Documente Academic

Documente Profesional

Documente Cultură

Metal Oxide/Zeolite Nafion Composite Membranes For PEMFC Operation Above 100 C

Încărcat de

shoemakerlevy9Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Metal Oxide/Zeolite Nafion Composite Membranes For PEMFC Operation Above 100 C

Încărcat de

shoemakerlevy9Drepturi de autor:

Formate disponibile

Metal Oxide/Zeolite Nafion Composite Membranes for PEMFC Operation above 100oC

Cell Potential / V

1.0

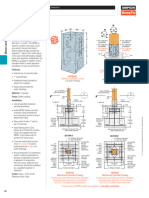

SiO2 - Surface Area 80 - 100 m2/g (R = 0.25)

K.T. Adjemian , S. Srinivasan , J. Benzigerb and A.B. Bocarslya Princeton University, Princeton NJ 08540, USA

0.8

SiO2 - Surface Area 115 - 145 m2/g (R = 0.24) SiO2 - Surface Area 300 - 350 m2/g (R = 0.18)

0.6

0.4

High temperature proton-exchange membrane fuel cells (PEMFCs) are being investigated to alleviate some of the problems encountered at the present temperature of 80oC. These difficulties include CO poisoning of the platinum electrodes, and thermal and water management. The proton conductivity of Nafion relies on water, and at higher temperatures the conductivity dramatically decreases due its loss by evaporation. Therefore, in order to maintain desirable proton conductivity at elevated temperatures, one possible approach is to modify Nafion from its original form. This was previously accomplished by incorporating silicon oxide via sol-gel within the Nafion membrane.[1] The purpose of this study is to investigate composite Nafion membranes for operation in PEMFCs at temperatures above 100oC. This was accomplished by incorporating various metal oxide and zeolite particles into the Nafion membrane using a recasting procedure that employs solubilized Nafion.[2] The particles varied in particle size, surface area, chemical makeup and surface chemistry. Results and Discussion - Shown in figure 1 are the PEMFC polarization curves obtained when silica, alumina or titania are incorporated in the Nafion membrane at a cell temperature of 130oC and a total pressure of 3 atm. All three metal oxides have the same particle size and surface area. Silica clearly provides the best response. This can be quantified by considering the liner portion of the polarization curve, which reflects the cell resistivity. (Reported as R values in figures 1 and 2)

1.0

0.2 0 200 400 600 800 1000 1200 1400 1600

Current Density / mA cm-2

Figure 2: PEMFC performance of silica with different surface areas Recast Nafion membranes at 130oC and 3 atm. Here we see that with increasing surface area, the resistances of the cells decrease (see R values in figure 2). This can be attributed to the increased number of sites the water molecules can form hydrogen bonds with. Conclusions The characteristics of PEMFC can be improved by increasing it operating temperature above 100oC. Composite membranes prepared by suspending metal oxide or zeolite particles in Nafion solution show improved PEMFC performance at elevated temperatures. The particles size, surface area, chemical makeup and surface chemistry all play vital roles in its ability to improve water retention, thereby improving high temperature PEMFC operation. In all four cases of the silicas shown here, current densities are high enough to manufacture a high temperature PEMFC with the added benefits of increased CO tolerance and improved water and heat management. References: 1. K. T. Adjemian, S. J. Lee, S. Srinivasan, J. Benziger, and A. B. Bocarsly, Journal of the Electrochemical Society In press 2002. 2. P. L. Antonucci, A. S. Arico, P. Creti, E. Ramunni, and V. Antonucci, Solid State Ionics 125 431-437, 1999.

SiO2/Recast Nafion (R = 0.29) Cell Potential / V

0.8

Al2O3/Recast Nafion (R = 0.36) TiO2/Recast Nafion (R = 0.5)

0.6

0.4

0.2 0 200 400 600 800 1000 1200 1400

Current Density / mA cm-2

Figure 1: PEMFC performance of silica, alumina and titania Recast Nafion membranes at 130oC and 3 atm. This variation in PEMFC performance can be attributed to the differences of metal oxide composition and the nature of the Nafion metal oxide interface. Figure 2 shows the polarization curve for three different silicas all with the same particle size and surface chemistry, but with different surface areas.

a b

Department of Chemistry Department of Chemical Engineering

S-ar putea să vă placă și

- Investigations On Composition and Morphology of Electrochemical Alumina and Alumina Yttria Stabilised Zirconia DepositsDocument9 paginiInvestigations On Composition and Morphology of Electrochemical Alumina and Alumina Yttria Stabilised Zirconia Depositssurresh07Încă nu există evaluări

- 1 s2.0 S0360319909015237 MainDocument7 pagini1 s2.0 S0360319909015237 MainThíchHọcHóaÎncă nu există evaluări

- Lead Dioxide 4Document4 paginiLead Dioxide 4Khobaib HayatÎncă nu există evaluări

- JurnalDocument10 paginiJurnalsyailendraÎncă nu există evaluări

- Electrochimica Acta 50 (2005) 4174-4181Document8 paginiElectrochimica Acta 50 (2005) 4174-4181Dulce BaezaÎncă nu există evaluări

- Nano-Silica Layered Composite Membranes Prepared by PECVD For Direct Methanol Fuel CellsDocument6 paginiNano-Silica Layered Composite Membranes Prepared by PECVD For Direct Methanol Fuel CellssggdgdÎncă nu există evaluări

- 2013 - Direct Synthesis of Single-Phase P-Type SNS by Electrodeposition From A Dicyanamide Etc - Steichen-JPC-C13Document11 pagini2013 - Direct Synthesis of Single-Phase P-Type SNS by Electrodeposition From A Dicyanamide Etc - Steichen-JPC-C13HamzaÎncă nu există evaluări

- Nafion/Analcime and Nafion/Faujasite Composite Membranes For Polymer Electrolyte Membrane Fuel CellsDocument5 paginiNafion/Analcime and Nafion/Faujasite Composite Membranes For Polymer Electrolyte Membrane Fuel Cellsshoemakerlevy9Încă nu există evaluări

- Preparation and Characterization of Novel Chitosan-Based Mixed Matrix Membranes Resistant in Alkaline MediaDocument10 paginiPreparation and Characterization of Novel Chitosan-Based Mixed Matrix Membranes Resistant in Alkaline MedianimzaiÎncă nu există evaluări

- The Corrosion Behaviour of Polypyrrole Coating Synthesized in Phenylphosphonic Acid SolutionDocument8 paginiThe Corrosion Behaviour of Polypyrrole Coating Synthesized in Phenylphosphonic Acid SolutionMarly Blanco VeraÎncă nu există evaluări

- Surface Modification of Polypropylene FiDocument5 paginiSurface Modification of Polypropylene FiEvelin Zuñiga barreraÎncă nu există evaluări

- Synthesis of Mxene/Ag Composites For Extraordinary Long Cycle Lifetime Lithium Storage at High RatesDocument7 paginiSynthesis of Mxene/Ag Composites For Extraordinary Long Cycle Lifetime Lithium Storage at High RatesHameed HusseinÎncă nu există evaluări

- Corona PretreatmentDocument8 paginiCorona PretreatmentcehigueraÎncă nu există evaluări

- Jana Bipolar PlatesDocument2 paginiJana Bipolar PlatesMohamed ZaghloulÎncă nu există evaluări

- Diamond-Like Carbon Protective Anti-Reflection Coating For Si Solar CellDocument4 paginiDiamond-Like Carbon Protective Anti-Reflection Coating For Si Solar CellnguyenthanhhopÎncă nu există evaluări

- Characterization of Anodic Spark-Converted Titanium Surfaces For Biomedical ApplicationsDocument5 paginiCharacterization of Anodic Spark-Converted Titanium Surfaces For Biomedical ApplicationstamilnaduÎncă nu există evaluări

- Enhancement of Reversibility of CR (III) /CR (II) Redox Couple in Fe-Cr Flow Cell With Bi-Pb Electroplated Carbon FeltsDocument7 paginiEnhancement of Reversibility of CR (III) /CR (II) Redox Couple in Fe-Cr Flow Cell With Bi-Pb Electroplated Carbon FeltsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Micro-Channel Reactor For Steam Reforming of MethanolDocument6 paginiMicro-Channel Reactor For Steam Reforming of MethanolWassachol SumarasinghaÎncă nu există evaluări

- Improvement of Silicon Direct Bonding Using Surfaces Activated by Hydrogen Plasma TreatmentDocument4 paginiImprovement of Silicon Direct Bonding Using Surfaces Activated by Hydrogen Plasma TreatmentToni HillÎncă nu există evaluări

- Steam Reforming of Methane Over Ni Catalyst in Micro-Channel ReactorDocument9 paginiSteam Reforming of Methane Over Ni Catalyst in Micro-Channel ReactorWassachol SumarasinghaÎncă nu există evaluări

- Tuning Interfacial Electron Transfer by Anchoring Nife LDH On in Situ Grown Cu O For Enhancing Oxygen EvolutionDocument9 paginiTuning Interfacial Electron Transfer by Anchoring Nife LDH On in Situ Grown Cu O For Enhancing Oxygen EvolutionIrlan SantosÎncă nu există evaluări

- 2 67 1589276798 23.ijmperdjun202023Document10 pagini2 67 1589276798 23.ijmperdjun202023TJPRC PublicationsÎncă nu există evaluări

- Enhancing Stability and Efficiency of Perovskite Solar Cells With Crosslinkable Silane-Functionalized and Doped FullereneDocument9 paginiEnhancing Stability and Efficiency of Perovskite Solar Cells With Crosslinkable Silane-Functionalized and Doped FullerenepeterÎncă nu există evaluări

- The Superior Electrochemical Performance of Oxygen-Rich Activated CarbonsDocument3 paginiThe Superior Electrochemical Performance of Oxygen-Rich Activated CarbonsSunnyÎncă nu există evaluări

- 1 s2.0 S1572665717301819 MainDocument10 pagini1 s2.0 S1572665717301819 MainMuhammad ImranÎncă nu există evaluări

- 1 s2.0 S1359836819300782 MainDocument10 pagini1 s2.0 S1359836819300782 Main779070870Încă nu există evaluări

- ScienceDocument3 paginiScienceDhirendra SinghÎncă nu există evaluări

- Electrochemical Behavior of Layered Solid Solution Li Mno 2limo (M 5 Ni, MN, Co) Li-Ion Cathodes With and Without Alumina CoatingsDocument7 paginiElectrochemical Behavior of Layered Solid Solution Li Mno 2limo (M 5 Ni, MN, Co) Li-Ion Cathodes With and Without Alumina CoatingsEYERUSALEM TADESSEÎncă nu există evaluări

- Polyaniline Coating On Stainless Steel PlatesDocument6 paginiPolyaniline Coating On Stainless Steel PlatesMatthew MarpleÎncă nu există evaluări

- JPC2006Document5 paginiJPC2006vumar83Încă nu există evaluări

- Enhancement of proton conductivity through Yb and Zn doping in BaCe0. 5Zr0. 35Y0. 15O3-δ electrolyte for IT-SOFCsDocument9 paginiEnhancement of proton conductivity through Yb and Zn doping in BaCe0. 5Zr0. 35Y0. 15O3-δ electrolyte for IT-SOFCsafif03.m21Încă nu există evaluări

- Enhancing Corrosion Resistance of Copper by Electrodeposition Mahmoud Abbas, Magdy KasemDocument28 paginiEnhancing Corrosion Resistance of Copper by Electrodeposition Mahmoud Abbas, Magdy KasemMoeÎncă nu există evaluări

- Hydrothermal Stability of Pure and Modified Microporous Silica MembranesDocument6 paginiHydrothermal Stability of Pure and Modified Microporous Silica MembranesDwi NandaÎncă nu există evaluări

- 1 s2.0 S1385894723001985 MainDocument10 pagini1 s2.0 S1385894723001985 MainJessica GattiÎncă nu există evaluări

- Nano Silica Modified Carbon-Phenolic CompositesDocument4 paginiNano Silica Modified Carbon-Phenolic CompositesAbrizal HaryadiÎncă nu există evaluări

- Advanced Ceramics - 4th Year - Lecture NotesDocument44 paginiAdvanced Ceramics - 4th Year - Lecture Notesdrsaadbhf100% (1)

- Bipolar Plate Development With Additive Manufacturing and ProtectiveDocument9 paginiBipolar Plate Development With Additive Manufacturing and Protectivev.babalo68Încă nu există evaluări

- Study of A New Polymer Electrolyte Poly (Ethylene Oxide) : Naclo With Several Plasticizers For Battery ApplicationDocument6 paginiStudy of A New Polymer Electrolyte Poly (Ethylene Oxide) : Naclo With Several Plasticizers For Battery ApplicationKRUNAL ParmarÎncă nu există evaluări

- Preparation of Plasma-Polymerized SiOx-like Thin Films From A MixtureDocument6 paginiPreparation of Plasma-Polymerized SiOx-like Thin Films From A MixturekgvtgÎncă nu există evaluări

- Self-Assembled Palladium Nanoparticles On Carbon NanofibersDocument6 paginiSelf-Assembled Palladium Nanoparticles On Carbon NanofiberswwÎncă nu există evaluări

- Corrosion % MoDocument13 paginiCorrosion % MoKheiro BzdÎncă nu există evaluări

- Composites: Part B: Chih-Chun Teng, Chen-Chi M. Ma, Kuo-Chan Chiou, Tzong-Ming LeeDocument7 paginiComposites: Part B: Chih-Chun Teng, Chen-Chi M. Ma, Kuo-Chan Chiou, Tzong-Ming LeeamirswtÎncă nu există evaluări

- Magnetoelectropolishing Treatment For Improving The Oxidation Resistance ofDocument36 paginiMagnetoelectropolishing Treatment For Improving The Oxidation Resistance ofmohammadreza hajialiÎncă nu există evaluări

- 4 - A High Entropy Perovskite Titanate Lithium Ion Battery AnodeDocument10 pagini4 - A High Entropy Perovskite Titanate Lithium Ion Battery Anodekenny5350Încă nu există evaluări

- Photocatalytic Reduction of Carbon Dioxide by Water On Titania: Role of Photophysical and Structural PropertiesDocument9 paginiPhotocatalytic Reduction of Carbon Dioxide by Water On Titania: Role of Photophysical and Structural PropertiesHameed Bin AhmadÎncă nu există evaluări

- Scale and Corrosion Prevention in Cooling Water Systems Part I: Calcium CarbonateDocument6 paginiScale and Corrosion Prevention in Cooling Water Systems Part I: Calcium CarbonateTAYYAB FAROOQÎncă nu există evaluări

- Preparation and One-Step Activation of Microporous Carbon Nanofibers For Use As Supercapacitor ElectrodesDocument11 paginiPreparation and One-Step Activation of Microporous Carbon Nanofibers For Use As Supercapacitor ElectrodesRizka Ayu YuniarÎncă nu există evaluări

- 3 - The Role of Oxygen-Permeable Ionomer For Polymer Electrolyte Fuel CellsDocument9 pagini3 - The Role of Oxygen-Permeable Ionomer For Polymer Electrolyte Fuel CellsFaseeh KKÎncă nu există evaluări

- Rochelle Q2 Report 2009Document299 paginiRochelle Q2 Report 2009drchobbesÎncă nu există evaluări

- Engineering Journal Anticorrosion Behavior of Deposited Nanostructured Polythiophene On Stainless Steel, Carbon Steel, and Aluminum in Sea WaterDocument7 paginiEngineering Journal Anticorrosion Behavior of Deposited Nanostructured Polythiophene On Stainless Steel, Carbon Steel, and Aluminum in Sea WaterEngineering JournalÎncă nu există evaluări

- Development and Operation of A 150 W Air-Feed Direct Methanol Fuel Cell StackDocument5 paginiDevelopment and Operation of A 150 W Air-Feed Direct Methanol Fuel Cell StackKaustubhÎncă nu există evaluări

- Surface ScienceDocument14 paginiSurface ScienceAnonymous ahNUZsrQpSÎncă nu există evaluări

- Pengujian Karakteristik Limbah Pasir PLTP Dieng Sebagai Bahan Pengisi Isolator Resin Epoksi SilaneDocument6 paginiPengujian Karakteristik Limbah Pasir PLTP Dieng Sebagai Bahan Pengisi Isolator Resin Epoksi SilaneRobiÎncă nu există evaluări

- Enhancement of Electrical Properties On Zno: Al Thin Film Due To Hydrogen Annealing and Sio Coating in Damp-Heat EnvironmentDocument4 paginiEnhancement of Electrical Properties On Zno: Al Thin Film Due To Hydrogen Annealing and Sio Coating in Damp-Heat Environmenthazbi2011Încă nu există evaluări

- Engineering Journal Corrosion Behaviour of Room Temperature Cured Polysilazane-Derived Silica Coatings On Al 5086Document8 paginiEngineering Journal Corrosion Behaviour of Room Temperature Cured Polysilazane-Derived Silica Coatings On Al 5086Engineering JournalÎncă nu există evaluări

- Chuang Et al-2019-JOM PDFDocument10 paginiChuang Et al-2019-JOM PDFJorge SanchezÎncă nu există evaluări

- Journal of Alloys and Compounds: SciencedirectDocument11 paginiJournal of Alloys and Compounds: SciencedirectEstudiante2346Încă nu există evaluări

- Growth PDFDocument21 paginiGrowth PDFginny_dootÎncă nu există evaluări

- LNMC ElectroquimicaDocument11 paginiLNMC ElectroquimicaHEIDY JOVANA HUANCA RAMOSÎncă nu există evaluări

- WP6 Dodds ProductionDocument22 paginiWP6 Dodds Productionamirul8686Încă nu există evaluări

- Urn 100616Document92 paginiUrn 100616shoemakerlevy9Încă nu există evaluări

- 421Document9 pagini421shoemakerlevy9Încă nu există evaluări

- Bioethanol-Magazin CE 2011-En 1 1Document16 paginiBioethanol-Magazin CE 2011-En 1 1softnet20Încă nu există evaluări

- J2EEDocument103 paginiJ2EEpedrix45Încă nu există evaluări

- J2EEDocument103 paginiJ2EEpedrix45Încă nu există evaluări

- Two-Stage Stochastic and Deterministic OptimizationDocument13 paginiTwo-Stage Stochastic and Deterministic Optimizationshoemakerlevy9Încă nu există evaluări

- Labrincha 09 07Document5 paginiLabrincha 09 07shoemakerlevy9Încă nu există evaluări

- 2012kale TMSDocument12 pagini2012kale TMSshoemakerlevy9Încă nu există evaluări

- 138 MartinDocument6 pagini138 Martinshoemakerlevy9Încă nu există evaluări

- 1420 5266 1 PBDocument16 pagini1420 5266 1 PBshoemakerlevy9Încă nu există evaluări

- 1mhd 2 08Document36 pagini1mhd 2 08shoemakerlevy9Încă nu există evaluări

- Materials 05 02101Document36 paginiMaterials 05 02101shoemakerlevy9Încă nu există evaluări

- V 111 N 03 P 199Document4 paginiV 111 N 03 P 199shoemakerlevy9Încă nu există evaluări

- 001Document12 pagini001shoemakerlevy9Încă nu există evaluări

- Jeas 0513 893Document7 paginiJeas 0513 893shoemakerlevy9Încă nu există evaluări

- Jose Granjo Set2013Document53 paginiJose Granjo Set2013shoemakerlevy9Încă nu există evaluări

- c01Document78 paginic01shoemakerlevy9Încă nu există evaluări

- Scalable and Secure Sharing of Personal Health Records in Cloud Computing Using Attribute Based EncryptionDocument13 paginiScalable and Secure Sharing of Personal Health Records in Cloud Computing Using Attribute Based EncryptionjosephÎncă nu există evaluări

- Real-Time Optimizing Nonlinear Control Applied To A Continuous Reactive Distillation ProcessDocument6 paginiReal-Time Optimizing Nonlinear Control Applied To A Continuous Reactive Distillation Processshoemakerlevy9Încă nu există evaluări

- Separ 06 Molecular WelkDocument19 paginiSepar 06 Molecular Welkshoemakerlevy9Încă nu există evaluări

- Materials 05 02101Document36 paginiMaterials 05 02101shoemakerlevy9Încă nu există evaluări

- 328Document6 pagini328shoemakerlevy9Încă nu există evaluări

- Beyond Operational EfficiencyDocument9 paginiBeyond Operational Efficiencyshoemakerlevy9Încă nu există evaluări

- 843183Document103 pagini843183Rimjhim Roy ChoudhuryÎncă nu există evaluări

- 030Document6 pagini030shoemakerlevy9Încă nu există evaluări

- 016Document6 pagini016shoemakerlevy9Încă nu există evaluări

- BioetanolDocument12 paginiBioetanolAnonymous mZEUquÎncă nu există evaluări

- DocDocument31 paginiDocshoemakerlevy9Încă nu există evaluări

- Spoon Injection Project ReportDocument73 paginiSpoon Injection Project ReportPaturu VijayÎncă nu există evaluări

- IG Chemsitry PapersDocument179 paginiIG Chemsitry PapersMurad88% (17)

- 0131 0136 PDFDocument6 pagini0131 0136 PDFWahid KarolÎncă nu există evaluări

- Grain Refinement of AluminiumDocument12 paginiGrain Refinement of AluminiumOmer Can EserÎncă nu există evaluări

- Noble Gases: B.Sc. Chemistry Semester I Dr. Ashok Kuingh Assistant Professor University of Lucknow LucknowDocument21 paginiNoble Gases: B.Sc. Chemistry Semester I Dr. Ashok Kuingh Assistant Professor University of Lucknow LucknowSergioÎncă nu există evaluări

- MEMSDocument21 paginiMEMSAppu Kumar67% (6)

- Micro Alloyed Steels Voestalpine EN 30102020Document4 paginiMicro Alloyed Steels Voestalpine EN 30102020pierocarnelociÎncă nu există evaluări

- Mercator's Projection: A Comparative Analysis of Rhumb Lines and Great CirclesDocument36 paginiMercator's Projection: A Comparative Analysis of Rhumb Lines and Great CirclesGeani MihaiÎncă nu există evaluări

- Safety Data Sheet Ethanol 99,8%: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument7 paginiSafety Data Sheet Ethanol 99,8%: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingpurinurul11Încă nu există evaluări

- NCERT Books For Class 10 Science Chapter 1 Chemical Reactions and EquationsDocument28 paginiNCERT Books For Class 10 Science Chapter 1 Chemical Reactions and EquationsKishu Chauhan100% (1)

- No Nama Bahan Satuan: Pengadaan Bahan Kimia Laboratorium Dinas Lingkungan Hidup Kabupaten Lebak Tahun 2022Document4 paginiNo Nama Bahan Satuan: Pengadaan Bahan Kimia Laboratorium Dinas Lingkungan Hidup Kabupaten Lebak Tahun 2022sri yusnia hastutiÎncă nu există evaluări

- Improved Version of The Fischer-Zach Synthesis of Glycals: Vitamin B-12 Catalyzed Reductive Elimination of Glycosyl BromidesDocument2 paginiImproved Version of The Fischer-Zach Synthesis of Glycals: Vitamin B-12 Catalyzed Reductive Elimination of Glycosyl BromidesscadvijayÎncă nu există evaluări

- Technical Data Sheet: DescriptionDocument5 paginiTechnical Data Sheet: DescriptiongldiasÎncă nu există evaluări

- 신소재과학 시험문제모음Document9 pagini신소재과학 시험문제모음Hanjin SeoÎncă nu există evaluări

- Drive MechanismsDocument12 paginiDrive Mechanismsl3gsdÎncă nu există evaluări

- Data Sheet Docol Tube R8 2022-09-20Document2 paginiData Sheet Docol Tube R8 2022-09-20miyoriiosuÎncă nu există evaluări

- MSDS Chlorpyrifos TechnicalDocument7 paginiMSDS Chlorpyrifos Technicalkeshav chaturvediÎncă nu există evaluări

- Technical Data: Blue SheetDocument9 paginiTechnical Data: Blue SheetforuzzÎncă nu există evaluări

- DensitometerDocument9 paginiDensitometerlvrevathiÎncă nu există evaluări

- (Total 1 Mark) : IB Questionbank Physics 1Document5 pagini(Total 1 Mark) : IB Questionbank Physics 1Irwansyah RamadhaniÎncă nu există evaluări

- Models of The Atom Through TimeDocument14 paginiModels of The Atom Through Timeveronica lunaÎncă nu există evaluări

- Self Heall PPT EditedDocument34 paginiSelf Heall PPT EditedYASHAS K CÎncă nu există evaluări

- Module Electricity and MagnetismDocument21 paginiModule Electricity and MagnetismNoorain PurhanudinÎncă nu există evaluări

- Notes For Vaccume Overload ProtectionDocument3 paginiNotes For Vaccume Overload ProtectionMd MoniruzzamanÎncă nu există evaluări

- 1 Wladimir SabugaDocument9 pagini1 Wladimir Sabugatimtim1111Încă nu există evaluări

- DDDocument11 paginiDDjamesdigolÎncă nu există evaluări

- Interpretations and DFT Calculations For Polypropylene/Cupper Oxide NanosphereDocument14 paginiInterpretations and DFT Calculations For Polypropylene/Cupper Oxide Nanosphereyousif husseinÎncă nu există evaluări

- Conectores PostesDocument2 paginiConectores PostesHabiran GonzalezÎncă nu există evaluări

- Gra 10 - Eng - Sci - T2 - PP II - 2018Document11 paginiGra 10 - Eng - Sci - T2 - PP II - 2018assadaÎncă nu există evaluări

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDe la EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseEvaluare: 3.5 din 5 stele3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDe la EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingEvaluare: 5 din 5 stele5/5 (5)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessDe la EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessÎncă nu există evaluări

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDe la EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincEvaluare: 3.5 din 5 stele3.5/5 (137)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionDe la EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionEvaluare: 4 din 5 stele4/5 (811)

- Fire Season: Field Notes from a Wilderness LookoutDe la EverandFire Season: Field Notes from a Wilderness LookoutEvaluare: 4 din 5 stele4/5 (142)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldDe la EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldEvaluare: 4.5 din 5 stele4.5/5 (18)

- Spoiled Rotten America: Outrages of Everyday LifeDe la EverandSpoiled Rotten America: Outrages of Everyday LifeEvaluare: 3 din 5 stele3/5 (19)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsDe la EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsEvaluare: 3.5 din 5 stele3.5/5 (13)

- The Other End of the Leash: Why We Do What We Do Around DogsDe la EverandThe Other End of the Leash: Why We Do What We Do Around DogsEvaluare: 5 din 5 stele5/5 (65)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDe la EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingEvaluare: 3.5 din 5 stele3.5/5 (35)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldDe la EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldEvaluare: 4 din 5 stele4/5 (595)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildDe la EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildEvaluare: 4.5 din 5 stele4.5/5 (44)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsDe la EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsEvaluare: 4 din 5 stele4/5 (223)

- Come Back, Como: Winning the Heart of a Reluctant DogDe la EverandCome Back, Como: Winning the Heart of a Reluctant DogEvaluare: 3.5 din 5 stele3.5/5 (10)

- When the Sahara Was Green: How Our Greatest Desert Came to BeDe la EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeEvaluare: 4.5 din 5 stele4.5/5 (6)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeDe la EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeEvaluare: 4.5 din 5 stele4.5/5 (699)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorDe la EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorEvaluare: 4.5 din 5 stele4.5/5 (137)

- Braiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsDe la EverandBraiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsEvaluare: 4.5 din 5 stele4.5/5 (1424)