Documente Academic

Documente Profesional

Documente Cultură

RakMek 28 1 1995 1

Încărcat de

ZoranTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RakMek 28 1 1995 1

Încărcat de

ZoranDrepturi de autor:

Formate disponibile

TRANSIENT STATE TENSILE TEST RESULTS OF STRUCTURAL STEEL

S355 (RAEX 37-52) AT ELEVATED TEMPERATURES

Jyri Outinen

Pentti Makelainen

ABSTRACT

Rakenteiden Mekaniikka, Vol.28

No.1, 1994,pp. 3-18

An experimental research is carried out for investigating mechanical properties of

structural steel S355 at elevated temperatures. Test values of thermal elongation,

modulus of elasticity and yield stress and stress-strain curves are compared with the

values and curves given in Eurocode 3 Ill, in the European Recommendations for the

Fire Safety of Steel Structures /2/ and in the Finnish Code of Steel Structures /10/.

INTRODUCTION

The main purpose of this research was to examine the mechanical properties of structural

steel S355 at temperatures 20C .. 700C using transient state tensile test method.

Transient state tensile tests have not been done before this in Finland for structural steel

S3 55 and therefore a comprehensive experimental study was of great importance.

3

Experimental work was carried out during September and October 1994 at Helsinki

University of Technology in the Laboratory of Steel Structures. Financing for the

research was provided by Rautaruukki Oy.

Results of this study are compared with the values of mechanical properties given in

Eurocode 3 Ill, in the European Recommendations for the Fire Safety of Steel

Structures /2/ and in the Finnish Code of Steel Structures /10/.

STEEL MATERIAL S355 (RAEX 37-52)

Test material used in this research was hot-rolled structural steel S355 (RAEX 37-52)

manufactured by Rautaruukki Oy. Test specimens were cut out from a hot-rolled steel

sheet with nominal thickness of 12l1llll, longitudinally to rolling direction. Structural

steel material is in accordance with the requirements of the European standard SFS-EN

10 025 /9/ for structural steel S355.

Mechanical properties of the test material at room temperature

Four tensile tests were carried out at room temperature to determine the mechanical

properties of the test material at room temperature. Results from the transient and

steady state tests were compared with these results. Six tensile tests were carried out to

determine modulus of elasticity for the test material. Tensile tests were carried out as

stress rate-controlled. The rate of loading was 0.52 (N/mm

2

)/s which caused a rate of

strain of 0.003 min"

1

to the test specimen. Stress-strain curves were used to determine

the tensile properties for each test specimen.

Test results from the tensile tests are compared in Table 1 with the minimum values

given by the manufacturer and the measured values given in the test report of the

inspection certificate of the test material .

4

Table I. Test results, minimum values given by the manufacturer and measured values

given in the test report of the inspection certificate.

Measured value Minimum Reported test value

requirement of inspection

certificate

Modulus of elasticity 210 600 206 000 not measured

E (N/mm

2

)

Yield stress 406.1 355 416

ReH(N/mm

2

)

Ultimate stress 526.9 490-630 548

R,(N/mm

2

)

Chemical C()mposition of the test material

Chemical composition of the test material including comparisons with maximum values

given by the manufacturer is presented in Table 2.

Table 2. Chemical composition of the steel material S355 (RAEX 37-52).

Elementary Measured value Maximum value

substance (%) (%)

Carbon c 0.150 0.180

Silicon Si 0.180 0.500

Manganese Mn 1.410 1.600

Niobium Nb 0.010 0.050

Sulphur s 0.011 0.020

Phosporus

p

0.019 0.025

Aluminium AI 0.041 minimum 0. 020

TESTING FACILITIES

Test specimen

The test specimen having so called proportional circular cross-section was in accordance

with the standard EN 10 002-5 /51. The test specimen is shown in Fig. 1. Dimensions of

the test specimen are given in Table 3.

5

A-A 8-8

Wto

Fig. 1. Test specimen

Table 3. Dimensions of the test specimen.

Total length

Lt

70mm

Parallel length Lc 40mm

Original gauge length

Lo

25mm

Diameter d 5 0.040 mm

Metric screw thread M10 10mm

Radius of curvature r 6mm

Testing device

The tensile testing machine used in this research was manufactured by the German

company Roeii+Korthaus. Testing machine is verified in accordance with the standard

EN 10 002-2 /6/. Loading range can be chosen between 0 .. 50 kN and 0 .. 250 kN.

Loading range used in these tests was 0 .. 50 kN. Maximum load used was about 11 kN.

Maximum loading capacity of the machine is 250 kN. Maximum error of the load cell is

0.05kN by the use of maximum loading capacity.

Gauge length of the extensometer used in this research was 25mm with elongation range

of 0 .. 2.5mm. The extensometer has an accuracy of 0.003mm. The extensometer is in

accordance with the standard EN 10 002-4/7/.

The heating device was manufactured by the German company Maytec GmbH. The

device is in accordance with the standard EN 10 002-5 /8/. The oven in which the test

specimen is situated during the tests was heated by using three separately controlled

resistor elements. The temperature-controlling unit is manufactured by the British

6

company Eurotherm Ltd. The air temperature in the oven was measured with three

separate temperature-detecting elements. The steel temperature was measured accurately

from the test specimen using temperature-detecting element that was fastened to the

specimen during the heating. The temperature-measuring device has an accuracy of

3C. The testing device is shown in Fig.2. The difference between the air temperature

and the steel temperature during the tests is given in Table 4.

Table 4. Measured temperature of the test specimen compared with the measured air

temperature in the heating oven.

Steel temperature Air temperature Steel temperature Air temperature

(OC) (OC) (OC) (OC)

20 20 400 432

50 96 450 470

100 173 500 509

150 226 550 551

200 268 600 600

250 310 650 650

300 352 700 700

350 392 750 750

Resistor elements

Fig.2. The transient state tensile testing device.

7

TEST RESULTS

Transient state tensile tests

Transient state tensile tests were carried out with two equal tests at each load level of 3,

20, 50, 80, 110, 140, 170, 200,230,260,290, 320 and 350 N/mm

2

. Thermal elongation

of the structural steel was determined with five tests at load level of 3N/mm

2

.

Heating rate in the transient state tests was l0C min-I Temperature was measured

accurately from the test specimen during the heating.

Test specimen was heated until the temperature was 750C or until breaking of the test

specimen. In the temperature-strain relationship, thermal elongation was subtracted from

the total strain. Final results were converted into stress-strain curves using the method

given in /5/ . The test method was in accordance with the standard /8/.

Temperature-strain relationships

Thermal elongation Elh has been considered by subtracting it from the total strain Etot :

Er; = Etot,Ti - Eth,Ti

where

Er; IS elongation at temperature T; ,

Etot,ri is total elongation at temperature T; and

Eth,Ti is thermal elongation at temperature T;.

(I)

Measured temperature-strain curves at stress levels of20-200 N/mm

2

are shown in Fig. 3

and at stress levels of230-380 N/mm

2

in Fig. 4.

8

800

700

600

Esoo

Cl)

5 400

~

~ 300

E

Cl)

1- 200

100

0

1. 2

-e:

/ ~

~

------

/((;

:::::---

}f

I

0 O.S

~

5.

-

1 . 20 N/mm

2

2. 50 N/mm

2

3. 80 Nlmm

2

I

4.110 Nlmm

2

5.140 Nlmm

2

6.170 Nlmm

2

7. 200 Nlmm

2

1.s 2 2s 3 as 4 ~ s s ~ s 6 as 7 ~ s 8 as

Strain(%)

Fig. 3. Temperature-strain curves at stress levels of 20-200 Nlmnl

600

E4oo

Cl)

5 300

l

I ~ /

!-----

~

(

!7 l/

v

::--

f----

f--

/

v--

~

~

)j

1/

I

1 0 230 Nlmrrf

-

2. 260 Ntmrrr

'r-

- 5.

_j

3. 290 Nlmrrf

-

6.

4. 320 Nlmrrf

soo

E 200

~

5. 350 Nlmm

2 '-----

6. 380 Nlmrrf

'

,________

~

100

0

0 O.S 1.S 2 2.S 3 3.S 4 4.S s S.S 6 6.S 7

Strain(%)

Fig.4. Temperature-strain curves at stress levels of 230-380 Nlmnl.

9

Thermal elongation

Thermal elongation of the structural steel was determined with five tests at load level of

3N/mm

2

Test specimen was heated with heating rate of 10C/min until temperature was

750C. Thermal elongation was measured during the heating process.

An analytical expression was fitted into the average test values by following equation:

(2)

where

~ 1 1 is relative thermal elongation and

T s is steel temperature.

The regression coefficient for equation (1) is 0. 9981. Results of the five tests and the

average are shown in Fig. 5. Average thermal elongation values of the five tests are

compared with the analytical expression in Fig. 6.

0.9

0.8

~

e...

0.7

~

0.6

c

0.5

0

~ 0.4

en

c

0

0.3

Qi

iii

0.2

e

Gl

.c

0.1

1-

0

....,.,..,

.--

0 100

~

~

v-----

d

~

.4ii

- Test1 .

~

- Test2.

~

~

- Test3.

~

~

- Test4.

,.

- Test5.

~

- Average value

200 300 400

Temperature (C)

500 600 700

-

~

c--

-

800

Fig. 5. Temperature dependence of thermal elongation of structural steel S355 (RAEX

37-52): Cun,esfromfive tests and the m

1

erage curve.

10

0.9

e...

0.8

5

0.7 <I

0.6

c

0.5

C) 0.4

c

0

0.3

Gi

;;;

0.2

E

CJ 0.1

.c

1-

0

.A>

_a/

_of)f}

)!Y

o Average (5 tests)

--t.tn = 5x1or,

2

+ 0.8x1o

5

r, -0.000197

0 100 200 300 400 500 600 700 800

Temperature (C)

Fig. 6. Temperature dependence of thermal elongation of structural steel S355 (RAEX

37-52): The average curve and an analytical expression fitted into the average curve.

In the Laboratory of Steel Structures at Helsinki University of Technology, the1mal

elongation has been measured earlier for structural steel S235 (Fe360) and for cold-

formed sheet steel Z32. In this research it was measured for structural steel S355 (RAEX

37-52). The thermal elongation of all these steels differs from the values given in

Eurocode 3: Part 1.2 for structural steels. Comparison of the thermal elongation of these

three materials is shown in Fig. 7. The results for structural steels S235 and S355 are

compared with the thermal strain according to Eurocode 3: Part 1.2 in Fig. 8.

0.9 +----+----lf-----+-----1----f-----+----+-- --1

0.8

5 o.

6

5

.

;;;

E

0.2

CJ

.c

0.1

1-

0

8 0.

4

:--::-=-= Gi 0.3 + :-;.. 8355 (RAEX 37-52) -

- - - 5235 (Fe3608) -

-

0 100 200 300 400 500 600 700 800

Temperature (C)

Fig 7. Thennal elongation determined for structural steels S235 (Fe360) and S355

(RAEX 37-52) and for cold-formed steel Z32.

11

1.1 -

1

0.9

5 0.8

<]

0.7

c

0.6 0

i

0.5 Cl

c

0

0.4

Qj

;;;

0.3

E

-- - -- Eurocode 3: Part 1.2

0.2

--S355 (RAEX 37-52)

.c

1-

0.1

0

'-- - - - S235(Fe360B)

0 100 200 300 400 500 600 700 800

Temperature ('C)

Fig. 8. Thermal elongation of structural steels S235 (Fe360) and S355 (RAEX 37-52)

compared with thermal elongation according to Eurocode 3: Part 1.2.

Stress-strain relationships

The transient state tensile test results converted into stress-strain curves at temperatures

100C-700C are shown in Fig. 9. Stress-strain curves for test material S3 55 (RAEX 3 7-

52) at temperatures 300C-700C are compared in Fig. l 0 with stress-strain curves given

in Eurocode 3: Part 1. 2 11/.

400

350

300

N"

E 250

.e

"'

150

U5

100

50

0

1.

!

2.

3. I--

I

v

r--

4. --

II v-:::

!----

'/

v f;

-

f/

--------

-

V-

--

0 0.2 0.4 0.6 0.8

J1.100' C 2. 200'C 3. 300'C 4.400'C r

I 5. 500'C 6. 600'C 7. 700'C

1.2 1.4 1.6 1.8 2

strain (%)

Fig.9. Stress-strain cun,esjor test material S355 (RAEX 37-52) at temperatures IOOOC-

7000C.

12

4 0 0 . - - - - - - - - . - - - - ~ - - - - . - - - - - - - - - - - - - - - - - - - - - - - - - - -

--+--30oc - - - EC3t3ooc

-4ooc - -- - EC3t4ooc

-&-sooc - --- EC3t5ooc

--o--6ooc ----- EC3t6ooc

0 0.2 0.4 0.6 0.8 1.2 1.4 1.6 1.8 2

Strain (%)

Fig. 10. Stress-strain cun,es for test material S355(RAEX 37-52) at temperatures

3000C-7000C compared with stress-strain curves of Eurocode 3: Part 1.2.

Modulus of elasticity

Modulus of elasticity of structural steel S355 (RAEX 37-52) was determined from the

stress-strain curves which were converted from the transient state test results. The

modulus of elasticity was determined as an initial slope of the stress-strain curves.

The modulus of elasticity for the steel material S355 (RAEX 37-52) at room temperature

was determined with six tensile tests and the average value of these tests was 210 600

N/mm

2

. The value given by the manufacturer is 206 000 N/mm

2

. The experimental value

is used as a reference value in analysing the transient state test results .

Test results at temperatures 20C - 700C are compared in Fig. 11 with the values of

mechanical properties given in Eurocode 3 Ill, in the European Recommendations for

the Fire Safety of Steel Structures /2/ and in the Finnish Code of Steel Structures /8/ .

13

--- RakMK B7

- - - - ECCSfTC3

- --- EC 3: Part1. 2

Test result s

--=::: :

~

0.9

~ 0. 8

>-

w 0.7

0

0.6

~

II) 0.5

~ __ - ,

~ ~

"'---

--- --'-:..::: -_

:I

'3

0.4

'0

0

E

0. 3

,.,

"' .l! 0.2

t;

..

0. 1

jjj ..... ....... ...... """"'

0

0 100 200 300 400 500 600 700

Temperature ('C)

Fig. 11. Comparison of elasticity modulus ratio ETIE

2

o'C at temperatures 20 'C -700 'C.

Yield stress

Yield stress was determined for the test material S355 (RAEX 37-52) from the stress-

strain curves based on the transient state test results. Test results for yield stress cr

0

.

2

(Rpo.2), based upon 0.2% non-proportional extension as defined in /8/, are shown in

Fig.1 2. Test results are compared with the values for cr

0

.

2

according to the Eurocode 3

/1/ and with the values according to the Finnish Code /10/. Test results for yield stress

cro.s ,cr1.o and cr2.o , based upon total extension of 0.5%, 1.0% and 2. 0 % , are shown in

Figs. 13, 14 and 15. Test results are compared with the values for cro.s ,cr1.o and cr

2

.

0

according to the Eurocode 3: Part 1.2 /11. The reduction factors for effective yield

strength given in Eurocode 3 are based on values of yield stress cr

2

.o.

450

400

N'

350

E

~

300

::1 250

t>

II)

200

II)

~

150

100

>

--Test results

~

- -- EC 3 :Part 1.2

- ....... . -<:"'--::.

::::--........

- RakMK B7

----- ~

-

--

-

~ . : :

I'..

-

-

~

-

-

-._ ........... ..........

~

---

~ : : : . . ...........

50

~ .......

0

0 100 200 300 400 500 600 700

Tern perature ('C)

Fig 12. Yield stress ao.lRpo2) for steel S355(RAEX 37-52) at temperatures 20 OC-700 OC.

14

450

N'

400

E

350

300

J

250

~

t1

200

~

150

i

100

:!!

..

50

>=

-- - Eurocode 3 : Part 1.2

r--

-........

- ~

--Test results

I--

~

-

-

-...

~

- - ~

...... _ ~

0

0 100 200 300 400 500 600 700

T emperature ("C)

Fig. 13. Yield stress cr

05

(R

10

.

5

) for steel S355(RAEX 37-52) at temperatures 20CC-

700CC.

450

I I

N'

400

E

350

...............

I

Test results

t

Eurocode 3: Part 1.2

,._

_ ,_

300

~

.

250

~

b 200

~

150

~

100

:!!

..

~

~

~

.......

~

....

>=

50

0 1-

0 100 200 300 400 500 600 700

Temperature ("C)

Fig. 14. Yield stress O"to(RtJ.o) for steel S355(RAEX 37-52) at temperatures 20 CC- 700 CC.

450

400

N'

E

350

E

~

300

-,

r! 250

~

"

200

~

~

i

150

:!!

100

..

I

--Test results

Part 1.2 ~

-

I

Eurocode 3 :

~ ~

- - ~

~

~

< ~

>=

50

0 100 200 300 400 500 600 700

Temperature ("C)

Fig. 15. Yield stress cr

2

.

0

{R

12

.

0

) for steel S355(RAEX 37-52) at temperatures 20 CC-

700CC.

15

Steady state tests

Steady state tensile tests were carried out for the test material S355 (RAEX 37-52) with

two equal tests at each temperature 400C, 500C and 600C.

Tensile tests were carried out as stress rate-controlled. The rate of loading was 0.52

(N/mm

2

)/s which caused a rate of strain of0.003 min-

1

in the test specimen.

Stress-strain relationships

Stress-strain curves measured from the steady state tests at temperatures 400C, 500C

and 600C are shown in Fig. 16. Stress-strain curves from the steady state tests are

compared with transient state test curves in Fig. 17.

500

450

400

~ 350

N

E 300

.E

~ 250

1/)

~ 200

iii

150

100

50

0

--

--

--

r--

,.--o---'

............

_...o---'

/

v/

if

~

~

rv

r-a-

ILf

~

0 0.2 0.4 06 0.8

Strain(%)

--

-

-

-steady state test 4ooc

,----

--o-- steady state test 500c ~

~ r steady state test 6ooc

-

1.2 1.4 1.6 1.8 2

Fig. 16. Stress-strain curves for steel S355 (RAEX 37-52) measured in the steady state

tests at temperatures 400 "C, 500 't.' and 600 't.'.

16

450

400

350

N" 300

E

.E 250

Ill

200

Ill

Ql

...

...

150

(/)

100

50

l

-- - - -

----

-- -

-x- ---

--

x-x- --

..

.---

----- -

....->t- - .::.:o--'

-----

-

----

---

,. .. -. -

Ill

v-- .. .. . ......

--------

-----

..........

/

...---..-

.

.. ..... -.

...........

...

...

rv

----

-x-Steady st. 4ooc - - - Trans.st. 4ooc

F.-

'!.

-o-Steady st. sooc - - Trans.st. sooc

--fr- Steady st. sooc Trans.st. 6ooc

0

0 0.2 0.4 0.6 0.8 1.2 1.4 1.6 1.8 2

strain (%)

Fig. 17. Measured steady state stress-strain curves for steel S355 (RAEX 37-52) at

temperatures 400 't:', 500 't:' and 600 't:' compared with the measured transient state

curves.

Mechanical properties of the test material based on steady state data

Mechanical properties of the test material S355 (RAEX 37-52) determined with the

steady state data are given in Table 5.

Table 5. Mechanical properties of the test material S355 (RAEX 37-52) at temperatures

400C, 500C and 600C based on steady state data.

Temperature (C) Yield stress cro.2 Yield stress cro.s Ultimate stress fu

(N/mm

2

) (N/mm

2

) (N/mm

2

)

400 249.5 280.0 515.0

500 230.2 245.0 380.0

600 167.8 170.0 226.0

17

ACKNOWLEDGEMENTS

The authors wish to acknowledge the support of the company Rautaruukki Oy in making

this experimental research project possible. The authors are especially grateful to Mr.

Jouko Kanerva M.Sc.(Eng) from the company Rautaruukki Oy for his efforts in

promoting and organizing this research programme.

REFERENCES

Ill European Committee for Standardisation (CEN), Eurocode 3: Design of steel

structures, Part 1.2 : Structural fire design, Brussels 1993.

/2/ European Convention for Constructional Steelwork (ECCS), European

Recommendations for the Fire Safety of Steel Structures, Elsevier Scientific Publishing

Company, Amsterdam 1983.

/3/ Preston R.R. ,ECCS, Technical Committee 3, The thermal expansion of structural

steels at elevated temperatures; A review of current data, Cleveland 1993.

/4/ Miller K.,Makelainen P., Mechanical properties of cold-rolled hot-dip zinc coated

sheet steel at elevated temperatures, Research report nr.58, Helsinki University of

Technology, Department of Civil Engineering, Espoo 1983.

!51 Narinen Pekka, Mechanical properties of structural steel at fire temperatures (in

Finnish), Master's Thesis, Helsinki University ofTechnology, Faculty of Civil

Engineering and Surveying, Espoo 1994.

/6/ Standard EN 10 002-2: Metallic materials. Tensile testing. Part 2: Verification on the

load cell of tensile testing machine, Brussels 1992.

171 Standard EN 10 002-4: Metallic materials. Tensile testing. Part 4: Verification of

extensometers used in uniaxial testing, Brussels 1992.

/8/ Standard SFS-EN 10 002-5: Metallic materials. Tensile testing. Part 5: Method of

testing at elevated temperature (in Finnish), Helsinki 1992.

/9/ Standard SFS-EN 10 025: Hot-rolled products ofnon-alloy structural steel (in

Finnish), Helsinki 1993.

11 Of Rakentarnismaarayskokoelma, ohjeet B7, Terasrakenteet (Finnish Codes of Building

Regulations, Code B7, Steel Structures), Helsinki 1987.

Jyri Outinen, Graduating student

Laboratory of Steel Structures

Helsinki University of Technology

18

Pentti Makelainen, Professor, Dr. Tech.

Laboratory of Steel Structures

Helsinki University of Technology

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Complete Practical DistillingDocument254 paginiComplete Practical DistillingMR X100% (5)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Vertical Pressure VesselDocument5 paginiVertical Pressure VesselEnriqueGDÎncă nu există evaluări

- Vertical Pressure VesselDocument5 paginiVertical Pressure VesselEnriqueGDÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Construction Safety ProgramDocument108 paginiConstruction Safety Programalvin100% (3)

- Project HSE Plan KOC - Ge.048Document4 paginiProject HSE Plan KOC - Ge.048Wellfro0% (1)

- 08 Eurocodes Steel Workshop DUBINA PDFDocument311 pagini08 Eurocodes Steel Workshop DUBINA PDFTopaca PaecÎncă nu există evaluări

- Crane Design Basics: Beam CalculatorDocument13 paginiCrane Design Basics: Beam CalculatorAnandh PsÎncă nu există evaluări

- Guide To Design of Anchors Bolts and Other Steel EmbedmentsDocument14 paginiGuide To Design of Anchors Bolts and Other Steel Embedmentsvinku90% (1)

- Superalloys - A Primer and HistoryDocument4 paginiSuperalloys - A Primer and Historyhemakumars100% (1)

- Hangar DesignDocument5 paginiHangar DesignZoran100% (1)

- Hangars PlaningDocument4 paginiHangars PlaningZoran0% (1)

- Gravimetric Analysis Laboratory ReportDocument9 paginiGravimetric Analysis Laboratory ReportShawn RizalÎncă nu există evaluări

- Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyDocument28 paginiInstallation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyRenārs BērtiņšÎncă nu există evaluări

- 11089-Article Text PDF-30776-3-10-20180320Document8 pagini11089-Article Text PDF-30776-3-10-20180320nazrulharizÎncă nu există evaluări

- 340AJ Spec SheetDocument2 pagini340AJ Spec SheetMikeÎncă nu există evaluări

- 24 Sample ChapterDocument14 pagini24 Sample ChapterRomyMohanÎncă nu există evaluări

- Design of Digester Biogas Tank Part 3: 3D Digester Biogas Tank ModelDocument6 paginiDesign of Digester Biogas Tank Part 3: 3D Digester Biogas Tank ModelZoranÎncă nu există evaluări

- Roof Truss Installation Manual 09 - 2011Document5 paginiRoof Truss Installation Manual 09 - 2011rotciv132709Încă nu există evaluări

- Document 1Document1 paginăDocument 1ZoranÎncă nu există evaluări

- ConSteel Getting Started7Document37 paginiConSteel Getting Started7ZoranÎncă nu există evaluări

- Thread CalculationsDocument2 paginiThread CalculationsilyaskureshiÎncă nu există evaluări

- The Modulus of Elasticity of Steel Is It 200 GPaDocument8 paginiThe Modulus of Elasticity of Steel Is It 200 GPaPratik PatelÎncă nu există evaluări

- Document 1Document1 paginăDocument 1ZoranÎncă nu există evaluări

- Whitepaper - Bolted ConnectionsDocument18 paginiWhitepaper - Bolted ConnectionsOğuzhan KocaÎncă nu există evaluări

- Relations Between Distributed Load Shear Force and Bending MomentDocument8 paginiRelations Between Distributed Load Shear Force and Bending MomentZoranÎncă nu există evaluări

- Thermal Stress Steps Double AnalasysDocument2 paginiThermal Stress Steps Double AnalasysZoranÎncă nu există evaluări

- Trepel Challenger 700Document2 paginiTrepel Challenger 700ZoranÎncă nu există evaluări

- Analysis NotesDocument10 paginiAnalysis NotesAhmed SayyidÎncă nu există evaluări

- Tips For Developing Models and SAP2000 and ETABSDocument30 paginiTips For Developing Models and SAP2000 and ETABSHector RuizÎncă nu există evaluări

- A380 Aircraft HangarDocument10 paginiA380 Aircraft HangarZoranÎncă nu există evaluări

- Plot 400X400X25 HeatDocument1 paginăPlot 400X400X25 HeatZoran MatevÎncă nu există evaluări

- Part 2Document17 paginiPart 2riprapÎncă nu există evaluări

- Printed Using Abaqus/CAE On: Sat Sep 13 18:35:11 Arabian Standard Time 2014Document1 paginăPrinted Using Abaqus/CAE On: Sat Sep 13 18:35:11 Arabian Standard Time 2014Zoran Matev0% (1)

- ATEM MRO Design Trends Article Dec12 Jan13Document7 paginiATEM MRO Design Trends Article Dec12 Jan13Tadi Fresco RoyceÎncă nu există evaluări

- Plot 400X400X25 HeatDocument1 paginăPlot 400X400X25 HeatZoran MatevÎncă nu există evaluări

- I Beam ConnectionDocument1 paginăI Beam ConnectionZoranÎncă nu există evaluări

- Phenol SDocument9 paginiPhenol SAnonymous 8rsxG4Încă nu există evaluări

- Different Manicure Equipment, Materials and CosmeticsDocument36 paginiDifferent Manicure Equipment, Materials and CosmeticsRenlen EstevesÎncă nu există evaluări

- SANDVIK - Steel Designation and Markings - STA-02-030EDocument4 paginiSANDVIK - Steel Designation and Markings - STA-02-030EPetr HavelÎncă nu există evaluări

- 10 Things You Need To Know About Premixes: by DSM Nutritional ProductsDocument2 pagini10 Things You Need To Know About Premixes: by DSM Nutritional ProductsanaÎncă nu există evaluări

- Masel Catalog - WiresDocument30 paginiMasel Catalog - WiresOrtho OrganizersÎncă nu există evaluări

- Enviromental Toxicity and EvaluationDocument25 paginiEnviromental Toxicity and EvaluationSalma ShadÎncă nu există evaluări

- Series LF210-5 Specification SheetDocument2 paginiSeries LF210-5 Specification SheetWattsÎncă nu există evaluări

- Oxidation NumberDocument21 paginiOxidation NumberChristian LopezÎncă nu există evaluări

- 2 6 12 Microbial Enumeration Tests PDFDocument5 pagini2 6 12 Microbial Enumeration Tests PDFThao TrangÎncă nu există evaluări

- IGNTU Econtent 674613883400 B.SC EnvironmentalSciences 2 PallaviDas EnvironmentalPollutionandHumanHealth 2Document136 paginiIGNTU Econtent 674613883400 B.SC EnvironmentalSciences 2 PallaviDas EnvironmentalPollutionandHumanHealth 2Neeraj Raushan KanthÎncă nu există evaluări

- Multiple Choice Questions (MCQ) Topic Quiz Biological MembranesDocument22 paginiMultiple Choice Questions (MCQ) Topic Quiz Biological MembranesVeluz Kirt Peter GuiribaÎncă nu există evaluări

- E - 2 - Effect of Casting Shape and Size On Solidification TimeDocument6 paginiE - 2 - Effect of Casting Shape and Size On Solidification Timeoğuz kağanÎncă nu există evaluări

- DELTA-FC 1022 Tds - EngDocument2 paginiDELTA-FC 1022 Tds - EngAhmed HassanÎncă nu există evaluări

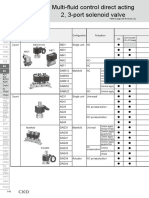

- General Purpose ValvesDocument46 paginiGeneral Purpose ValvesbataÎncă nu există evaluări

- Are Red Flowers Really Red?Document4 paginiAre Red Flowers Really Red?Mikaella CapiralÎncă nu există evaluări

- Waste Management Write-UpDocument5 paginiWaste Management Write-UpGounassegaraneDuraisamy100% (1)

- Outdoor-Indoor Air Pollution in Urban EnvironmentDocument8 paginiOutdoor-Indoor Air Pollution in Urban EnvironmentNikolas Jalu Padma IswaraÎncă nu există evaluări

- Eisco Industrial Catalogue - FinalDocument276 paginiEisco Industrial Catalogue - FinalSOHAM AlhatÎncă nu există evaluări

- pg1 PDFDocument1 paginăpg1 PDFSanjeev GuptaÎncă nu există evaluări

- Tsubaki ChainDocument8 paginiTsubaki Chainbmihaiela100% (1)

- Aerospace Material SpecificationDocument7 paginiAerospace Material SpecificationAnonymous T6GllLl0Încă nu există evaluări

- tmpA3C2 TMPDocument11 paginitmpA3C2 TMPFrontiersÎncă nu există evaluări

- Determination of Heavy Metals in Soil by Atomic Absorption Spectrometry (AAS)Document11 paginiDetermination of Heavy Metals in Soil by Atomic Absorption Spectrometry (AAS)Irvine MupambaÎncă nu există evaluări

- Poster Carica PDFDocument1 paginăPoster Carica PDFBimo A.SÎncă nu există evaluări