Documente Academic

Documente Profesional

Documente Cultură

Design of Carton Air Blast Freezing Systems

Încărcat de

vickersDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design of Carton Air Blast Freezing Systems

Încărcat de

vickersDrepturi de autor:

Formate disponibile

1 of 5

A

ir freezing of carton meat has been a feature of

the meat industry for many years. Despite this

and the fact that much practical research and

development has been carried out some 30 years ago, the

refrigeration industry is still designing freezing tunnels that

are ineffective and do not provide the end user with what

he wants. This paper summarises the information now

available from this development programme and also

compares the economic factors relating to one day as

against two day turnaround cycles as well as automatic

tunnels as against batch freezing units. With this summarised

information, any good refrigeration company should be

able to design and install effective systems.

Introduction

Air freezing of cartons of meat or other food

substances has been carried out virtually since refrigeration

began. However, the rapid freezing of such product came

into its own in the 1960s and 1970s when the southern

hemisphere countries in Australasia and South America

started to bone meat carcasses into primal cuts for export.

Previously the major export had been carcasses only.

Due to the size of the meat packing plants involved,

the freezing of cartons became a science in terms of the

most efficient and economical way to proceed. Much

test data was accumulated particularly in New Zealand

from research programmes by MIRINZ, the industry

research body and further expertise built up in the meat

plants themselves.

This paper compiles the most relevant information

now available for operators and refrigeration designers

THE INTERNATIONAL INSTITUTE OF REFRIGERATION

Design of Carton Air Blast Freezing Systems

By F J. BOWATER, MA. (CANTAB), C. ENG., M.I..MECH.E., M.I..Nuc.E., M.I.Mare.E. M.Inst.R.

FJB Systems

Engineering & Management Services

to configure effective freezing tunnels to match the

requirement of any particular operation and it also

encompasses many years of our own practical experiences

in these matters.

It should be noted that many UK and European

carton freezing plants are being designed without using

this knowledge today and it is hoped this paper will help

those in the industry involved with these responsibilities

to improve such designs for the benefit of the industry as

a whole.

1. Heat Transfer Data

The most common method of freezing carton

meat is the batch air blast freezer as diagrammatically

shown on Figure 1. Cartons are placed onto pallets with

air spaces between them, provided by corrugated sheeting

or plastic egg carton spacers and air is circulated through

the stow and over a suitable evaporator by means of

powerful fans and closely fitted false ceilings. Much work

has been carried out on freezing times for such tunnels

and Figure 2 is the result of these many tests carried out in

New Zealand and Australia during the 1960s and 1970s.

From Figure 2 it is possible to calculate the air

velocities and temperatures necessary to arrive at a suitable

freezing time for a specific type of cardboard carton.

Due to the pattern of factory or cold store operating

schedules, it is usual to design tunnels for either 24 or 48

hour turnaround times. The 24 hour design is expensive

to operate due to the faster extraction of heat and the

low refrigeration temperatures necessary.

In looking at the necessary requirements for a simple

2 of 5

batch freezer as shown in Figure 1, the first requirement is

to determine the worst type of carton from a heat transfer

point of view expected for the long-term operation.

Generally cartons are either made up in corrugated board

or solid board, the latter having the far superior heat transfer

value. Unfortunately it is usual for the general management

of the factory to have chosen the carton type prior to asking

the engineers to design the freezing tunnel. The advantage

usually of the corrugated board is that it is cheaper to make

and can sometimes be formed by bending layers over each

other which can become disastrous from the heat transfer

point of view.

Furthermore, some cartons are formed with lids

which fit over the basic body of the carton resulting in two

thicknesses of corrugated board through which the heat is

to be extracted. One of the first such tunnels I personally

designed many years ago in South America used double

formed corrugated cartons with lids which resulted in a 24

hour cycle design freezing in 48 hours. Assuming fibreboard

material with glued tops i.e. no lid, then for the normal 150

mm thick meat carton (27 kg) it can be seen from Figure 2

that an air velocity of 5 metres/ second with an air

temperature of -30

0

C will be necessary to freeze the meat

within 24 hours. These figures will change to a velocity of

7 metres/ second and an air temperature of almost

40

0

C to achieve the same results with a corrugated type

carton. Thus consideration of carton type is of paramount

importance.

2. Automatic & Batch Freezing Systems

In order to reduced the operational costs of loading

batch tunnels with forklift trucks and eliminating the high

labour costs of introducing spacers which requires double

handling of pallet stacking, the automatic tunnel was

introduced into high volume meat works in New Zealand

in the late 1960s. Figure 3 gives a basic flow pattern showing

how the system works.

Figure 3 shows an automatic loading model. The

cartons arrive from the high volume boning room on

conveyors and then by means of electronic eyes, when the

load platform is full, a hydraulic ram pushes the cartons

into the tunnel (in this case six cartons), which results in the

six cartons at the far end being pushed out to the transfer

annex, which in turn moves up to the return leg of the

tunnel, when a further hydraulic ram pushes the cartons to

allow the six frozen cartons to be discharged into a take-

away conveyor. The tunnel shown shows a configuration

of 72 cartons per 24 or 48 hour period, but can be made

as long as required to meet the boning room output.

The top section of Figure 3 shows the refrigeration

and air distribution system. The design requirements must

conform to the air velocities and temperatures as indicated

in Figure 2. No spacers are required because the freezing

unit is made on steel frames with the cartons thus being

separated for the correct sized air gap to obtain the

necessary air velocities.

Figure 4 shows a general arrangement for a batch

freezing operation.

In comparing this configuration with the automatic

tunnel in Figure 3, it can be seen that a large palletising/

depalletising area is required for building up freezer pallets

with air spacers and then disassembling them after freezing

and rebuilding onto cold store pallets. Thus labour costs

are high but the fabrication of the tunnels is simple by

AXIAL FLOW FANS

REFRIGERATION

AIR FLOW

TEMPERATURE -26C

(48 HOUR FREEZE)

CARTONS PALLET AIR GAPS TO PROVIDE

3M/SEC AIR VELOCITY

EVAPORATORS

Figure1 - Air Batch Freezer

50 40 30 20 10 100 125 150 175

Freezing Time (h) Carton Depth (mm)

200

-40

-35

-30

-25

-20

-15

AIR TEMP C

Solid Fibreboard

Corrugated Fibreboard

AIR VEL./[m/s]

2.0

3.0

5.0

7.0

2.0

3.0

5.0

7.0

Figure2 - Air Blast Carton FreezingTunnels -

Temperature/ TimeRelationships

3 of 5

using insulation panels supported from the main building

structures. The whole system is usually built into the works

cold storage loading bays so that distribution to designated

stores becomes easy. The air velocities and temperatures

must conform to the Figure 2 heat exchange data.

3. Refrigeration System Design

It is essential that the air temperature chosen in Figure

2 for a specific duty is maintained throughout the freezing

time. It is necessary therefore to size the evaporators to at

least 50% larger than the average refrigeration load for one

day turnaround units. In the case of 48 hour freezing, this

requirement is not so critical. The reason why this evaporator

oversizing is essential is to ensure that the air freezing

temperature chosen is maintained over the full freezing

period. The point here is that in the first few hours of

freezing when the product is at a high temperature, the heat

given off by the product is many times higher than in the

last few hours. Thus the evaporators must be sized to take

allowance for this high heat load. It is simply not good

enough to size the units on an average heat rejection rate

over the full freezing period.

In sizing the evaporators, a frost build-up factor must

be considered and an average heat transfer rate of no higher

than 2 watts/ hr/

0

C/ m

2

should be used with fin spacing of

no more than 4 fins per inch. Most refrigeration contractors

undersize evaporators.

As far as the refrigeration system is concerned, a two

stage pumped system should be employed for air

temperatures below 30

0

C, while a superfeed screw system

could be used for temperatures between 20

0

C and 30

0

C.

Both arrangements must be pumped so that a high wetted

surface area within the evaporators is achieved.

Our experience has shown over the years that high

capacity outputs with a variable refrigeration requirement

over the total freezing cycle, which will always be the case,

means that direct expansion systems never provide the

necessary performance.

Although direct expansion systems are officially only

some 25% down on heat transfer rates, increasing the

evaporator areas should result in similar refrigeration

performance, but in practice I have never found direct

EVAPORATOR

COILS

LOADING

ANNEX

TRANSFER

ANNEX

End and side elevations of automatic blast freezer

Figure3 - AutomaticAir Blast ContinuousTunnel

PALLET LOADING AREA

+10C

BLAST 1 BLAST 2

BLAST 3 BLAST 4

PLAN VIEW

TYPICAL SECTION

Figure4 -Batch FreezingTunnels

Carton carrier movement

4 of 5

expansion systems can provide the required evaporator

performance for carton freezing. I can only assume that

the reason for this is that the large refrigeration loads and

larger evaporators required in the first hour of freezing just

cannot be consistently managed with the type of direct

expansion valve available on the market. This valve

operation results in large areas of the evaporator becoming

gas locked. A pumped system which keeps the coil surfaces

continually wetted is the only system that can deliver the

performance required for such freezing systems.

4. Economics of 24 and 48 hr Batch Freezing

Systems

The comparative economics of installing 24 hour

freezers as against 48 hour units rest on two specific factors,

namely-

4.1 Operating cost

4.2 Capital cost.

4.1 Operating Cost

If we consider the two options for the batch freezer concept,

the operating cost factor is related solely to the electrical

consumption of the refrigeration plant. For both options

the labour cost for palletising and depalletising so many

tonnes of product per day are the same. It simply means

that the 2 day turnaround option has two batch freezers

with one freezer being loaded each day with the other being

discharged.

The electricity consumption will be significantly less

for the 48 hour units as the refrigeration plant will run with

a compressor suction temperature of 32

0

C rather than

40

0

C. Furthermore, the fan loading will be less with a lower

air velocity requirement, but two units will always be running

rather than one. These factors of fan load balance out.

However, the operation at 40

0

C will result in a COP

of the plant at around 1.6 as against almost 2 for the 48

hour operation. Taking these factors into account, the 24

hour unit will consume approximately 4.1 kws electricity

per tonne of product under refrigeration, while the 48 hour

unit will consume approximately 3.3 kws per tonne, or 98

kw hrs/ tonne and 79 kw hrs/ tonne respectively of product

frozen. On the basis of an electricity charge of 5.0 pence/

kw hr, the electricity cost per tonne of product frozen will

be 5.00 and 3.95 respectively. These cost differentials

will be equally applicable for batch or automatic operation.

4.2 Capital Cost

Again looking at the batch freezer operation only, the capital

cost of the refrigeration plant will be lower for 48 hour

freezing, as discussed above, but 2 tunnels will have to be

built rather than one so that the building costs and the plant

area will be larger.

In viewing Figure 4 which shows 2-10 tonne tunnels,

if 10 tonnes of product was required per day, then one

tunnel with 24 hour freezing would be sufficient while 2

would be necessary for a 2 day turnaround. Each tunnel

would cost approximately 22,000 to build, including

palletising space, which would mean a capital cost of

44,000 for the 2 day turnaround as against 22,000 for

the 1 day option, or 2200/ tonne frozen. However, the

refrigeration plant for the faster freezer would cost

approximately 25,000 more, or 2,500 per tonne frozen.

Thus for the batch tunnels, there would be virtually no

difference overall in capital cost. Table 1 gives a rough

guide to calculating the costs involved:

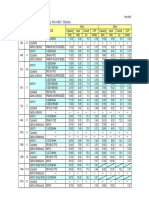

24 hour 48 hour

cycle cycle

Electricity 5.00 3.95

Refrig. Capital 5000 3700

Building Works 2200 4400

Table1 ComparativeCostsfor 1 & 2 DayCyclesper 1 Tonne

Product/ Day

5. Economics of 24 and 48 Hour Automatic

Freezing Tunnels

Due to the large cost of building small automatic

air freezing tunnels, this high capital cost excludes the

economic use of such tunnels unless the throughput of

the tunnels reaches some 2000 cartons per day or some 54

tonnes per day where the capital building costs of the 24

hour turnaround tunnels, excluding refrigeration, would

be in the order of 400,000 as against some 120,000 for

the previously discussed batch tunnels. Refrigeration capital

charges would be approximately the same for each tunnel

type at approximately 380,000 and the electricity cost again

would be similar.

The advantage of spending this additional 280,000

excluding refrigeration comes in the labour saving possible.

To palletise and de-palletise some 60-80 pallets per shift

or building and restacking some 120-160 pallets (18-23

pallets per hour) would require at least 4 extra employees

or some 75,000 per year in employment costs. Under

these circumstances, a three and three quarter year payback

would be possible on the extra 280,000 for building the

tunnels in the first instance. Bearing in mind that the

automated tunnel starts becoming effective at some 50-60

tonne of product per day, then Table 1 will turn into Table

2 below, but again these figures are a rough guide and each

5 of 5

project needs careful analysis to conclude the right course

of action: -

24 hour 48 hour

cycle cycle

Electricity 5.00 3.95

Refrig Capital 5000 3700

Building Works 7500 15000

Table2 - ComparativeCostsfor 1 & 2 DayCyclesper 1 Tonne

Product/ Day

CONCLUSION

Rapid air blast freezers for carton meat became

commonly used in the late 1960s when the southern

hemisphere meatworks started to bone carcasses to ship

frozen primal cuts and manufacturing meat.

At this stage extensive research went into the heat

transfer rates between the cooling air and the cardboard

cartons. MI RI NZ, the New Zealand research body

provided detailed data for designing freezing tunnels.

Shortly after this period the New Zealanders

developed automatic freezing tunnels to eliminate labour

costs compared with the accepted batch freezing tunnels.

Much experience has been accumulated with respect

to the most effective refrigeration plant to service these

tunnels. Pumped refrigerant systems are essential and

generous evaporator sizing necessary for effective

performance.

The tunnels are usually designed on the basis of one

or two day turnaround cycles to fit into the factory or

cold storage routines. The question of the economies of

one option as against the other needs concluding for each

individual plant. However in general terms, provided

electricity costs are reasonable, the one day turnaround cycle

is the most economic while the application of automatic

tunnels which eliminates much of the double handling costs

of the batch tunnel can only be justified with a regular

daily freezing requirement of at least 50 or 60 tonnes of

product per day.

REFERENCES

New Measurements of Cooling Times in Blast Freezers

L.S. Herbert & D.A. Lovett, CSIRO Queensland,

Australia

S-ar putea să vă placă și

- Tehcnical Paper: Calculating Freezing Times in Blast and Plate Freezers by Dr. Andy PearsonDocument36 paginiTehcnical Paper: Calculating Freezing Times in Blast and Plate Freezers by Dr. Andy PearsonBerry_1986_Berry100% (1)

- Blast Freezing Applications inDocument21 paginiBlast Freezing Applications inJoz TeaÎncă nu există evaluări

- Air Blast FreezerDocument15 paginiAir Blast FreezerRahul PatilÎncă nu există evaluări

- R744 Guide Parts 1 2 3Document182 paginiR744 Guide Parts 1 2 3alessandro silvaÎncă nu există evaluări

- TA Handbook 2 EngDocument72 paginiTA Handbook 2 Engmkalamaras100% (3)

- Carcass Freezing Time Predication by Plate FreezerDocument6 paginiCarcass Freezing Time Predication by Plate FreezerSiti Farah LokmanÎncă nu există evaluări

- Krueger Fan Coil EngineeringDocument15 paginiKrueger Fan Coil EngineeringYutt WattÎncă nu există evaluări

- Roy J Dossat Principles of Refrigeration PDF - p448 461Document14 paginiRoy J Dossat Principles of Refrigeration PDF - p448 461deckyÎncă nu există evaluări

- HVAC Handbook Applications Engineering Manual For Desiccant SystemsDocument72 paginiHVAC Handbook Applications Engineering Manual For Desiccant SystemsMustafa Vatansever100% (1)

- Simultaneous Heating & Cooling With ChillersDocument23 paginiSimultaneous Heating & Cooling With ChillersashishtanjeaaÎncă nu există evaluări

- Chilled Water Thermal StorageDocument4 paginiChilled Water Thermal Storagemad_sam282729Încă nu există evaluări

- DR ApichitDocument139 paginiDR ApichitMuh. Yousuf KhanÎncă nu există evaluări

- Trane Coil Guide - COIL-PRC002GDocument24 paginiTrane Coil Guide - COIL-PRC002GTrever TomesÎncă nu există evaluări

- Ammonia or R22?: A Design ApproachDocument26 paginiAmmonia or R22?: A Design ApproachSail Vessel J&K Kat100% (1)

- Refrigeration Tech Student VersionDocument94 paginiRefrigeration Tech Student VersionAbdalhady JoharjiÎncă nu există evaluări

- 3 Simple WaysDocument7 pagini3 Simple WaysAruna Prasanna DewasurendraÎncă nu există evaluări

- Dectron DSV Series CatalogDocument4 paginiDectron DSV Series Catalogbluemojo0% (2)

- Technical Data PRIHODADocument32 paginiTechnical Data PRIHODAAlex PotaÎncă nu există evaluări

- Design and Performance Analysis of Water PDFDocument7 paginiDesign and Performance Analysis of Water PDFDiyar NezarÎncă nu există evaluări

- Report Technical Vol41 - 3Document8 paginiReport Technical Vol41 - 3rojanmathewÎncă nu există evaluări

- Liebert Challenger 3000 With Liebert ICOM - Operation & Maintenance ManualDocument48 paginiLiebert Challenger 3000 With Liebert ICOM - Operation & Maintenance Manualluis100% (1)

- Chiller System Design and Control1Document11 paginiChiller System Design and Control1حيدر محمدÎncă nu există evaluări

- Air PurgingDocument14 paginiAir PurgingjgdberizoÎncă nu există evaluări

- The World: A Brief Introduction To CO Refrigeration PossibilitiesDocument21 paginiThe World: A Brief Introduction To CO Refrigeration PossibilitiesCarlos YzaguirreÎncă nu există evaluări

- Stulz White Paper Free Cooling For Data Centers V1Document15 paginiStulz White Paper Free Cooling For Data Centers V1Mangatur Simamora100% (1)

- IceDocument4 paginiIcemuzammilkhatibÎncă nu există evaluări

- Evaporative Condenser Control in Industrial Refrigeration SystemsDocument21 paginiEvaporative Condenser Control in Industrial Refrigeration SystemsMichael BasaÎncă nu există evaluări

- 4 - Refrigerant Pumping - Monika Witt Presentation PDFDocument90 pagini4 - Refrigerant Pumping - Monika Witt Presentation PDFme641sivaÎncă nu există evaluări

- Cooling Towers Design and Operation ConsiderationsDocument8 paginiCooling Towers Design and Operation ConsiderationsThieuhuyen Ky100% (1)

- Heat Recovery AhuDocument28 paginiHeat Recovery AhuSameera Sri Viduranga100% (1)

- Trane - Coil Sizing Guide PDFDocument42 paginiTrane - Coil Sizing Guide PDFyousuffÎncă nu există evaluări

- Dehumidification Equipment Advance ASHRAE Journal PDFDocument6 paginiDehumidification Equipment Advance ASHRAE Journal PDFThomás ArévaloÎncă nu există evaluări

- Chiller Selection & District Cooling 7Document7 paginiChiller Selection & District Cooling 7Marzook50% (2)

- Mostafa-Understanding Expansion Tanks PDFDocument22 paginiMostafa-Understanding Expansion Tanks PDFmostafaabdelrazikÎncă nu există evaluări

- Residential Cooling Load CalculationDocument24 paginiResidential Cooling Load CalculationAngeloTomalonÎncă nu există evaluări

- Chapter 3. Central Cooling and Heating PlantsDocument21 paginiChapter 3. Central Cooling and Heating PlantsRolando Valdez GutierrezÎncă nu există evaluări

- Riesenberger J. and J. Koeller (2005) Commercial Laundry FacilitiesDocument30 paginiRiesenberger J. and J. Koeller (2005) Commercial Laundry FacilitiesTilakjiÎncă nu există evaluări

- Water Cooled PackageDocument37 paginiWater Cooled PackageLeed EN100% (1)

- Process Water Cooling IWSeptember2014Document4 paginiProcess Water Cooling IWSeptember2014FrancisÎncă nu există evaluări

- Iplv NPLVDocument5 paginiIplv NPLVKamal HaziqÎncă nu există evaluări

- Large Heat Pumps in Europe MDN II Final4 Small PDFDocument44 paginiLarge Heat Pumps in Europe MDN II Final4 Small PDFChristineÎncă nu există evaluări

- Chilled BeamsDocument1 paginăChilled BeamsrkibÎncă nu există evaluări

- Kathabar Liquid Desiccant Product Guide DigitalDocument9 paginiKathabar Liquid Desiccant Product Guide Digitalnathanielek1989Încă nu există evaluări

- Daikin VAV With Reheat Systems AppGuide AG31-021 LRDocument2 paginiDaikin VAV With Reheat Systems AppGuide AG31-021 LRMIGUELÎncă nu există evaluări

- P030 Chiller Operating ManualDocument44 paginiP030 Chiller Operating ManualshsecoÎncă nu există evaluări

- Ashrae 15-34-Rev 3 MitsubishiDocument7 paginiAshrae 15-34-Rev 3 MitsubishiJosho SandovalÎncă nu există evaluări

- Copeland Refrigeration ManualDocument44 paginiCopeland Refrigeration ManualArmando ChilinÎncă nu există evaluări

- HVAC Report FINALDocument65 paginiHVAC Report FINALIanÎncă nu există evaluări

- HVAC Design For Sustainable Lab: by Gregory R. Johnson, P.E., Member ASHRAEDocument11 paginiHVAC Design For Sustainable Lab: by Gregory R. Johnson, P.E., Member ASHRAEAu NguyenÎncă nu există evaluări

- Chiller - An OverviewDocument21 paginiChiller - An OverviewDtl SarozÎncă nu există evaluări

- Heat Gain From PeopleDocument1 paginăHeat Gain From Peoplehasanadel88Încă nu există evaluări

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963De la EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Încă nu există evaluări

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideDe la EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideÎncă nu există evaluări

- Refrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsDe la EverandRefrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsEvaluare: 3 din 5 stele3/5 (2)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDe la EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationÎncă nu există evaluări

- Clinker CoolerDocument22 paginiClinker CoolerNael100% (9)

- United States Patent (19) (11) Patent Number: 5,207,074Document18 paginiUnited States Patent (19) (11) Patent Number: 5,207,074KrozeÎncă nu există evaluări

- Danfoss Banana Ripening Application BrochureDocument6 paginiDanfoss Banana Ripening Application BrochurevickersÎncă nu există evaluări

- McQuay MCW-C-H Technical Manual EngDocument20 paginiMcQuay MCW-C-H Technical Manual EngCarlos Can PootÎncă nu există evaluări

- Thermal Applications CategoryDocument19 paginiThermal Applications CategoryvickersÎncă nu există evaluări

- Danfoss Facts Worth Knowing About ACDrivesDocument208 paginiDanfoss Facts Worth Knowing About ACDrivesvickersÎncă nu există evaluări

- ASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFDocument74 paginiASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFvickers100% (1)

- Building Sustainability AnalysisDocument25 paginiBuilding Sustainability AnalysisvickersÎncă nu există evaluări

- Sanyo ScrollDocument24 paginiSanyo Scrollworker359567Încă nu există evaluări

- INT69 KRIWAN Diagnosis SystemDocument6 paginiINT69 KRIWAN Diagnosis Systemvickers100% (1)

- Direct Expansion (DX) and Secondary Loop (SN) SystemsDocument2 paginiDirect Expansion (DX) and Secondary Loop (SN) SystemsvickersÎncă nu există evaluări

- Replacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)Document10 paginiReplacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)vickersÎncă nu există evaluări

- Cooling Load Temperature Difference Calculation MethodDocument3 paginiCooling Load Temperature Difference Calculation Methodvickers50% (2)

- Temperature To Resistance Chart NTC Thermistor: Temp C Temp F Resistance OhmsDocument1 paginăTemperature To Resistance Chart NTC Thermistor: Temp C Temp F Resistance OhmsvickersÎncă nu există evaluări

- 6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandDocument10 pagini6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandvickersÎncă nu există evaluări

- Comparative Table of ScrollsDocument11 paginiComparative Table of ScrollsvickersÎncă nu există evaluări

- Cypetherm SuiteDocument72 paginiCypetherm SuitevickersÎncă nu există evaluări

- Chiller Types and ApplicationsDocument73 paginiChiller Types and Applicationsvickers100% (3)

- Chiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonDocument152 paginiChiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonvickersÎncă nu există evaluări

- Multi V Water PDB (08.04.10 - ) Final PDFDocument123 paginiMulti V Water PDB (08.04.10 - ) Final PDFMaxiaires RefrigeracionÎncă nu există evaluări

- Fast, Easy Furnace TuningDocument2 paginiFast, Easy Furnace TuningvickersÎncă nu există evaluări

- ThermostatCatalog 570-280Document12 paginiThermostatCatalog 570-280vickers0% (1)

- R-22 en ChillersDocument4 paginiR-22 en ChillersvickersÎncă nu există evaluări

- 30RB Opt28B Low Ambient OperationDocument1 pagină30RB Opt28B Low Ambient OperationvickersÎncă nu există evaluări

- Fasco Full Catalog PDFDocument184 paginiFasco Full Catalog PDFvickersÎncă nu există evaluări

- Supco TimersDocument7 paginiSupco Timersvickers100% (1)

- HVACR Service Trobleshooting With The Professor John TomczykDocument48 paginiHVACR Service Trobleshooting With The Professor John TomczykvickersÎncă nu există evaluări

- Bul-30RB Brine OptionDocument1 paginăBul-30RB Brine OptionvickersÎncă nu există evaluări

- Unilever Solar Assisted Ice Cream Cabinet With Danfoss Direct Current Operated Propane CompressorDocument2 paginiUnilever Solar Assisted Ice Cream Cabinet With Danfoss Direct Current Operated Propane CompressorvickersÎncă nu există evaluări

- Maggi 2 - Minute NoodleDocument10 paginiMaggi 2 - Minute Noodlealifiya100% (9)

- BBQ Cajun ShrimpDocument5 paginiBBQ Cajun ShrimpHoàng Hạnh PhươngÎncă nu există evaluări

- Import Procedures of Republic of Indonesia: A Guide Line For Pakistani CompaniesDocument22 paginiImport Procedures of Republic of Indonesia: A Guide Line For Pakistani Companiesgalih purwasaputraÎncă nu există evaluări

- Nestle SynopsisDocument19 paginiNestle SynopsisanitikaÎncă nu există evaluări

- IGCSE English As A Second Language Past Year May 2021 51021 Question PapersDocument16 paginiIGCSE English As A Second Language Past Year May 2021 51021 Question PapersT42 李佳恩 Lee Jia En100% (1)

- History of Coffee in The CordilleraDocument3 paginiHistory of Coffee in The CordilleraMACARTHY MALANESÎncă nu există evaluări

- The Golden Rice CaseDocument5 paginiThe Golden Rice Caseekang oardeÎncă nu există evaluări

- PictionaryDocument5 paginiPictionarypatymonge9Încă nu există evaluări

- Mother and Child Protection Card (MCP Card)Document40 paginiMother and Child Protection Card (MCP Card)Venkat67% (3)

- Class 6 1 PDFDocument4 paginiClass 6 1 PDFBrittomanoharÎncă nu există evaluări

- Present 1 2021Document1 paginăPresent 1 2021Amanda CañizaÎncă nu există evaluări

- Literature Review of Asteroidea Sea StarsDocument11 paginiLiterature Review of Asteroidea Sea StarsSett SambajonÎncă nu există evaluări

- Fitness TrackerDocument7 paginiFitness TrackerAngeles De la Fuente100% (2)

- Final Milk Lab ReportDocument15 paginiFinal Milk Lab Reportapi-272749175Încă nu există evaluări

- Monogatari Series Short Stories Book - First Edition - Print VersionDocument323 paginiMonogatari Series Short Stories Book - First Edition - Print VersionPhonemune100% (1)

- Container Cleaning in Food Processing OperationsDocument4 paginiContainer Cleaning in Food Processing OperationsJohn Henry WellsÎncă nu există evaluări

- Indian Constitution and Gender EqualityDocument2 paginiIndian Constitution and Gender EqualityWifi Internet Cafe & Multi ServicesÎncă nu există evaluări

- Current Status of Dairy Goat Farming in IndonesiaDocument10 paginiCurrent Status of Dairy Goat Farming in IndonesiaJaffaralyÎncă nu există evaluări

- 2013-11705-01 Brewing Handbook Final SpreadsDocument63 pagini2013-11705-01 Brewing Handbook Final SpreadsCheverry Beer80% (5)

- Kira Pearce - HL English Y2 - Senior Exit Project - Integrity EssayDocument3 paginiKira Pearce - HL English Y2 - Senior Exit Project - Integrity Essayapi-462209151Încă nu există evaluări

- Mathlinks8 CH 10textbookDocument30 paginiMathlinks8 CH 10textbookapi-171445363Încă nu există evaluări

- I. Choose the best answers: A. Trắc NghiệmDocument8 paginiI. Choose the best answers: A. Trắc NghiệmTrang Trang DoÎncă nu există evaluări

- Polish Pronunciation Guide PDFDocument5 paginiPolish Pronunciation Guide PDFSebastián MooreÎncă nu există evaluări

- Case Study.Document10 paginiCase Study.Eucille SilvaÎncă nu există evaluări

- Stern Rams in Antiquity PDFDocument522 paginiStern Rams in Antiquity PDFfoxeosÎncă nu există evaluări

- DNV Clean DesignDocument13 paginiDNV Clean DesignleotvrdeÎncă nu există evaluări

- Standard Chocolate Milk Shake@IFFDocument2 paginiStandard Chocolate Milk Shake@IFFsubhra bhattacharjeeÎncă nu există evaluări

- The Omission PDFDocument2 paginiThe Omission PDFrodrigoÎncă nu există evaluări

- Buttered Vegetables 1Document1 paginăButtered Vegetables 1Christie Mae TorrefielÎncă nu există evaluări

- Seaweed CultivationDocument13 paginiSeaweed Cultivationmaria dulceÎncă nu există evaluări