Documente Academic

Documente Profesional

Documente Cultură

Tests for Cement, Concrete, Aggregates, Bricks, Steel & Water

Încărcat de

Swaroopa Ravinder GoudDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tests for Cement, Concrete, Aggregates, Bricks, Steel & Water

Încărcat de

Swaroopa Ravinder GoudDrepturi de autor:

Formate disponibile

TEST FOR CEMENT

Sl. No. 1 I) II) III) IV) V) Test Physical Requirement Fineness Specific surface areain sq-cm/gm Soundenes Expansion in Lechatlier's mould Intial setting time Final setting time Compressive strength a) 3 days b) 7 days c) 28 days Consistancy of standard cement paste Test Method IS: 4031 IS: 4031 Frequencey OPC 43 grade(IS 8112-1989)

Not les than 2250 sq-cm/gm IS: 4031 IS: 4031 IS: 4031 IS: 4031 1 Test fo 1000 bags Not more than 10 mm Not less thatn 30 minutes Not less thatn 60 minutes Not les than 23 N/sqmm Not les than 33 N/sqmm Not les than 43 N/sqmm IS: 4031

VI)

TEST FOR SAND

Sl. No. Test Test Method Frequency IS Sieve Designation 10.0 mm 4.75 mm 1 Test for 40 cum 2.36 mm 1.18 mm 600 micron 300 micron 150 micron 1 Test for 20 cum 1 Test for 20 cum Accepting Criteria Percentage passing for Grading Zone-II 100 90-100 75-100 55-90 35-59 8-30 0-10 Shall not exceed 5%

Pactical size distribution

As per CPWD Specification

2 3

Silt content Bulking of sand

As per CPWD Specification As per CPWD Specification

Criteria entage passing for Grading Zone-III 100 90-100 85-100 75-100 60-79 Dec-40 0-10

ceed 5%

TEST FOR WATER

Sl. No. 1 2 3 4 Test Ph value Limits of Acidity Limits of Alkanity' Percentage of solids a) Chlorides Sulphate c) Suspended matters d) Inorganic solids e) Organic solids Test Method IS:3025 IS:3025 IS:3025 IS:3025 Frequency Accepting Criteria Not less than 6.0 Maximum 5.0 ml Maximum 25.0 ml Maximum 500 mg/ltr for RCC Maximum 2000 mg/ltr for RCC Maximum 400 mg/ltr Maximum 2000 mg/ltr Maximum3000 mg/ltr for RCC Maximum 200 mg/ltr

1 Test in 3 months

TEST FOR PLAIN CEMENT CONCRETE 1:2:4 RICHER MIX

Sl. No. 1 Test Slump Test Test Method As per CPWD Specification Frequence Accepting Criteria

TEST FOR REINFORCED CEMENT CONCRETE NOMINAL MIX

Sl. No. 1 Test Slump Test Test Method Frequence As per CPWD Column- 1 Test for 5 cum, Other Specification RCC 1 Test fo 20 cum Column-1 Test for 20 cum IS:516 Slab, Beam- 1 Test for 20 cum Other RCC- 1 Test for 20 cum Nominal Mix 1:1:2 1:1.5:3 1:2:4 Accepting Criteria

Cube Test

Compressive Strength(kg/sqcm) 7 days 28 days 210 315 175 265 140 210

TEST FOR STONE AGGREGATE FOR CEMENT CONCRETE/RCC

Sl. No. 1 2 3 4 5 6 7 8 9 Test Percentage of soft/Deleterious Materials Estimation of Organic Impurites Surface Moisture Determination of 10% Fine Value Specified Gravity Bulk Density Crushing Strength Impact Value Particle Size Distribution Test Method IS:2386 IS:2386 IS:2386 IS:2386 IS:2386 IS:2386 IS:2386 IS:2386 As per CPWD Specification Frequence 1 test for each source 1 test for40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 10 cum Accepting Criteria

TEST FOR STONE AGGREGATE FOR DESIGN MIX CONCRETE

Sl. No. 1 2 3 4 5 6 7 8 9 Test Percentage of soft/Deleterious Materials Estimation of Organic Impurites Surface Moisture Determination of 10% Fine Value Specified Gravity Bulk Density Crushing Strength Impact Value Particle Size Distribution Test Method IS:2386 IS:2386 IS:2386 IS:2386 IS:2386 IS:2386 IS:2386 IS:2386 As per CPWD Specification Frequence 1 test for each source 1 test for 40 cum 1 test for 10 cum 1 test for 10 cum 1 test for 10 cum 1 test for 10 cum 1 test for 10 cum 1 test for 10 cum 1 test for 40 cum Accepting Criteria

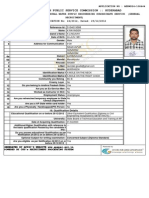

PROFORMA FOR SUBMITTING TEST CARRIED OUT AS PER CTE

Sl. No. Test Limit of Acidity Limit s of Alkanity Percent of solids a) Chlorides b) Sulphate c) Suspanded matters d) Inorganic solids e) Organic solids Physical Requirement Fineness Specific surface areain sq-cm/gm Soundeness Exapnsion in Lechatlier's mould Intial setting time Final setting time Compressive strength a) 3 days b) 7 days c) 28 days Consistancy of standard cement paste Partice size distribution Silt content Organic Impurities Bilking of sand Percentage of soft/Deleterious Materials Estimation of Organic Impurities Surface Moisture Detemination of 10% Fine Value Specified Gravity Bulk Density Crushing Strength Impact Value Frequency Quantity Test Required Test carried out

Water

1 Test in 3 months

Cement

1 Test for 1000 bags

Sand Aggregate

1 Test for 40 cum 1 Test for20 cum 1 Test for 20 cum 1 Test for 20 cum 1 test for each source 1 Test for10 cum 1 Test for10 cum 1 Test for10 cum 1 Test for10 cum 1 Test for10 cum 1 Test for10 cum 1 Test for10 cum Page 2 of 2

mix design

Test Particle Size Distribution Percentage of soft/Deleterious Materials Estimation of Organic Impurities Surface Moisture Detemination of 10% Fine Value Aggregate for Specified Gravity other work Bulk Density Crushing Strength Impact Value Particle Size Distribution Tensile Strength Retest Rebound Test Steel Nominal Mass Bend Test Elongation Test Proof Test Dimentional Tolerance Bricks Copmressive Strength Water Absorption Efflorescene Slump Test RCC Cube Test

Sl. No. mix design

Frequency As per CPWD Specification 1 test for each source 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum 1 test for 40 cum As per CPWD Specification A) Under 10mm diameter 1 sample for 25 T

Quantity

Test Required

Test carried out

B) 10mm to 16mm dia. 1 sample for 35 T

C) Over 16mm dia. 1 sample 1 Test in evary 50000 bricks (20 bricks to be selected) 1 Test in evary 50000 bricks (15 bricks to be selected) 1 Test in evary 50000 bricks (15 bricks to be selected) 1 Test in evary 50000 bricks (15 bricks to be selected) Column- 1 Test for 5 cum, other RCC 1 Test for 20 cum Column- 1Test for 5 cum Slab, Beam - 1 Test for 20 cum Other RCC - 1 Test for 20 cum

Page 2 of 2

TEST FOR BRICKS

Sl. No. 1 2 3 4 Test Dimentional Tolerance Compressive Strength Water Absorption Efflorecene Test Method As per CPWD Specification As per CPWD Specification As per CPWD Specification As per CPWD Specification Frequence Accepting Criteria 1 Test in every 5000 bricks Length=490+8cm, Width=242+4cm, (20 bricks to be selected) Height= 145+4cm 1 Test in every 5000 bricks Not less than 75M/sqmm (15bricks to be selected) 1 Test in every 5000 bricks Not less than 20% (15 bricks to be selected) 1 Test in every 5000 bricks (15 bricks to be selected) Not more than 'Moderate'

TEST FOR DESIGN MIX CONCRETE

Sl. No. Test Test Method Frequence for

3

Accepting Criteria

Slupm Test

1 Test per 5 m per column, 1 As per CPWD 3 Specification Test per 20 m for other thatn column 1 Test per 20 m

3

Slump shall be checked at the time of loading & placement location. At placement location the slump measure shall confirmthe design slump.

Consistancy of Concrete Weight per As per CPWD cum,Cament factor & Specification Air Contest Test Cube Test IS:516

1.6 to 4.5 for concrete transported and placed by normal methods. 0.80 to 3.5 for concrete transported and placed by pumping methods. As decided By Engineer- in charge Number of Sample 1 2 3 4 4 plus 1 additional sample for each 50.0 cum or part thereof Compressive Strength Design Mix M-25 7 days Av. Strength 17+4=21.0 N/sqmm Individual Strength 17.0N/sqmm As per Design Mix 28 days Av. Strength 25+4=29.0 N/sqmm Individual Strength 25.0N/sqmm As per Design Mix

1 Test per 20 m Quantity of Concrete(cum) Les than 5.0 6.0 to 15.0 15.0 to 30.0 31.0 to 50.0

3 4

51 and above

M-30

Av. Strength 20+5=25.0 N/sqmm

Av. Strength 30+5=35.0 N/sqmm

Individual Strength 20.0 N/sqmm Individual Strength 30.0 N/sqmm As per Design Mix As per Design Mix Individual variation should not be more than + 15% of the average

PARTICLE SIZE DISTRIBUTION OF COARSE AGGREGATE

GRADED STONE AGGREGATE % passing by weight fof nominal size IS Sieve Designation 40mm 20mm 12.5mm 75mm 100 37.5mm 95-100 100 19.0mm 30-70 95-100 16mm 100 11.2mm 90-100 9.5mm Oct-35 35-55 40-85 4.75m 0-5 0-10 0-10 UNGRADED STONE AGGREGATE % passing by weight fof nominal size IS Sieve Designation 40mm 20mm 10 mm 63mm 100 40mm 85-100 100 20mm 0-25 85-100 16mm 12.5mm 100 10mm -5 0-20 85-100 4.75mm 0-5 0-20 2.30mm 0-5

TEST FOR STEEL

MECHANICAL PROPERTIES Sl. No. Test Test Method 1 2 3 4 5 6 7 Tensile Strength Retest Rebound Test Nominal Mass Bend Test Elongation Test Proof Stress IS:1608 IS:1786 IS:1786 IS:1786 IS:1786 IS:1786 IS:1786 A) Under 10mm diameter 1 sample for 25T B) 10mm to 16mm dia. 1 sample for 35 T C) Over 16mm dia. 1 sample for 45 T Frequence Accepting Criteria Sail - 500, Tiscon - 510, Vizag - 520

Sail - 22, Tiscon - 20, Vizag - 20 Sail - 415 Tiscon - 450, Vizag - 460

CHEMICAL PROPERTIES Chemical As per Is 1786 Fe Sl. No. Composition 415 1 CARBON 0.3 2 SULPHER 0.06 3 PHOSPHORUS 0.06 SULPHER & 4 0.11 PHOSPHORUS

Sail TMT 415 0.25 0.05 0.05 0.10

TISCON TMT-42 0.17 0.045 0.045 0.09

Vizag Steel 0.20 0.04 0.05 0.09

vennalamacharla@gmail.com

sravinder.goudk@sg.com

S-ar putea să vă placă și

- Quality Control Format For MPR Ex Dsc-2Document7 paginiQuality Control Format For MPR Ex Dsc-2Rahmat mulyadiÎncă nu există evaluări

- Consultant: ContractorDocument17 paginiConsultant: ContractorKreesthu Reddy0% (1)

- Quality TestDocument22 paginiQuality TestUmair Shaikh100% (1)

- Six Lanning of Delhi Agra Section Wet Mix Macadam CalibrationDocument12 paginiSix Lanning of Delhi Agra Section Wet Mix Macadam CalibrationRSBIPL NH17 LABÎncă nu există evaluări

- M30 Concrete Mix DesignDocument4 paginiM30 Concrete Mix DesignrajupetalokeshÎncă nu există evaluări

- RMM CalibrationDocument18 paginiRMM CalibrationPrasanna S KulkarniÎncă nu există evaluări

- 122-354019 GSB-I CoarseDocument32 pagini122-354019 GSB-I CoarseARTI PALEKARÎncă nu există evaluări

- FT004 - FLAKINESS & ELONGATION INDICESdDocument23 paginiFT004 - FLAKINESS & ELONGATION INDICESdjjksite voyantsÎncă nu există evaluări

- Department of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurDocument10 paginiDepartment of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurAjayvidyanand SharmaÎncă nu există evaluări

- Ade and FineDocument7 paginiAde and FineBscpl Repalle to EeppurpalemÎncă nu există evaluări

- Seal CoatDocument30 paginiSeal CoatMujahid choudharyÎncă nu există evaluări

- Cement Treated Base Test Results Summary: National Highways Authority of India (Ministry of Road Transport & Highways)Document61 paginiCement Treated Base Test Results Summary: National Highways Authority of India (Ministry of Road Transport & Highways)Fariha Azad100% (1)

- Summary of Quality Control Tests Required For BridgesDocument4 paginiSummary of Quality Control Tests Required For BridgesJakka LakshmikanthÎncă nu există evaluări

- 122-291019 Gsb-IDocument33 pagini122-291019 Gsb-IARTI PALEKARÎncă nu există evaluări

- Maximum Dry Density (Proctor)Document3 paginiMaximum Dry Density (Proctor)ratoooooja24Încă nu există evaluări

- REGIONAL LABORATORY P.W.D. ZONE JODHPUR MIX DESIGNDocument11 paginiREGIONAL LABORATORY P.W.D. ZONE JODHPUR MIX DESIGNer_kenedyÎncă nu există evaluări

- SDBC With FillerDocument8 paginiSDBC With Fillerer_kenedyÎncă nu există evaluări

- Punjab Water Supply & Sewerage Division Brick Test ReportsDocument34 paginiPunjab Water Supply & Sewerage Division Brick Test ReportsAnbuÎncă nu există evaluări

- Road Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All MaterialsDocument53 paginiRoad Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All Materialssunil kuldeepÎncă nu există evaluări

- Pavement Crust ThicknessDocument10 paginiPavement Crust ThicknessHarsh DeepÎncă nu există evaluări

- Construction of Flyover at Km.77+750 on NH-44 in MaharashtraDocument1 paginăConstruction of Flyover at Km.77+750 on NH-44 in MaharashtraMangeysh S. Chauhan100% (1)

- Calculations For Safe Bearing CapacityDocument3 paginiCalculations For Safe Bearing Capacityimran khanÎncă nu există evaluări

- SDBC Without FillerDocument9 paginiSDBC Without Fillerer_kenedyÎncă nu există evaluări

- L&T Aggregate Blending for Bituminous ConcreteDocument18 paginiL&T Aggregate Blending for Bituminous ConcreteKrunal Shah100% (1)

- SDBC-Job Mix FinalDocument31 paginiSDBC-Job Mix FinalAchintya DasÎncă nu există evaluări

- Cement Test ReportsDocument2 paginiCement Test ReportsShubham SingaÎncă nu există evaluări

- Project Report Design of Dense Bituminous Macadam: ClientDocument11 paginiProject Report Design of Dense Bituminous Macadam: ClientHarshit MoreÎncă nu există evaluări

- QA in Highway Sector-Part-4Document10 paginiQA in Highway Sector-Part-4boomiÎncă nu există evaluări

- FREQUENCY OF TEST & ACCEP. LIMITS Ajit Pratap SinghDocument10 paginiFREQUENCY OF TEST & ACCEP. LIMITS Ajit Pratap SinghAjit P. SinghÎncă nu există evaluări

- WMM Calibration 05.01.2016Document8 paginiWMM Calibration 05.01.2016SRR QAQCÎncă nu există evaluări

- Combine Flakiness & Elongation TestDocument1 paginăCombine Flakiness & Elongation TestFariha AzadÎncă nu există evaluări

- Sector Project-Package A:Mahua-Chuwahi RoadDocument6 paginiSector Project-Package A:Mahua-Chuwahi RoadVIMAL TIWARIÎncă nu există evaluări

- Vane Shear TestDocument4 paginiVane Shear TestMuhammad Faiz Zafuan Idrus100% (1)

- Class'C' Concrete-2Document9 paginiClass'C' Concrete-2Tewodros TadesseÎncă nu există evaluări

- GSB (Coarse Graded) Summary Sheet: Physical PropertiesDocument10 paginiGSB (Coarse Graded) Summary Sheet: Physical PropertiesjitendraÎncă nu există evaluări

- Job Mix For Bituminous MacadamDocument2 paginiJob Mix For Bituminous MacadamArun Kogta100% (1)

- Geotechnical Investigation Report for Proposed BridgeDocument30 paginiGeotechnical Investigation Report for Proposed BridgeAaron WilsonÎncă nu există evaluări

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 paginiTest Report: M/S Pcil & MBPCL Joint VentureImran KhanÎncă nu există evaluări

- Plate Load Test ResultsDocument4 paginiPlate Load Test ResultsDeepak100% (1)

- Consolidation PDFDocument113 paginiConsolidation PDFalnisÎncă nu există evaluări

- Sieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Document1 paginăSieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Mitendra Kumar ChauhanÎncă nu există evaluări

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 paginiSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarÎncă nu există evaluări

- Kship GVR: Sorce: Sankanur Cross CrusherDocument9 paginiKship GVR: Sorce: Sankanur Cross CrusherVijay Jamadar100% (1)

- 42 DBM GradationDocument2 pagini42 DBM GradationPrasanna S Kulkarni100% (1)

- Client Caterpillar Signs PMC Compaction Test by Sand ReplacementDocument1 paginăClient Caterpillar Signs PMC Compaction Test by Sand ReplacementBrahammanand BairwaÎncă nu există evaluări

- Shear TestDocument3 paginiShear TestRajesh Kumar SrivastavaÎncă nu există evaluări

- Bill of Quantities for Bituminous Road Work at Suzlon GeneratorsDocument8 paginiBill of Quantities for Bituminous Road Work at Suzlon GeneratorsEr. Naseem SayyedÎncă nu există evaluări

- Public Works Department Government of Rajasthan: I. Source and Location of All MaterialsDocument50 paginiPublic Works Department Government of Rajasthan: I. Source and Location of All MaterialsSUNIL JHILMILÎncă nu există evaluări

- GSB Mix DesignDocument1 paginăGSB Mix Designp. kiran kuamrÎncă nu există evaluări

- Transportation Lab Manual Particle Size and Specific Gravity TestsDocument57 paginiTransportation Lab Manual Particle Size and Specific Gravity Testsrohit kumarÎncă nu există evaluări

- Compaction Test Results for 0.5m Depth Soil (IS 2720Document2 paginiCompaction Test Results for 0.5m Depth Soil (IS 2720Shankar KhanalÎncă nu există evaluări

- Annexure 2 Form 72 (Scope) Annexure IDocument4 paginiAnnexure 2 Form 72 (Scope) Annexure IVaghasiyaBipinÎncă nu există evaluări

- Developing rural roads agency in BiharDocument2 paginiDeveloping rural roads agency in Biharvijay kumarÎncă nu există evaluări

- Compaction Test by Core Cutter (Is: 2720, Part 29)Document2 paginiCompaction Test by Core Cutter (Is: 2720, Part 29)Francis Aw Soon LeeÎncă nu există evaluări

- WMM Mix DesignDocument23 paginiWMM Mix DesignEnd EndÎncă nu există evaluări

- Morth 2013Document903 paginiMorth 2013Gunjan KumarÎncă nu există evaluări

- WMM Design DataDocument42 paginiWMM Design DatapreranaÎncă nu există evaluări

- Akhil Bharatvarshiya Marwari Aggarwal Jatiya Kosh Plate Load Test ReportsDocument2 paginiAkhil Bharatvarshiya Marwari Aggarwal Jatiya Kosh Plate Load Test ReportsGaneshÎncă nu există evaluări

- 08 Shotcrete Quality Control & Testing For An Underground Mine in CanadaDocument42 pagini08 Shotcrete Quality Control & Testing For An Underground Mine in Canadajusselino100% (3)

- Test Rate BUETDocument5 paginiTest Rate BUETEngr Swapan82% (11)

- Is Code CivilDocument10 paginiIs Code CivilgwaliorwalaÎncă nu există evaluări

- August 2012Document92 paginiAugust 2012whi7efea7herÎncă nu există evaluări

- Teaming Up To ExcelDocument46 paginiTeaming Up To ExcelSwaroopa Ravinder GoudÎncă nu există evaluări

- Power PointDocument14 paginiPower PointSwaroopa Ravinder GoudÎncă nu există evaluări

- ml81n ScreenshotDocument16 paginiml81n ScreenshotSwaroopa Ravinder GoudÎncă nu există evaluări

- Project BookDocument59 paginiProject BookSwaroopa Ravinder GoudÎncă nu există evaluări

- Sap FileDocument96 paginiSap FileSwaroopa Ravinder GoudÎncă nu există evaluări

- Excel Product GuideDocument37 paginiExcel Product Guidekalu420Încă nu există evaluări

- RWSDocument2 paginiRWSSwaroopa Ravinder GoudÎncă nu există evaluări

- Chart TitleDocument3 paginiChart TitleSwaroopa Ravinder GoudÎncă nu există evaluări

- Shriram Global Entropolis Construction ProgressDocument4 paginiShriram Global Entropolis Construction ProgressSwaroopa Ravinder GoudÎncă nu există evaluări

- B152 01 00 00 00Document517 paginiB152 01 00 00 00lsep_bellaÎncă nu există evaluări

- Behavior Intervention PlanDocument6 paginiBehavior Intervention Planapi-308475283Încă nu există evaluări

- Brian Cody Mcgonegal ResumeDocument2 paginiBrian Cody Mcgonegal Resumeapi-348833348Încă nu există evaluări

- Worksheet - Solubility - Water As A SolventDocument2 paginiWorksheet - Solubility - Water As A Solventben4657Încă nu există evaluări

- M96SC05 Oleo StrutDocument6 paginiM96SC05 Oleo Strutchaumont12345Încă nu există evaluări

- Tabata Its A HIITDocument8 paginiTabata Its A HIITbertabastionniÎncă nu există evaluări

- Galapagos Penguins: Shelter, Niche and NeedsDocument8 paginiGalapagos Penguins: Shelter, Niche and Needsjim munkÎncă nu există evaluări

- Year 8 Drama ScriptDocument8 paginiYear 8 Drama ScriptTISMSecondaryÎncă nu există evaluări

- Agri & Food Processing - Biscuit Manufacturing UnitDocument6 paginiAgri & Food Processing - Biscuit Manufacturing Unitvijayind2006Încă nu există evaluări

- Kathrein Antenna Dual BandDocument4 paginiKathrein Antenna Dual BandAmine AchrafÎncă nu există evaluări

- Archives of Oral Biology 100 (2019) 42-48Document7 paginiArchives of Oral Biology 100 (2019) 42-48pedro cuellar proÎncă nu există evaluări

- DQ RMGDocument23 paginiDQ RMGDhaval ChaplaÎncă nu există evaluări

- Frontier DL650 Maintenance Guide Ver 1.0Document25 paginiFrontier DL650 Maintenance Guide Ver 1.0philippe raynalÎncă nu există evaluări

- Bill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsDocument8 paginiBill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsCtv MontrealÎncă nu există evaluări

- 'S Outfits and Emergency Escape Breathing Devices (Eebd)Document11 pagini'S Outfits and Emergency Escape Breathing Devices (Eebd)Thurdsuk NoinijÎncă nu există evaluări

- A Text Book On Nursing Management AccordDocument790 paginiA Text Book On Nursing Management AccordMohammed AfzalÎncă nu există evaluări

- Yoga Nidra MethodDocument13 paginiYoga Nidra MethodPrahlad Basnet100% (2)

- Intermediate Alloy Steels Properties and SpecificationsDocument15 paginiIntermediate Alloy Steels Properties and Specificationsanon_558118723100% (1)

- PE1 q1 Mod6 ProperEtiquetteand-Safetyinthe-UseofFacilitiesEquip v1-ADMDocument12 paginiPE1 q1 Mod6 ProperEtiquetteand-Safetyinthe-UseofFacilitiesEquip v1-ADMelvira.raagas2Încă nu există evaluări

- Anexo A2 - Ficha Panel CSUN250-60PDocument2 paginiAnexo A2 - Ficha Panel CSUN250-60PRobin Andres Quezada SanhuezaÎncă nu există evaluări

- Objectives and Aspects of School Health ServicesDocument4 paginiObjectives and Aspects of School Health ServicesRaed AlhnaityÎncă nu există evaluări

- PatternPro Variable Pitch GunDocument2 paginiPatternPro Variable Pitch GunVõ HòaÎncă nu există evaluări

- Materi Bahasa Inggris Kelas 9 - LabelsDocument12 paginiMateri Bahasa Inggris Kelas 9 - LabelsEnglish Is fun67% (3)

- Fuel System D28Document4 paginiFuel System D28Ian MuhammadÎncă nu există evaluări

- Akron Grad School Statement of Purpose PDFDocument2 paginiAkron Grad School Statement of Purpose PDFapi-406039291Încă nu există evaluări

- SECOND PERIODICAL TEST in TLE 9Document3 paginiSECOND PERIODICAL TEST in TLE 9Lima Alpha91% (103)

- Venkateshwara Institute of MedicalDocument10 paginiVenkateshwara Institute of Medicalbolhari070Încă nu există evaluări

- Registration Hike2help 15Document2 paginiRegistration Hike2help 15api-275580337Încă nu există evaluări

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADocument3 paginiBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaÎncă nu există evaluări

- We Think About Rotary Valve ReliabilityDocument8 paginiWe Think About Rotary Valve ReliabilityAhmed KhairyÎncă nu există evaluări