging of the battery. PWM

(pulse width modulation) or constant

voltage charge controllers are

recommended for most applications.

3. Battery to store energy for use

during nights and cloudy weather.

Batteries also supply high power to

the load that can exceed the power

rating of the array (e.g., motors,

microwave ovens or compressors).

4. DC distribution panel (could be as

simple in-line fuse)

5. Other fuses or circuit breakers for

fire protection as required by the

National Electrical Code

More complex systems could include:

1. Optional Inverter. An inverter and

ac distribution panel to power ac

loads (these are typical for stand-

alone residential systems). Inverters

can be as small as a few hundred

watts at 115 Vac or as large as

several hundred KW at 480 Vac,

three phase.

2. Optional Generator. A standby or backup generator to automatically charge batteries at some predefined minimum

state of charge (e.g., 50%). A generator can increase system availability and reduce life-cycle cost. Systems with a

prime-power generator are often call hybrid systems. The generator shown in Figure 4 shows two options: 1) a d.c.

generator that directly charges the battery and 2) an a.c. generator that supplies power to a special port on a bi-mode

inverter. The bi-mode inverter serves as a normal inverter when the generator is not operating and as a battery charger

when the generator is operating. In the charging mode, a.c. loads are supplied from the generator and the batteries are

charged with the balance of power available from the generator. An a.c. generator could also feed a conventional

battery charger instead of the inverter.

3. Other Power Sources. Other power sources can operate in parallel with the PV array (or displace the PV array) to

charge the batteries (e.g., wind generators, hydroelectric generators, or fuel cells). These sources are not shown in

Figure 4.

Systems with critical loads (e.g., remote communications sites) nearly always have a backup generator. Large

communications systems and residential applications typically include a standby generator and an inverter. Some remote

sites also include wind generators and/or hydroelectric generators, depending on the availability of these resources.

All system components and hardware other than PV modules/arrays are called balance of system or BOS. In addition to

the components listed above, BOS includes the supporting structure, wiring, bolts and nuts, disconnects, and fuses, for

example. Essentially it includes any cost item that is directly related to the cost of the PV system.

S O L A R

P V

Charge

Controller

Battery

Option: Inverter

Option: Generator

DC

Distribution

Inverter

Gen Set

AC

Distribution

+ +

-

+

-

Basic DC System

y:\personal folders\bob\hybrid\hybriddiagram.vsd

Figure 4. BLOCK DIAGRAM OF A PV SYSTEM

7 - 4

THE SOLAR RESOURCE

The amount of energy that the PV modules can produce is proportional to the available solar energy (i.e., the solar

resource) on the PV module surface over a given period of time. The solar resource varies from site to site, day to day,

season to season and year to year, and varies with the orientation of the modules. The Solar Radiation Data Manual for

Flat-Plate and Concentrating Collectors

3

(also called the Red Book) is an excellent source of solar resource data for 239

locations in the United States and its territories.

S O L A R R A D I A T I O N : U S C I T I E S ( N R E L " R E D B O O K " )

0

1

2

3

4

5

6

7

8

9

1 0

0 2 0 4 0 6 0 8 0 1 0 0 1 2 0 1 4 0 1 6 0 1 8 0 2 0 0 2 2 0 2 4 0

C I T Y ( R A N K O R D E R N U M B E R )

k

W

h

/

m

^

2

/

d

a

y

D A I L Y ( A N N U A L A V E R A G E ) : F i x e d ( a t l a t i t u d e ) a n d 2 - A x i s F l a t - P l a t e C o l l e c t o r s

# 2 P H O E N I X ( 8 . 9 ; 6 . 5 )

2 - A X I S

F I X E D ( L a t i t u d e )

# 1 D a g g e t t , C A ( 9 . 4 , 6 . 6 )

# 2 3 6 C o l d B a y , A K ( 3 . 0 , 2 . 4 )

Figure 5. Solar Radiation Data, Annual Daily Average for 239 US cities

Note in Figure 5 that the amount of solar energy in Daggett, California is about 2.75 times greater than Cold Bay, Alaska. In

addition to considering the average annual energy for a given site, it is also necessary to look at the monthly values of solar

energy. Figure 6 shows the solar resource in December to be 5.2 times higher in Daggett than in Cold Bay. Since the output

of a PV system is proportional to solar energy at a given site, the geographic location is a critical part of the design process.

Solar energy on a PV array is a function of the

orientation of the array (and array shading, if any).

Figures 5 describes two array orientations: 1) Array

perpendicular to the sun, 2-axis tracker, and 2) a

south-facing array tilted from the horizontal at the

latitude angle. The 2-axis tracker represents optimum

surface orientation (i.e., maximum energy available).

Sunlight energy on a surface is proportional to the

cosine of the angle between a line from the array to

the sun and a line normal to the surface of the array

(assuming that reflections from the surface are

ignored). A comparison of solar energy available in

Miami, Florida, on a surface for several array

orientations is shown in Figure 7.

SOLAR ENERGY BY MONTH

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Month

H

o

u

r

s

o

f

F

u

l

l

S

u

n

,

k

W

h

/

m

2

/

d

a

y

Daggett 6.6

Cold Bay 2.4

Figure 6. Solar Energy by Month, Fixed Array at Latitude

7 - 5

DESIGN CONSIDERATIONS

Step 1. Define Electrical Loads

4

PV system design starts with a

definition of the electrical loads. The

initial system cost will be directly

proportional to the amount of energy

that the system is designed to provide.

Energy conservation and efficient

loads are essential if system costs are

to be minimized. Reducing the load

requirements (kWh) by 50 percent will

reduce the initial system cost by

approximately 50 percent - which could

save thousands of dollars.

The size, and subsequently the cost, of

a photovoltaic system depends upon

two factors: 1) the electrical energy

requirements of the devices relying on

the system, commonly referred to as

the daily energy load, and 2) the amount of sunshine on the modules. These factors determine the quantity and size of

modules, batteries, and other components.

The load is usually measured as the amount of electric power being used at any given moment. For the purposes herein, the

term "average daily load" will refer to the wattage of the electrical devices multiplied by the average daily use in hours per

day. To determine the load, it is necessary to identify the devices that will rely on the system for power. If the system is

used to power a home, the load might consist of lights, coffee pot, microwave oven, hair dryer, vacuum cleaner, radio, TV,

power tools, water pump, and other common household items. Phantom loads, such as GFIC, wall power cubes, receivers

for remote controls, and clocks must be included in the load

The general strategy in selecting electrical loads include a) use propane instead of electricity for producing heat (e.g., space

heater, hot water, cooking), b) selecting electrical loads with high efficiency, and c) avoiding unnecessary load.

Step 2. Determine load wattage

Once the individual electrical loads have been identified, determine the wattage of each item. Nameplate ratings are

generally maximum design limits of the device, which could be two to four times the actual power consumed. If possible,

measure the actual power of every electrical load to be used.

Step 3. Estimate usage of individual loads

Next, decide how many hours per day (average) each item is to be used. If the load varies from day-to-day or season-to-

season, then develop a weekly, monthly, or annual load profile. The load estimate must be as precise as possible to avoid

over sizing or under sizing the systems. If system design is oversized, money is wasted on excess capacity. If it is

undersized, power shortages during operation may result. This step must be completed before any estimates of array and

battery requirements can be initiated.

Step 4. Sizing the System.

Details of system sizing and system design are beyond the scope of this paper. Comprehensive software programs are

available to facilitate the system sizing process and some include irradiance and a module database

5

. Such programs walk

you through the design options and allow you to select appropriate system configurations and system variables.

Solar Resource: Miami, FL

0

1

2

3

4

5

6

7

8

9

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Month

H

o

u

r

s

o

f

F

u

l

l

S

u

n

2-Axis TNI (kWh/m2/day) [Annual Ave. 6.7]

N-S Axis: Horz. (kWh/m2/day) [Annual Ave.6.2]

Fixed: +15, -15, +15 (kWh/m2/day) [Annual Ave. 5.4]

Fixed: latitude (kWh/m2/day) [Annual Ave. 5.2]

Horizontal (kWh/m2/day) [Annual Ave. 4.8]

2-Axis DNI-Concentrator (kWh/m2/day) [Annual Ave. 4.0]

Figure 7. Array Energy as a function of Array Orientation

7 - 6

For organizations desiring assistance with PV system design, companies that specialize in PV system design (i.e. system

integrators), can be found in the Index to Advertisers in Home Power Magazine, www.homepower.com, and from the

comprehensive PV Power WEB site: http://www.pvpower.com/pvinteg.html.

BATTERIES

Batteries used in typical stand-alone PV systems experience moderate to deep daily discharge cycles and harsh

environmental condition. Elevation of installation sites vary from sea level to above15,000 feet (4,572 meters) above sea

level, while ambient temperatures may vary from 60F to +122F (-51C to +50C). Proper battery selection, installation,

operation and maintenance are essential for good performance and expected life. Management of daily depth of discharge

(DOD) and periodic equalization are essential.

It is unfortunate that the battery industry often use the terms stationary and standby interchangeable when referring to

batteries in float applications

6

. Batteries used in PV stand-alone applications are stationary batteries, but these applications

are a far cry from a float application. Treating PV batteries as a float application will quickly destroy the battery. Frequent

equalization of PV batteries (both flooded and valve regulated) are essential if expected cycle life is to be achieved. The

optimum equalization frequency will depend on the cycle depth.

Battery performance for two applications will be reviewed to demonstrate the cycling behavior of batteries in PV

applications. The first application is a stand-alone home application and the second application is a communications

mountain top repeater.

Stand-Alone Home Application

This case study consists of a 2,700 square-foot stand-alone home in Prescott, Arizona. The PV system consists of a 2,800-

Watt PV array

7

, a 24V-1000 amp-hour battery bank

8

, and a 4-KW bi-mode sine-wave inverter. Loads consist of a full range

of appliances (e.g., lights, refrigerator, microwave oven, coffeepot, toaster, satellite TV, stereo, computers, fax, clothes

washer and dryer, shop tools, two evaporative coolers, and water pump). The average battery load current in December 2001

was 10.1 amps (242.4 amp-hours per day). With the batteries fully charged, the system would support the load for 3.3 days

with no sunlight, resulting in an 80% depth of discharge. A manual-start emergency generator is available to recharge the

batteries during extended cloudy days and/or other causes of low battery voltage. The generator has logged 38 hours of run

time since installation in October 1998, or about 12 hours per year. (No backup generator was available from 1987 to 1998,

so load were carefully managed during extended cloudy weather to avoid blackouts.) The generator is an emergency standby

generators intended for occasional use.

Figure 8 shows battery voltage, battery load current and PV current during the month of December 2001. The inverter

switches from the inverting mode to the battery charger mode when the generator is running. This is seen as a negative load

current (since the inverter is d.c. current source instead of a d.c. current sink) in Figure 8. The generator ran three times

(December 4, 9, and 31).

Battery state of charge (SOC) and bus voltage are shown in Figure 9. The deep-cycle golf-cart batteries are well suited for

the occasional 50% depth of discharge and the typical 20 % daily depth of discharge during winter months. Although this is

a stationary battery application, it is clearly a cycling application. Note that the 24Vdc (nominal) battery bank was

equalized at 30.2 Vdc (2.52 volts per cell) prior to the capacity test on 8-9 December in order to ensure a fully charged

battery prior to the capacity test. It was also equalized after the capacity test to ensure a prompt full.

This PV system has been in service for 15 years and has experienced only one unscheduled outage. The outage lasted two

hours and it was due to a failed charge controller. The first set of batteries (1100 AH) was replaced after 7.5 years. The

second set of batteries (660 AH) was replaced after 5.5 year. The current set of batteries (1,000 AH) was installed in January

2001.

7 - 7

BATTERYVOLTAGE; PVCURRENT; LOAD CURRENT

22

23

24

25

26

27

28

29

30

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

V

b

b

,

B

a

t

t

e

r

y

V

o

l

t

a

g

e

,

V

d

c

-100

-80

-60

-40

-20

0

20

40

60

80

100

P

V

&

L

o

a

d

C

u

r

r

e

n

t

,

A

d

V-24 I-PV I-load

Capacity Test

Genset, 1 hr.

Genset, 2 hr. Genset, 3 hr.

PV

Figure 8. Battery Voltage, PV Current, and Load Current

S O C A N D V b b , P R E S C O T T H O U S E : D E C E M B E R 2 0 0 1

2 0

2 1

2 2

2 3

2 4

2 5

2 6

2 7

2 8

2 9

3 0

3 1

3 2

1 3 5 7 9 1 1 1 3 1 5 1 7 1 9 2 1 2 3 2 5 2 7 2 9 3 1

V

b

b

,

B

a

t

t

e

r

y

B

u

s

V

o

l

t

a

g

e

,

V

d

c

0 %

1 0 %

2 0 %

3 0 %

4 0 %

5 0 %

6 0 %

7 0 %

8 0 %

9 0 %

1 0 0 %

1 1 0 %

1 2 0 %

S

t

a

t

e

o

f

C

h

a

r

g

e

,

%

V - 2 4 A H

H o u r l y a v e r a g e s o f s i x - s e c o n d d a t a

V r , 3 0 . 2 1 2 / 0 1 / 0 1

C a p a c i t y T e s t

V r , 2 9 . 2 1 2 / 2 1 / 0 1

F o u r C l o u d y D a y s

Figure 9. Battery Voltage and State of Charge for a residential PV system (December 2001)

Telecommunications System - Hybrid

Arizona Public Service commissioned a remote stand-alone PV hybrid system atop Carol Spring Mountain (SCM) in

October 1995. At 6,600 feet (2012 meters) elevation, this system powers communications equipment, including cellular

telephone, cable television, and new services microwave repeaters. The PV system consisted of a 25-KW PV array, a 192V-

3100AH-battery bank, a bi-mode 30-KW-ac inverter, and a 60-KW-ac diesel fueled generator (and a 50-KW backup

generator). The loads (communications and heating/cooling equipment) are fairly constant year round at 10-12 KW-ac.

Most hybrid PV systems are designed to deliver energy at the lowest levelized energy cost. It is not uncommon for the

generator to provide 20-50% of the total annual energy. These generators are prime-power generators, which are designed

for continuous duty and require an overhaul about every 10,000 hours. (The generator used in the earlier residential case

study was an emergency generator that has a life of about 1,500 hours of run time.)

7 - 8

The original set of VRLA-AGM

9

technology batteries was still in service after 6.25 years in January 2002, but it was rapidly

approaching end of life. In January, the batteries had degraded to about 50% of rated value; however, the batteries were still

functional, although the generator was supplying more than the typical 25% of the monthly load. The availability of power

to the load was still 100%. The old rule of thumb that batteries should be replaced when they reach 80% of rated capacity is

not appropriate for hybrid PV systems. Batteries were replace in April 2002 with a similar set of VRLA-AGM batteries.

Figure 10 shows the CSM Load-KWH, the PV-KWH, the generator-KWH, and the battery voltage. The generator is

providing about 65% of the total energy, while PV is providing the remaining 25%. This high contribution by the generator

is due to the weak batteries, the reduced amount of sunlight in January, and the loads doubling since installation six years

ago.

Battery state of charge (SOC) is shown in Figure 11, with battery voltage included for reference. Batteries are working hard

with a typical cycle depth of 50% to 80%. This clearly is not a float application. Battery voltage frequently dropped to 1.92

volts per cell during January. Batteries were equalized at 2.35 volts per cell frequently during the month due to the deep

cycling.

C S M : L o a d , P V , G e n e r a t o r P o w e r , B a t t r e y V o l t a g e : J a n u a r y 2 0 0 2

0

5

1 0

1 5

2 0

2 5

3 0

3 5

4 0

4 5

5 0

0

1

T

u

e

0

3

T

h

u

0

5

S

a

t

0

7

M

o

n

0

9

W

e

d

1

1

F

r

i

1

3

S

u

n

1

5

T

u

e

1

7

T

h

u

1

9

S

a

t

2

1

M

o

n

2

3

W

e

d

2

5

F

r

i

2

7

S

u

n

2

9

T

u

e

3

1

T

h

u

D a y o f M o n t h

P

o

w

e

r

(

K

W

)

0

2 5

5 0

7 5

1 0 0

1 2 5

1 5 0

1 7 5

2 0 0

2 2 5

2 5 0

B

a

t

t

e

r

y

V

o

l

t

a

g

e

,

V

b

b

(

V

d

c

)

2 . 3 5 v p c

1 . 9 2 v p c

B a t t e r y V o l t a g e

L o a d

G e n e r a t o r

P V

Figure 10. CSM Load KWH, PV KWH, Generator KWH, and Battery Voltage

C S M , J A N 0 2

1 7 0

1 8 0

1 9 0

2 0 0

2 1 0

2 2 0

2 3 0

0

1

T

u

e

0

3

T

h

u

0

5

S

a

t

0

7

M

o

n

0

9

W

e

d

1

1

F

r

i

1

3

S

u

n

1

5

T

u

e

1

7

T

h

u

1

9

S

a

t

2

1

M

o

n

2

3

W

e

d

2

5

F

r

i

2

7

S

u

n

2

9

T

u

e

3

1

T

h

u

D a t e

B

a

t

t

e

r

y

V

o

l

t

a

g

e

,

V

d

c

0

2 0

4 0

6 0

8 0

1 0 0

1 2 0

S

t

a

t

e

-

o

f

C

h

a

r

g

e

,

%

V b b

S O C

V R L A B A T T E R I E S A s s u m e 5 0 % o f R a t e d C a p a c i t y : 3 1 0 0 A H > > 1 5 5 0 A H

S O C

2 . 3 5 v p c

1 . 9 2 v p c

Figure 11. Battery Voltage and State-of-Charge for Carol Spring Mountain, January 2002

7 - 9

CONCLUSIONS

Photovoltaic systems can be designed to provide non-polluting, reliable power. Proper design practices will minimize

maintenance and maximize performance. Use of the suns energy can either eliminate the requirement for fossil fuel, or it

can significantly minimize their use. These are ideal characteristics for remote power applications.

The solar energy available for PV at a site is dependent on the geographic location and the orientation of the PV array. If

possible avoid shading any part of the array.

The size and cost of a PV system is proportional to the energy consumption by the load. Reducing the electrical load by

selecting energy efficient equipment will result in a corresponding reduction in PV system cost. Defining the system load is

the first step is PV system design.

Nearly all batteries used in PV systems are deep-cycle lead-acid technologies. Even though PV batteries are stationary,

they are nearly always in a cycling application. Rarely would they ever be in a float mode. Batteries that are cycled must be

equalized periodically (e.g., every two week to every two months, depending on the cycle depth. VRLA batteries are not

excluded from this required, although VRLA-Gel technologies seem to require the least amount of equalization.

For more information specific to PV battery applications, see Photovoltaic Battery and Charge Controller Market and

Applications Survey

10

and Photovoltaic in Cold Climates

11

. Several others references for PV applications are listed under PV

WEB SITES, Bibliography, and EndNotes.

PV WEB SITES

www.pvpower.com [Whats new, History, Technology , FAQ, Industry, Applications, Jobs, Calendar, Resources]

www.sandia.gov/pv/ [Sandia National Laboratories (SNL)PV Components, BOS, Handbook, Publications

www.nrel.gov/pv/ information/html [ National Renewable Energy Lab. (NREL)

http://www.osti.gov/html/techstds/standard/std3003/std3003a.html#ZZ28, Backup Power Sources for DOE Facilities.

3.17 Stationary Battery

BIBLIOGRAHPY

1. K Zweibel, Harnessing Solar Power: The Photovoltaic Challenge, Plenum Press, New York and London, ISBN 0-306-

43564-0, 1990

2. SJ Strong, The Solar Electric House: A Design Manual for Home-Scale Photovoltaic Power Systems, Rodale Press,

Emmaus, Pennsylvania, 1987

3. Home Power Magazine, www.homepower.com

4. Maintenance and Operation of Stand-Alone Photovoltaic Systems. Naval Facilities Engineering Command, Southern

Division Photovoltaic Review Committee, Department of Defense, Prepared by Architectural Energy Corporation,

December 1991

5. Stand-Alone Photovoltaic Systems, A Handbook of Recommended Design Practices. Sandia National Laboratories,

SAND87-7023, March 1995

ENDNOTES

1

Definitions for abbreviations used in Figure 3:

Voc open-circuit voltage

Isc short-circuit current

Pp the maximum power available from a PV device at specified operating conditions (irradiance, temperature, etc.)

Vp voltage at Pp

Ip current at Ip

7 - 10

2

Database of Module Performance Parameters. A Microsoft Access database of PV module performance parameters has

been developed and is continuously updated on this site. This database contains performance and physical data as specified

by manufacturers, plus other measured parameters required to implement the module performance model developed by

Sandia National Laboratories and documented elsewhere. The database can be used directly by the IVTracer program which

implements the Sandia performance model providing current-voltage (I-V) characteristics for commercial photovoltaic

modules at user selected operating conditions. The IVTracer software is available by contacting David King at Sandia

(dlking@sandia.gov). In addition, the module database can be used directly by commercially available PV system design

software, such as PV-DesignPro by Maui Solar Energy Software Corporation.

3

Solar Radiation Data Manual for Flat-Plate and Concentrating Collectors, National Renewable Energy Laboratory,

NREL/TP-463-5067, April 1994.

4

Root, B. Doing a Load Analysis: The First Step in System Design, Home Power #58, April/May 1997, pp38-44.

5

For example, see Solar Design Studio, Maui Solar Energy Software Corporation, 810 Haiku Road #113, Box 1101, Haiku,

HI, 96708, 808-573-6712, www.mauisolarsoftware.com

6

Large battery installations which are called upon only occasionally to supply power, usually in emergency or auxiliary

power supply circumstances, are referred to as stationary or standby batteries. Battery Reference Handbook, Reed

Educational and Professional Publishing Ltd 1996, ISBN 1 56091 805 5, pg. 32/3

7

2,700 Watts at 1000 watt/m

2

and 20C ambient temperature

8

1000 amp-hours at the 100 hour rate

9

VRLA-AGM: Valve Regulated Lead Acid-Absorbed Glass Mat

10

Hammond, RL, J. Turpin, G. Corey, T. Hund, S. Harrington. Photovoltaic Battery & Charge Controller Market and

Applications Survey, Arizona State University TR-96-12-01-ECT; Sandia Report, SAND96-2900, UC1350, December 1996.

11

Ross, M and J. Royer. Photovoltiacs in Cold Climates, James and James, UK, ISBN 1 873936 89 3, 1999

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- PowerEdge Portfolio BrochureDocument22 paginiPowerEdge Portfolio Brochurejcrodriguez83Încă nu există evaluări

- Blade Servers 0611 WebcastDocument39 paginiBlade Servers 0611 Webcastjcrodriguez83Încă nu există evaluări

- Series 6 Plus Datasheet - USDocument2 paginiSeries 6 Plus Datasheet - USjcrodriguez83Încă nu există evaluări

- S 5 U Standing Seam Metal Roof Clamp Manual 60170904.6900053Document2 paginiS 5 U Standing Seam Metal Roof Clamp Manual 60170904.6900053jcrodriguez83Încă nu există evaluări

- BS 7671 Appendix 4 guide to cable ratings and calculationsDocument5 paginiBS 7671 Appendix 4 guide to cable ratings and calculationsTy PhanÎncă nu există evaluări

- Virtualization Technology OverviewDocument24 paginiVirtualization Technology Overviewjcrodriguez83Încă nu există evaluări

- System Management Part 1Document24 paginiSystem Management Part 1jcrodriguez83Încă nu există evaluări

- SS NGCS All PresentationsDocument82 paginiSS NGCS All Presentationsjcrodriguez83Încă nu există evaluări

- SS NGCS All PresentationsDocument78 paginiSS NGCS All Presentationsjcrodriguez83Încă nu există evaluări

- Virtualization Technology OverviewDocument24 paginiVirtualization Technology Overviewjcrodriguez83Încă nu există evaluări

- Take The Guesswork Out of Virtualization With BRCDocument34 paginiTake The Guesswork Out of Virtualization With BRCjcrodriguez83Încă nu există evaluări

- Area Classification ExplainedDocument112 paginiArea Classification ExplainedNissi JimmyÎncă nu există evaluări

- System Management Part 2 - FinalDocument29 paginiSystem Management Part 2 - Finaljcrodriguez83Încă nu există evaluări

- Training and Certification Manual - 082011Document51 paginiTraining and Certification Manual - 082011jcrodriguez83Încă nu există evaluări

- Dell Solution Tools for Latin America Channel DevelopmentDocument26 paginiDell Solution Tools for Latin America Channel Developmentjcrodriguez83Încă nu există evaluări

- Dell Solution ToolsDocument26 paginiDell Solution Toolsjcrodriguez83Încă nu există evaluări

- Measuring Soil Resistivity for Grounding System DesignDocument34 paginiMeasuring Soil Resistivity for Grounding System DesignRamesh AnanthanarayananÎncă nu există evaluări

- Master S Thesis EPSH4 1034Document110 paginiMaster S Thesis EPSH4 1034jcrodriguez83Încă nu există evaluări

- 1comparison of Approaches (SESTLC, ROW & HIFREQ) For AC Interference StudyDocument11 pagini1comparison of Approaches (SESTLC, ROW & HIFREQ) For AC Interference StudyDadi AzizÎncă nu există evaluări

- Combinerbox Dus120718w PDFDocument2 paginiCombinerbox Dus120718w PDFjcrodriguez83Încă nu există evaluări

- L.27.MX.P.55995.00.002.01 Re001Document17 paginiL.27.MX.P.55995.00.002.01 Re001jcrodriguez83Încă nu există evaluări

- Arcmap 1Document18 paginiArcmap 1jcrodriguez83Încă nu există evaluări

- How Gas Electricity WorksDocument1 paginăHow Gas Electricity WorksVinoth KumarÎncă nu există evaluări

- 1.2 - Distribution Line Post Cat D-LP - 131003 PDFDocument4 pagini1.2 - Distribution Line Post Cat D-LP - 131003 PDFjcrodriguez83Încă nu există evaluări

- Recloser ReliabilityDocument12 paginiRecloser ReliabilityArzapalo Figueroa MiguelÎncă nu există evaluări

- Combox Uus120824 PDFDocument21 paginiCombox Uus120824 PDFjcrodriguez83Încă nu există evaluări

- Clint Inverter PaperDocument13 paginiClint Inverter PaperDiego RoméÎncă nu există evaluări

- Nema SymbolsDocument44 paginiNema SymbolsSwitchelectric SwitchelectricÎncă nu există evaluări

- Wattage ApplianceDocument2 paginiWattage Appliancehweston2871Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Tilf Out 2 Tilf Out 2Document3 paginiTilf Out 2 Tilf Out 2Yamendra GurungÎncă nu există evaluări

- Hoppecke RTM2-RPM2 Ficha (Cargador) (Ingles 2017) PDFDocument2 paginiHoppecke RTM2-RPM2 Ficha (Cargador) (Ingles 2017) PDFJuan Carlos Rubio Fresco0% (1)

- ACSR AluminumConductorSteelReinforcedDocument3 paginiACSR AluminumConductorSteelReinforcedkkn1234Încă nu există evaluări

- DSLP of Sub-Station Using Shield Wire by Razevig MethodDocument1 paginăDSLP of Sub-Station Using Shield Wire by Razevig MethodSomen Sarkar100% (1)

- Floating Solar SystemDocument8 paginiFloating Solar SystemSgurr Energy IndiaÎncă nu există evaluări

- Installation Guide Master Pact LV Power AirDocument142 paginiInstallation Guide Master Pact LV Power AirOthoniel FabianÎncă nu există evaluări

- Sample Companies DataDocument16 paginiSample Companies DataShrutiMarwahÎncă nu există evaluări

- Microwave Filters-Applications and TechnologyDocument12 paginiMicrowave Filters-Applications and Technologyalokcena007Încă nu există evaluări

- Supplied AccessoriesDocument6 paginiSupplied AccessoriesHad CorsoÎncă nu există evaluări

- Factors of A Safe Residential Electrical InstallationDocument32 paginiFactors of A Safe Residential Electrical InstallationjporangecubeÎncă nu există evaluări

- Ground Penetrating Radar - Shawna Jones, Meghan McGinn, Nicholas RiordanDocument19 paginiGround Penetrating Radar - Shawna Jones, Meghan McGinn, Nicholas RiordanRafael Manfrin MendesÎncă nu există evaluări

- L (Na) 02031eng-F (1712) 17a PDFDocument390 paginiL (Na) 02031eng-F (1712) 17a PDFFerdi Bayu0% (1)

- UF-1000i SM 03 ElectronicsDocument40 paginiUF-1000i SM 03 ElectronicsCARLOSÎncă nu există evaluări

- Ammeter N VoltmeterDocument56 paginiAmmeter N VoltmeterPrerna AgrawalÎncă nu există evaluări

- Nmos350 500ConstructionGuideDocument3 paginiNmos350 500ConstructionGuidetrkonjicÎncă nu există evaluări

- Device List for Prayagraj STPP TG Unit 1Document12 paginiDevice List for Prayagraj STPP TG Unit 1apsÎncă nu există evaluări

- Ad9833 PDFDocument21 paginiAd9833 PDFfabiobonadiaÎncă nu există evaluări

- What is a FilterDocument5 paginiWhat is a Filtermuhammad irfanÎncă nu există evaluări

- ELECTRICAL CIRCUITS AND COMPONENTSDocument22 paginiELECTRICAL CIRCUITS AND COMPONENTSCedric Zamora100% (1)

- Basic Electrical Terms and DefinitionsDocument6 paginiBasic Electrical Terms and DefinitionsJericho CunananÎncă nu există evaluări

- Varibles DIgSILENTDocument58 paginiVaribles DIgSILENTIsrael FonsecaÎncă nu există evaluări

- General Description: Plug Fan ER..C With Standard MotorDocument7 paginiGeneral Description: Plug Fan ER..C With Standard MotorwildanÎncă nu există evaluări

- +5 Volt, Serial Input, Dual 12-Bit DAC AD8522Document8 pagini+5 Volt, Serial Input, Dual 12-Bit DAC AD8522Zoran ConstantinescuÎncă nu există evaluări

- Beckercom: Welcome To The Becker ElectronicsDocument68 paginiBeckercom: Welcome To The Becker ElectronicsMichael Erdis50% (2)

- Emd ManualDocument17 paginiEmd ManualBina HinglajiyaÎncă nu există evaluări

- Submittal For Al Barsha 1451 Rev0 PDFDocument55 paginiSubmittal For Al Barsha 1451 Rev0 PDFGokulÎncă nu există evaluări

- Speed Control of 2-Pole DC Motor Using PWM PROTEUS VSM 7.9 & AVR STUDIO (SOFTWARE)Document4 paginiSpeed Control of 2-Pole DC Motor Using PWM PROTEUS VSM 7.9 & AVR STUDIO (SOFTWARE)IJSTEÎncă nu există evaluări

- Instruction Manual Remote Control System 4Document34 paginiInstruction Manual Remote Control System 4Sebastian Torres FloresÎncă nu există evaluări

- Electronics & Communication Engineering R13 Iv-I Elective Ii Optical Communications (Rt4104A) Previous End Examination Questions (R13 & R10)Document7 paginiElectronics & Communication Engineering R13 Iv-I Elective Ii Optical Communications (Rt4104A) Previous End Examination Questions (R13 & R10)jaganmohanrsÎncă nu există evaluări

- Rev 1 Module2 PLCDocument293 paginiRev 1 Module2 PLCMuhd IzzatÎncă nu există evaluări